Product Introduction

Overview

The Food-Grade Hardness 2.8/5.6 T1-T5 Tinplate Sheet is a specialized metal packaging material designed to meet strict food safety standards. Composed of a low-carbon steel substrate coated with a thin layer of tin, this sheet offers exceptional corrosion resistance and mechanical properties. The hardness grades (T1 to T5) indicate varying degrees of temper, allowing customization for different forming requirements, from deep drawing to simple bending.

With a thickness range of 2.8 to 5.6 microns for the tin coating, these sheets ensure hermetic sealing and product protection, making them the top choice for packaging sensitive food and beverage products. The production process adheres to international food contact safety regulations (such as FDA and EU 10/2011), guaranteeing no migration of harmful substances into the packaged contents.

Features

Food-Grade Safety: The electrolytic tin coating is non-toxic and non-reactive, preventing contamination and preserving the flavor, aroma, and nutritional value of food products.

Controlled Hardness Grades:

T1/T2: Soft temper for easy deep drawing, ideal for complex shapes like aerosol cans.

T3/T4: Medium temper for general-purpose applications such as beverage cans.

T5: Hard temper for rigid structures requiring high strength, like paint cans.

Excellent Formability: The combination of steel strength and tin ductility allows precise stamping, welding, and seaming, enabling the production of intricate packaging designs.

Corrosion Resistance: The tin layer acts as a sacrificial barrier, protecting the steel core from moisture and oxygen, even in high-humidity environments.

Smooth Surface Finish: A mirror-like surface enables high-quality printing and labeling, enhancing product visibility on store shelves.

Application

Food Packaging: Used for cans of fruits, vegetables, meats, and ready-to-eat meals, ensuring long shelf life without refrigeration.

Beverage Industry: Manufactures soda cans, beer kegs, and juice containers, providing a lightweight yet durable packaging option.

Cosmetics & Pharmaceuticals: Ideal for packaging creams, lotions, and medical supplies that require airtight and sterile containers.

Industrial Packaging: Protects chemicals, lubricants, and paints from degradation during storage and transportation.

FAQ

Q: Is the tin coating lead-free?

A: Yes, all our tinplate sheets use lead-free electrolytic tin coatings compliant with global food safety standards.

Q: Can it be used for acidic foods?

A: While tin is resistant to most food acids, highly acidic products (e.g., tomatoes) may require an internal polymer coating for added protection, which we can provide as an option.

Q: What is the shelf life of packaged food in tinplate cans?

A: Properly sealed cans can preserve food for 2-5 years, depending on the product and storage conditions.

Q: How does hardness grade affect usage?

A: Softer grades (T1-T2) are suitable for deep drawing, while harder grades (T4-T5) are better for rigid, non-deformable containers.

Standard | GB/T ,JIS,ASTM,EN |

Material | SPCC,SPHC |

Brand | Shandong Great Steel |

Thickness | 0.1-0.8mm |

Width | 50-1000 mm |

Tolerance | +/-0.01mm |

Tin thickness coating | 0.005-0.015mm |

Surface treatment | Oil film, pickling, phosphating, coating, oxidation |

Spangle | Regular spangle,minimal spangle, zero spangle,big spangle |

Technique | Electrolytic tin plating and hot dip tin plating |

Package | Standard seaworthy export packing:

3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve |

Certification | ISO 11949:2012,JIS,ASTM,EN |

MOQ | 22 TONS (in one 20ft FCL) |

Delivery | 15-20 days |

Monthly Output | 30000 tons |

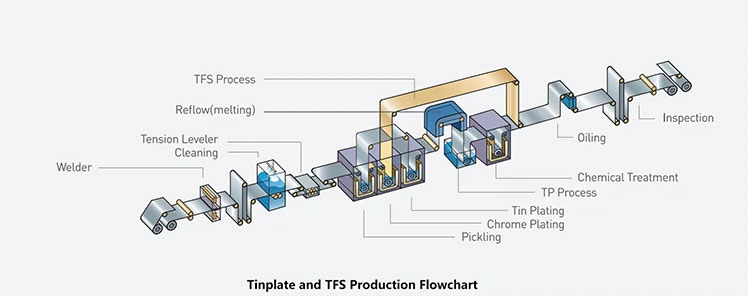

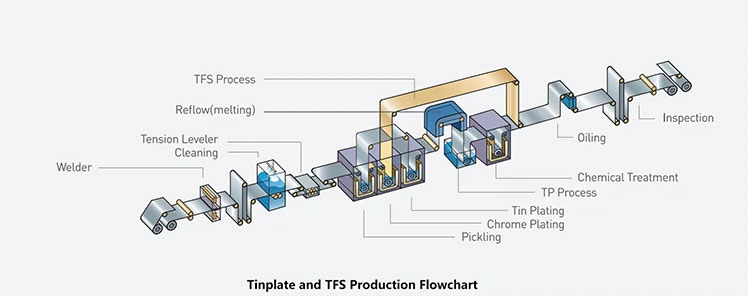

Description | Tinplate is a type of metal plate that has undergone tin plating treatment, usually made of steel or iron plate through surface cleaning, pre-treatment, tin coating, and heating processes. It has characteristics such as anti-corrosion, corrosion resistance, and aesthetics. It is widely used in fields such as food packaging, construction, automobiles, electronics, etc. |

Payment | T/T, LC, Kun Lun Bank,Western Union, Paypal |

Remarks | Insurance is all risks and accept the third party test |