Product Thuhmahruai .

| Brand hming . |

Shandong Sino Steel a ni a, a man pawh a tlawm hle. |

| Product hming . |

Galvanized steel coil 1000 a ni. |

| Bungrua |

A rilru a buai em em a, a rilru a hah em em bawk a. |

| Zinc coating a awm em? |

20-275g/m2 a ni. |

| Thickness . |

0.13-0.8 mm a ni. |

| Vang |

600-1250 mm a ni. |

| Coil ID 1000 a ni. |

508/610mm a ni. |

| Coil rit zawng . |

3-8 ton a ni. |

| Bawm |

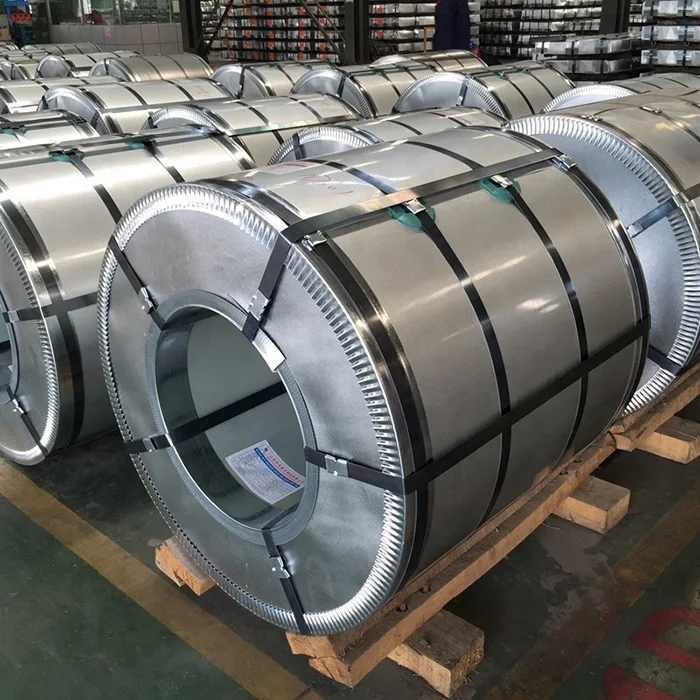

Standard Export Package (Thlalak chipchiar tak chu hetiang hi a ni) |

| Harsatna . |

A nem (normal), a khauh, a khauh zawng zawng(G300-G550) |

| A lo chhuahna ram . |

China 1000 a ni. |

| A chung lam structure . |

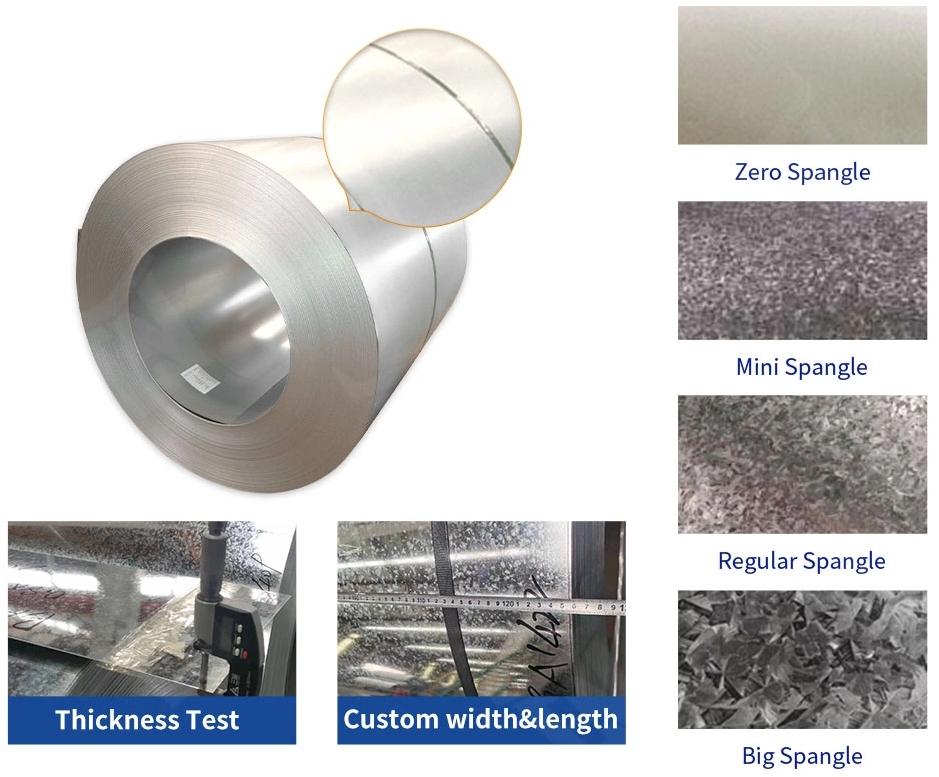

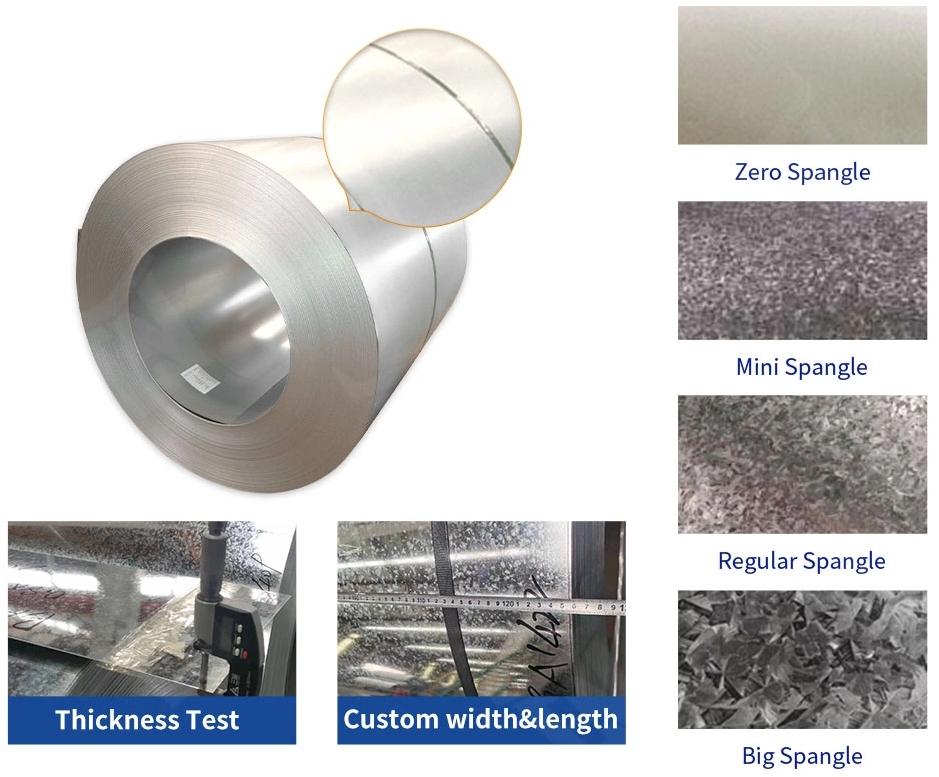

Zero spangle 1000 a ni. |

Spangle lian tak . |

| Zinc coating a rit zawng . |

Zinc > 20g/sqm a ni. |

Zinc > 30g/sqm a ni. |

A tlangpui .

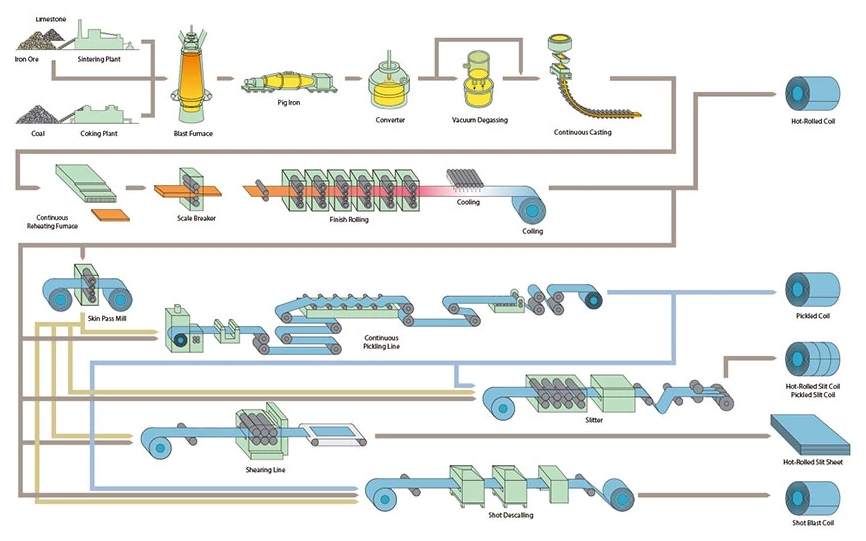

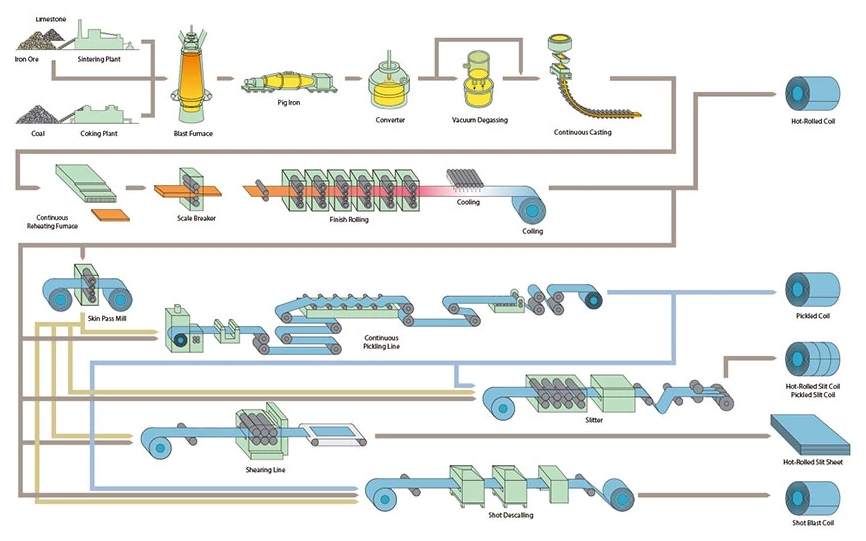

JIS G3302 compliant DX51D Galvanized Steel Coil hi industry hrang hranga precision fabrication atana siam, high-performance metallurgical product a ni a, corrosion resistance, formability, leh mechanical adaptability balance a pe a ni. Japanese Industrial Standard (JIS G3302)-a siam a ni a, he coil hian hot-dipped galvanized coating (SGCC: steel galvanized with aluminum-zinc alloy) a nei a, carbon hniam tak steel substrate-ah a awm a, 0.11mm atanga 2.5mm atanga 2.5mm thleng leh soft (full hard) leh hard (spring hard) temper-ah te a awm a ni.

DX51D designation hian general-purpose grade a tarlang a, spangle surface pangngai a nei a, hei hi bending, cutting, leh simple stamping ang chi, moderate forming mamawhna atan a tha hle. Dual protective layer—zinc-aluminum alloy coating (55% AL, 43.4% Zn, 1.6% SI)—chu pure zinc nena khaikhin chuan corrosion resistance sang zawk a pe a, chutih laiin customizable temper (soft for ductility, hard for strength) chuan manufacturing mamawh hrang hrang a huam thung.

Nihphung

Dual temper versatility : 1.1.

Soft Temper (full hard) : elongation ≥26%, deep drawing, embossing, leh complex stamping (eg, automotive inner panels, appliance shells) atan a tha hle.

Hard Temper (Spring Hard) : Yield strength ≥350 MPa, structural components rigidity sang tak mamawh (eg, storage racks, steel frames) tan a tha.

JIS zawmtu corrosion laka invenna : 1.1.

SGCC Coating (Z60-Z275 G/M⊃2;) hian humid environment-ah chuan pure zinc aiin dam rei zawk 3x a pe a, Z275 grade-ah chuan salt spray resistance darkar 1,000 aia tam a pe thei bawk.

Self-healing properties: Zinc-aluminum layer hian steel hi a chil a, a hrual lai pawhin inthawinain a venghim a, cut edge-a rust siam a tikhawtlai a ni.

Precision Engineering : 1.1.

Tight thickness tolerance (0.11-1.0mm atan +/-0.01mm; 1.0-2.5mm tan +/-0.02mm) chuan automated production line-ah uniform performance a siam thei.

Spangle-free surface option (DX51D+Z) chu seamless painting emaw powder coating emaw atan hman theih a ni a, hmuh theiha hmanna atan chuan a awlsam zawngin a thleng thei bawk.

Process efficiency : 1.1.

Coil lian tak tak (5-20 tons) a supply a, optional slitting to custom widths (minimum 300mm), roll-forming leh stamping process-a bawlhhlawh tihtlem.

Oil-free surface treatment hian pre-cleaning tel lovin welding emaw coating emaw a siam nghal thei a, preprocessing time-ah 20%+ a humhim thei bawk.

Dilna

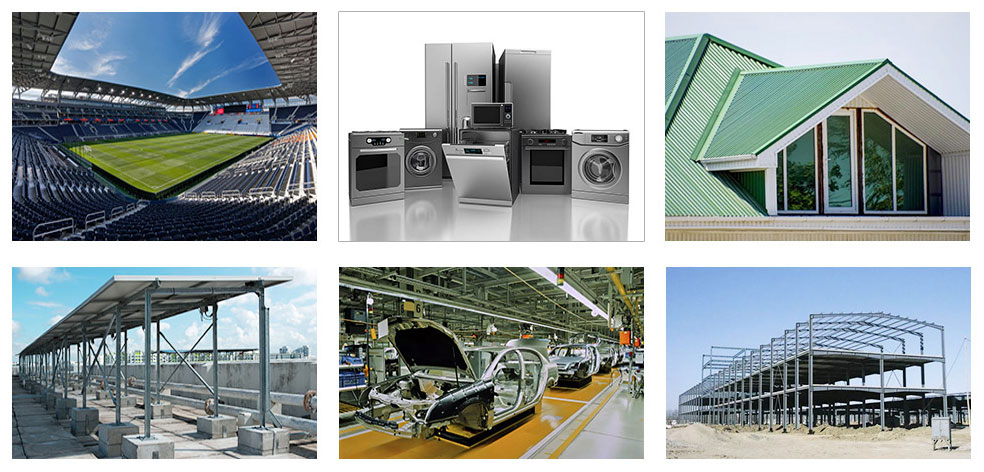

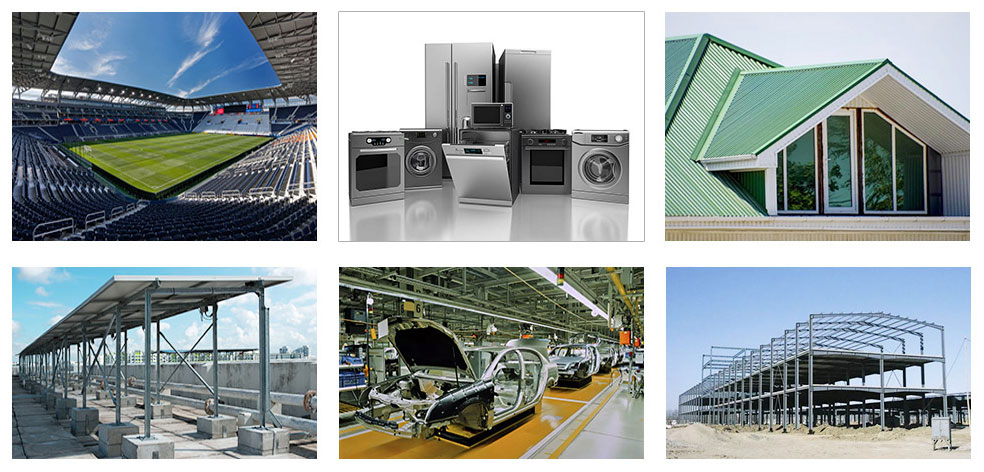

Appliance Manufacturing : Refrigerator kawngkhar, washing machine drum, leh air conditioner panel te chu deep drawing atan soft temper hmangin a siam a, enamel adhesion atan surface smooth tak tak a awm theih nan a enkawl bawk.

Light Steel Construction : C/Z purlins, roof trusses, leh wall studs te chu a tithinur hle a, prefab home leh industrial shed-a steel framework lightweight tak tak a support bawk.

Automotive Components : Door inner panels, trunk lids, leh underbody shields te a siam chhuak a, SGCC coating hian tuipui kama kawngpui chi leh tuihna a do thei bawk.

General Fabrication : Metal furniture, signage, leh HVAC ductwork atan a tha hle a, indoor/outdoor hmanna atana formability leh rust resistance balance man tlawm tak a pe bawk.

FAQ a ni.

Q: Soft leh hard temper zingah engtin nge ka thlan ang .?

A: Soft temper hi bending/stamping (eg, curved panels) atan a ni a, hard temper erawh chu load-bearing parts (eg, structural brackets) atan a ni thung. Bend Radius kaihhruaina tur kan technical sheet en rawh.

Q: He coil hi pawn lam roofing atan a tha em??

A: Ni e, mahse Coastal/High-Humidity Zone-te tan Z275 SGCC-ah upgrade rawh; UV resistance tihchak nan polyester topcoat nen pair la (value-added service angin a awm thei ang).

Q: SGCC leh GI (galvanized iron) te hi eng nge an danglamna tih hi eng nge ni .?

A: SGCC (galvanized aluminum-zinc) hian wet environment-ah corrosion resistance a nei tha zawk a, GI (pure zinc) erawh chu dry indoor use atan a man a tlawm zawk thung.

Q: JIS compliance atan mill certificate ka dawng thei ang em .?

A: Ni e, coil tin hian JIS G3302 standard khata chemical composition, coating weight, leh mechanical property te endikna test report a keng tel a ni.