Product Description

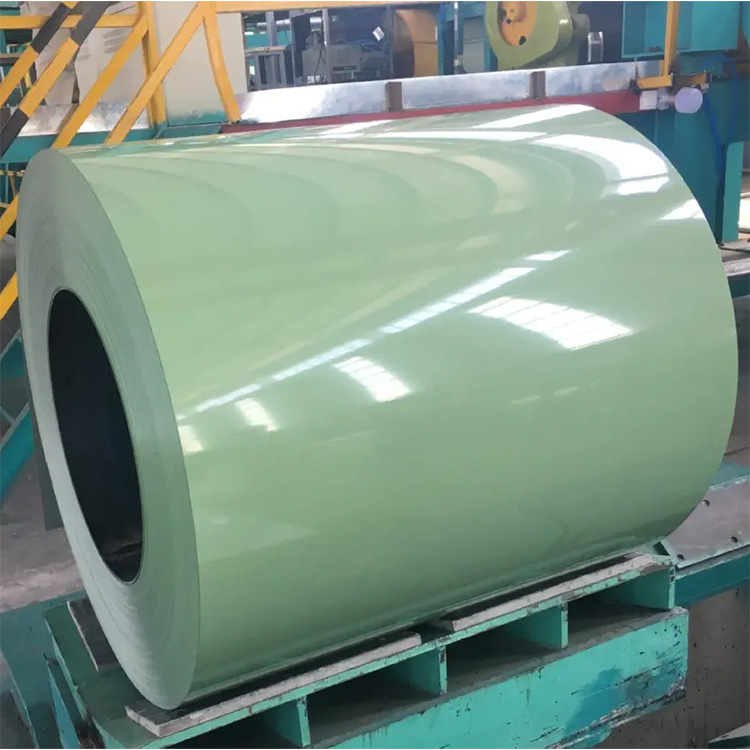

Shandong Sino Steel supplies high-quality 16-24 Gauge Prepainted GI Steel Coil / PPGI / Color Coated Coil, tailored for manufacturers and suppliers. The product meets diverse industrial needs, offering custom sizes and colors to suit specific applications.

These coils are coated with PE paint for enhanced durability and corrosion resistance. Zinc coating ensures long-lasting protection against environmental factors. Rigorous quality testing, including SGS-certified checks, guarantees consistent performance for aftermarket users.

Available in a thickness range of 0.11mm to 1.2mm, these coils can support cost-effective solutions for various industries. They are packed securely using waterproof materials, galvanized or coated sheets, and robust steel belts to ensure safe delivery.

Designed for industries like construction, automotive, and appliance manufacturing, this product provides reliable solutions at competitive costs. It is available for sale globally, with customization options to meet every client’s needs.

Product Parameter

| Product Name | 16-24 Gauge Prepainted GI Steel Coil / PPGI/ Color Coated Coil |

| Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ,SECC,SECE, BLCE+Z, BLDE+Z, BUSDE+Z or Customer’s Requirement |

| Keywords | PPGI/PPGL coil |

| PPGI Thickness | 0.11mm-1.2mm |

| PPGI Width | 750mm-1250mm |

| PPGI Color | According to RAL color or clients sample |

| Painting Thickness | PE paint top coating 15-25micron , back coating is 5-10micron

if back coating is double ,thickness can be 22micron |

| Zinc Coating | 99% pure zinc coating ,zinc weight from 40GSM to 275 GSM |

| Quality Control | SGS testing , test zinc coating thickness/PE coating thickness/ T testing and others by every coil |

| PPGI Package | water proof paper is inner packin galvanized steel or coated steel sheet is outer packing side guard plate then wrapped by seven steel belt |

Features of Prepainted GI Steel Coil / PPGI/ Color Coated Coil

Wide Thickness Range: Available from 0.11mm to 1.2mm, suitable for various applications.

Customizable Colors: Colors can be selected according to RAL standards or client samples.

Durable Zinc Coating: Zinc coating ranges from 40 GSM to 275 GSM for improved corrosion resistance.

High-Precision Coating: PE paint top layers are carefully controlled for enhanced durability.

Environmentally Protected Packaging: The product is packed with waterproof materials and reinforced with steel belts for safe transport.

Advantages

Corrosion Resistance: Zinc and PE coatings offer excellent protection against rust and wear.

Customizable Specifications: Thickness, width, and coating options can be tailored to meet specific needs.

Aesthetic Finishes: Provides visually appealing finishes, ideal for both industrial and architectural applications.

Consistent Quality: Rigorous quality control ensures reliable performance across all orders.

Secure Packaging: Designed for safe transport, ensuring protection during global shipping.

Applications

Construction: Used for roofing, siding, and structural panels.

Home Appliances: Common in the manufacturing of refrigerators and washing machines.

Automotive: Ideal for automotive body panels and interior parts.

Industrial: Used in electrical cabinets, enclosures, and other industrial applications.

Agricultural Equipment: Suitable for storage facilities and agricultural machinery.

Company Profile

Shandong Sino Steel Co.,Ltd has been engaged in thesteel for many years. lt has long maintained a good co-operative relationship with famous steel mills at homeand abroad to provide a stable source of goods.

Qualified quality control system and efficient after-salesservice, can provide customers with standardized, per-sonalized products. Qualified quality control system andefficient after-sales service, can provide customers withstandardized products.

Quality Control

SGS testing ensures that the zinc coating thickness, PE coating thickness, T testing, and other quality parameters are checked for every coil.

This rigorous testing process guarantees that the corrugated metal meets industry standards and specifications. By conducting thorough inspections and measurements, SGS testing helps to verify the quality and performance of the material, ensuring that it is suitable for its intended use in construction projects.

This attention to detail and commitment to quality control are essential for maintaining the integrity and reliability of corrugated metal as a building material.