Product Introduction

| Galvanized sheet /Galvanized coil |

Production Standard | ASTM, AISI,JIS, DIN, EN,GB, GOST |

Material | DX51D,DX52D,DX53D,Z275,G90,G350,G450,G550,SGCC,,SGCH,GECC,,SPHC,A36,E235/S235JR,Q235B,E355/S355JR,Q345A,Q345B,Q345C,Q345D,Q345E,ST35,ST37,ST45,ST52,DC01,DC02,SS400,HC340LA,HC380LA,HC420LA,B340LA,B410LA |

Size

| Thickness | 0.105-4mm |

Width | 600-1250mm |

Tolerance | +/-0.02mm |

Zinc coating | Z30-600g/㎡ |

Surface | Bright,Mill, polished, oiled, galvanized, or as required |

Payterm | Ex-work, FOB, CIF, CFR, etc |

Payment | T/T, L/C, Western Union, Alibaba Trade Assurance, etc |

Delivery Time | Within 3-5 days for our stock size, 15-20 days for our production |

Package | Dustproof kraft sheet

Iron packing

Angle protective

packing belt |

MOQ | 25 TONS (in one 20ft FCL) |

Sample | Free and available |

Quality | Mill Test Certificate, ISO9001, CE,SGS, TVE |

Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

Mechanical properties of galvanized steel

|

Usage | Grade | Yield strength(MPa) | Tensile strength(MPa) |

Punching galvnaized steel

| DC51D+Z | - | 270-500 |

DC52D+Z | 140-300 | 270-420 |

DC53D+Z | 140-260 | 270-380 |

Structure galvanized steel

| S280GD+Z | ≥280 | ≥360 |

S350GD+Z | ≥350 | ≥420 |

S550GD+Z | ≥550 | ≥560 |

(1) Spangle coating

During the normal solidification process of the zinc layer, the zinc grains grow freely to form a coating with obvious spangle morphology.

(2) Minimized spangle coating

During the solidification process of the zinc layer, the zinc grains are artificially restricted to form a spangle coating as small as possible.

(3) Spangle-free coating

A coating with no visible spangle morphology and uniform surface obtained by adjusting the chemical composition of the plating solution.

(4) Zinc-iron alloy coating

The steel strip after passing through the galvanizing tank is heat treated to form an alloy layer of zinc and iron on the entire coating. This coating has a dark gray appearance and no metallic luster. It is easy to powderize during the intense forming process. It is suitable for coatings that can be directly painted without further treatment except general cleaning.

(5) Differential coating

For the two sides of the galvanized steel plate, a coating with different zinc layer weight is required.

(6) Skin pass

Skin pass is a cold rolling process with a small amount of deformation performed on galvanized steel sheets for one or more of the following purposes.

To improve the surface appearance of galvanized steel sheets to make them suitable for decorative coatings; to make the slip lines (Lüders lines) produced during processing invisible in the finished product or to temporarily minimize the crease phenomenon, etc.

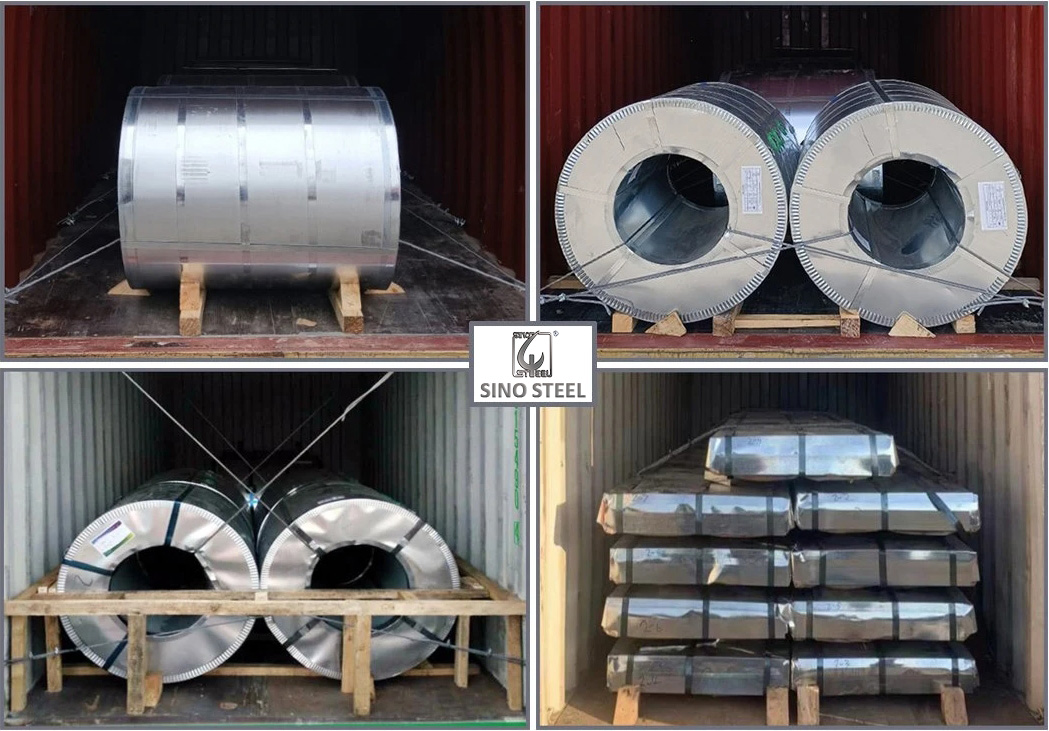

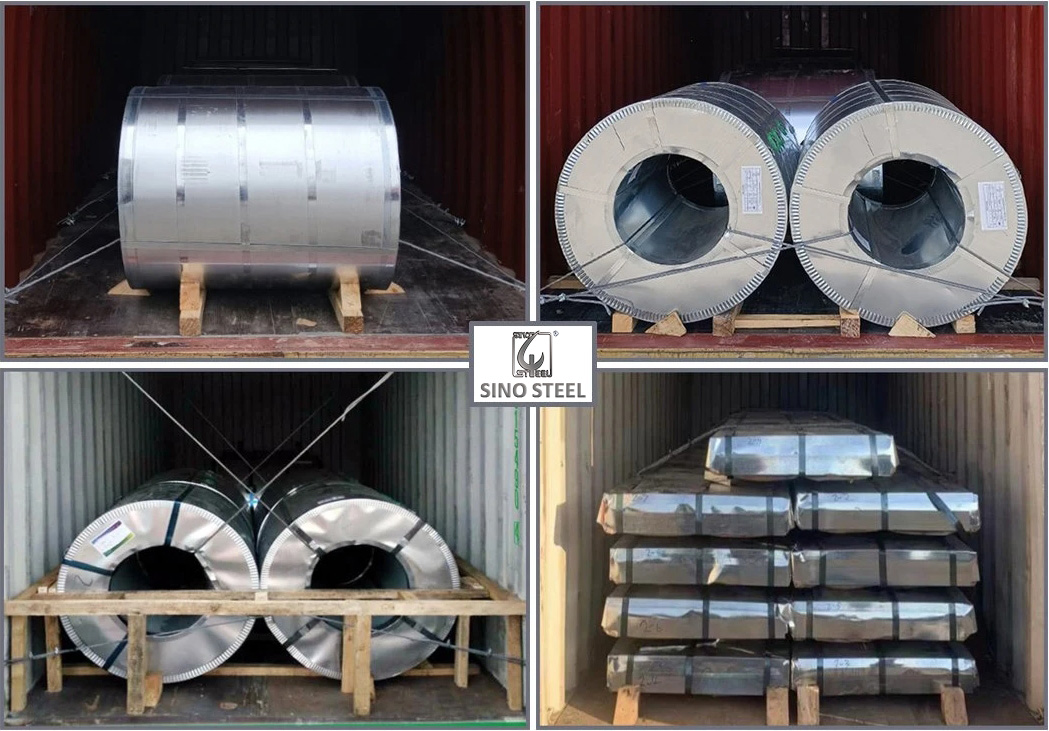

Packing & Shipping

Overseas Warehouse

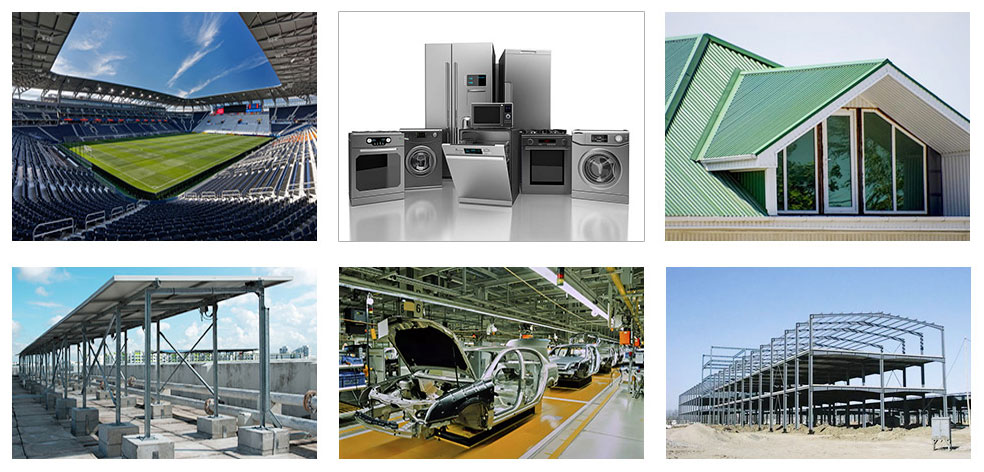

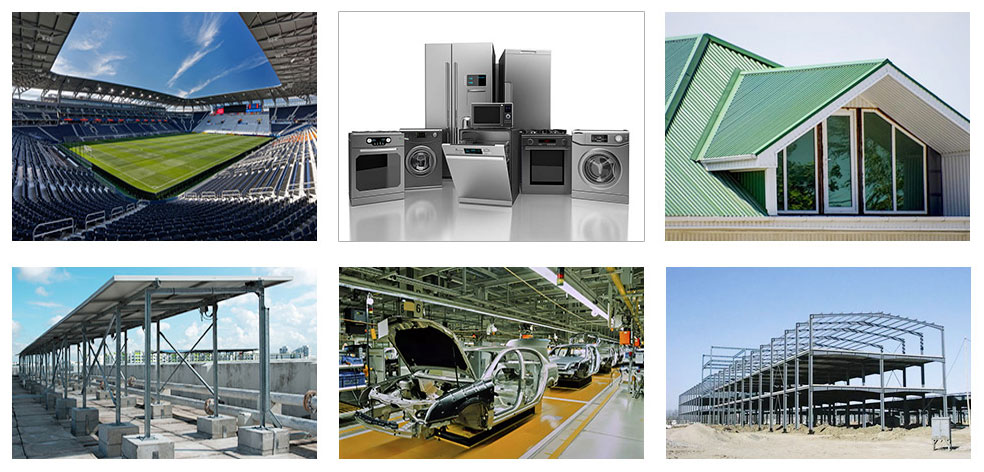

Applications of Galvanized Steel

Galvanized sheets are mainly used in the construction, home appliances, automobile and metallurgical industries. In the construction industry, they are mainly used for roofs, doors and windows, rolling doors, ceiling keels, etc.; household appliances such as refrigerators and washing machines; the automobile industry is mainly used for body shells, chassis, doors, fuel tanks, fenders, etc.; the metallurgical industry is mainly used for steel window blanks, color-coated plate substrates, etc.