Product Introduction

| Brand name | SHANDONG SINO STEEL |

| Product name | Galvanized Steel Coil |

| Material | DX51D, DX52D,DX53D,ect. |

| Zinc Coating | 20-275g/m2 |

| Thickness | 0.13-0.8 mm |

| Width | 600-1250 mm |

| Coil ID | 508/610mm |

| Coil weight | 3-8 tons |

| Package | standard export package (Detailed picture is as follows) |

| Hardness | soft (normal), hard, full hard(G300-G550) |

| Country of origin | China |

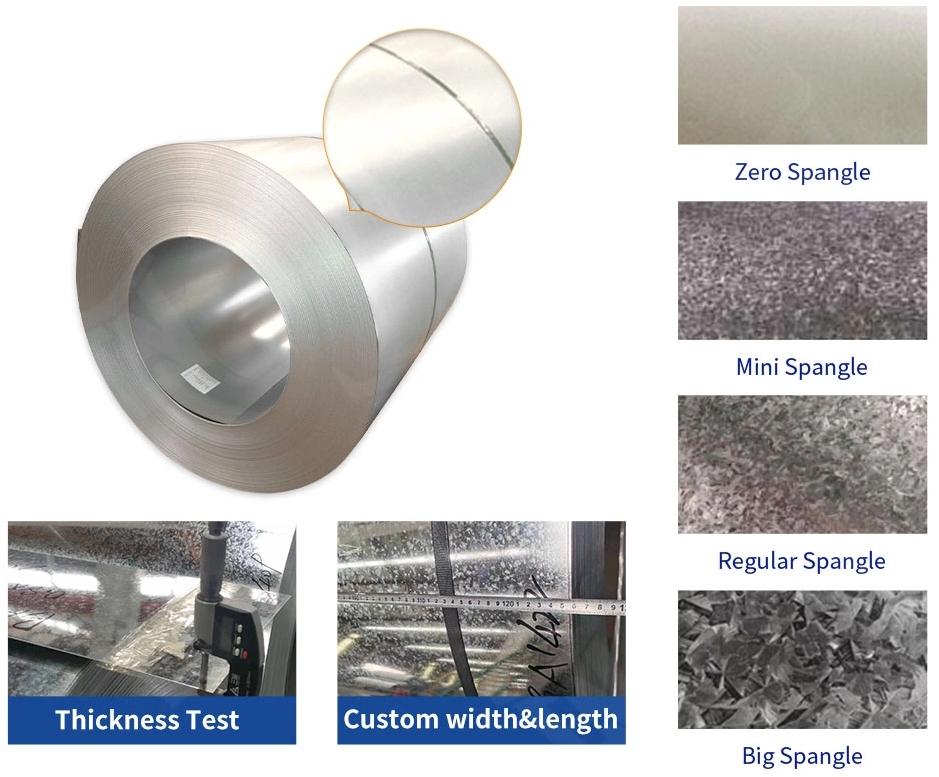

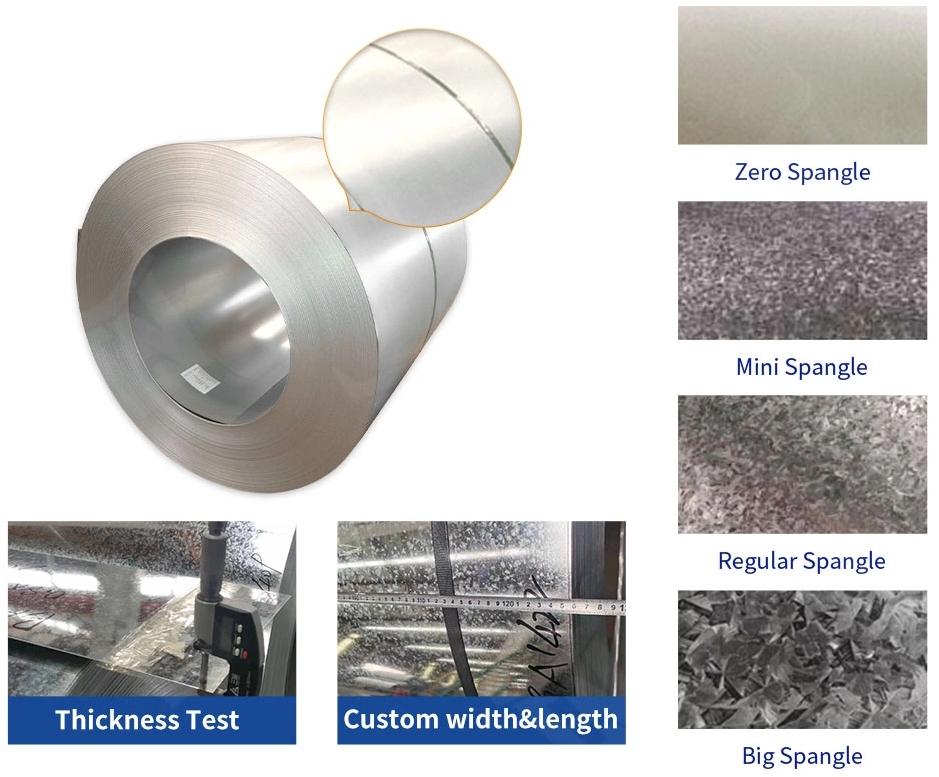

| Surface Structure | Zero Spangle | Big Spangle |

| Weight of zinc coating | Zinc > 20g/sqm | Zinc > 30g/sqm |

Overview

The JIS G3302 Compliant DX51D Galvanized Steel Coil is a high-performance metallurgical product designed for precision fabrication across industries, offering a balance of corrosion resistance, formability, and mechanical adaptability. Manufactured to Japanese Industrial Standard (JIS G3302), this coil features a hot-dipped galvanized coating (SGCC: steel galvanized with aluminum-zinc alloy) on a low-carbon steel substrate, available in thicknesses from 0.11mm to 2.5mm and in both soft (full hard) and hard (spring hard) tempers.

The DX51D designation indicates a general-purpose grade with normal spangle surface, ideal for applications requiring moderate forming such as bending, cutting, and simple stamping. The dual protective layer—zinc-aluminum alloy coating (55% Al, 43.4% Zn, 1.6% Si)—provides superior corrosion resistance compared to pure zinc, while the customizable temper (soft for ductility, hard for strength) caters to diverse manufacturing needs.

Features

Dual Temper Versatility:

Soft Temper (Full Hard): Elongation ≥26%, ideal for deep drawing, embossing, and complex stamping (e.g., automotive inner panels, appliance shells).

Hard Temper (Spring Hard): Yield strength ≥350 MPa, suitable for structural components requiring high rigidity (e.g., storage racks, steel frames).

JIS-Compliant Corrosion Protection:

SGCC coating (Z60-Z275 g/m²) offers 3x longer life than pure zinc in humid environments, with salt spray resistance exceeding 1,000 hours for Z275 grade.

Self-healing properties: Zinc-aluminum layer sacrificially protects steel even when scratched, delaying rust formation on cut edges.

Precision Engineering:

Tight thickness tolerance (+/-0.01mm for 0.11-1.0mm; +/-0.02mm for 1.0-2.5mm) ensures uniform performance in automated production lines.

Spangle-free surface option (DX51D+Z) for seamless painting or powder coating, achieving a smooth finish for visible applications.

Process Efficiency:

Supplied in large coils (5-20 tons) with optional slitting to custom widths (minimum 300mm), reducing waste in roll-forming and stamping processes.

Oil-free surface treatment enables immediate welding or coating without pre-cleaning, saving 20%+ in preprocessing time.

Application

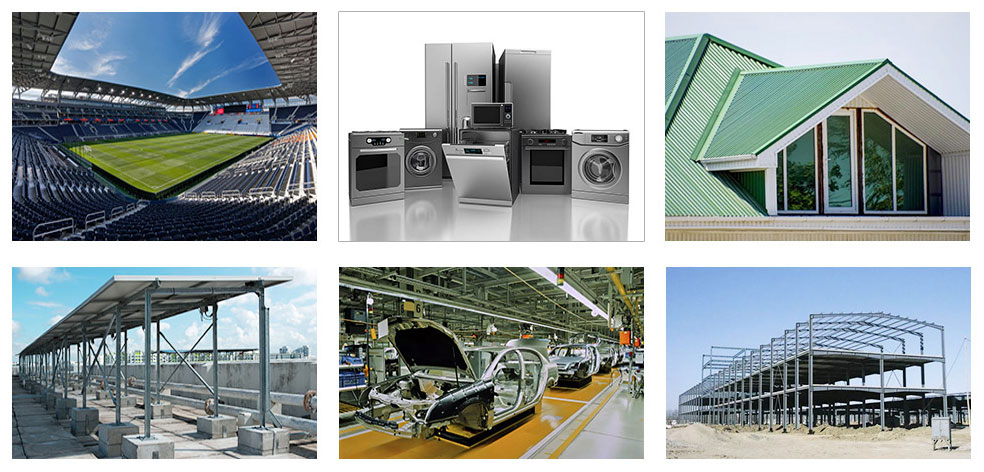

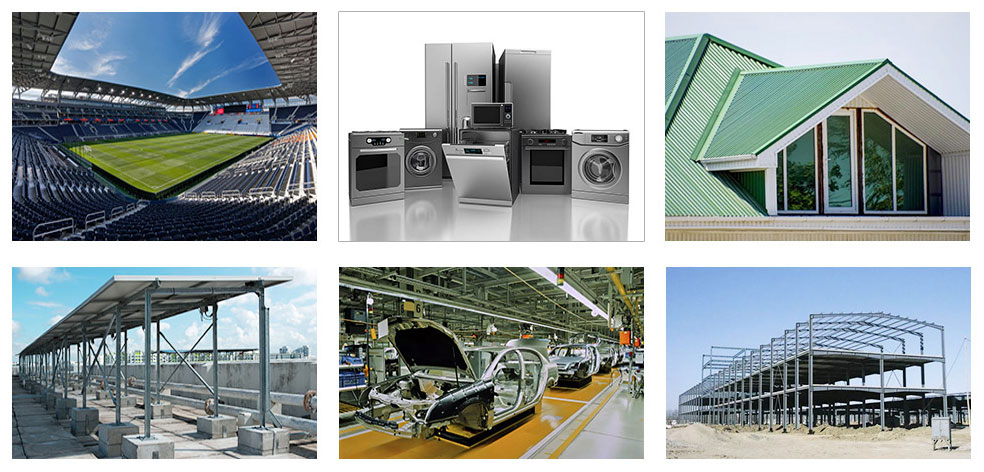

Appliance Manufacturing: Forms refrigerator doors, washing machine drums, and air conditioner panels with soft temper for deep drawing, ensuring smooth surfaces for enamel adhesion.

Light Steel Construction: Fabricates C/Z purlins, roof trusses, and wall studs with hard temper, supporting lightweight steel frameworks in prefab homes and industrial sheds.

Automotive Components: Produces door inner panels, trunk lids, and underbody shields, with SGCC coating resisting road salt and moisture in coastal regions.

General Fabrication: Ideal for metal furniture, signage, and HVAC ductwork, offering a cost-effective balance of formability and rust resistance for indoor/outdoor use.

FAQ

Q: How do I choose between soft and hard temper?

A: Soft temper is for bending/stamping (e.g., curved panels), while hard temper is for load-bearing parts (e.g., structural brackets). Consult our technical sheet for bend radius guidelines.

Q: Is this coil suitable for outdoor roofing?

A: Yes, but upgrade to Z275 SGCC for coastal/high-humidity zones; pair with a polyester topcoat for enhanced UV resistance (available as a value-added service).

Q: What is the difference between SGCC and GI (galvanized iron)?

A: SGCC (galvanized aluminum-zinc) has better corrosion resistance in wet environments, while GI (pure zinc) is more cost-effective for dry indoor use.

Q: Can I get mill certificates for JIS compliance?

A: Yes, each coil is accompanied by a test report verifying chemical composition, coating weight, and mechanical properties per JIS G3302 standards.