Product Overview

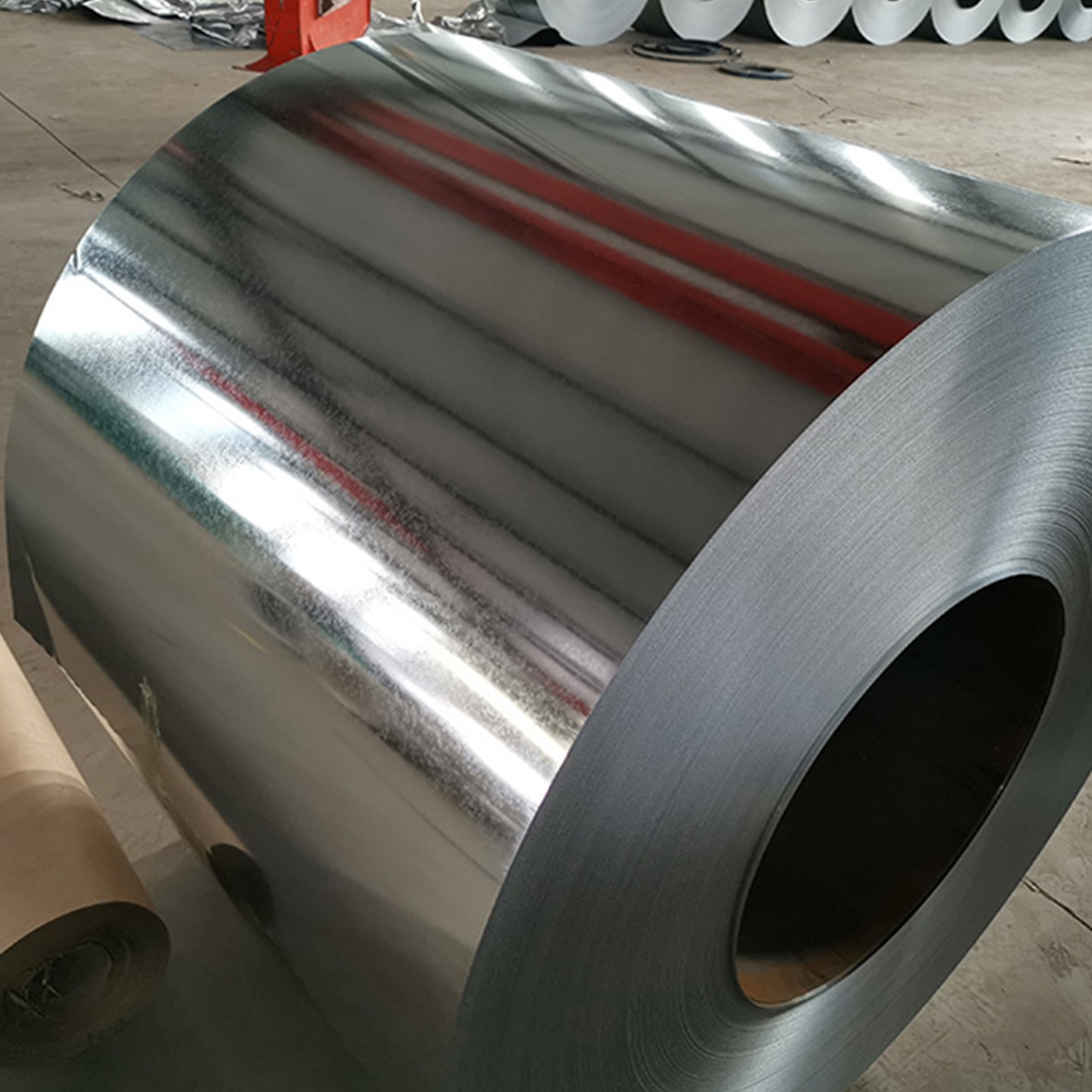

The Dx51d Hot Dipped Coil is a high-quality galvanized steel coil manufactured through advanced hot-dip galvanizing technology. With zinc coating weights ranging from Z40–Z275 g/m², this product delivers long-lasting corrosion resistance and mechanical durability. Its versatile specifications make it suitable for a wide range of industrial and construction applications.

Product Description

Our Dx51d Hot Dipped Coil is engineered to combine strength, versatility, and superior protection. Each coil is submerged in a molten zinc bath to ensure complete coverage, forming a metallic bond between steel and zinc. This process creates a bright, smooth surface that is not only visually appealing but also resistant to rust, scratches, and extreme weather conditions.

The coils are designed to balance mechanical strength with ease of processing, making them suitable for cutting, bending, welding, and shaping without compromising surface integrity. With its uniform zinc layer, the coil ensures excellent adhesion of paints and coatings, giving manufacturers more flexibility in product finishing.

Technical Parameters

| Parameter | Value |

| Thickness | 0.105~4.0 mm |

| Width | 30-1500 mm |

| Zinc Coating | 30~600 G/M2 |

| Coil ID | 508 / 610 mm |

| Coil Weight | 3-5 Tons |

| Standard | ASTM-A653; JIS G3302; EN10147; etc. |

| Payment Terms | T/T, LC, Western Union, Paypal, O/A, DP |

| Regular Order | 25 tons or one container (contact for smaller orders) |

| Hardness | Soft hard (HRB60), medium hard (HRB60-85), full hard (HRB85-95) |

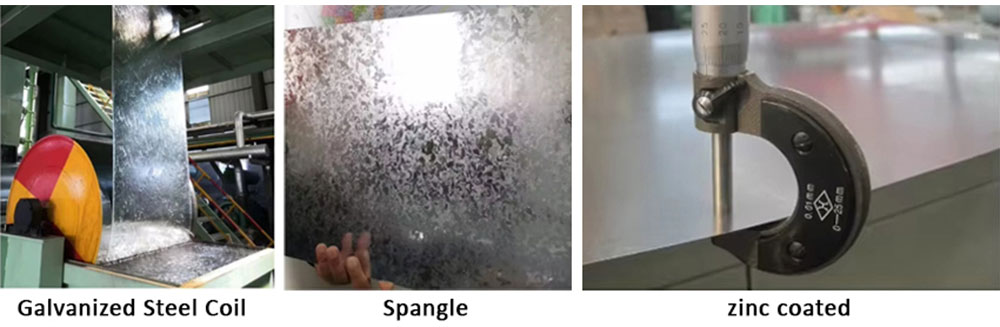

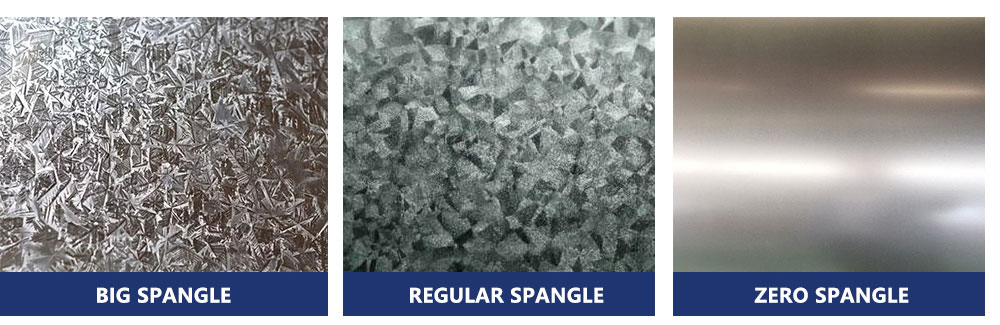

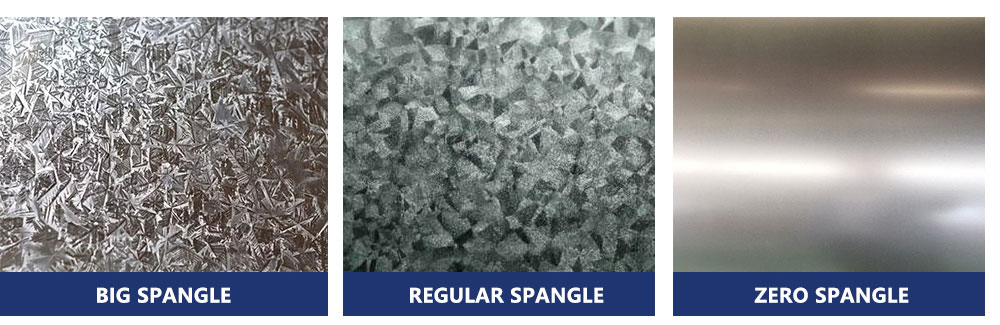

| Surface Structure | Regular spangle, Minimum spangle, Zero spangle, Big spangle |

| Surface Treatment | Chromated/Non-Chromated, Oiled/Non-oiled, Skin pass |

| Standard | ASTM, JIS, GB, AISI, DIN, BS |

| Certification | ISO, RoHS, IBR |

| Technique | Hot Rolled |

| Application | Container Plate |

| Edge | Slit edge |

Key Features & Highlights

Corrosion Resistance: Zinc coating ensures protection even in coastal or humid environments.

Versatility: Applicable for roofing, wall cladding, automotive panels, household appliances, and agricultural structures.

Customizable Surface: Options for spangle, chromated, oiled, or unoiled finishes.

Strength & Formability: Maintains high yield strength while remaining easy to process.

Eco-Friendly: Fully recyclable steel with reduced maintenance costs.

Applications

The Dx51d Hot Dipped Coil provides unmatched flexibility across industries:

Construction: Roofing sheets, wall panels, structural frames.

Automotive: Car body panels, underbody components.

Household Appliances: Refrigerator panels, washing machines, ovens.

Agriculture: Silos, barns, fencing, and storage structures.

Light Industry: Furniture, electrical enclosures, and packaging.

Why Choose Us

Advanced Production Lines: High-speed continuous hot-dip galvanizing equipment.

Strict Quality Control: 100% surface inspection and mechanical property testing.

Global Certification: ISO, ASTM, EN compliance for international markets.

Customization: Zinc coating, thickness, width, and surface treatments tailored to customer needs.

Export Expertise: Long-term supply to over 80 countries with professional logistics support.

FAQ

Q1: What is the minimum order quantity?

A: Standard MOQ is 25 MT, equivalent to one container load.

Q2: Can you provide samples?

A: Yes, free A4-size samples are available; courier costs borne by the customer.

Q3: How long is the delivery time?

A: Generally 15–30 days after order confirmation, depending on quantity.

Q4: Can I request custom coatings or surface finishes?

A: Absolutely. We offer customized zinc coatings, surface treatments, and coil dimensions.

Q5: What standards do your products comply with?

A: All coils meet ASTM, JIS, EN, and GB international standards.

DX51D Galvanized steel is a type of steel that has been treated with zinc to enhance its corrosion resistance.

1.Surface structure code / Not just polished

Normal zinc flower N NS Small zinc flower M MS Zinc free flower F FS Zinc ferroalloy ZF ZFS

2.Surface quality code

Ordinary surface FA Advanced surface FC Higher surface FB

3.Surface treatment symbol

Passivation C Unction O Paint sealant L Phosphating P Don't deal with U

Service

Custom Orders: Tailored sizes, thicknesses, and coatings to meet customer needs.

Quality Assurance: Rigorous testing for surface quality and coating thickness to ensure high standards.

Flexible Payment Options: Multiple payment methods like T/T, LC, and PayPal.

Global Delivery: Timely and reliable worldwide delivery for large and small orders.

Packaging: Safe packaging suitable for international shipment.