You can find aluminum coil in many new buildings. It comes in big rolls. It is strong and light. It does not get damaged by weather easily. Builders use it for roofing and cladding. They also use it for insulation. In the last ten years, more projects have used aluminum coil. This is because it lasts a long time. It does not rust or break down easily. In 2024, about 38% of aluminum coil was used in building projects. This shows it is becoming more important. Our company sees more people want it. They want building materials that are strong and good for the planet.

Key Takeaways

Aluminum coil is light and tough. It works well for roofing, cladding, and insulation in buildings.

New coatings in 2025 will make aluminum last longer. These coatings help aluminum stand up to bad weather. This means buildings will stay strong for more years.

Being green is important. Aluminum coil can be recycled completely. More green building projects use aluminum coil now.

Digital fabrication technology will make aluminum parts faster. It will help cut down on waste. It also lets builders change designs more easily.

The aluminum coil market will get much bigger soon. New technology and eco-friendly materials help this growth.

Aluminum Coil Overview

What Is Aluminum Coil

Aluminum coil is used in many buildings. It is a flat sheet rolled up. Builders like it because it is easy to move and bend. There are different kinds of aluminum coil. Each kind works best for certain jobs:

1000 series aluminum coil: People use this for packaging and building. It is cheap and does not rust.

2000 series aluminum coil: This kind is strong and lasts long. It is used in cars and machines.

3000 series aluminum coil: It can handle heat and does not wear out fast. It is good for tanks and frames.

5000 series aluminum coil: This one bends the most. You see it in drink cans and boats.

7000 series aluminum coil: It is the strongest type. It is used in planes and big buildings.

Raw aluminum coil can be made into many things. Most builders pick coated aluminum coils. These have a layer that keeps them safe from weather. The coating also makes them look nice. You can choose from many colors and styles. Coated aluminum coils help buildings last longer and look new.

Manufacturing Process

You may wonder how aluminum coils are made. The process starts with raw aluminum coil. Factories use special ways to make coated aluminum coils. Here is a table that shows the main steps:

Manufacturing Method | Description |

Hot Rolling | Aluminum is heated and rolled into coils. This makes it easier to shape. |

Cold Rolling | The coil is rolled again to make it smoother and stronger. |

Surface Treatments | The coil can be coated or polished. The coating adds color and protects it. |

It is important to know how aluminum coils are made. Factories check the materials and watch each step. They test the finished coated aluminum coils. They follow rules like ISO 9001 and ASTM B209. This makes sure the coated aluminum coils are high quality. When you pick coated aluminum coils, you get something safe and strong for your building.

Characteristics of Aluminum Coil

Durability and Strength

People want building materials that last a long time. Aluminum coil is special because it does not get damaged easily. It keeps its shape for many years. When you look at aluminum coil and other metals, you see some differences. Here is a table that shows how they compare:

Metal | Tensile Strength Comparison | Weight Comparison | Applications |

Aluminum | Lower than steel, copper, titanium, brass | Lighter than all | Preferred in lightweight applications like aerospace and automotive |

Steel | Stronger than aluminum | Heavier | Used in structural applications where strength is paramount |

Copper | Stronger than aluminum | Heavier | Utilized in electrical applications and plumbing due to conductivity |

Titanium | Stronger than aluminum | Denser but lighter than steel | Used in aerospace and military applications for strength and lightness |

Brass | Stronger than aluminum | Heavier | Known for corrosion resistance, used in plumbing and decorative hardware |

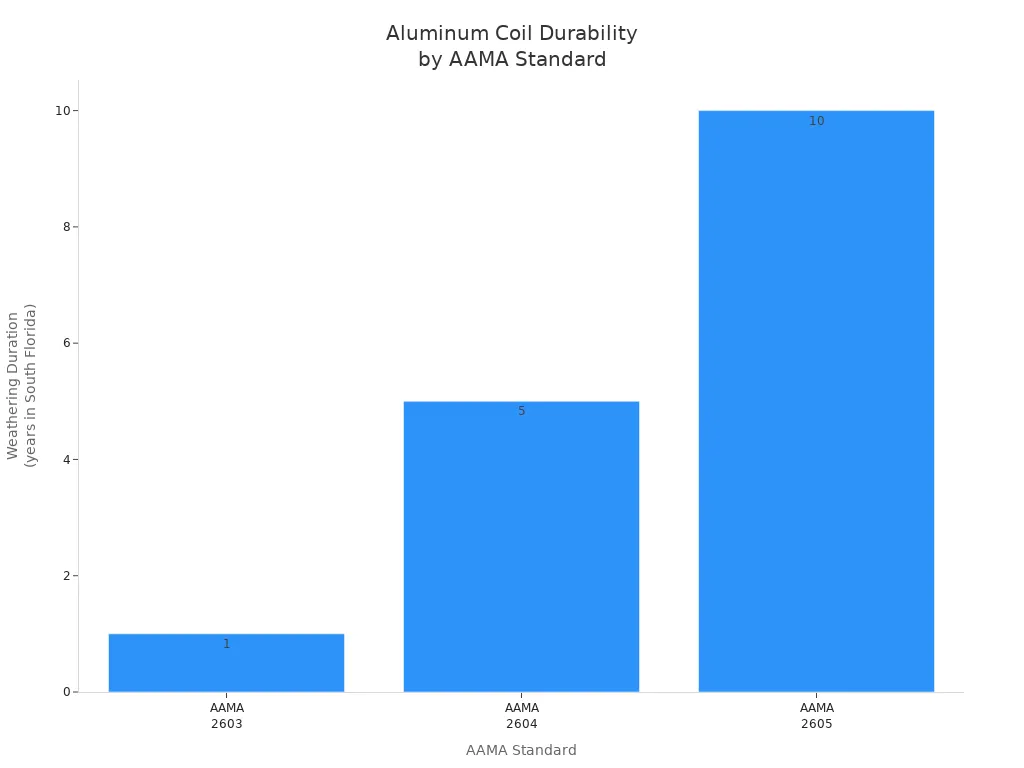

Aluminum coil is not as strong as steel. But it is much lighter and still strong enough for many jobs. Tests in labs show aluminum coil is tough and lasts a long time. The AAMA standards help check how long aluminum coil can last outside. Here is a chart that shows how long it lasts in different tests:

AAMA 2605 aluminum coil can last up to 10 years outside. This shows that aluminum coil is strong and lasts in buildings.

Lightweight and Flexibility

Aluminum coil is very light. It weighs less than steel. Here is a table that shows how dense each material is:

Material | Density (kg/m²) | Suitability for Building Applications |

3004 Colored Aluminum Coil | 2730 | Lightweight requirements |

Color Coated Steel Coil | 7850 | Hardness and strength requirements |

You can carry and put up aluminum coil without much trouble. It is also easy to bend and shape for different designs. The T-bend test shows you can bend aluminum coil without cracks. This makes it great for new building styles. Aluminum coil is not as strong as steel and can dent if you are not careful. But its light weight and flexibility make it useful for many projects.

Weather Resistance

Aluminum coil does not rust or break down in bad weather. You can use it in places with lots of rain, sun, or snow. Tests show aluminum coil can handle UV light, heat, and water. Here is a table with the test cycles:

Test Cycle Option | UV Irradiation | Temperature | Condensation | Application |

Option 1 | 8 hours at 60℃ | 60℃ | 4 hours at 50℃ | General applications (e.g., outdoor furniture) |

Option 2 | 8 hours at 60℃ | 60℃ | 0.25 hours water spray, 3.75 hours at 50℃ | Thermal vibration applications |

Option 3 | 8 hours at 70℃ | 70℃ | 4 hours at 50℃ | Automatic surface applications |

Studies show that aluminum coil can change color in different weather and pollution. Anodized materials can last outside for many years. Sometimes, aluminum coil can fade in places with lots of pollution or humidity. Even so, aluminum coil is a good choice for most building needs.

Common Uses of Aluminum in Construction

Aluminum coil is used a lot in new buildings. It is strong and light. Builders like it because it is easy to shape. You can see aluminum coil in many places. It is important in construction today. Builders pick it for many jobs because it works well.

Roofing and Cladding

Aluminum coil is often used for roofs and walls. It is simple to put on buildings. It does not make the building heavy. Aluminum coil can handle rain, sun, and wind. You can pick from many colors and looks. This helps match any building style. The table below shows why builders like aluminum coil for roofs and walls:

Benefit | Description |

Lightweight Yet Strong | Aluminum is about 1/3 the weight of steel, reducing structural load and speeding up installation. |

Corrosion Resistance | Forms a protective oxide layer, ideal for harsh environments, resistant to UV rays and pollutants. |

Aesthetic Versatility | Available in various finishes and colors, enhancing architectural appeal. |

Sustainability | 100% recyclable and energy-efficient, making it eco-friendly for green buildings. |

Long Lifespan with Minimal Maintenance | Can last 30–50 years or more with little upkeep required. |

Tip: If you want a roof that lasts and is easy to care for, aluminum coil is a good pick.

Siding and Facades

Aluminum coil is used for siding and outside walls. It keeps the building safe and looks nice. Aluminum siding costs less than wood. Sometimes, it is even cheaper than vinyl. Here is a quick look:

Aluminum siding costs about $11,750.

Vinyl siding costs about $12,200.

Wood siding costs the most because it needs more care.

Builders use aluminum coil for walls for many reasons:

Pre-coated aluminum is tough and can handle bad weather.

It keeps its shine and color even when bent.

The color stays the same everywhere.

Aluminum coil comes in many colors and styles. You can make it look like other metals. It is light, so it is easy to move and put up. You get a strong and pretty wall that lasts a long time.

Window Frames and Trim

Aluminum coil is a top pick for window frames and trim. You can wrap windows with aluminum to keep out water. This helps stop air from getting in or out. It makes the building save more energy. Aluminum’s shiny surface keeps heat out in summer and in during winter. Here are some good things about it:

Aluminum window wrap helps save energy by stopping air leaks.

It adds a layer that makes windows work better.

The shiny part of aluminum bounces heat away, which saves energy.

Your windows look nice and help lower your energy bills.

Gutters and Downspouts

Most houses use aluminum coil for gutters and pipes. In 2020, 77% of these parts in homes were made from aluminum. Aluminum gutters last a long time and do not rust. The table below shows how different aluminum types work in gutters:

Alloy Type | Corrosion Resistance | Applications |

General-purpose aluminum | Good | Structural frame molding, bridge components, marine applications |

Non-heat treatable alloy | Excellent | Shipbuilding, extreme environments like seawater immersion |

Performance alloy | Good | Automotive industry, high-quality surface finishing |

Aluminum gutters are easy to put up because they are light. They do not rust, so you do not have to worry about leaks.

Insulation and Energy Efficiency

Aluminum coil helps keep buildings warm or cool. It stops heat from moving in or out. This means you spend less money on heating and cooling. Here are some ways aluminum coil helps:

Thermal Insulation: Aluminum coil blocks heat, so you use less energy.

Reflectivity: Aluminum coil bounces back over 80% of heat after treatment.

When you use aluminum coil with rock wool or aerogel, you can get very low thermal conductivity.

In cold storage, aluminum coil with special panels can save up to 40% energy.

Your building stays comfy all year and uses less power.

Fascia, Soffits, and Flashing

Aluminum coil is used for fascia, soffits, and flashing. These parts protect the edges of roofs and walls. Aluminum coil is easy to cut and bend. It stands up to water and bad weather. Here are the main good things:

Durability: Aluminum flashing lasts a long time and keeps buildings safe.

Resistance to Corrosion: It does not rust, even when it is wet.

Ease of Installation: Aluminum is light, so you can put it up fast.

You can count on aluminum coil to keep your building strong and looking good.

Note: These common uses show that aluminum coil is flexible and reliable for many building jobs.

Trends for 2025

Advanced Coatings

In 2025, new coatings will be used on metal. Companies are making PVDF and low-temperature cure systems. These coatings help make building materials lighter and stronger. They are good for saving energy and stopping rust. Many companies now use water-based and bio-based coatings. These coatings are better for the environment and follow new safety rules.

Here is how advanced coatings help metal last longer:

Benefit | Description |

Corrosion Resistance | Stops rust and damage from water or chemicals. |

UV Protection | Blocks harmful sunlight, so colors do not fade or weaken. |

Durability | Makes metal last longer, so you do not need to fix or replace it often. |

These coatings protect against heat, cold, and wet weather. They also help buildings look new for a long time.

Green Building Integration

More buildings will use green materials soon. Builders pick products that save energy and help nature. Many metal products now have special sustainability certifications. These show the product is made safely and can be recycled.

Certification Name | Certification Period | Scope of Certification |

Performance Standard V3 (2022) | 02.05.2024 - 01.05.2027 | Covers making and recycling flat-rolled metal coils at U.S. factories. |

When you choose certified products, you help the planet.

New Architectural Uses

Designers are using metal in new ways. Here are some trends you will see in 2025:

Builders use more recycled metals to help the environment.

New metal composites are stronger and more flexible.

Metal is important for the look and use of building facades.

Warm metallic finishes make rooms feel modern and nice.

Smart technology works with metal to save energy.

These changes help you build safer, greener, and better-looking spaces.

Digital Fabrication

More digital tools are used in building now. Machines cut and shape metal very accurately. This means you get custom parts faster and waste less material. Digital fabrication saves time and money. It also lets you try new designs that were hard to make before.

The market for metal products in construction is growing quickly. Experts think it will grow by 8.6% each year from 2025 to 2032. You will see more choices and better products as these trends continue.

Aluminum coil helps buildings stay strong and light. It also keeps them safe from bad weather. Builders use aluminum coil for roofs, walls, and windows. It bends easily and lasts a long time. This makes it a good pick for many building jobs. In 2025, new coatings and green building ideas will be important. Digital tools will also change how buildings are made.

Here is what experts found out lately:

Key Takeaways | Description |

Market Size and Growth Projections | Experts think the aluminum coil market will keep growing until 2032. |

Geopolitical Impact | Problems between countries can change how building materials are traded. |

Regional Market Outlook | The market looks different in each country and region. |

Trends and Drivers | New technology and caring for the planet are changing the industry. |

Competitive Analysis | Top companies use new ideas to stay ahead. |

Keep learning about new changes so you can pick the best materials for your projects.

Our company helps builders and designers get good metal products. We make sure our products are strong and safe. We also care about the planet. You can trust us to give you what you need to build great things for the future.

FAQ

What makes aluminum coil a good choice for building projects?

Aluminum coil is strong and light. It does not rust or get damaged by weather. You can bend it into many shapes. Builders like it because it lasts long and is easy to take care of.

Can you recycle aluminum coil after use?

Yes, you can recycle aluminum coil. ♻️

Aluminum stays good even after recycling. Recycling saves energy and helps the earth.

How does aluminum coil help with energy efficiency?

Aluminum coil reflects heat away from buildings. This keeps buildings cooler in summer and warmer in winter.

Is aluminum coil safe for outdoor use?

Feature | Benefit |

Corrosion resistance | No rust in rain or snow |

UV protection | Keeps color and strength |

Aluminum coil works well outside in many kinds of weather.