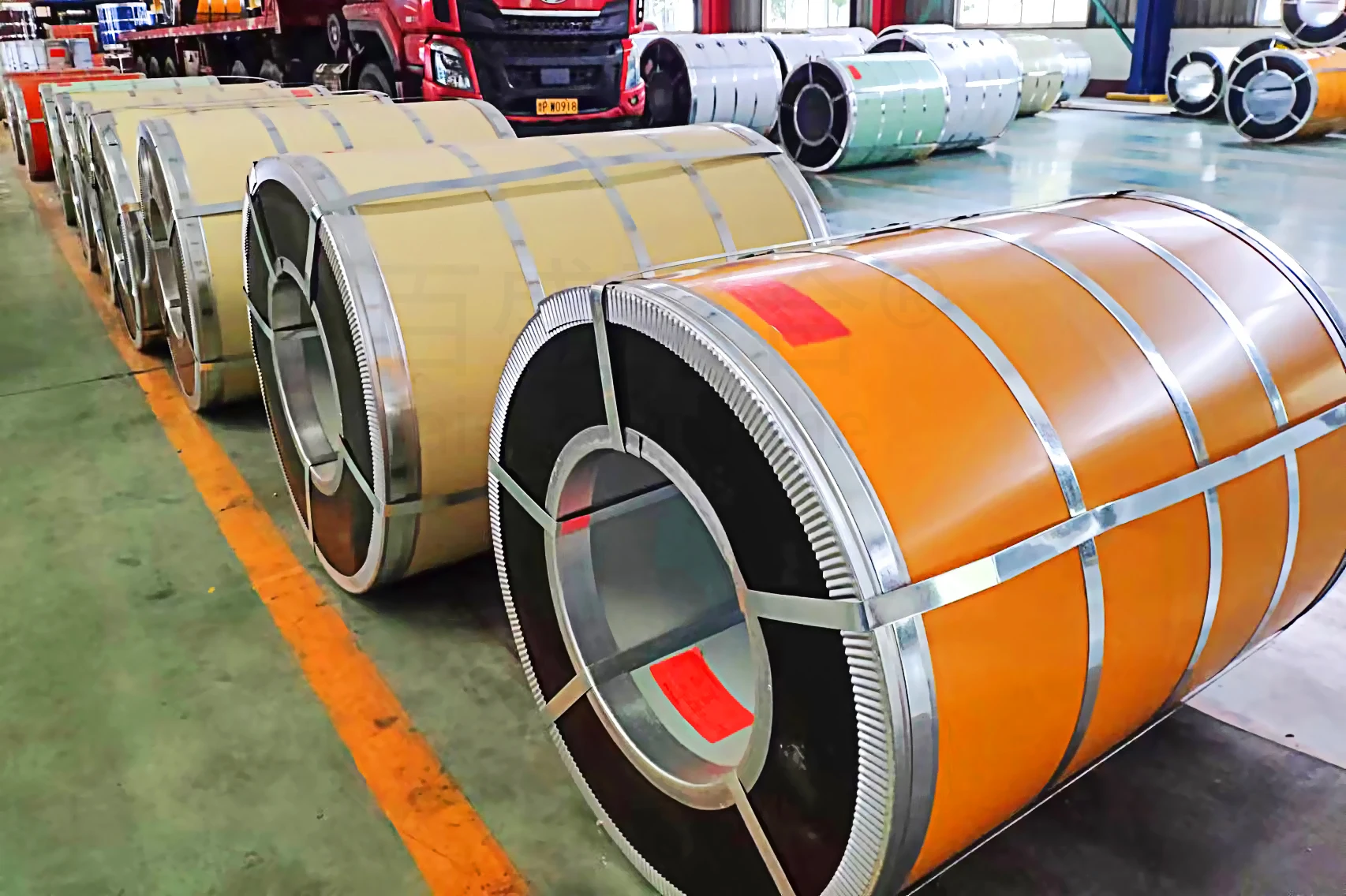

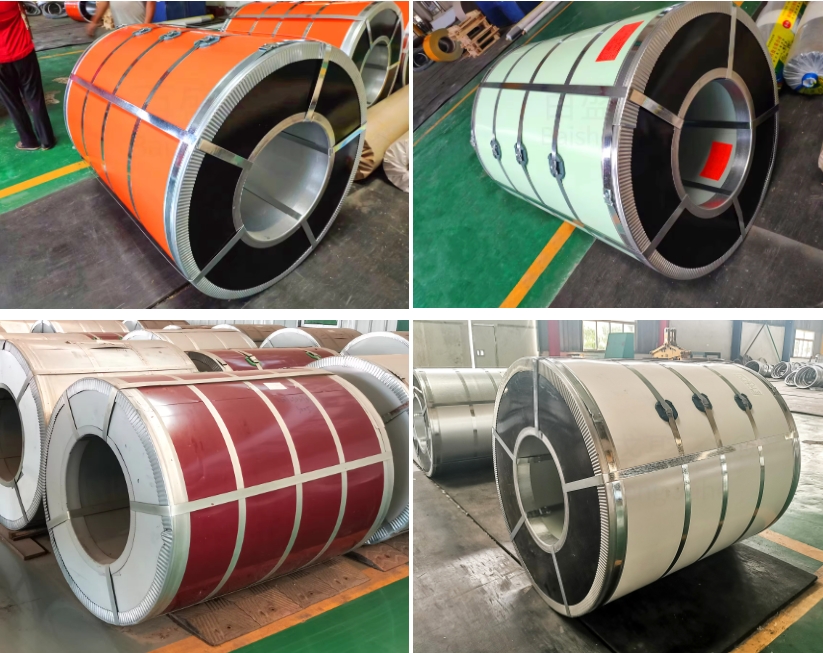

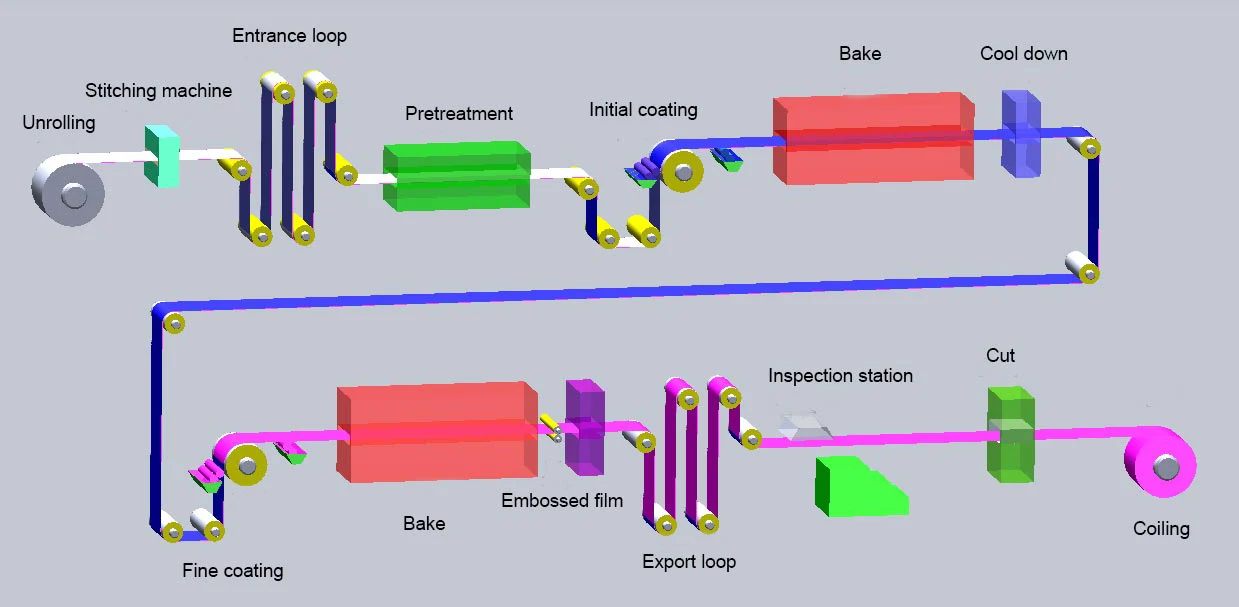

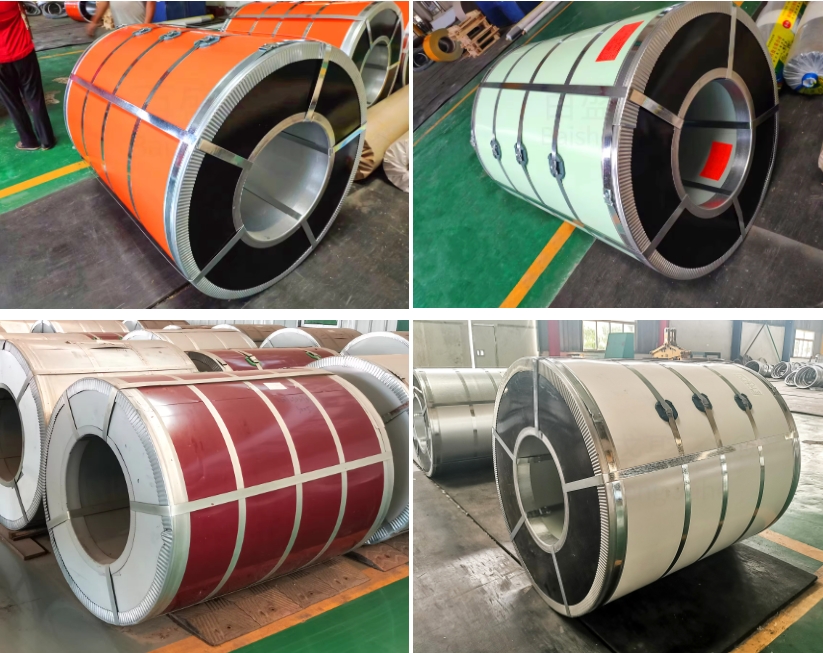

Pre-painted coils are produced by coating a layer of paint on the surface of cold rolled, galvanized or galvalume coils. Aesthetic appeal and durability are the key features of color coated steel coils. A wide selection of colors is available to the customer and paints designed to meet specific end use could be specified. The pre-painted coils are suitable for direct interior as well as exterior application, sandwich panels and so on.

Type 1 color coated

Type 2-patterned

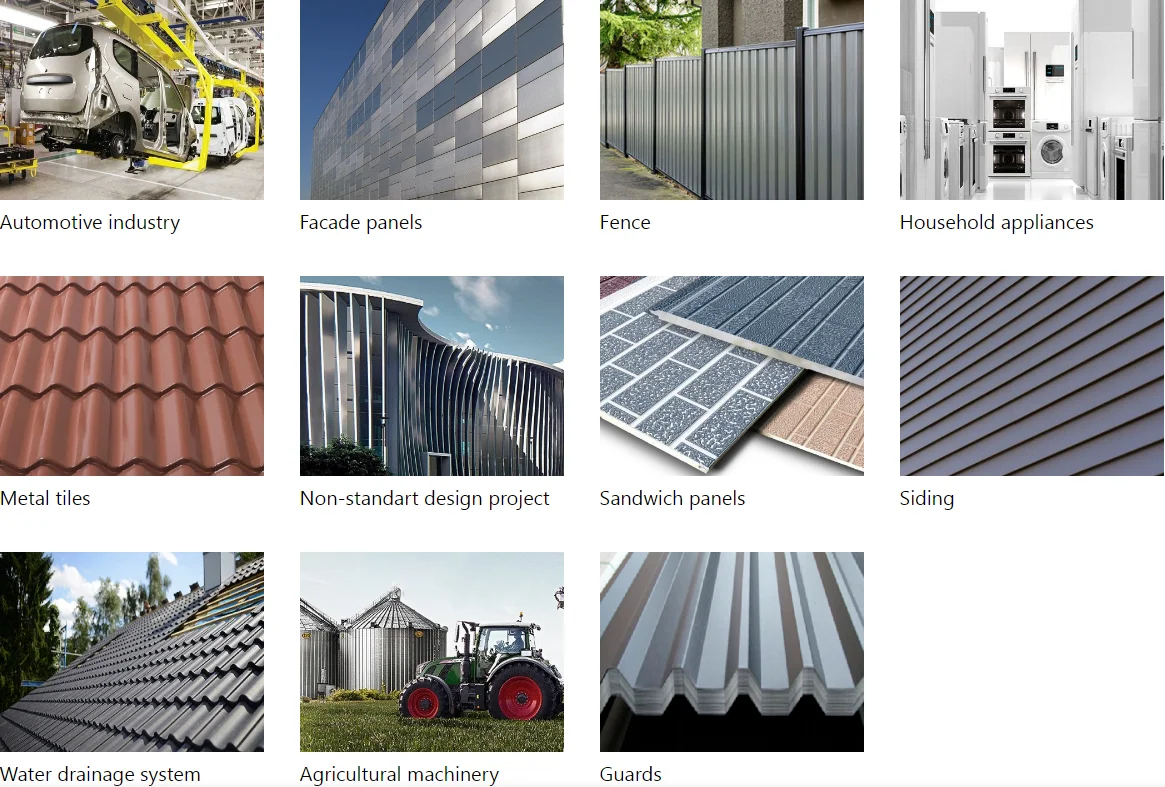

Colour coated coil is light, beautiful, good anti-corrosion performance, can be directly processed, the colour is generally divided into off-white, navy blue, brick red, mainly used in advertising, construction, home appliances, electrical appliances, furniture, transportation and other industries.

1, durability, good corrosion resistance, long service life.

2、Good heat resistance, not easy to change colour under high temperature.

3, Good heat reflectivity and weldability.

4、The two main features of strong durability and high cost performance make it widely used in industrial buildings, steel structures and civil buildings.

| Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

|

Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ,

SECC,SECE, BLCE+Z, BLDE+Z, BUSDE+Z or Customer’s Requirement |

| Base Steel | Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

| Thickness | 0.12-6.0mm |

| Width | 600-1500mm |

| Surface Color | RAL,wood grain pattern, camouflage pattern , stone pattern, matte pattern , high gloss pattern , flower pattern, etc |

| Quality | Approved by SGS,ISO |

| Coil Weight | 3-20metric ton per coil |

|

Package | Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped byseven

steel belt.or according to customer's requirement |

| Export market | Europe,Africa,Central Asia,Southeast Asia,Middle East,South America,North America, etc |

| | | |

| | | | | |

| cold rolled steel sheet | DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | | | | | |

| DC52D+Z (St04Z), DC52D+ZF | | | | | |

| DC53D+Z (St05Z), DC53D+ZF | | | | | |

| DC54D+Z (St06Z), DC54D+ZF | | | | | |

| DC56D+Z (St07Z), DC56D+ZF | | | | | |

| hot rolled steel sheet | DD51D+Z (St01ZR, St02ZR) | | | | | |

| DD54D+Z (St06ZR) | | | | | |

Substrate Type

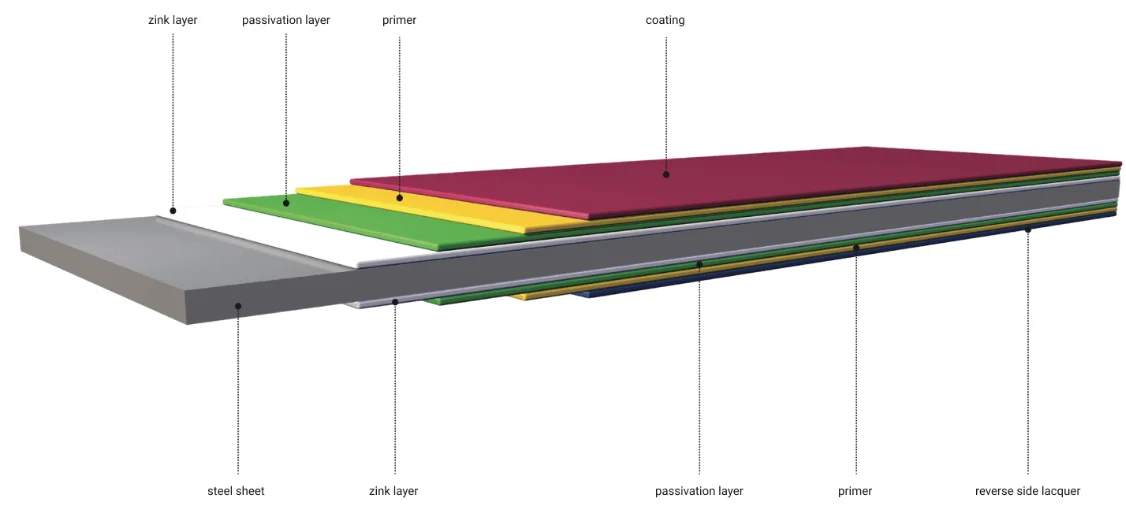

1. Hot-dip galvanised colour coated steel sheet (colour coated steel sheet) The product obtained by applying organic coating on hot-dip galvanised steel sheet is hot-dip galvanised colour coated sheet, hot-dip galvanised colour coated sheet has rust-proofing effect in addition to zinc protection, and its service life is longer than hot-dip galvanised sheet;

2. Hot-dip galvanised colour coated sheet (colour coated steel sheet) Hot-dip galvanised steel sheet can also be used as colour coated substrate (55% AI-Zn and 5% AI-Zn);

3. Electro-galvanised colour coated sheet takes electro-galvanised sheet as the substrate, and the product obtained after baking with organic coating is electro-galvanised colour coated sheet. With its exquisite appearance and excellent processing performance, it is mainly used for home appliances, audio, steel furniture and interior decoration.

Types of colour coating: standard polyester, matt polyester, decoprint.

Coating type polyester (PE): good adhesion, rich colour, wide range of formability, good outdoor durability, medium chemical resistance, low cost. Silicon Modified Polyester (SMP): good abrasion and heat resistance, good outdoor durability and resistance to chalking, good light retention, general flexibility, medium cost. Highly durable polyester (HDP): good colour retention and UV resistance, good outdoor durability and chalking resistance, good adhesion of paint film, rich colour, good cost performance. Polyvinylidene fluoride (PVDF): good colour retention and UV resistance, good outdoor durability and chalking resistance, good solvent resistance, good formability, good dirt resistance, limited colour, high cost.