Overview

The 0.55mm PPGL Color Coated Corrugated Roofing Sheets are designed for demanding roofing applications that require both structural strength and weather resistance. Constructed with a galvalume (55% aluminum, 43.4% zinc, 1.6% silicon) steel substrate, these sheets feature a pre-painted polymer coating (polyester or PVDF) and a classic corrugated profile, enhancing load-bearing capacity and water drainage efficiency.

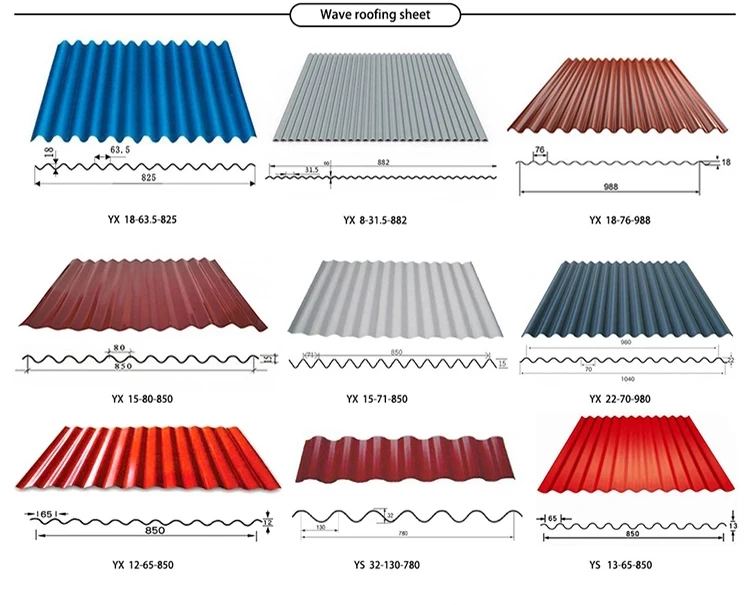

The 0.55mm thickness provides robust resistance to hailstones (up to 30mm diameter) and heavy snow loads (up to 300 kg/m²), while the galvalume coating offers 4-6 times the corrosion resistance of traditional galvanized steel. Available in standard wave profiles (e.g., 31-1000, 25-900) and a range of vibrant colors, they balance durability with aesthetic appeal for diverse architectural needs.

Features

Superior Weather Resistance:

Galvalume Substrate: Inhibits rust in coastal salt spray, industrial pollution, and high-temperature environments, with a predicted lifespan of 30-50 years.

PVDF Coating Option: Extends color retention to 20+ years, ideal for tropical regions with intense UV exposure.

Structural Rigidity: Corrugated design increases moment of inertia, allowing spans up to 3.5 meters without additional supports, reducing framework costs.

Efficient Water Management: Deep wave troughs (25-35mm height) ensure rapid rainwater runoff, minimizing ponding and leak risks on pitched roofs.

Fire & Impact Resistance: Non-combustible steel core meets fire safety standards, while the 0.55mm thickness resists dents from falling debris or hail.

Lightweight Design: Weighs 8-10 kg/m², easier to handle than concrete tiles, and compatible with lightweight steel or wooden truss systems.

Application

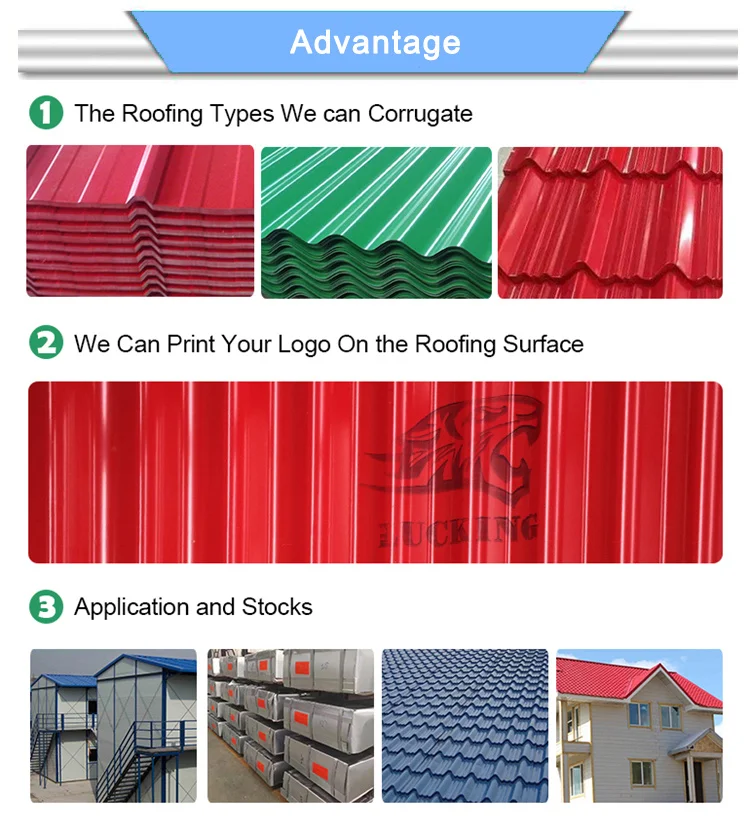

Industrial Roofing: Perfect for factories, power plants, and logistics centers, enduring exposure to chemical emissions, heavy machinery vibrations, and extreme weather.

Commercial Buildings: Used in shopping malls, sports complexes, and hotels, offering long-lasting protection with customizable colors to match architectural designs.

Residential Projects: Suitable for luxury villas, townhouses, and suburban homes, combining durability with curb appeal in both modern and traditional styles.

Agricultural Structures: Provides reliable roofing for barns, greenhouses, and livestock shelters, resisting corrosion from moisture, fertilizer, and animal waste.

FAQ

Q: Can these sheets be installed on flat roofs?

A: They are optimized for pitched roofs (minimum 5° slope). For flat roofs, consider a standing seam profile with additional waterproofing layers.

Q: How does galvalume compare to galvanized steel for roofing?

A: Galvalume offers better heat resistance and corrosion protection in harsh environments, while galvanized is more cost-effective for mild climates.

Q: What is the recommended maintenance schedule?

A: Annual inspection and cleaning with non-abrasive soap to remove debris; touch up cut edges with zinc-rich paint to prevent rust.

Q: Are there options for energy-efficient coatings?

A: Yes, reflective white or light-colored coatings can reduce heat absorption by 30%, lowering cooling costs in hot climates.

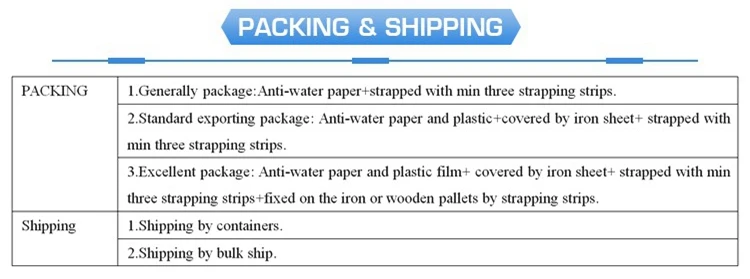

| Item | Value |

| Product Name | Corrugated Galvanized Prepainted Roofing Sheet |

| Material | SGCC, DX51D, DX53D, DX54D, SPHC, Q195 and etc. |

| Thickness | 0.12mm-0.8mm or customized |

| Width | 600mm-1500mm or customized |

| Zinc Coating | 30-500 g/㎡ |

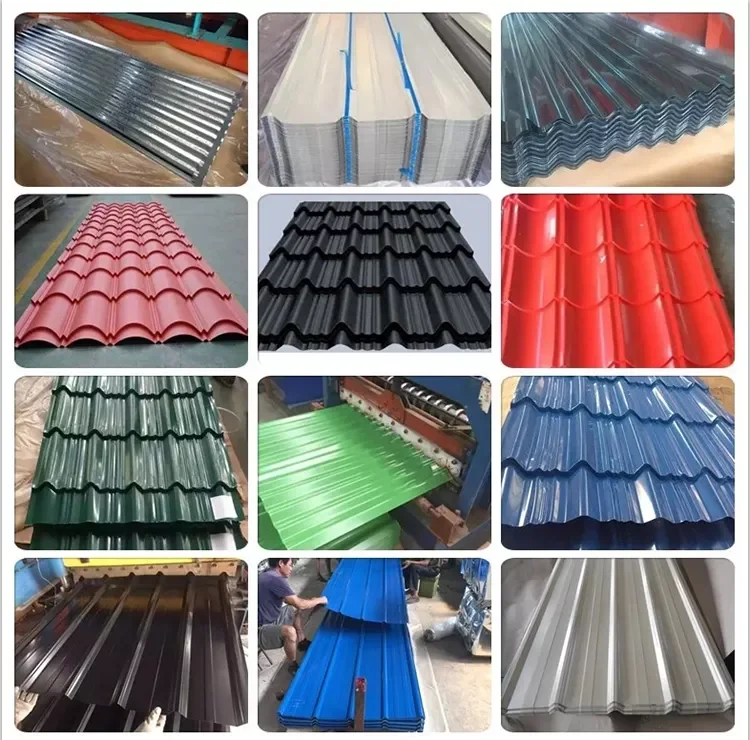

| Color Choice | Natural color, blue, green, yellow, red, grey, black, white and others |

| Standard | ASTM, BS, GB, JIS and etc. |

| Surface | Finished or unfinished is avaliable, coat or without coat |

| Application | Widely used in construction, home, appliance, decoration, wear resistant steel and etc. |