Product Introduction

Overview

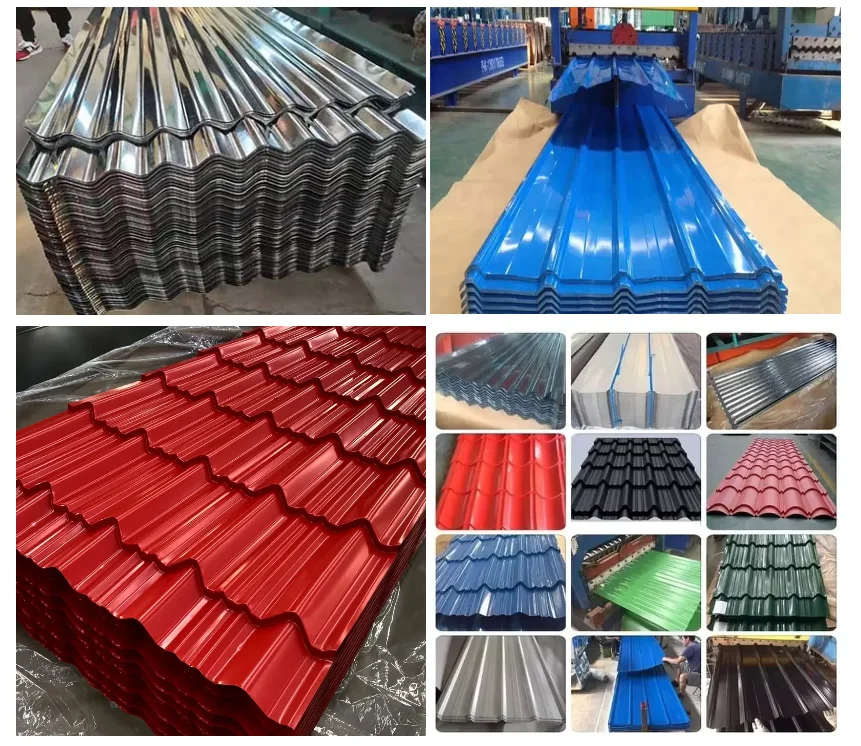

The Weather-Resistant Color Coated PPGI/PPGL Steel Roofing Sheet is a premium building material designed to withstand harsh environmental conditions while delivering aesthetic appeal. Constructed with hot-dipped galvanized steel (PPGI) or galvalume steel (PPGL) as the base, this roofing sheet is coated with a protective polymer layer in various vibrant colors. The manufacturing process involves precise surface treatment, primer coating, and topcoat application, ensuring excellent adhesion and long-lasting color retention.

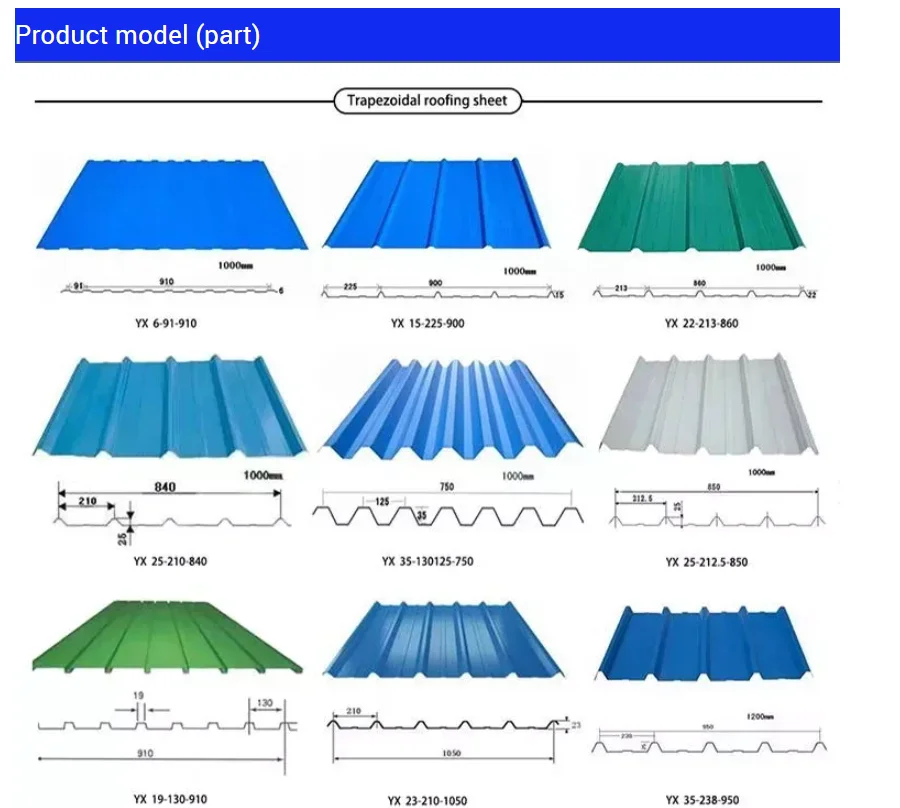

PPGI (Pre-Painted Galvanized Iron) offers a zinc-rich protective layer, while PPGL (Pre-Painted Galvalume) combines zinc and aluminum for enhanced corrosion resistance. These sheets are lightweight yet structurally robust, making them ideal for both new constructions and retrofitting projects. Available in standard sizes and customizable thicknesses, they provide a versatile roofing solution for diverse architectural needs.

Features

1. Superior Weather Resistance: The polymer coating resists UV radiation, rain, snow, and temperature fluctuations, preventing fading, chalking, and rusting even in coastal or industrial areas with high humidity or air pollution.

2. Vibrant Aesthetic Options: A wide range of colors and surface textures allow architects and homeowners to choose designs that complement building exteriors, from modern minimalism to traditional styles.

3. High Mechanical Strength: The galvanized or galvalume core provides excellent load-bearing capacity, resisting impact from hailstones and strong winds (tested to withstand up to 120 mph wind loads).

4. Energy Efficiency: Reflective coatings can be applied to reduce heat absorption, lowering cooling costs in hot climates and creating a more comfortable indoor environment.

5. Easy Installation: Lightweight design and pre-cut profiles enable quick installation, reducing labor costs and project timelines. The sheets are compatible with standard roofing accessories and fasteners.

Application

• Residential Roofing: Perfect for single-family homes, townhouses, and villas, offering durable protection and enhancing curb appeal.

• Commercial Buildings: Used in office complexes, shopping malls, and hotels to balance functionality with aesthetic requirements, especially in urban areas with strict building codes.

• Industrial Facilities: Suitable for factories, warehouses, and logistics centers, where resistance to chemical emissions and heavy usage is critical.

• Agricultural Structures: Provides reliable roofing for barns, greenhouses, and livestock shelters, enduring exposure to moisture, dust, and agricultural chemicals.

FAQ

Q: How long does the color coating last?

A: Under normal environmental conditions, the color retention warranty ranges from 10 to 20 years, depending on the coating type and maintenance practices.

Q: Can these sheets be recycled?

A: Yes, both the steel core and coating materials are recyclable, making them an eco-friendly choice for sustainable construction.

Q: Are they suitable for flat roofs?

A: While primarily designed for pitched roofs, they can be adapted for flat roofs with proper drainage systems and slope adjustments.

Q: How to maintain the roofing sheets?

A: Regular cleaning with mild soap and water is recommended to remove debris. Avoid using abrasive tools or harsh chemicals that may damage the coating.