Product Overview

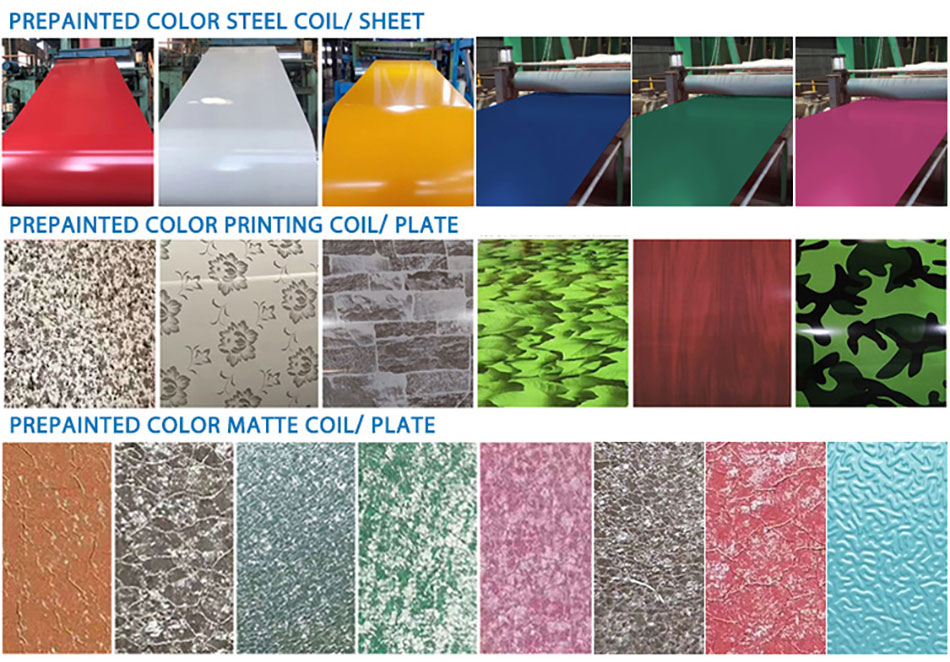

High-quality RAL color prepainted steel coil with customizable colors and coating systems.

Manufactured using top-grade substrates SGCC, DX51D, SGCH, G550 for superior strength.

Thickness range 0.12–1.2 mm, widths 600–1250 mm, coil weight 3–8 tons.

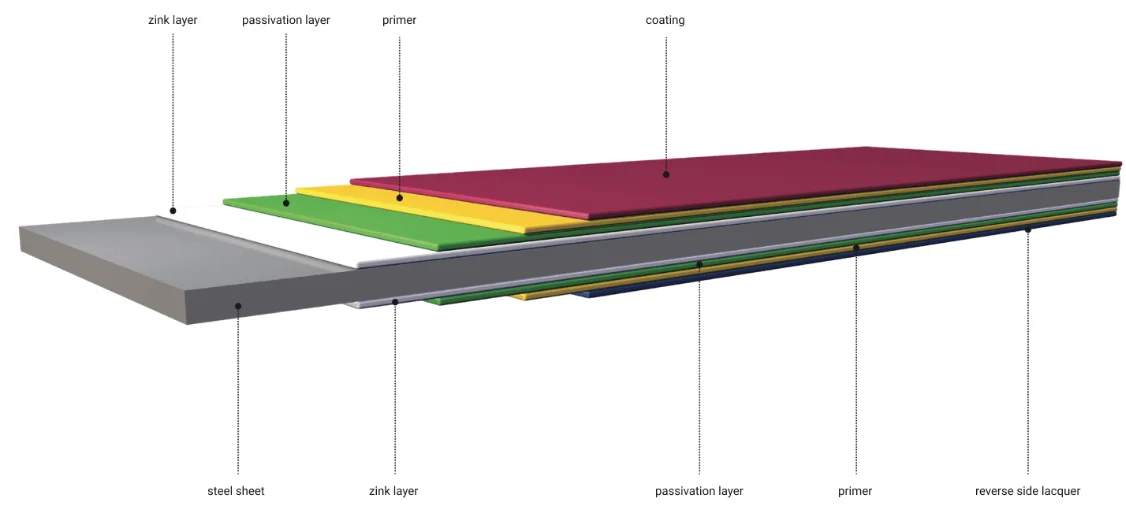

Zinc coating up to Z275 g/m² and primer/topcoat layers up to 25 μm.

Complies with ASTM, JIS, DIN, EN standards, certified by ISO 9001.

Widely applied in construction, appliances, wall panels, and decorative projects.

Product Description

The RAL Prepainted Steel Coil is more than just coated steel—it is the embodiment of durability, precision, and design freedom. Each coil is coated with a carefully engineered paint layer that not only protects against rust and corrosion but also delivers a flawless, vibrant surface finish. Imagine the smoothness of a freshly painted wall, but on robust steel that can be shaped, cut, or rolled into almost any form.

Customers choose this coil because it combines functional strength with visual elegance. The bright, uniform RAL colors remain stable even under harsh sun or heavy rain, ensuring that buildings, appliances, or panels maintain their look for years. When touched, the surface feels sleek and polished, while its underlying strength resists bending and deformation.

This is not just a product—it’s a solution for businesses needing reliable materials that reduce maintenance costs, enhance visual appeal, and offer flexibility in fabrication.

| Prepainted steel coil/ Color coated steel coil/ ppgi/ppgl |

Standard | JIS G3322 CGLCC ASTM A755 CS-B | Surface coating color | RAL colors |

Back side coatingcolor | Light grey ,white and so on | Package | export standard package or as request |

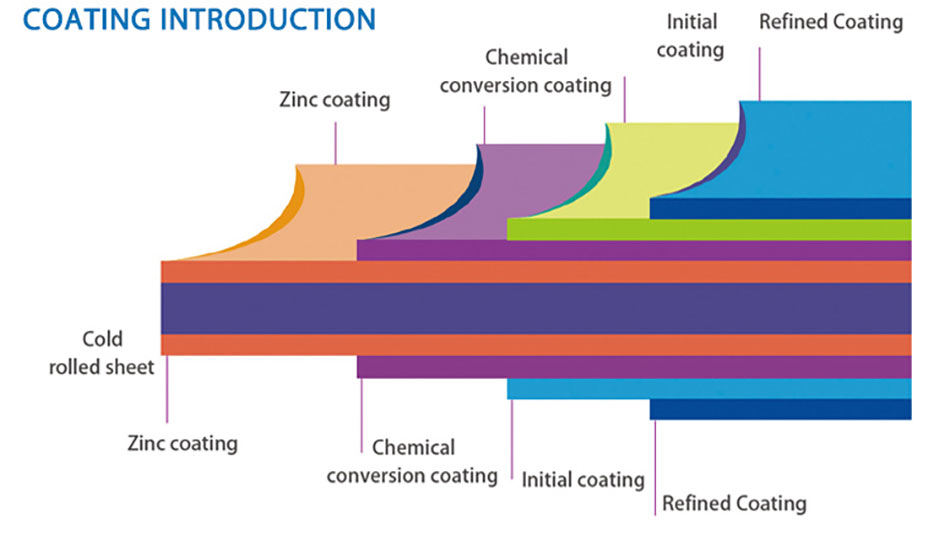

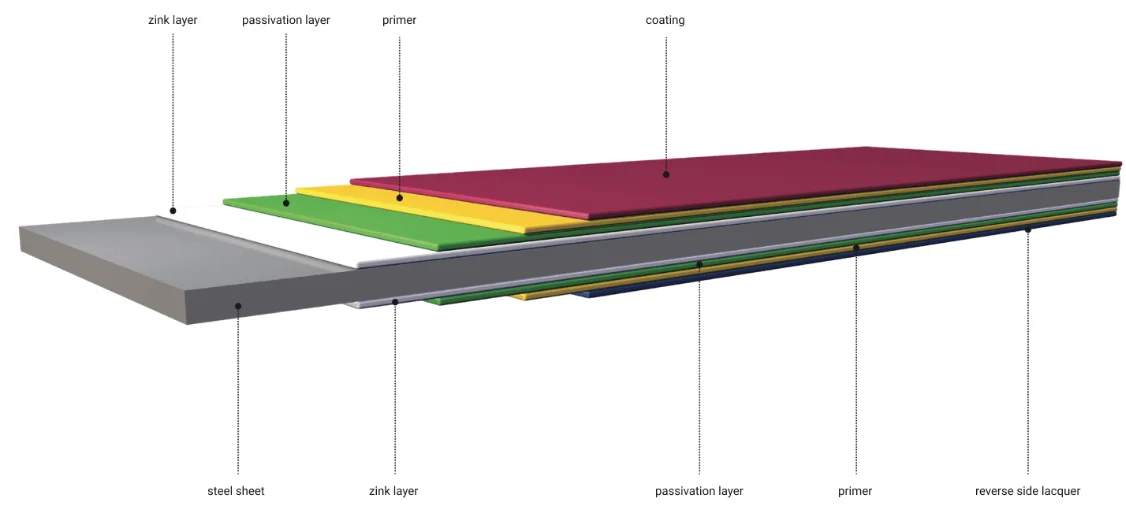

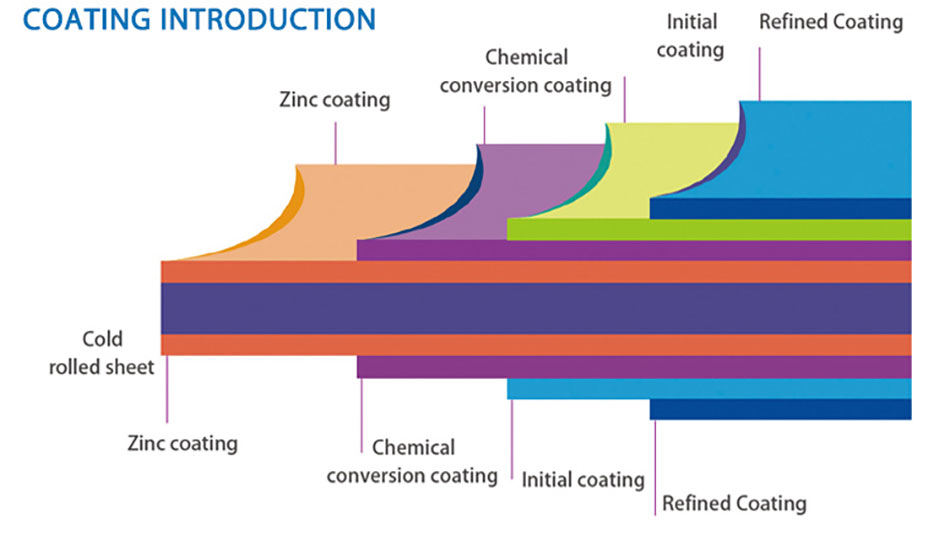

Type of coating process | Front: double coated&double drying. Back: double coated&double drying, single-coated&double drying |

Type of substrate | hot dipped galvanzied, galvalume, zinc alloy, cold rolled steel, aluminum |

Thickness | 0.11-2.5mm | Width | 600-1250mm |

Coil Weight | 3-9Tons | Inside Diameter | 508/610mm |

Zinc Coating | Z50-275g/㎡ | Painting Coating Thickness | Top: 8-35 um |

AZ30-150g/㎡ | Back: 3-25 um |

Painting Color Style | 2/1,2/2 | Length | As,require |

Coating introduction | Top paint: PVDF, HDP, SMP, PE, PU |

Prime paint: Polyurethane, Epoxy, PE |

Back paint: Epoxy, Modified polyester |

Productivity | 150,000Tons/year |

| Production core strengths |

Resistance to acid rain: |

Coating protection mechanism: It is very easy to form acid rain in the high level of industrial emissions or pollutants environment. Acidic penetration is formed in the surface of pre-painted steel, and accelerates the corrosion, forming blistering, peeling and so on. |

Resistance ultraviolet rays: |

Coating protecting Mechanism: pre-painted sheet in ultraviolet or strong sunlight conditions, the coating will exhibit chalking degeneration, manifested as discoloration and loss of gloss, lose paint quickly. |

Resistance to humid heat: |

Coating protecting mechanism: in hot and humid environments, high osmotic pressure of water vapor accelerates penetration, forming the degeneration of painting film, then the corrosion of the substrate, with the phenomenon of bubbles and peeling. |

Resistance to low temperature: |

Coating protecting mechanisms: most of the paint can keep stable processing performance above 0 degree, but at alpine region, the temperature will be below 20-40 degree, normal paint will become brittle,bend cracking, or even lose paint, thus protection function is lost totally. |

Features & Highlights

Superior Corrosion Resistance

Zinc coating up to Z275 g/m² acts like a shield against moisture, salt, and chemical exposure.

Vibrant and Lasting Colors

Choose from any RAL shade—colors that stay rich and glossy, resisting fading even in outdoor use.

Excellent Formability

Despite its strength, the coil bends and shapes easily, making it ideal for roofing, siding, and fabrication.

Smooth Touch & Elegant Finish

The painted surface feels sleek and refined, enhancing not just performance but also the sensory experience.

Low Maintenance, High Value

Reduces repainting and replacement costs, providing a longer service life and better ROI.

Applications

| Industry / Use | Benefits |

Construction (Roofing, Wall Cladding, Panels) | Strong, weather-resistant, colorful; creates modern architectural finishes. |

Home Appliances (Refrigerators, Washing Machines, Ovens) | Sleek finishes, durable, easy to clean surfaces. |

Interior Decoration | Aesthetic flexibility with customizable RAL colors. |

Furniture & Fabrication | Lightweight, durable, attractive finishes. |

Automotive & Industrial Equipment | Resistant to scratches, UV damage, and corrosion. |

Customization Options

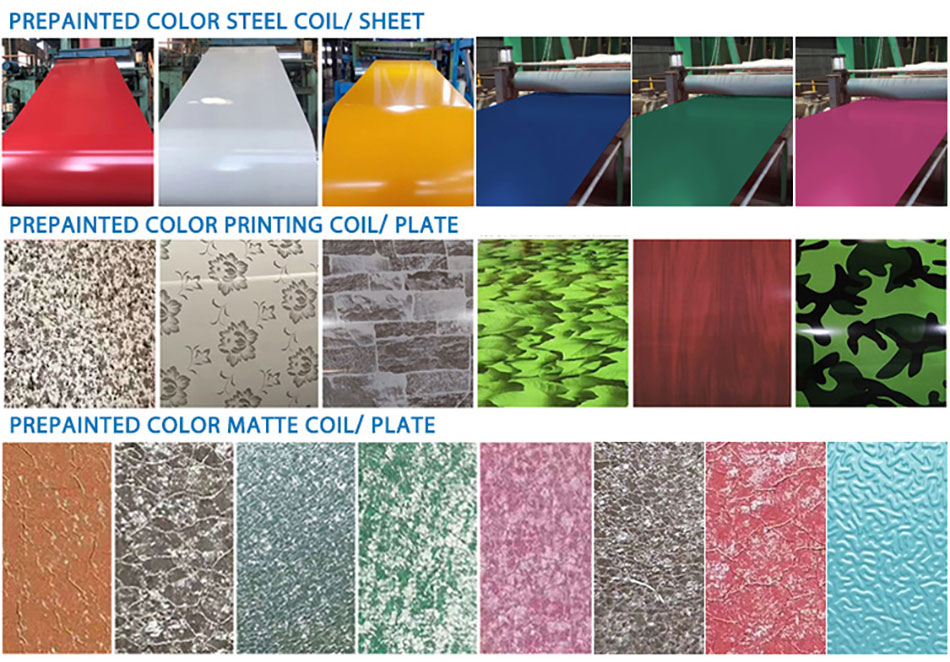

Color Selection: Full RAL color chart available. Glossy, matte, or textured finishes.

Coating Types: PE, PVDF, SMP, or customized coating systems.

Dimensions: Width, thickness, coil weight, and coil ID tailored to customer requirements.

Packaging: Export-grade seaworthy packaging; moisture-proof wrapping, edge protection, steel strapping.

MOQ Flexibility: Smaller trial orders supported alongside bulk orders.

Why Choose Us

Professional Expertise: Decades of experience in steel coil manufacturing, serving diverse global markets.

Strict Quality Control: ISO 9001 certified, full QC from raw material to finished coil.

Global Export Capability: Successfully shipped to Asia, Middle East, Europe, and Africa.

Customization Strength: Flexible in size, coating, and RAL colors—tailored to your business.

Reliable Delivery: Fast lead times, stable supply capacity, and strong logistics partnerships.

Partnership Approach: We work with clients to solve technical and commercial challenges, building long-term trust.

FAQ

1. What is the lifespan of RAL prepainted steel coils?

Typically 15–25 years depending on coating thickness, environment, and maintenance. PVDF coatings can last even longer.

2. Can I order a custom RAL color not in your stock?

Yes. We support all RAL colors and can match custom shades based on your project needs.

3. What is your minimum order quantity (MOQ)?

Flexible. We support small trial orders and large bulk orders. Contact us for specific details.

4. How fast can you deliver?

Lead time is usually 15–30 days depending on order size and customization. Stock items ship faster.

5. How are the coils packaged for export?

Seaworthy standard packaging with waterproof paper, edge protection, steel bands, and wooden pallets or crates.

6. Do you provide quality certificates?

Yes. We provide mill test certificates, ISO certification, and other requested inspection documents.