Product Overview

The Hot Dipped Galvanized Coil is a premium steel coil coated with a protective layer of zinc through advanced hot-dip galvanizing technology. This process not only enhances corrosion resistance but also provides a smooth, bright surface that conveys strength and reliability.

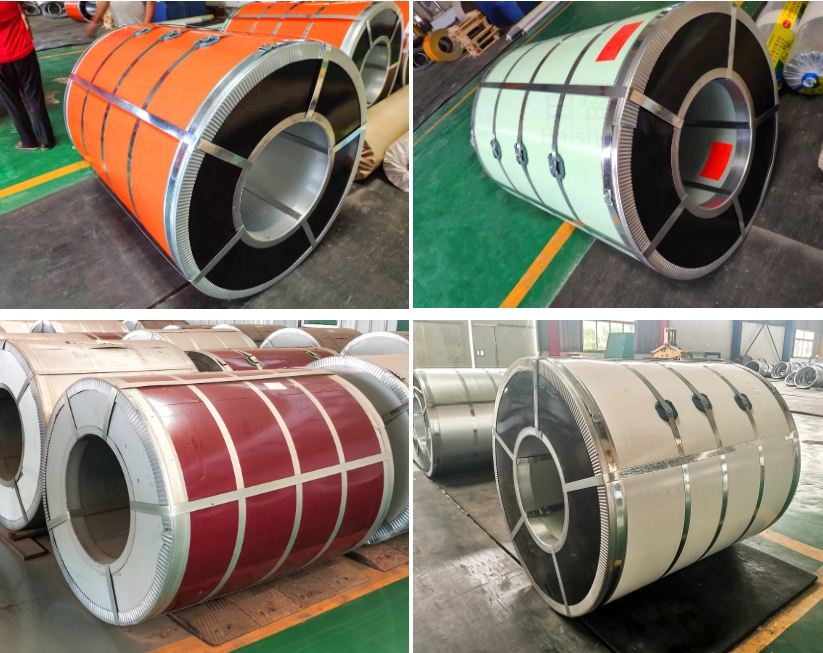

Quick Highlights

Thickness: 0.12–1.5 mm

Width: 600–1250 mm

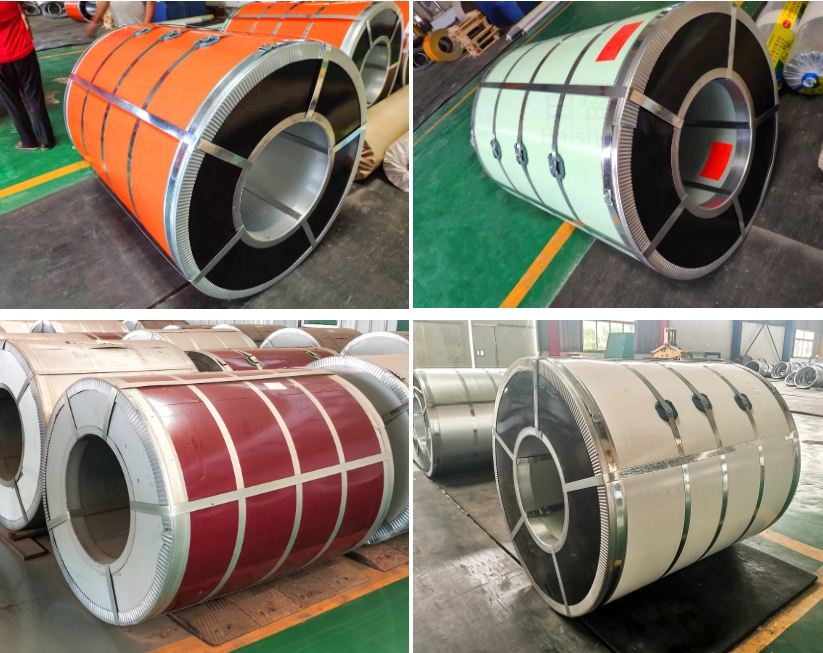

Coil Weight: 3–6 tons

Coil ID: 508 / 610 mm

Zinc Coating: 30–275 g/m²

Standards: ASTM, JIS, EN, ISO

Surface Finish: Regular spangle / zero spangle / skin-passed

Applications: Construction, appliances, automotive, and industrial use

Product Description

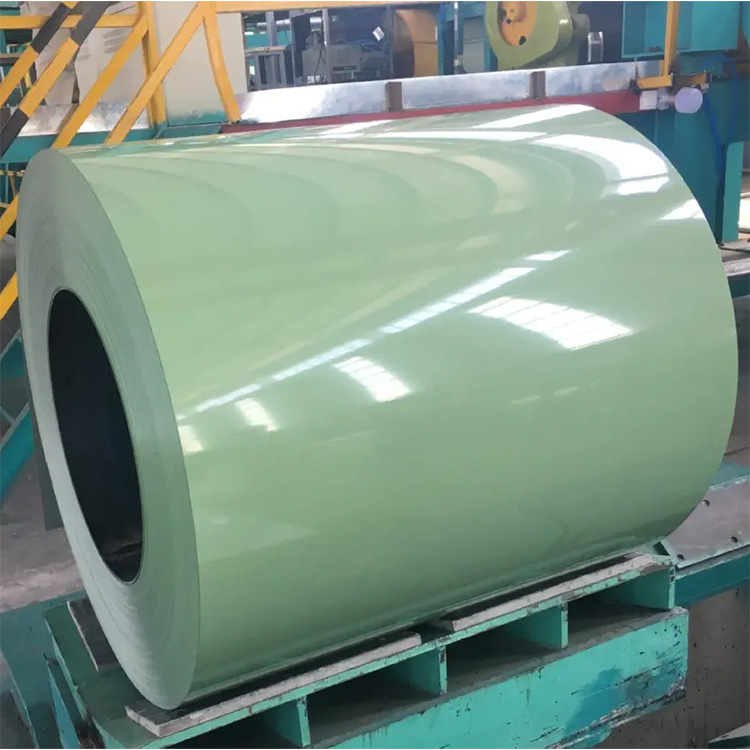

Our Hot Dipped Galvanized Coil is crafted for industries that demand long-lasting performance under tough conditions. Produced with a cold-rolled steel base, each coil undergoes a molten zinc bath, ensuring complete surface coverage. The result is a brilliant silver-gray appearance that feels smooth to the touch and resists scratches.

When uncoiled, the sheets emit a crisp metallic sound—an auditory confirmation of their density and strength. This combination of tactile smoothness and robust structure gives buyers confidence that the material will withstand decades of exposure without losing its protective qualities.

Ideal for roofing, siding, HVAC ducts, or automobile body panels, these coils reduce the need for frequent maintenance and painting, ultimately lowering lifecycle costs for end users.

Key Features and Benefits

Superior Corrosion Resistance – Zinc coating forms a barrier against rust.

Long-Term Durability – Withstands weather, moisture, and chemical exposure.

Aesthetic Appeal – Smooth, reflective finish available in spangle variations.

Easy Formability – Excellent bending, stamping, and welding properties.

Cost Savings – Reduced maintenance and painting expenses.

Eco-Friendly – 100% recyclable, aligning with global sustainability standards.

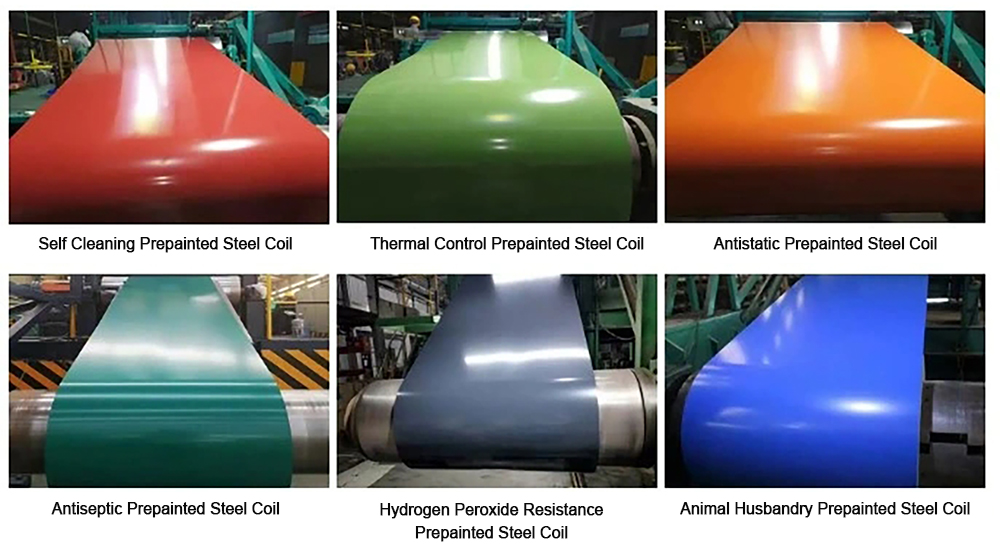

0.12~1.5mm Gi Gl PPGI PPGL Color Coated Hot Dipped Prepainted Galvanized Steel Coil

1.Thick: 0.12 ~1.5 mm;

2.Width:20-1500 mm ;

3.Material : SGCC,DX51D~DX53D,G350-G550 .

4.Zinc coating :40~275G/M2 .

5.Payment terms: T/T, LC, Kun Lun Bank, Western Union, Paypal, O/A, DP, SINOSURE

Technical Specifications

| Material | CGCC,SGCH,G350,G450,G550,DX51D,DX52D,DX53D |

| Width | 20-1500mm |

| Zinc coating | Z40-275g/m2 |

| Painting Coating | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Painting | Nippon, KCC,AkzoNobel, etc |

| Coating type | PE, SMP, HDP, PVDF |

| Resin con-structure | Double painting and double baking process |

| Back side coating color | Light grey, white and so on |

| Coil ID | 508 / 610MM |

| Coil Weight | 3-5 Tons |

| Annual Output Quantity | 350,000MT |

| MOQ | 25 tons or one container |

| Payment | T/T, LC, Kun Lun Bank, Western Union, Paypal, O/A, DP |

| Hardness | Soft hard(60),medium hard(HRB60-85),full hard(HRB85-95) |

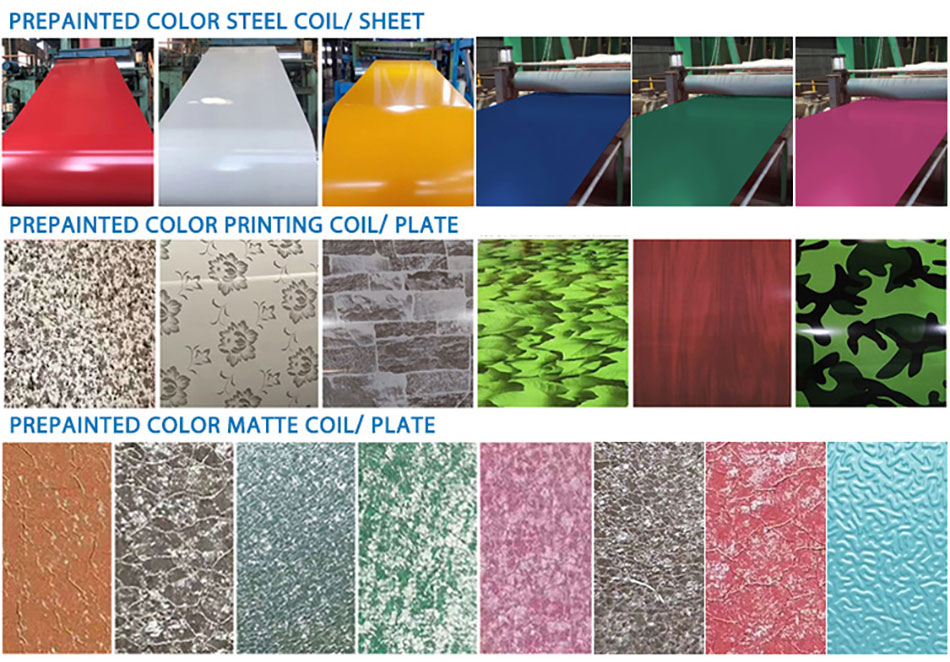

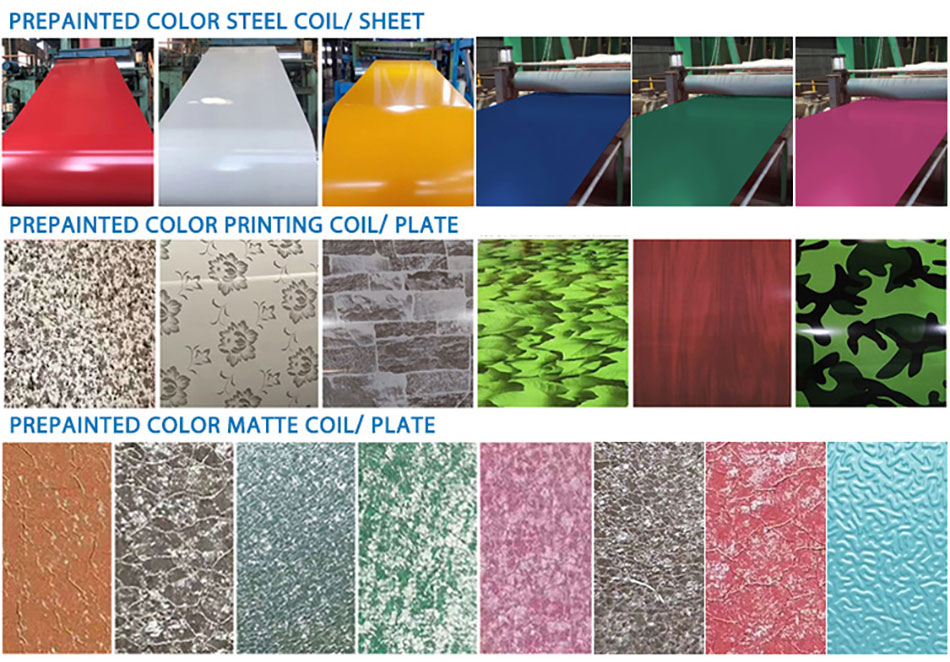

| Surface structure | Norma,Matt,PVC film,wood grain,Flower Grained,embossed, etc |

| Color chart | RAL color number |

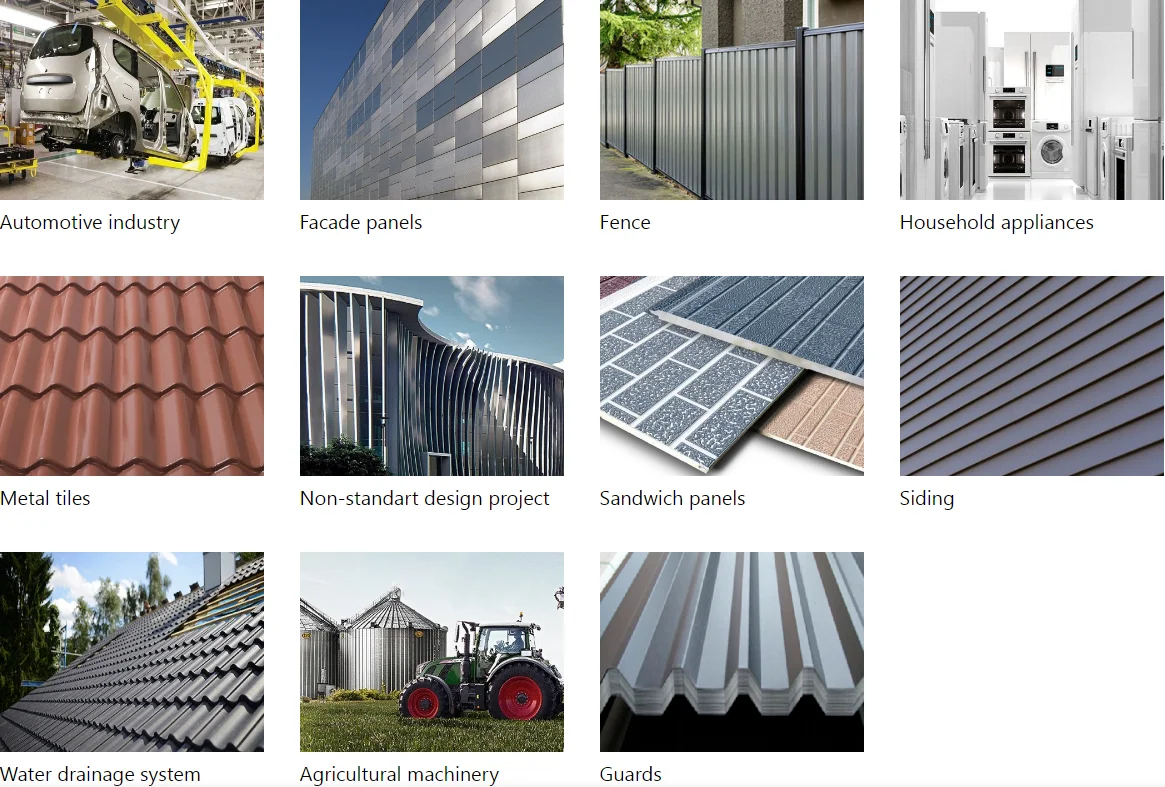

| Application | PPGI is featured with lightweight, good looking and Anti corrosion.

It can be processed directly,mainly used for construction industry,

home electronic apparatus industry,electronic apparatus industry,

furniture industry and transportation. |

Advantages of Hot Dipped Galvanized Coil

High Versatility: Suitable for indoor and outdoor applications.

Reliable Supply: Available in large volumes for long-term contracts.

Customization Options: Thickness, width, zinc coating tailored to project needs.

Standard Compliance: Meets ASTM, EN, JIS, and ISO requirements.

Trusted Globally: Exported to 80+ countries with proven customer satisfaction.

Why Choose Us

Advanced Production Line – Equipped with continuous galvanizing technology.

Strict Quality Control – Coating thickness, adhesion, and corrosion resistance tested for every batch.

Flexible Order Quantities – Support for both bulk and trial shipments.

Competitive Pricing – Direct factory supply reduces procurement cost.

Comprehensive Service – Pre-sale consultation and after-sale support for smooth project execution.

FAQ

Q1: What is the lifespan of hot dipped galvanized steel?

Typically 20–30 years in rural conditions and 10–15 years in marine or industrial environments.

Q2: Can you customize zinc coating thickness?

Yes, zinc coating from 30–275 g/m² is available upon request.

Q3: Do you provide free samples?

Yes, samples are free; buyers cover courier charges.

Q4: Is the coil suitable for painting?

Absolutely, galvanized surfaces can be post-painted for specific requirements.

Q5: What is your MOQ?

The minimum order quantity is usually 25 tons, but flexible options are available.

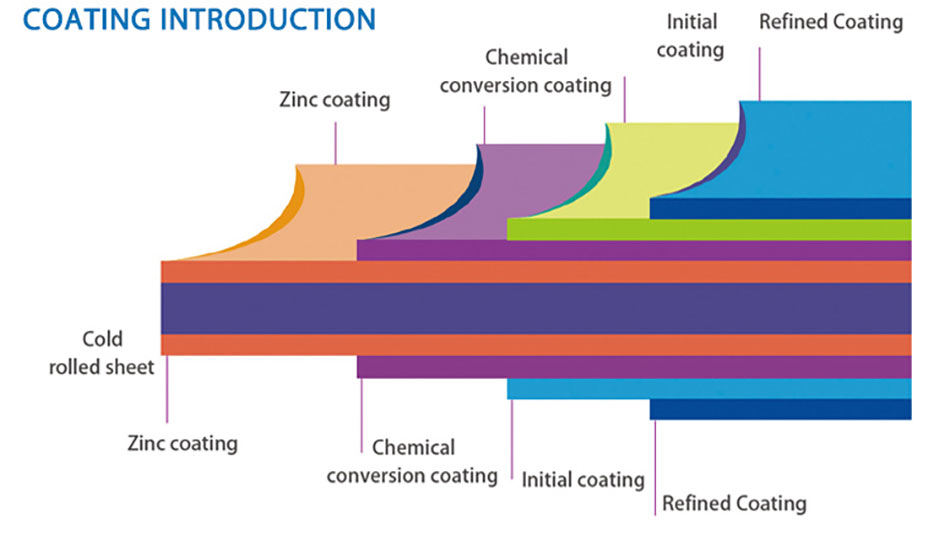

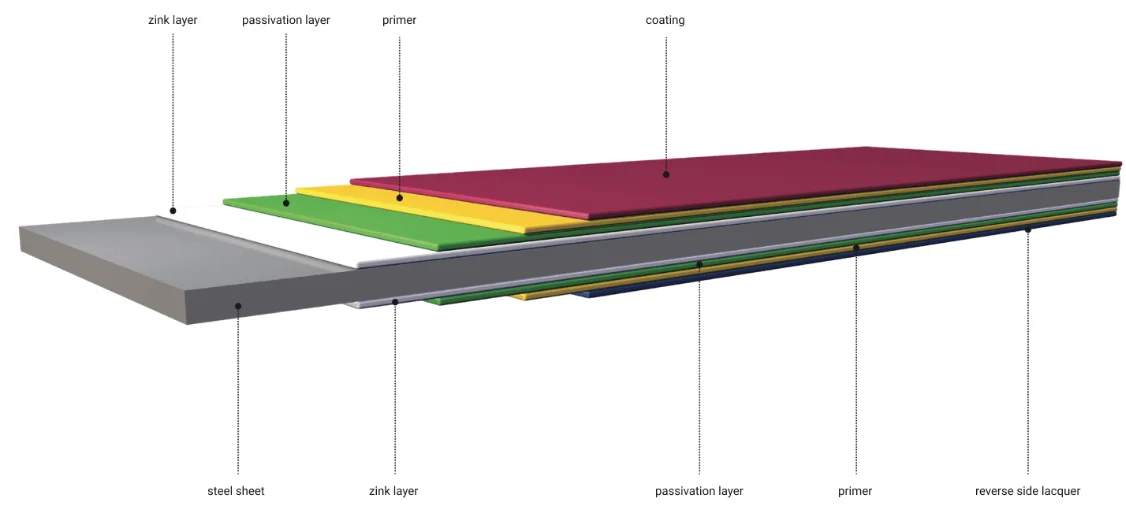

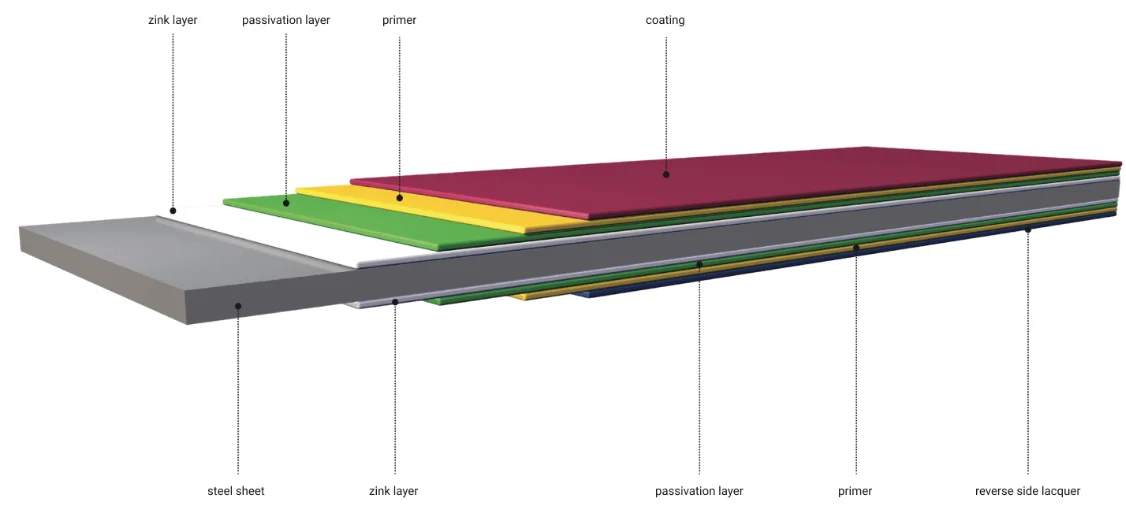

Substrate Type

1. Hot-dip galvanized color-coated steel sheet (pre-coated galvanized steel sheet). The product of coating the steel sheet with an organic coating is a hot-dip galvanized color-coated sheet. In addition to the protective effect of zinc, it also has an anti-rust effect and a longer service life than the galvanized sheet;

2. Hot-dip aluminum-zinc color-coated sheet (color-coated aluminum steel sheet) color-coated substrate (55% AI-Zn and 5% AI-Zn);

3. Electro-galvanized color-coated sheets use electro-galvanized sheets as the base material, and are coated with organic coatings and baked to become electro-galvanized color-coated sheets. It is mainly used for home appliances, furniture and other decorative items.

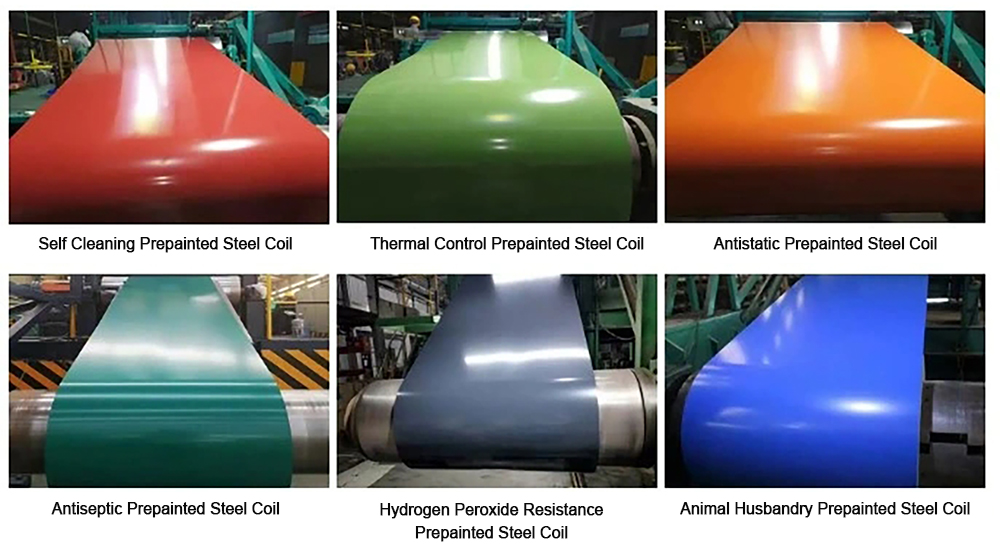

Color coating types: Standard polyester, matte polyester, decorative print.

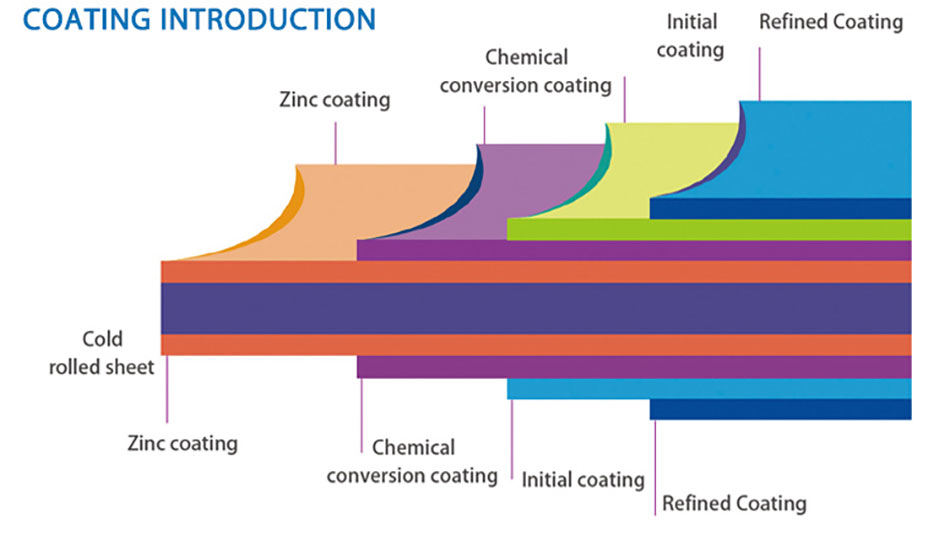

Coating Type

-

Polyester (PE):Excellent adhesion, various colors, wide range of molding and outdoor durability, moderate chemical resistance, low cost

-

Silicon modified polyester(SMP): Good abrasion resistance, heat resistance, exterior durability, and powder resistance; average gloss retention and flexibility; medium cost.

-

High Durability Polyester(HDP): Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good paint film adhesion, and moderate cost performance.

-

Polyvinylidene Fluoride(PVDF): Excellent color retention, UV resistance, durability, anti-chalk and solvent resistance, good formability, good stain resistance, limited colors and higher cost.