When it comes to constructing or renovating a building, selecting the right roofing material is one of the most important decisions a property owner or contractor can make. Among the various factors that determine the quality and performance of a roof, the thickness of a metal roofing sheet is crucial. Roofing sheet thickness directly influences the roof's durability, load-bearing capacity, resistance to harsh weather, and long-term performance. Choosing an appropriate thickness is not just about material specifications; it is a key step to ensure the roof performs well over time and delivers a strong return on investment.

Metal roofing sheets have gained immense popularity due to their lightweight nature, longevity, and versatility. However, a common mistake in roofing projects is underestimating the importance of sheet thickness. Many property owners assume that all metal roofing sheets are created equal, but the difference of just a few millimeters can significantly affect strength, insulation, maintenance, and cost.

1. Common Metal Roofing Sheet Thickness Specifications

Metal roofing sheets are available in various thicknesses, commonly expressed in gauge numbers. The gauge number system is inversely proportional to thickness: the lower the gauge, the thicker the sheet. While multiple thicknesses are available for different applications, the most frequently used gauges are 24, 26, and 28. Understanding the characteristics of each gauge is essential for selecting the right metal roofing sheet.

24 Gauge (0.0223 inches / 0.567 mm)

The 24 gauge metal roofing sheet is thicker and heavier, making it highly suitable for industrial and commercial buildings. Its increased thickness provides greater strength and superior durability, allowing it to withstand heavy loads, high winds, and harsh weather conditions. In large-span industrial warehouses or commercial structures with minimal roof support, 24 gauge sheets are often preferred due to their structural reliability. While slightly more expensive than thinner alternatives, the long-term benefits in performance and maintenance savings make 24 gauge roofing sheets a cost-effective choice for high-demand applications.

26 Gauge (0.0179 inches / 0.455 mm)

The 26 gauge metal roofing sheet strikes a balance between performance and affordability. This thickness is commonly used in residential and light commercial buildings, offering sufficient strength for typical roof spans while remaining lightweight and easy to handle during installation. Homeowners and contractors often choose 26 gauge sheets for single-family homes, townhouses, or small commercial buildings. Its relatively lower cost compared to 24 gauge makes it an attractive option for projects where budget considerations are significant without compromising overall roof performance.

28 Gauge (0.0149 inches / 0.379 mm)

The 28 gauge metal roofing sheet is thinner and lighter than the other commonly used gauges. It is generally suitable for budget-conscious projects or areas with minimal exposure to extreme weather. While 28 gauge roofing sheets can be effective for certain applications, they may perform poorly under heavy snow loads, strong winds, or other demanding environmental conditions. As such, this gauge is less recommended for industrial or coastal projects, where higher structural integrity is required. However, for residential sheds, small garages, or temporary structures, 28 gauge can provide an economical and practical solution.

2. How to Choose the Right Thickness Based on Project Requirements

Selecting the appropriate metal roofing sheet thickness requires careful consideration of several factors, including building type, climate conditions, and budget. Choosing the wrong thickness can lead to roof failure, higher maintenance costs, and reduced lifespan. Here is a detailed breakdown to guide your decision-making process.

Building Type

Industrial Buildings: Large-scale industrial facilities, warehouses, and factories often require 24 gauge sheets or thicker to withstand heavy machinery vibrations, frequent roof traffic, and exposure to chemicals or pollutants. The added thickness ensures the roof remains structurally sound over decades, reducing the need for frequent repairs.

Residential Buildings: For single-family homes, townhouses, or multi-unit residential structures, 26 gauge roofing sheets are usually sufficient. They provide excellent protection while maintaining an affordable price point and ease of installation.

Light Commercial Buildings: Offices, small retail spaces, and low-rise commercial structures may also benefit from 26 gauge sheets, balancing durability, cost, and aesthetic appeal.

Climate Conditions

The local climate significantly impacts the choice of sheet thickness. Metal roofing sheets must be able to resist environmental challenges such as wind, snow, hail, and temperature fluctuations.

High Wind Areas: Coastal regions or storm-prone zones require thicker sheets, such as 24 gauge, to withstand strong gusts without deformation.

Snowy Regions: Areas with heavy snowfall benefit from thicker sheets to prevent bending or collapse under snow loads.

Extreme Temperature Zones: Thicker sheets provide better resistance to thermal expansion and contraction, reducing the risk of warping and joint stress.

Budget Considerations

While thicker sheets provide enhanced durability and performance, they also come at a higher initial cost. It is essential to balance performance requirements with budget constraints.

Projects with tight budgets may opt for 28 gauge sheets, but only where environmental and structural demands are minimal.

For long-term investments, thicker sheets (24–26 gauge) often result in lower maintenance costs and longer lifespan, ultimately providing a better return on investment.

3. Impact of Thickness on Metal Roofing Sheet Performance

The thickness of a roofing sheet affects several aspects of roof performance. Understanding these effects will help property owners make choices that optimize both durability and energy efficiency.

Durability

Thicker metal sheets are generally more durable and resistant to dents, scratches, and corrosion. A 24 gauge sheet, for example, will maintain its structural integrity for decades even under harsh weather conditions. Thinner sheets, such as 28 gauge, may be more susceptible to damage and wear, especially in industrial or coastal environments.

Wind Resistance

Roofing sheets must withstand wind uplift forces, especially in regions prone to storms. Thicker sheets provide higher resistance to bending and displacement, reducing the risk of roof damage. In contrast, thinner sheets may flex under strong winds, potentially compromising the roof’s waterproofing and structural safety.

Snow and Ice Loads

In areas with heavy snowfall, the weight-bearing capacity of the roof is crucial. Thicker sheets can support the accumulation of snow and ice without warping or failure. Residential properties with lighter snow loads may safely use 26 gauge sheets, but industrial buildings or northern climates may require 24 gauge for safety.

Thermal Insulation

While the primary role of metal roofing is structural, sheet thickness can influence thermal performance. Thicker sheets can provide slightly better insulation, reducing heat transfer and contributing to energy efficiency. This is particularly beneficial in extreme climates where HVAC costs can be significant.

4. How to Evaluate the Quality of Metal Roofing Sheets

Selecting the right thickness is important, but quality evaluation is equally critical. Even a thick sheet can fail prematurely if the material or coating is substandard.

Material Certification

Ensure the roofing sheets comply with international standards such as ASTM, ISO, or EN certifications. These certifications indicate the steel's quality, strength, and performance consistency, providing assurance of long-term durability.

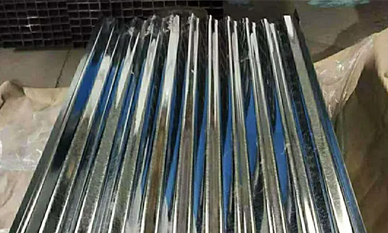

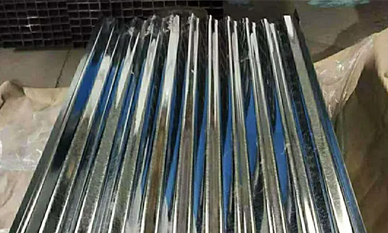

Coating Type

Metal roofing sheets are often coated with protective layers such as galvanized zinc, aluminum-zinc alloys, polyester, or PVDF coatings. These coatings prevent corrosion, enhance UV resistance, and contribute to aesthetic appeal. Higher-quality coatings can extend the lifespan of the roof, particularly in coastal, industrial, or high-precipitation regions.

5. Common Misconceptions About Metal Roofing Sheet Thickness

Choosing the right metal roofing sheet often involves misconceptions that can lead to higher costs or reduced performance.

Misconception 1: Thicker Sheets Are Always Better – While 24 gauge sheets offer higher strength and better resistance to wind and snow, thicker sheets are not always necessary. Residential buildings in moderate climates often perform well with 26 gauge sheets at lower cost.

Misconception 2: All Metal Sheets Are the Same – Material grade, coating type, and manufacturer quality greatly impact durability, corrosion resistance, and thermal performance. Sheets of the same gauge from different manufacturers can vary significantly.

Misconception 3: Thicker Sheets Are More Energy-Efficient – Energy efficiency depends more on coatings, reflective finishes, and insulation than on thickness alone. A 26 gauge sheet with reflective coating can outperform a thicker uncoated sheet.

Misconception 4: Thinner Sheets Cannot Withstand Harsh Weather – Proper installation, adequate support, and reinforced fasteners allow thinner sheets to perform reliably in less extreme conditions.

6. Conclusion: Making the Right Choice for Your Roofing Sheets

Selecting the appropriate thickness for your metal roofing sheets is crucial for balancing structural performance, environmental resilience, and cost-effectiveness. Understanding the differences between 24, 26, and 28 gauge sheets, and evaluating your project’s specific needs—including building type, climate conditions, and budget—ensures a roof that delivers long-lasting durability, safety, and energy efficiency. It is equally important to assess material quality, coating type, and the manufacturer’s reputation, rather than assuming thicker sheets are always better. A carefully chosen metal roofing sheet can provide decades of protection with minimal maintenance, enhancing both performance and peace of mind. For professional guidance and high-quality roofing solutions tailored to your project, consider consulting the experts at Shandong Sino Steel Co., Ltd., who can help you select the ideal sheet thickness and material to meet your construction goals.