Product Thuhmahruai .

A tlangpui .

Food-grade Hardness 2.8/5.6 T1-T5 Tinplate Sheet hi specialized metal packaging material a ni a, ei tur himna dan khauh tak zawm thei tura siam a ni. Tin, tin layer te tak te hmanga khuh, low-carbon steel substrate atanga siam niin, he sheet hian corrosion resistance danglam tak leh mechanical property a pe a ni. Hardness grades (T1 to T5) hian temper degree hrang hrang a tarlang a, chu chuan forming requirement hrang hrang atan customization a phalsak a, deep drawing atanga simple bending thlengin.

Tin coating atan hian thickness range 2.8 to 5.6 microns a awm a, heng sheets te hian hermetic sealing leh product protection a tichiang a, chu chuan sensitive food leh beverage products te packaging atan top choice a siam a ni. Production process hian international food contact safety regulations (FDA leh EU 10/2011 ang chi) a zawm a, hei hian thil tha lote chu a chhunga thil awmteah a luhtir lo tih a tichiang a ni.

Nihphung

Food-grade safety : Electrolytic tin coating hi non-toxic leh non-reactive a ni a, contamination a veng a, ei tur thil siam chhuah flavor, aroma leh nutritional value te a humhim thei bawk.

Controlled Hardness Grades : 1.1.

T1/T2 : Deep drawing awlsam tak atan soft temper, aerosol can ang chi complex shape tan pawh a tha hle.

T3/T4 : Beverage can ang chi general-purpose dilna atan medium temper.

T5 : Rigid structures chakna sang tak mamawh, paint can ang chi te tan chuan hard temper.

Excellent formability : Steel strength leh tin ductility inzawmkhawm hian stamping, welding, leh seaming dik tak a siam thei a, chu chuan intricate packaging design siam theihna a siam thei a ni.

Corrosion Resistance : Tin layer hian inthawina inkharkhip angin hna a thawk a, steel core chu tui leh oxygen laka a humhim a, mihring tamna hmunah pawh a veng thei a ni.

Smooth Surface Finish : Mirror ang chi surface hian printing leh labeling quality sang tak a siam thei a, store shelf-ah product visibility a ti sang thei bawk.

Dilna

Food Packaging : Thlai, thlai, sa, leh ei tur pe thei ei tur can-a hman thin, refrigeration tel lova shelf life rei tak awm theihna tur.

Beverage Industry : Soda can, beer keg, leh juice container te a siam a, a rit lo hle a, mahse a chhe thei lo a, a chhe thei lo.

Cosmetics & Pharmaceuticals : Packaging cream, lotion, leh medical supply te tan a tha hle a, airtight leh sterile container a ngai a ni.

Industrial Packaging : Chemical, lubricant leh paint te chu dahkhawm leh phurh chhuah laiin a chhe thei lo.

FAQ a ni.

Q: Tin coating hi a lead-free a ni.?

A: Ni e, kan tinplate sheet zawng zawng hian lead-free electrolytic tin coatings an hmang a, khawvel pum huapa ei leh in himna tehfung zawm thei an ni.

Q: Acid foods atan hman theih a ni?

A: Tin hian ei tur acid tam zawk a do theih laiin, acidic products sang tak (eg, tomato) chuan added protection atan internal polymer coating a mamawh thei a, chu chu option angin kan pe thei a ni.

Q: Tinplate can-a packaged food-te shelf life chu eng nge ni .?

A: Can sealed dik tak chuan kum 2-5 chhung zet ei tur a humhim thei a, chu chu a siam dan leh a dahna hmun a zirin a ni.

Q: Hardness grade hian engtin nge hman a nghawng .?

A: Softer grades (T1-T2) te hi deep drawing atan a tha a, harder grades (T4-T5) te hi rigid, non-deformable container atan a tha zawk.

Nihphung pangngai |

GB/T ,Jis,Astm,en . |

Bungrua |

SPCC,SPHC 1000 a ni. |

Chhinchhiah |

Shandong steel ropui tak a ni. |

Thickness . |

0.1-0.8mm a ni. |

Vang |

50-1000 mm a ni. |

Dawhtheihna |

+/-0.01mm a ni. |

tin thickness coating a awm bawk. |

0.005-0.015mm a ni. |

A chung lam enkawlna . |

Oil film, pickling, phosphating, coating, oxidation te pawh a awm nual. |

Spangle a ni a. |

A rilru a buai em em a, a rilru a hah em em bawk a, a rilru a buai em em bawk a. |

technique hman dan . |

Electrolytic tin plating leh hot dip tin plating te pawh a awm bawk. |

Bawm |

Standard Seaworthy Export Packing:

Packing layer 3, a chhungah Kraft paper a awm a, water plastic film chu a laiah a awm a, a pawnah GI steel sheet chu steel strip hmanga khuh tur a ni a, a chhungah chuan inner coil sleeve a awm bawk. |

Certification 1000 a ni. |

ISO 11949:2012,JIS,ASTM,EN |

MOQ 10 a ni. |

ton 22 (20ft FCL pakhatah) |

Sem |

Ni 15-20 chhung . |

Thla tin output . |

30000 tons a ni. |

Hrilhfiahna |

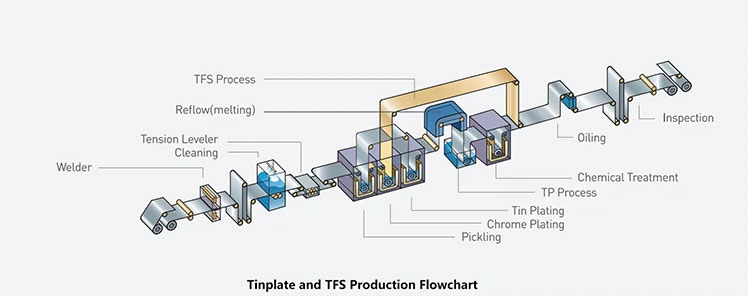

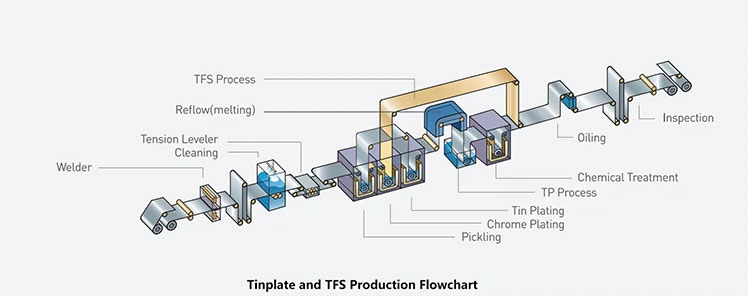

Tinplate hi metal plate chi khat a ni a, tin plating treatment a nei tawh a, a tlangpuiin steel emaw iron plate a siam a ni a, chu chu surface cleaning, pre-treatment, tin coating, leh heating process hmanga siam a ni. Anti-corrosion, corrosion resistance, leh aesthetics te ang chi mizia a nei a ni. ei tur bungrua, sakna, lirthei, electronics, etc. ang chi field-ah te hman a ni nasa hle. |

Pe |

T/T, LC, Kun Lun Bank,Western Union, PayPal te chuan an lo hmuak a. |

Thusawi . |

Insurance hi risk zawng zawng a ni a, third party test 1000 a pawm bawk. |