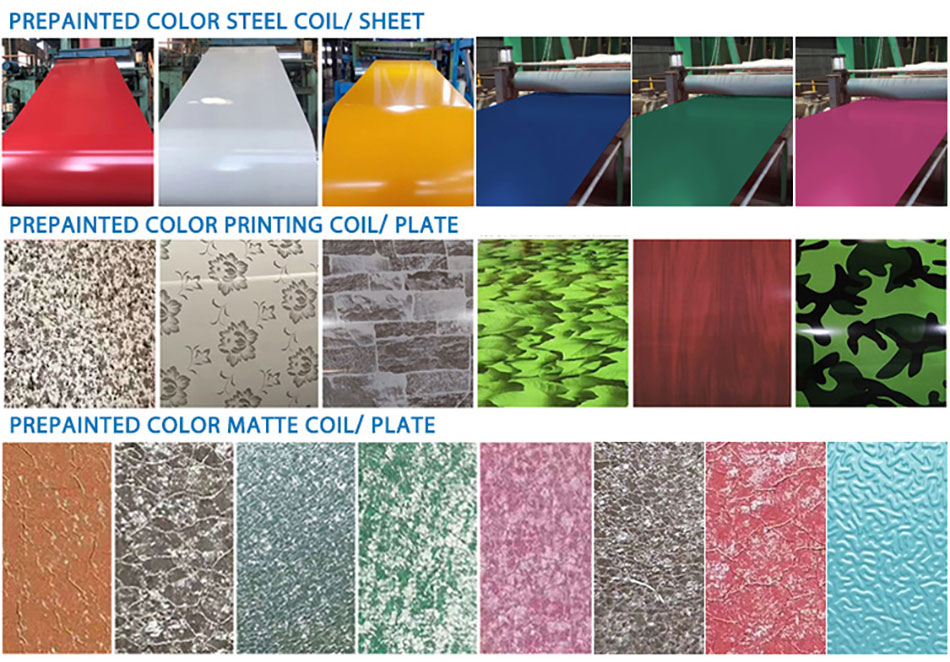

Product Highlights

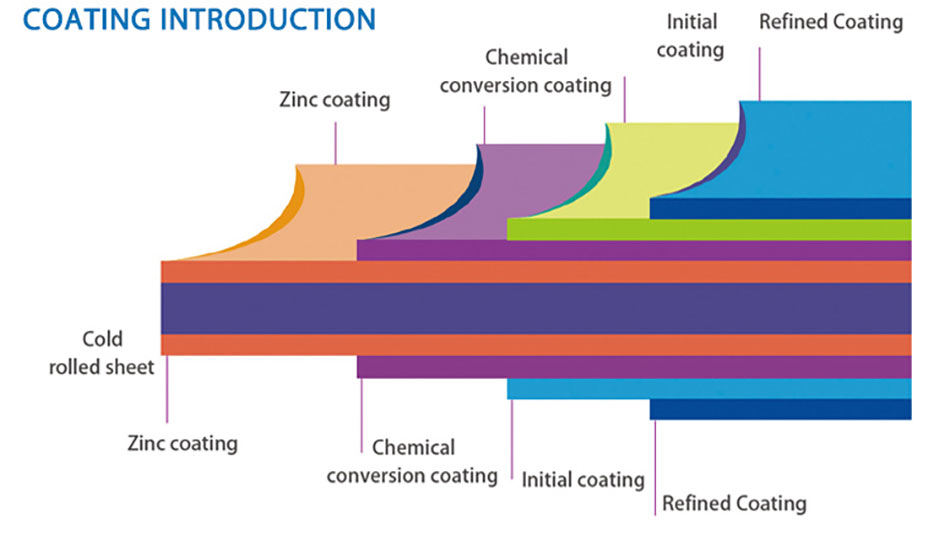

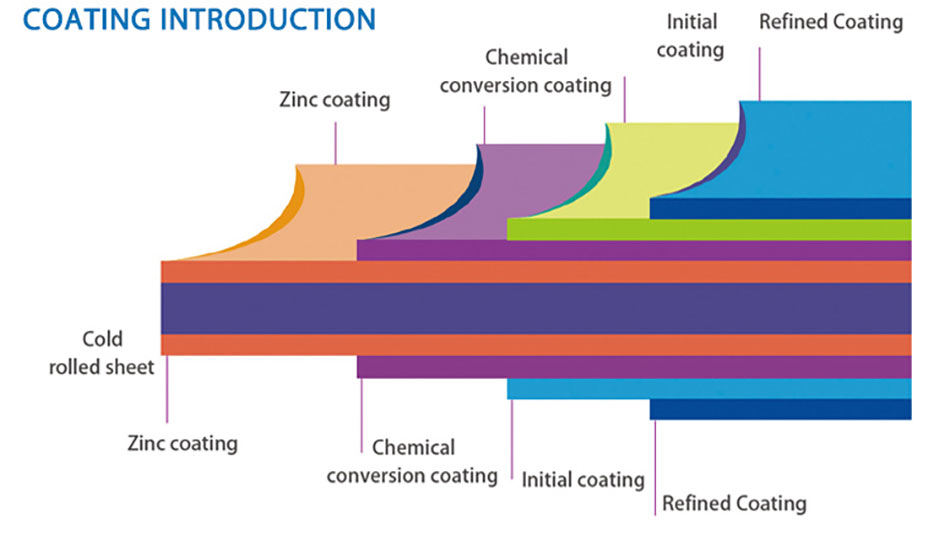

Material: Cold rolled steel / galvanized steel base

Thickness: 0.12–1.5 mm

Width: 600–1250 mm

Coating: PE, SMP, HDP, PVDF (as per request)

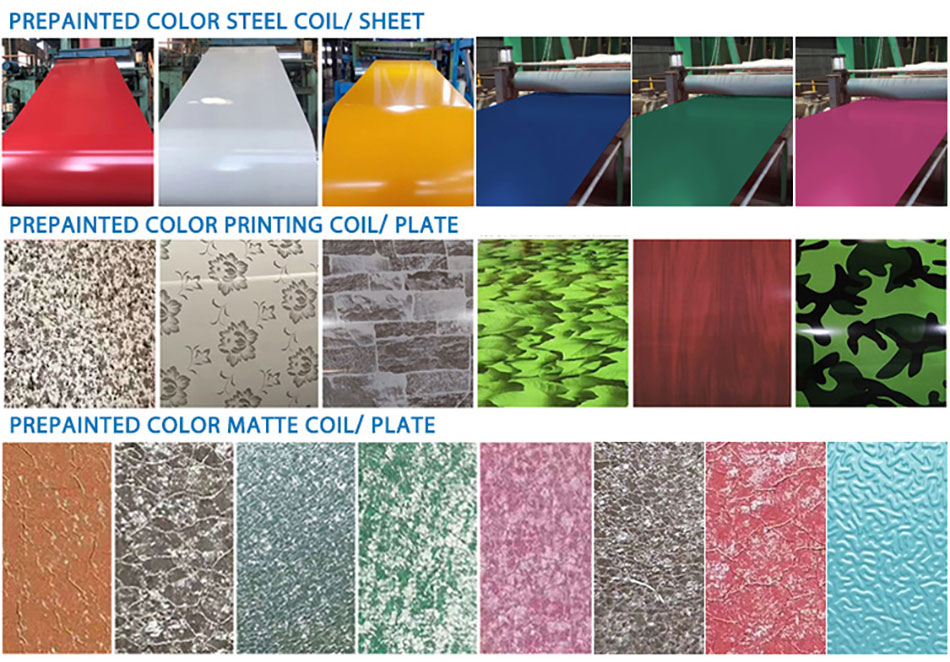

Surface: Smooth, glossy, or matte finish

Standards: ASTM, JIS, EN, GB

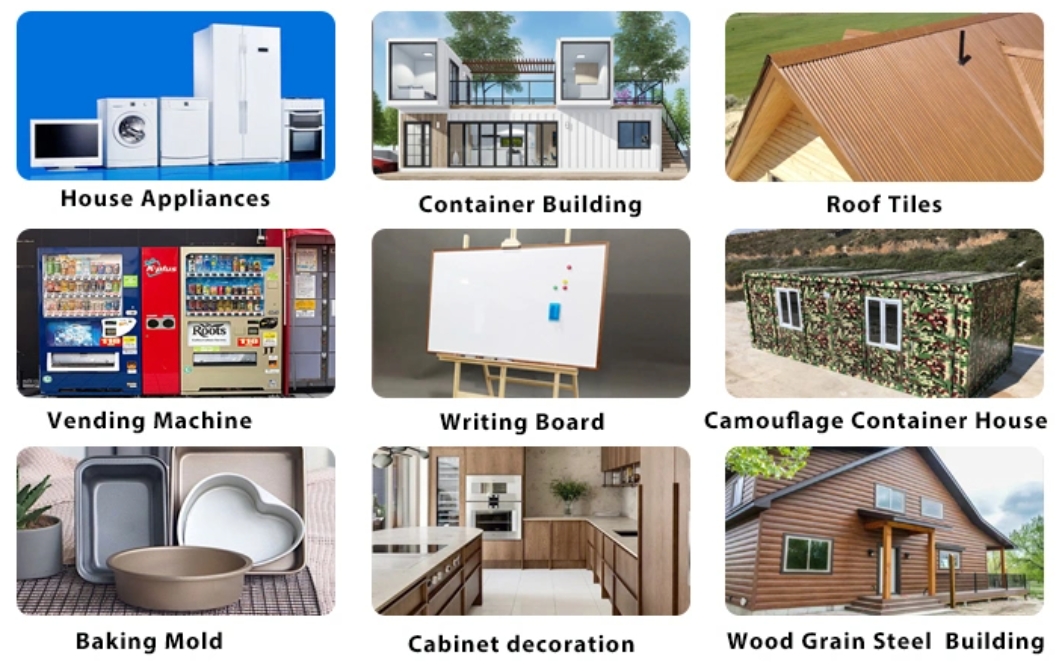

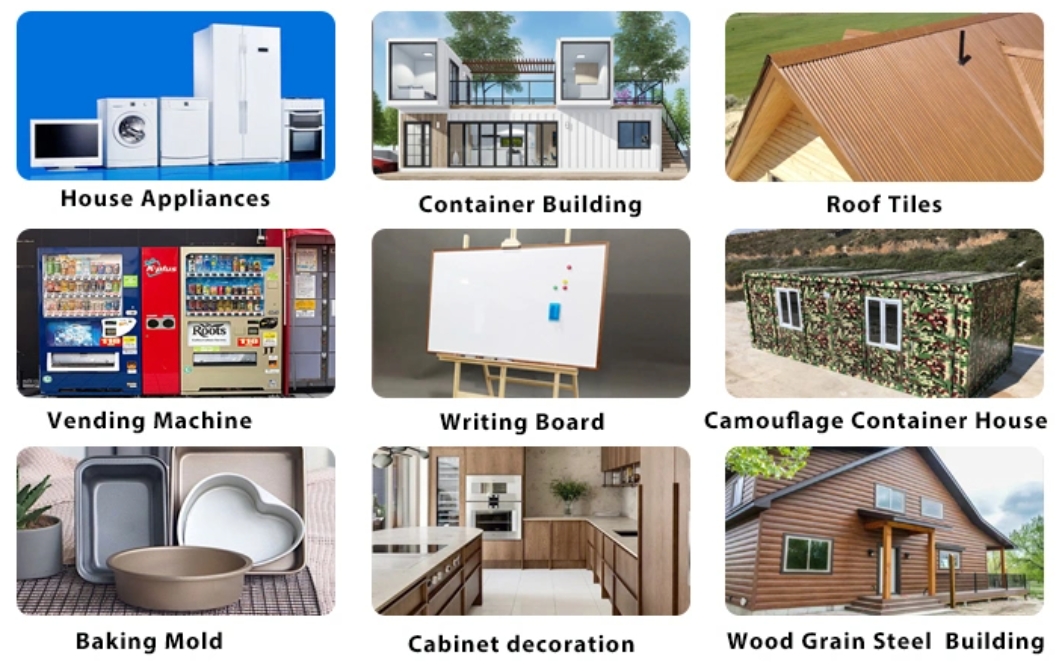

Applications: Roofing, cladding, panels, appliances, decorative

Product Description

Our Prepainted Steel Sheet is designed to meet the needs of modern architecture, fabrication, and industrial applications. Produced by coating galvanized or cold-rolled steel with high-quality paints, it combines corrosion resistance with long-lasting visual appeal. The sheets come in a wide range of RAL colors, finishes, and textures to enhance both functionality and aesthetics.

Touch its surface and you will immediately notice the smooth coating, free from ripples or unevenness. The vibrant colors reflect sunlight beautifully, while the protective paint layers shield the steel core against rust, scratches, and harsh weather. Whether used for roofing systems, wall cladding, or interior applications, these sheets add both durability and style.

This product is not only about protecting structures; it also tells a story of innovation in construction materials—providing solutions that reduce maintenance costs, extend building life, and offer design flexibility to architects and contractors worldwide.

Key Features & Benefits

Durability: Long-lasting paint coating protects against corrosion and scratches.

Aesthetic Appeal: Wide color and texture options to match modern design trends.

Weather Resistance: Excellent protection in humid, coastal, and industrial environments.

Cost Efficiency: Reduced need for repainting and repairs compared to traditional sheets.

Lightweight & Strong: Easy to transport, install, and fabricate without compromising strength.

Eco-Friendly: Paint systems are compliant with RoHS and environmentally safe.

Customizable: Thickness, width, coating, and color can all be tailored to customer specifications.

Why Choose Us

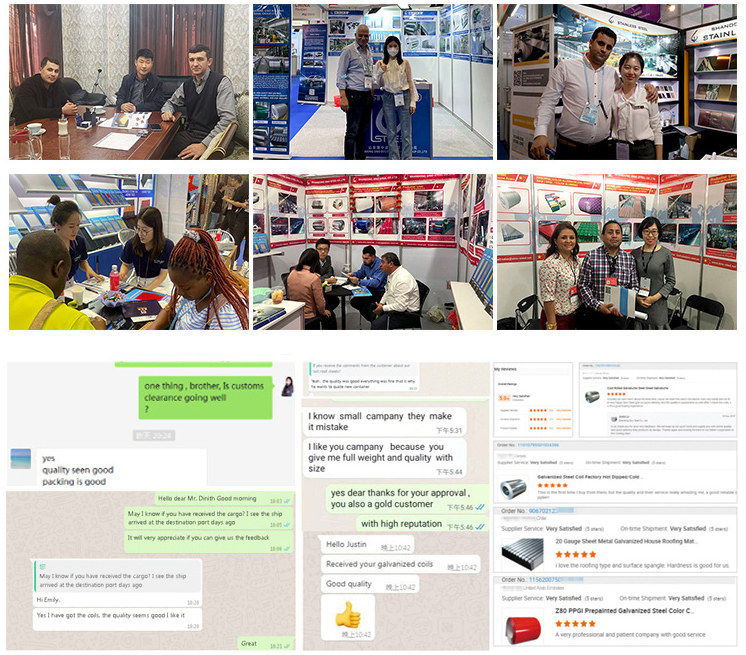

Expertise: Over 15 years of experience in steel coil and sheet production.

Certifications: ISO, SGS, CE, and strict quality control processes.

Customization: Flexible options for size, coating, and packaging.

Global Reach: Exported to more than 60 countries in Asia, Middle East, Africa, and Europe.

Customer Focus: OEM/ODM available, quick response support, reliable after-sales service.

When you partner with us, you don’t just buy steel—you invest in trust, efficiency, and long-term value.

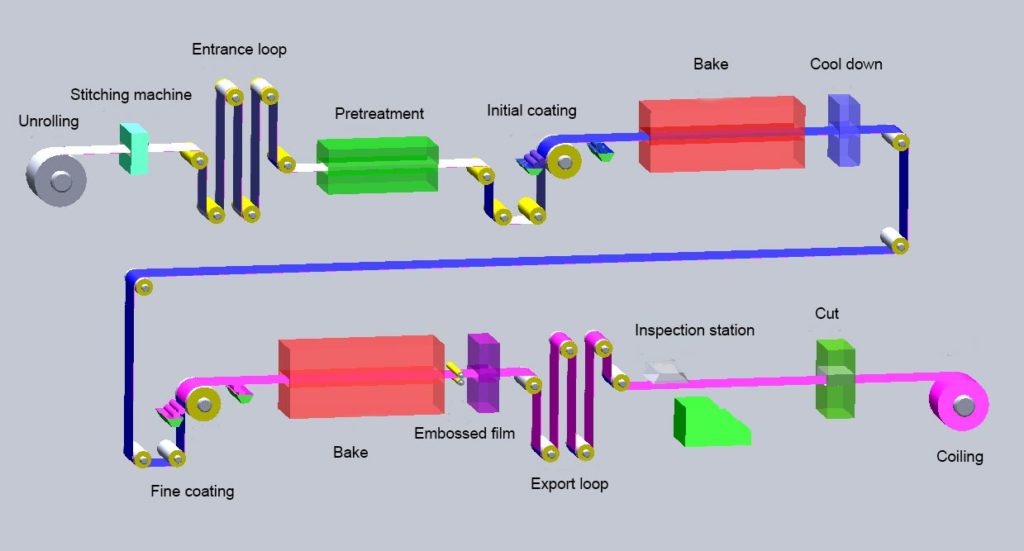

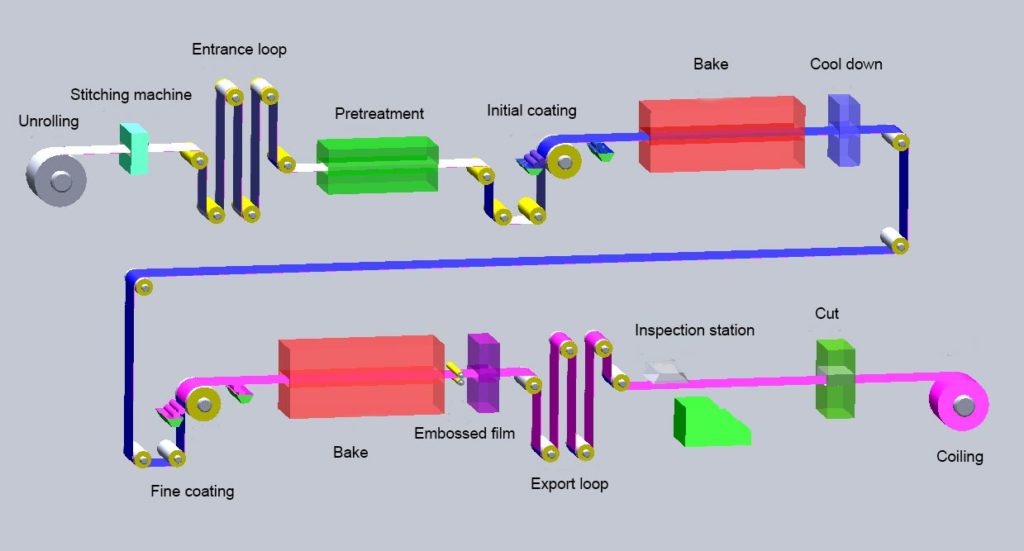

Color coating production process

Coating Type of PPGI & PPGL

Polyester (PE):Color coated steel coils are valued for their excellent adhesion, vibrant color options, and extensive formability, making them suitable for a variety of design possibilities. With exceptional outdoor durability, these coils can withstand harsh weather conditions while maintaining their aesthetic appeal. Additionally, they offer moderate chemical resistance, further enhancing their longevity and performance in different environments. Despite their impressive qualities, color coated steel coils remain cost-effective, providing a cost-efficient solution for various industries seeking a durable and visually appealing material for their projects.

Silicon modified polyester(SMP): One possible material that fits these criteria is polyurethane. Polyurethane coatings are known for their excellent abrasion and heat resistance, making them suitable for a wide range of applications. They also have good external durability and chalking resistance, as well as good gloss retention and flexibility. Additionally, polyurethane coatings are relatively cost-effective compared to other high-performance coatings.

High Durability Polyester(HDP): In addition to these qualities, the paint also boasts exceptional resistance to harsh weather conditions, making it ideal for long-term outdoor use. Its anti-ultraviolet properties ensure that the vibrant colors will remain intact even under direct sunlight exposure. Furthermore, the paint's anti-pulverization feature guarantees a smooth and pristine finish that will last for years to come. With its strong adhesion to various surfaces, the paint creates a durable and long-lasting film that enhances the overall appearance of any project. The wide range of rich colors available provides endless possibilities for creative expression, all while maintaining excellent cost performance.

Polyvinylidene Fluoride(PVDF): These characteristics describe a high-quality, durable coating or paint that is specifically designed for outdoor applications. The excellent color retention and UV resistance indicate that the coating will not fade or deteriorate when exposed to sunlight, while the solvent resistance ensures that it will not be easily damaged by chemicals or other harsh substances. The good moldability means that the coating can be easily shaped or molded to fit different surfaces, and the stain resistance indicates that it will be easy to clean and maintain. However, the limited color options and high cost suggest that this coating may be more expensive and less customizable than other options. Overall, this coating would be a great choice for outdoor applications where durability and longevity are important.

Polyurethane (PU): Polyurethane coating is known for its exceptional durability and resistance to wear, corrosion, and damage. It is a popular choice for buildings and structures that are exposed to harsh environmental conditions, such as extreme temperatures, moisture, and chemical exposure. The coating can withstand these conditions for an extended period, with a typical shelf life of more than 20 years. This makes it a cost-effective and long-lasting solution for protecting surfaces from corrosion and deterioration. Overall, polyurethane coating is a reliable option for applications where high performance and longevity are essential.

PPGI PPGL Steel Quality Inspection

Color coating test

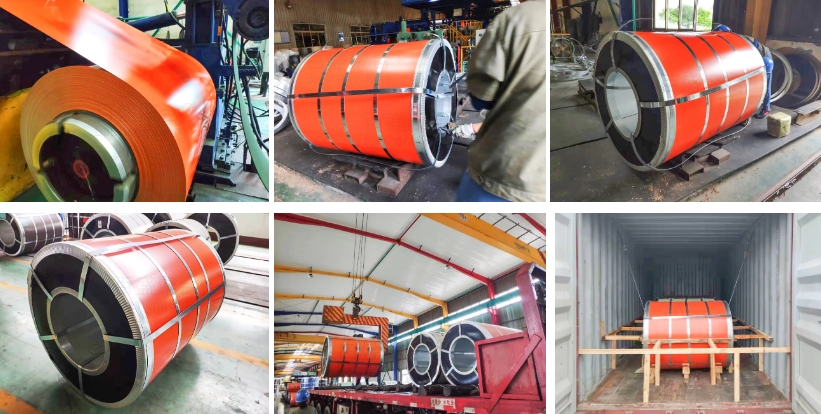

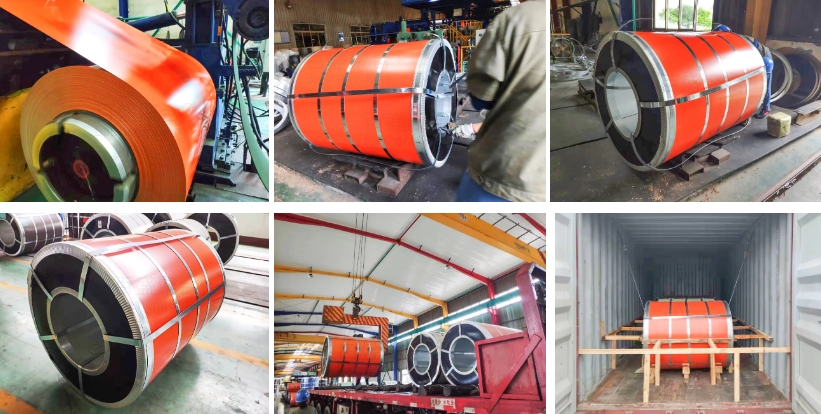

Packing and Shipping

PPGI & PPGL sheets

Customer Reviews

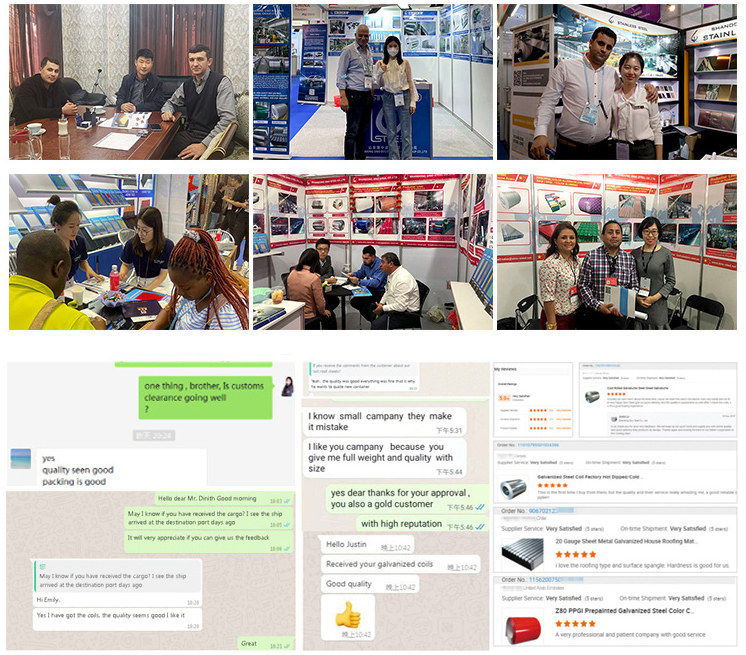

Exhibitions, Offline Visits, Customer Reviews

Overseas Warehouse