| Base Steel | Galvanized Steel | Galvalume Steel | PPGI | PPGL |

| Thickness(mm) | 0.13-1.5 | 0.13-0.8 | 0.13-0.8 | 0.13-0.8 |

| Width(mm) | 750-1250 | 750-1250 | 750-1250 | 750-1250 |

| Surface Treatment | Zinc | Aluzinc Coated | RAL Color Coated | RAL Colorcoated |

| Standard | ISO,JIS,ASTM,AS,EN |

| Width(mm) | 610-1250mm |

| Color Coating(Um) | Top:5-25m Back:5-20m or as client's requirement |

| Paint Color | RAL code No.or customer' color sample |

| Pallet Weight | 2-5MT or as client's requirement |

| Quality | Softy , half hard and hard quality |

| Supply Ability | 2000-5000MT/month |

| Price Item | FOB, CFR, CIF |

| Payment terms | T/T, L/C at sight |

| Delivery Time | 15-30days after confirmed order |

| Packaging | Export standard, seaworthy |

Overview

The High-Strength Z30-Z275 Galvanized Steel Roofing Sheet is engineered for rapid deployment in prefab houses, modular buildings, and temporary structures, combining galvanized corrosion resistance with customizable mechanical properties. Available in coating weights from Z30 (30g/m²) to Z275 (275g/m²), this sheet balances cost-efficiency for indoor use with extreme durability for coastal or industrial environments.

Constructed from SGCC (steel galvanized with aluminum-zinc alloy) or GI (pure zinc) substrates, the sheet features a smooth or spangled surface finish, ideal for direct use or as a base for additional coatings. Its standardized dimensions (e.g., 0.3-1.0mm thickness, 914-1220mm width) align with prefab industry standards, enabling quick integration into modular framing systems.

Features

Tailored Corrosion Protection: Coating weights range from Z30 (indoor/storage) to Z275 (severe coastal/chemical environments), with SGCC offering 3x longer life than GI in humid conditions.

Prefab-Ready Design: Precise cut-to-length service (tolerance ±2mm) and compatibility with clip-lock or screw-down fastening systems reduce on-site cutting and waste in modular assembly.

Structural Versatility: High yield strength (270-550 MPa) supports lightweight steel frames in prefab homes while resisting wind uplift (tested to 160 km/h) and moderate hail impact (25mm diameter).

Thermal Compatibility: Low thermal expansion coefficient minimizes stress on modular joints, critical for structures exposed to temperature fluctuations in regions like deserts or mountainous areas.

Eco-Friendly Prefabrication: 100% recyclable at end-of-life, with galvanized coatings free of CFCs and heavy metals, contributing to sustainable modular construction certifications.

Application

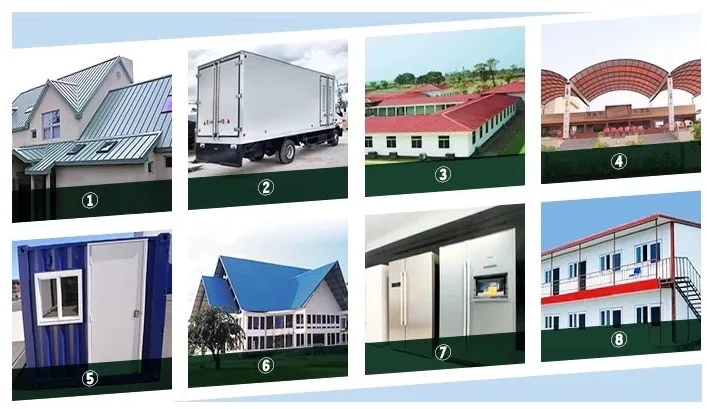

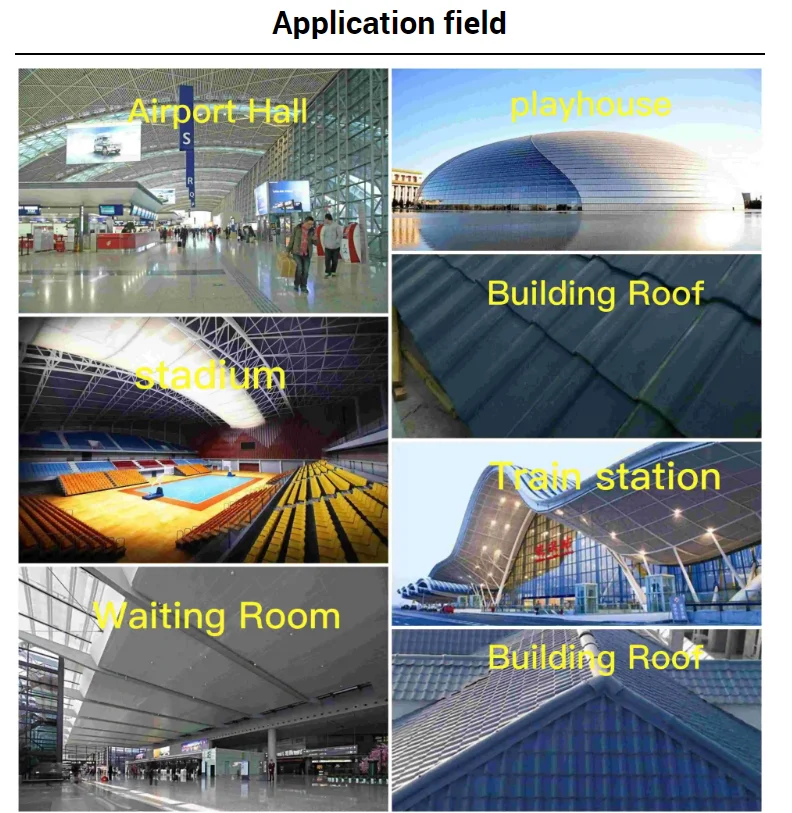

Prefab Houses & Cabins: Forms waterproof, durable roofs for flat-pack homes, tiny houses, and granny pods, enabling rapid installation in remote or urban sites.

Modular Offices & Healthcare Units: Used in temporary clinics, construction site offices, and disaster relief shelters, where quick setup and long-term weather resistance are essential.

Industrial Prefabrication: Fabricates roofs for pre-built warehouses, storage tanks, and equipment enclosures, with Z275 coating protecting against industrial emissions and high humidity.

Agricultural Modular Structures: Provides reliable roofing for prefab barns, greenhouses, and livestock shelters, resisting corrosion from fertilizer dust and animal waste.

FAQ

Q: Which coating weight should I choose for a coastal prefab home?

A: Z150 (SGCC) or Z275 (GI) is recommended for coastal areas, with SGCC offering better salt spray resistance (1,500+ hours in ASTM B117 testing).

Q: Can these sheets be painted on-site for prefab color matching?

A: Yes, the galvanized surface can be primed and painted with acrylic or epoxy coatings, though pre-painted options (e.g., RAL colors) offer more uniform results and longer life.

Q: What is the typical installation time per 100m²?

A: Two workers can install 100m² in 4-6 hours using pre-cut sheets and mechanical fasteners, 30% faster than traditional tile roofing.

Q: Do they comply with fire safety codes for modular buildings?

A: Yes, steel is non-combustible (Class A fire rating), meeting strict fire codes in regions like California and Australia for prefab constructions.