Product Description

The PPGI (Polyester-Painted Galvanized Iron) Roofing Sheet is a premium roofing solution integrating the corrosion resistance of galvanized steel with the decorative and protective benefits of a pre-painted polyester coating. Manufactured from 24-26 gauge (0.4-0.5mm) GI steel substrate with a 50-150g/m² zinc coating, the sheet features a dual-layer coating system: a epoxy primer for adhesion and a polyester topcoat (20-30μm thickness) in vibrant RAL colors. The surface may be smooth or stucco-embossed to enhance anti-slip properties and hide minor imperfections. Meeting ISO 15716 and AS/NZS 2728 standards, it offers a service life of 10-15 years in moderate climates, with optional PVDF coatings for 20+ years in harsh environments.

Features

Weathertight Performance: The polyester coating resists UV degradation, rain penetration, and thermal expansion, ensuring long-term waterproofing for roofs.

Aesthetic Flexibility: Available in 50+ RAL colors and customizable textures, enabling architects to match building designs while reducing on-site painting costs.

Lightweight & Strong: At 0.4-0.5mm thickness, it weighs 3-4kg/m², reducing structural load while supporting wind speeds up to 150km/h (with proper installation).

Energy-Efficient Design: Solar-reflective coatings (optional) can lower indoor temperatures by 3-5°C, reducing air conditioning costs in commercial and residential buildings.

Easy Installation: Pre-cut to standard lengths (e.g., 3m, 6m) with trapezoidal or corrugated profiles, compatible with common roofing accessories like ridge caps and gutters.

Application

Residential Roofing: Ideal for pitched or flat roofs in houses, villas, and townhomes, offering low maintenance and long-lasting color retention.

Commercial Buildings: Used for warehouse roofs, factory sheds, and retail complexes, combining durability with cost-effective thermal insulation.

Infrastructure Projects: Suitable for stadium roofs, airport terminals, and agricultural greenhouses, where fire resistance (non-combustible steel substrate) and weather resistance are critical.

Retrofitting Projects: Lightweight design allows easy installation over existing roofs without structural reinforcement, popular for renovation projects.

FAQ

Q: How does PPGI roofing compare to metal tile roofing?

A: PPGI sheets are more cost-effective and easier to install, while metal tiles offer superior aesthetics but higher weight and cost.

Q: Can I walk on PPGI roofing sheets?

A: Yes, with caution—use non-slip footwear and walk on purlin supports to avoid denting; embossed surfaces provide better traction.

Q: What is the recommended overlap for installation?

A: Overlap 80-100mm for corrugated profiles and 50-60mm for trapezoidal profiles to ensure water tightness.

Q: How do I repair a scratched coating?

A: Clean the area and apply a matching touch-up paint within 24 hours to prevent rust initiation.

Q: Is PPGI roofing compliant with fire safety standards?

A: Yes, the galvanized steel substrate is non-combustible, meeting Class A fire resistance ratings in most regions.

Roofing sheet / Corrugated Steel Sheet |

|

Standard | AISI,ASTM,GB,JIS | Material | SGCC,SGCH,G550,DX51D,DX52D,DX53D |

Thickness | 0.105—0.8mm | Length | 16-1250mm |

Width | Before Corrugated:762-1250mm |

After corrugated:600-1100mm |

Color | Top side is made according to RAL color, Back side is white grey in normal |

Tolerance | +-0.02mm | Zinc | 30-275g |

Weight |

Top Panit | 8-35 Microns | Back | 3-25 Microns |

Panit |

Basal Plate | GI GL PPGI | Normal | Wave Shape,T Shape |

Roof |

Shape |

Certification | ISO 9001-2008,SGS,CE,BV | MOQ | 25 TONS (in one 20ft FCL) |

Delivery | 15-20 days | Monthly Output | 10000 tons |

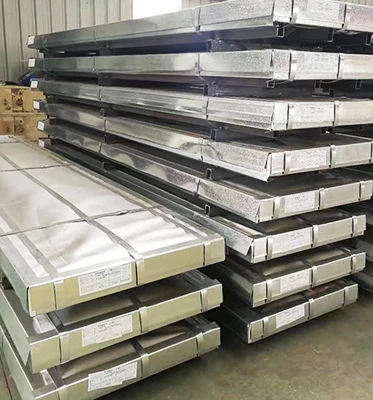

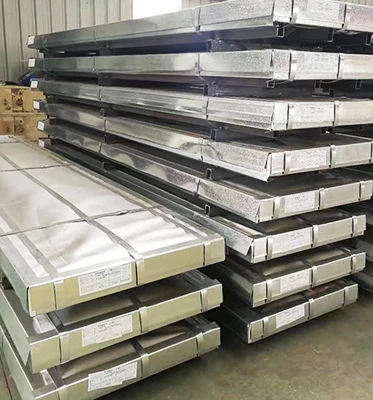

Package | seaworthy package |

Surface treatment | unoil,dry,chromate passivated, non-chromate passivated |

Spangle | regular spangle,minimal spangle, zero spangle,big spangle |

Payment | 30%T/T in advanced+70% balanced;irrevocable L/C at sight |

Remarks | nsurance is all risks and accept the third party test |