Product Overview

Standard & Compliance: ASTM A653 / A653M hot-dip galvanized steel coil

Coating: Zinc coating via continuous hot-dip process, G-grade options (e.g. G60, G90, Z180, Z275)

Thickness Range: 0.12 mm – 6.00 mm (customizable)

Width Range: Up to 1,250 mm (commonly 1,000-1,250 mm)

Coil Weight: Standard coils 5-10 metric tons (other weights on request)

Surface Finish: Regular / small / zero spangle finish; smooth, clean, ready for further processing

Specifications

| Galvanized sheet /Galvanized coil |

Production Standard | ASTM, AISI,JIS, DIN, EN,GB, GOST |

Material | DX51D,DX52D,DX53D,Z275,G90,G350,G450,G550,SGCC,,SGCH,GECC,,SPHC,A36,E235/S235JR,Q235B,E355/S355JR,Q345A,Q345B,Q345C,Q345D,Q345E,ST35,ST37,ST45,ST52,DC01,DC02,SS400,HC340LA,HC380LA,HC420LA,B340LA,B410LA |

Size

| Thickness | 0.105-4mm |

Width | 600-1250mm |

Tolerance | +/-0.02mm |

Zinc coating | Z30-600g/㎡ |

Surface | Bright,Mill, polished, oiled, galvanized, or as required |

Payterm | Ex-work, FOB, CIF, CFR, etc |

Payment | T/T, L/C, Western Union, Alibaba Trade Assurance, etc |

Delivery Time | Within 3-5 days for our stock size, 15-20 days for our production |

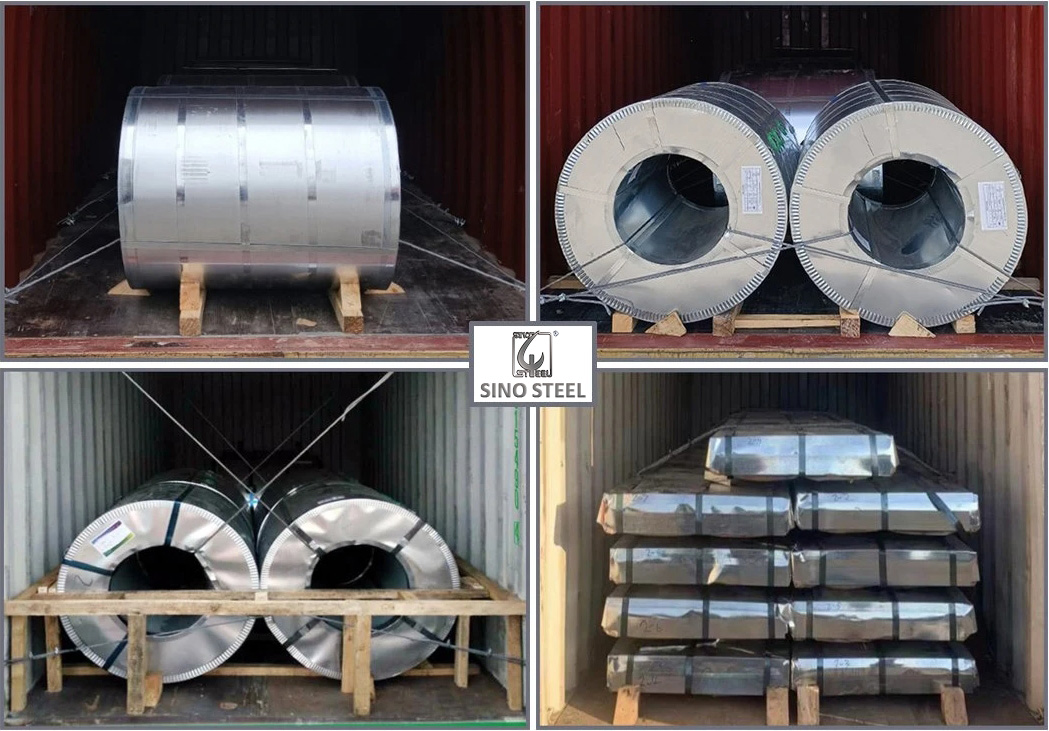

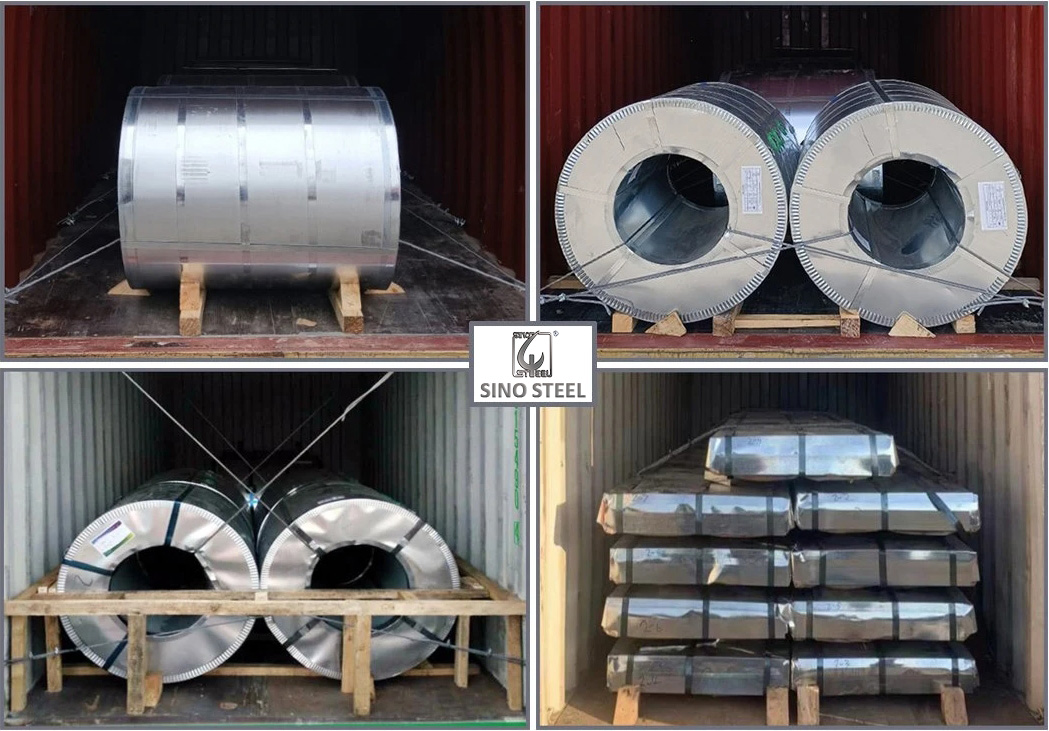

Package | Dustproof kraft sheet

Iron packing

Angle protective

packing belt |

MOQ | 25 TONS (in one 20ft FCL) |

Sample | Free and available |

Quality | Mill Test Certificate, ISO9001, CE,SGS, TVE |

Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

Mechanical properties of galvanized steel

|

Usage | Grade | Yield strength(MPa) | Tensile strength(MPa) |

Punching galvnaized steel

| DC51D+Z | - | 270-500 |

DC52D+Z | 140-300 | 270-420 |

DC53D+Z | 140-260 | 270-380 |

Structure galvanized steel

| S280GD+Z | ≥280 | ≥360 |

S350GD+Z | ≥350 | ≥420 |

S550GD+Z | ≥550 | ≥560 |

Product Description

Imagine a steel coil so resilient that it stands firm in the face of salt-laden air, heavy storms, or industrial fumes. That’s what our ASTM A653 Compliant Hot-Dipped Galvanized Steel Coil delivers. Forged with the highest care, it merges tough weather resistance with smooth, protective zinc layers that feel solid to the touch and look crisp in appearance.

When you handle the coil, you’ll notice:

A weighty, robust feel—no paper-thin giving;

A metallic sheen with texture that shows high-quality zinc finish—regular or zero spangle—that holds up under inspection;

Edges cut clean, surface nearly free of blemishes, ready to form, weld, press, or paint without extra prep.

This product was born out of industrial necessity: in many heavy applications—even in harsh external environments—traditional steel fails due to rust, corrosion, frequent maintenance, or early replacement. Our galvanized coil solves these problems by offering:

Long-lasting corrosion protection, reducing rust and extending life span;

Lower maintenance costs, saving you from frequent repainting or replacement;

Improved structural integrity, retaining strength even in demanding bending, cutting, or forming operations;

A clean, professional appearance, which supports any downstream finishing you require.

Here’s how it works: steel substrate is cleaned, fluxed, then continuously passed through molten zinc. The result is a uniform zinc layer that bonds tightly and protects both mechanically and cathodically. The combination of correct coating weight, high base steel strength, and precise surface finish ensures reliability across many environments.

Key Features & Highlights

ASTM A653 Compliance: Guarantees chemical composition, coating adhesion, thickness, and mechanical performance to internationally recognized standard.

High Corrosion Resistance: With coatings like Z275 or G90, you get superior zinc protection that resists rust in outdoor, marine, industrial settings.

Durability & Strength: Strong base steel with yield and tensile strengths ensuring your components maintain shape, load capacity, and form under stress.

Surface Options for Clean Finish: Choose from zero spangle for sleek look, or regular/small spangle if preferred; minimal visible defects; ready for paint or coating.

Flexible Thickness, Width & Customization: Whether you need thinner coils for formability or thicker ones for structural strength, we adapt; widths and coil weight per project.

Excellent Fabrication Performance: Clean shearing, precise bending, roll forming, welding without compromising coating integrity.

Cost-Efficiency Over Lifecycle: Lower upkeep, fewer replacements, extended warranty better ROI.

Reliable Supplier Backing: Factory with full QA/QC protocols, certifications, consistent batch reports; supply stability and customization.

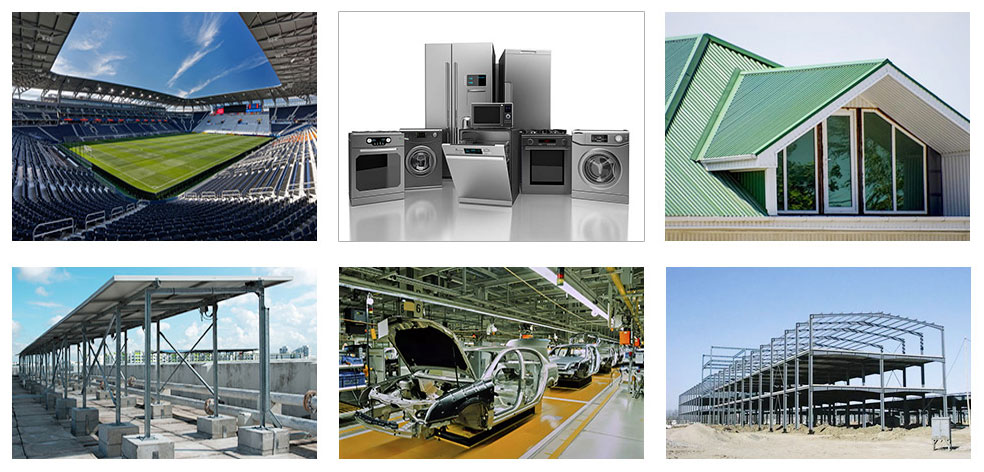

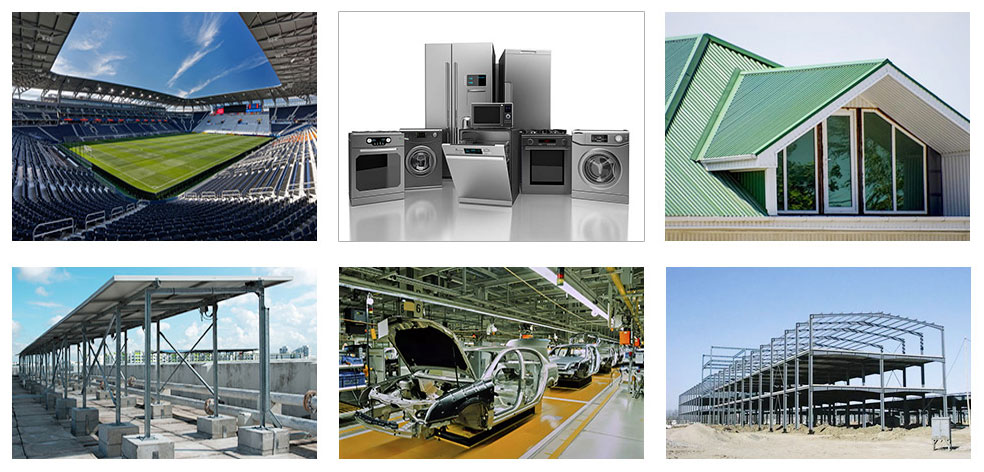

Applications

This galvanized coil is especially suited for B2B heavy-duty and industrial uses, such as:

Roofing, siding, and architectural cladding for warehouses, industrial plants, agricultural buildings, and commercial halls

Structural supports, framing, beams, brackets, guard rails, fencing that require long-term strength and rust resistance

Components in transportation infrastructure: bridges, guardrails, road signage, platforms, traffic barriers

Equipment enclosures, cabinets, ducting, HVAC systems exposed to moisture or outdoor environments

White goods (appliances), machinery bodies, where aesthetic and functional corrosion protection is both needed

Marine or coastal installations where salt spray and humidity are expectant, and durable zinc coating is critical

Why Choose Us

We understand B2B buyers demand more than numbers—they demand consistency, integrity, and value. Here’s why our galvanized steel coil stands out:

Proven Expertise & Industry Credibility: Our facility strictly adheres to ASTM A653 standards; we have ISO 9001 certification and third-party quality verification.

Robust Supply & Scalability: Large production capacity to meet bulk orders without compromising on lead time or consistency.

Customization & Flexibility: From coating weight to thickness, width to surface finish, we tailor to project specifications.

Rigorous Quality Control: Every batch comes with a Mill Test Certificate (chemical, physical, coating test etc.); inspection before packing.

Superior After-Sales Support: Technical advice for application, bending, welding; assistance with selecting correct G-grade or Z-weight; guidance on transport and handling to prevent transit damage.

Better Total Cost of Ownership: Though initial investment is competitive, your maintenance, replacement and downtime costs go down significantly, delivering long-term savings.

FAQ

Q1: What do the “Z” and “G” coating designations mean, and which should I choose?

A: “Z-” designations (e.g. Z180, Z275) refer to grams per square meter of zinc coating (total both sides). “G-” designations (G30, G60, G90) are similar, often used in ASTM specifications, expressing coating weight in oz/ft⊃2;. Higher values give stronger corrosion resistance but may cost more. Choose based on exposure: humid or coastal → higher coating; indoor or mild climate → lower.

Q2: What steel grades are available, and how do they affect strength?

A: We offer mild/low-carbon steels (e.g. DX51D) and higher strength structural grades (e.g. S350GD+Z, etc.). Higher grade steels deliver greater yield and tensile strength—meaning thinner metal can sometimes be used while still meeting load requirements.

Q3: Can this coil be used for further painting or color coating?

A: Yes. If you require pre-painting or post-painting, we provide appropriate surface finish (e.g. zero spangle or regular spangle), ensure clean, properly passivated surfaces, and can provide treat-ments to ensure paint adhesion.

Q4: How is packaging handled to prevent damage in transit?

A: Coils are wrapped in moisture-proof paper, banded, placed on standard export pallets or crates. Inner and outer diameters protected; optional protective film; shipping methods (FOB, CIF etc.) can be arranged per contract.

Q5: What is typical lead time for orders, especially customized specifications?

A: For standard specs (commonly used thicknesses, widths, coating weights), lead time is about 30-45 days. For custom requirements (very high coating, special steel grade, or custom widths), lead time may extend; we’ll provide exact schedule with quotation.

Q6: Do you supply test certificates and guarantees?

A: Yes. We supply Mill Test Certificates (chemical composition, mechanical tests, coating weight tests) with every order. Optional third-party inspection can be arranged. We stand behind our product and provide warranty/guarantee of coating integrity per ASTM standard.

If your projects demand steel coil that resists rust, holds up under severe weather or industrial exposure, and reduces long-term maintenance cost, then choosing our ASTM A653 Hot-Dipped Galvanized Steel Coil is a smart investment. Contact us today with your specification (thickness, width, coating weight, surface finish) for a detailed quote. Let’s partner to build reliably, durably, and cost-efficiently.