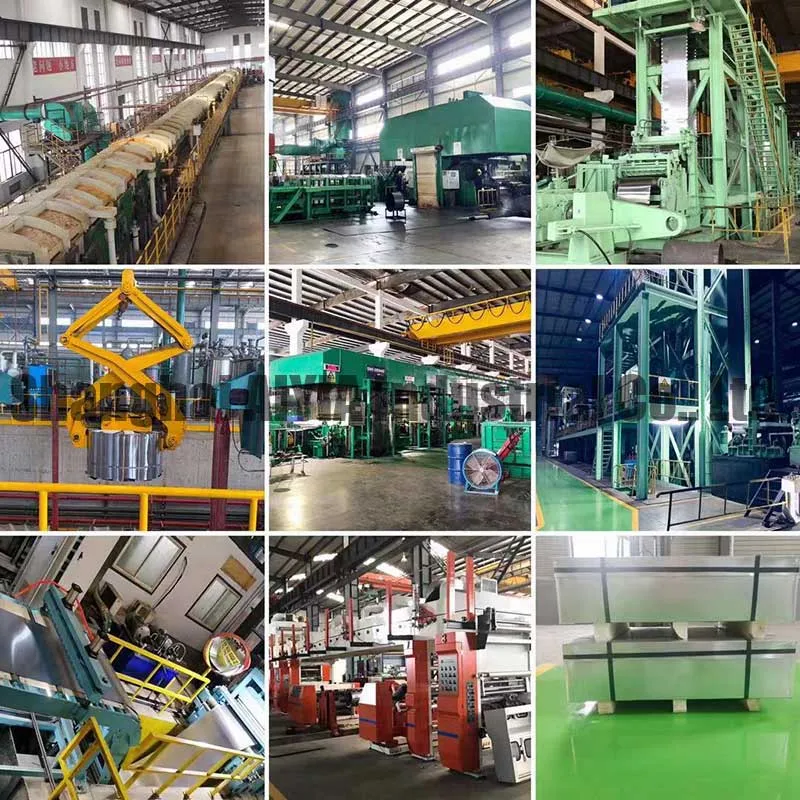

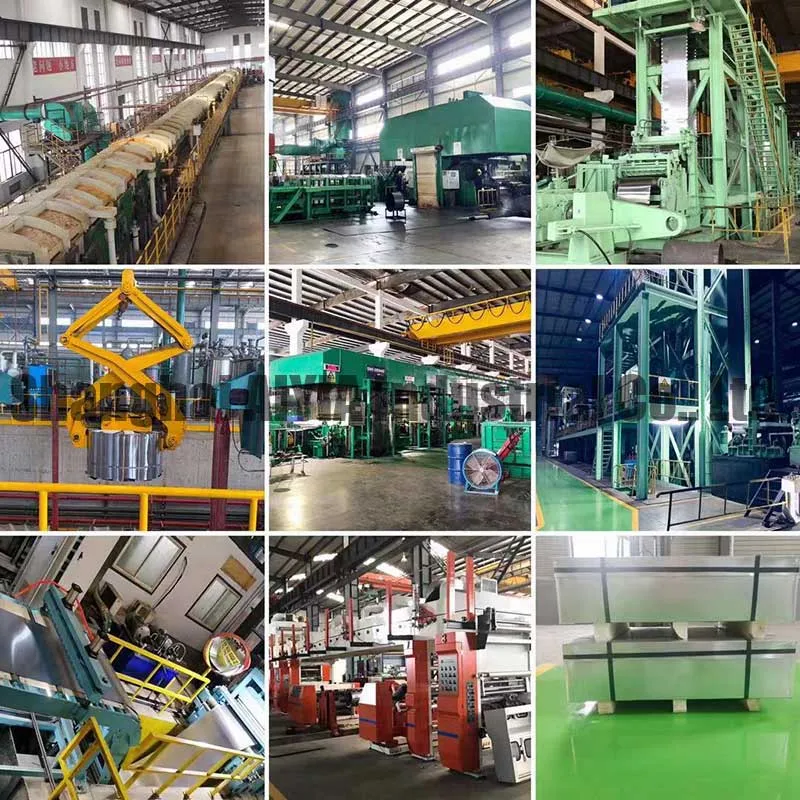

Tin Free Steel Coil/Sheet Product Description

Tin Free Steel Coil/Sheet from Shandong Sino Steel is a reliable choice for manufacturers and suppliers. Designed for strength and durability, it meets the needs of various industries. This product is widely used for packaging and other applications.

The material is made of SPCC, MR, or SPCH grade steel. It offers a range of thicknesses from 0.12 mm to 0.60 mm. Widths vary between 20 mm and 1020 mm, and lengths range from 600 mm to 1200 mm.

The product features tin coatings tailored to customer specifications. Available options include 2.8g/2.8g and 5.6g/5.6g per square meter. Coating thickness ensures resistance to corrosion and extended service life.

Tin Free Steel comes in several tempers, such as T2 to T5, and DR7 to DR8. Annealing processes include Continuous Annealing (CA) and Batch Annealing (BA). These treatments improve the product’s strength and flexibility.

Surface finishes include bright, stone, or silver with passivation treatment. The addition of DOS oil enhances protection. These finishes suit both aesthetic and functional requirements.

Applications include food and beverage packaging, chemical containers, and decorative uses. Industries rely on this product for its cost-effectiveness and versatility. Shandong Sino Steel offers global shipping and consistent quality.

Product Description

Material | SPCC,MR,SPCH |

Thickness | 0.12 to 0.60mm |

Width | 20 to 1020 mm |

Length | 600 to 1200 mm |

Tin coating | 2.8g/2.8g, 5.6g/5.6g, 2.8/5.6,2.0/2.0 gr/m² or according to customer's requirement |

Temper | T2, T2.5, T3, T3.5, T4,T5 ,DR7,DR7M,DR8 BA & CA |

Annealing | CA(Continuous annealing) and BA(Batch annealing) |

Surface | Bright/Stone/Silver finish with passivation treatment; DOS oil |

MOQ | 25 tons or one container |

Payment | T/T, LC, Kun Lun Bank, Western Union, Paypal, O/A, DP |

Reference standard | GB/T 2520-2008, JIS G3303-2008 ,DIN EN 10203-1991 and ASTM A623M-2011 |

Applications: | Widely used for metal packaging industry. |

Such as making cans for food, tea, oil, paints, chemicals, aerosol, gifts, printing |

The Main Characteristics of Tinplate

Opaqueness

Light exposure can trigger food deterioration and alter proteins and amino acids. Vitamin C, in particular, reacts easily with other food components when exposed to light, resulting in significant loss. Research shows that vitamin C loss in milk stored in transparent glass bottles is 14 times higher than in dark bottles. Light exposure also causes milk to develop oxidative odors and decompose nutrients like radionuclides and methionine, reducing nutritional value. Tinplate cans block light completely, ensuring the highest preservation of vitamin C.

Good Sealing Performance

Effective sealing is critical for preserving nutritional value and sensory quality. Packaging that blocks air and volatile gases better protects contents. Studies comparing juice containers found that oxygen permeability directly impacts browning and vitamin C retention. Metal cans, glass bottles, aluminum foil, and paper boxes with low oxygen permeability perform well, but tin cans offer the best preservation of vitamin C.

Reduction Effect of Tin

The tin layer on the inner walls of tinplate reacts with residual oxygen inside the container, minimizing oxidation of food components. This reduction effect preserves the flavor and color of light-colored fruits and juices. Juice packed in unpainted tin cans shows superior flavor retention and milder browning compared to other materials, allowing for longer storage periods.

Source of Effective Iron

Tinplate canned foods, particularly those with painted interiors, offer an additional benefit: a small amount of iron dissolves into the food during storage. This iron is present as divalent iron, which the human body easily absorbs. For example, a 350 ml beverage in a tin can contains approximately 5 ppm of iron, providing 1.75 mg per can—about one-tenth of the recommended daily intake. When paired with vitamin C-rich beverages, iron absorption is enhanced, making tin canned foods an important nutritional source.

Complete Environmental Isolation

Tinplate cans create a fully sealed system, protecting food from light, oxygen, moisture, and environmental odors. This isolation prevents discoloration, taste changes, and nutrient degradation. Compared to other packaging materials, tinplate provides superior stability for stored food, maintaining the highest vitamin C preservation rates and nutritional value.

Advantages

Excellent Preservation: Prevents light, air, and moisture penetration to maintain product quality.

Enhanced Durability: Tin coating increases the lifespan of the steel sheet.

Reduced Oxidation: Tin reacts with oxygen to minimize oxidation of food contents.

Source of Iron: Provides dietary iron through minor dissolution during storage.

Cost-Effective: A reliable and economical solution for various industries.