Product Description

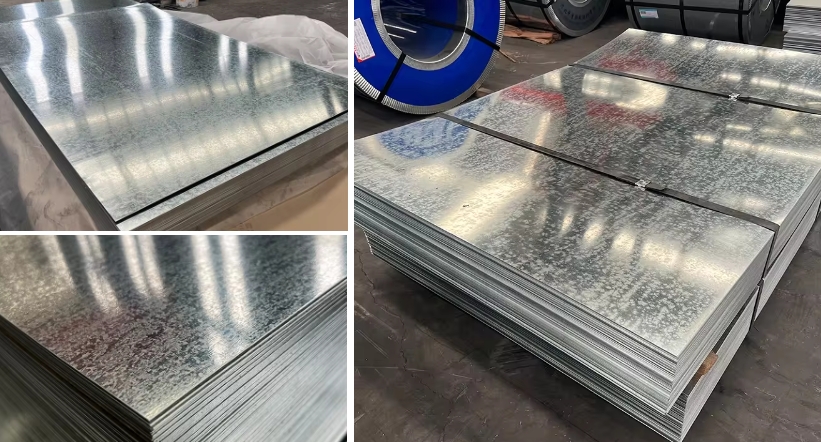

The Hot Dip GI Sheet is engineered for durability and protection. Produced through a hot-dip galvanizing process, each sheet is submerged in molten zinc to form a dense, uniform coating that resists rust and extends the life of the steel beneath. Unlike untreated steel, this product retains its strength and form even in humid, coastal, or industrial settings.

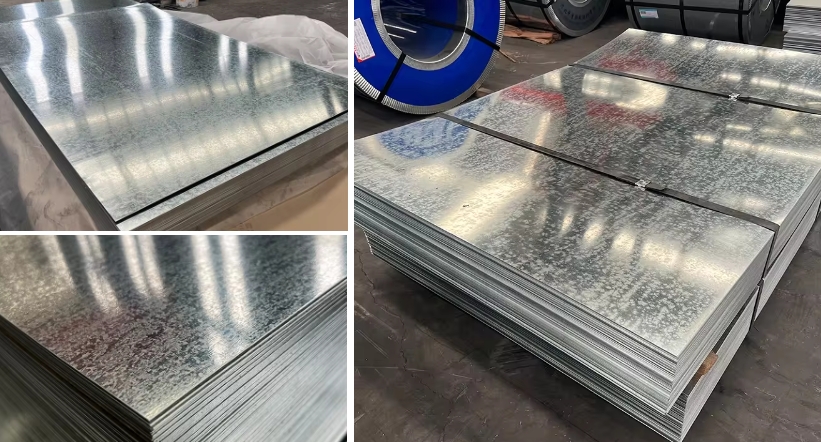

The result is a smooth metallic surface that catches the light with a clean, silver sheen. In its regular spangle form, the sheet displays a crystal-like pattern, while the zero spangle finish offers a sleek, uniform appearance. Both options are more than just aesthetic—they signal long-lasting reliability.

By combining structural strength with long-term corrosion resistance, Hot Dip GI Sheets help builders, manufacturers, and fabricators deliver safer, longer-lasting projects while reducing maintenance and replacement costs.

Product Parameters

Parameter | Value |

Thickness | 0.18 mm (BWG 34) |

Zinc Coating | 30–275 g/m² (Z30–Z275) |

Width | Customizable (typically 600–1250 mm before corrugation) |

Length | 1–12 meters (customizable) |

Surface Finish | Regular spangle, minimal spangle, zero spangle |

Standards | ASTM A653, EN 10346, JIS G 3302 |

| item | value |

| Place of Origin | China Shandong |

| Brand Name | GUOGANG |

| Application | construction, light industry, automobile, agriculture, animal husbandry, fishery and commercial industries |

| Standard | a653, a792, jis g3302, en10142, en1012 |

| Thickness | 0.12-5.0mm customized |

| Width | 600-1500mm custom |

| Length | 1-12m as buyer needs |

| Spangle | Big Regular Small Zero |

| Certificate | CE, SGS, ISO9001 |

| Grade | SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 |

| SGHC SGH340 SGH400 SGH440 SGH490 SGH540 |

| DX51D DX52D DX53D DX54D DX55D DX56D DX57D |

| S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD |

| Zinc coating | 30g/m2 to 275g/m2 |

| Coil Weight | 3-8 Tons |

| Coil ID | 508mm or 610mm |

| Surface treatment | Unoil, Dry, Chromate Passivated, Non-chromate Passivated |

| Delivery time | 7-15 days, for stock size and customized size, please chat with our sales person |

| Capacity | 500,000MT/year |

Key Features & Highlights

Long-Term Protection – Zinc coating creates a physical and chemical barrier against corrosion.

Structural Integrity – Maintains mechanical strength across various thicknesses.

Versatile Surface Options – From decorative spangle finishes to uniform zero spangle designs.

Low Maintenance – Reduced need for repainting or repair compared to bare steel.

Weldable & Formable – Easy to cut, bend, and join without losing coating protection.

Eco-Friendly – Fully recyclable steel with sustainable production practices.

Customizable Sizes – Width, thickness, and length tailored to project requirements.

Surface & Coating Options

Regular Spangle – A crystal-like surface, ideal for roofing and decorative panels.

Zero Spangle – Smooth finish, preferred in appliances and interior uses.

Oiled Surface – Prevents white rust during transport and storage.

Unoiled – Natural finish, ready for immediate fabrication.

Chromated/Passivated – Enhanced corrosion resistance for long-term performance.

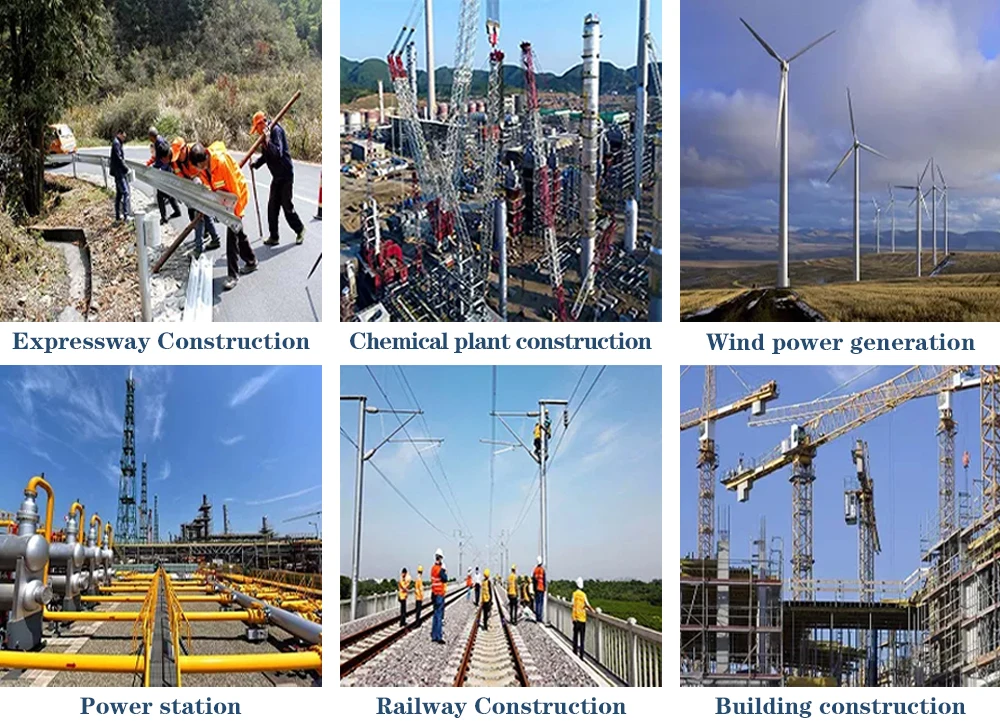

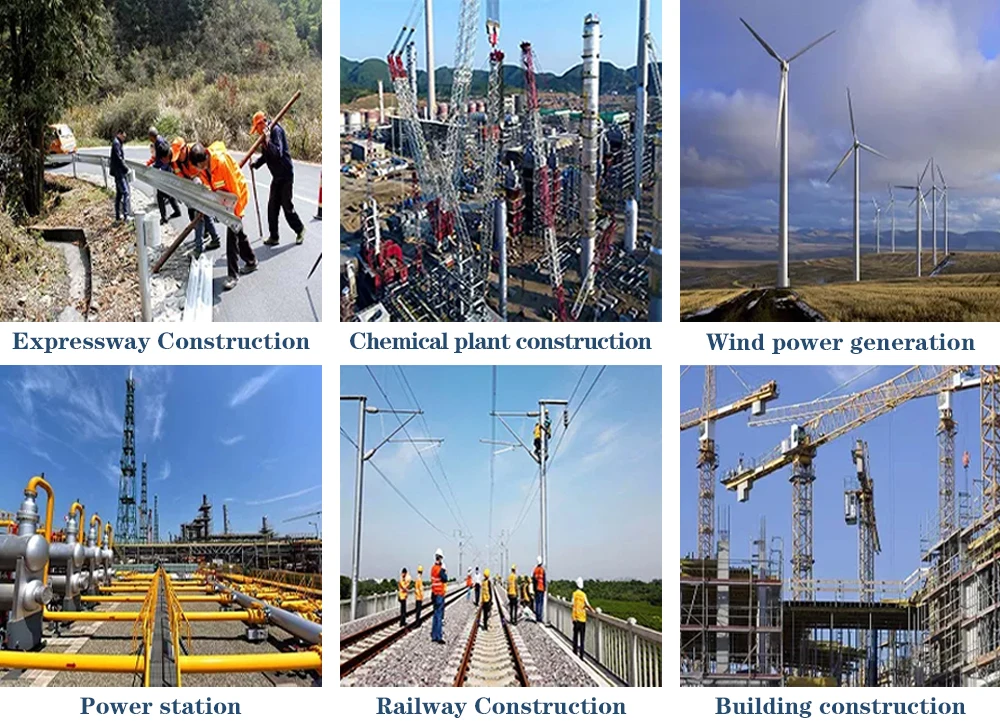

Applications

Construction & Roofing – Wall panels, roofing sheets, ceilings, and structural reinforcement.

Automotive Industry – Body panels, chassis, and protective parts.

Household Appliances – Refrigerator panels, washing machines, air conditioners.

Industrial Fabrication – Cable trays, guardrails, ventilation ducts, and machinery parts.

Agricultural Use – Storage tanks, silos, fencing, and greenhouse structures.

Advantages of Hot Dip GI Sheet

Cost Efficiency – Longer service life means lower total project costs.

Superior Resistance – Zinc barrier resists moisture, chemicals, and harsh climates.

Aesthetic Appeal – Clean metallic finish enhances product and project appearance.

Adaptability – Supports multiple fabrication processes including welding, punching, and bending.

Safety Assurance – Stable mechanical properties improve reliability in critical structures.

Packaging & Delivery

Standard Export Packaging – Waterproof kraft paper and galvanized steel wrapping with steel straps.

Delivery Options – Coil form or cut-to-length sheets.

Lead Time – Normally 15–25 days depending on order size.

Loading Capacity – 25–28 MT per 20ft container.

Protection – Edge guards and inner/outer protective wrapping to prevent transit damage.

Why Choose Us

Proven Experience – Decades of steel production expertise with global market presence.

Strict Quality Control – Comprehensive testing for coating weight, thickness, and surface finish.

Certifications – Compliance with ASTM, JIS, EN standards, ISO & SGS certifications available.

Customization – Dimensions, coatings, and branding tailored to client needs.

Global Supply Chain – Reliable export network covering more than 80 countries.

Dedicated B2B Service – OEM/ODM support, technical assistance, and responsive after-sales service.

FAQ

Q1: What is your minimum order quantity (MOQ)?

A1: Typically 25 MT per size, but smaller trial orders can be arranged.

Q2: Can you provide free samples?

A2: Yes, samples are available; customers only cover shipping costs.

Q3: How do you guarantee quality consistency?

A3: Every batch is tested for coating weight, mechanical strength, and surface appearance.

Q4: What surface treatments do you offer?

A4: Regular spangle, zero spangle, oiled/unoiled, and chromated/passivated.

Q5: What is your typical delivery time?

A5: Around 15–25 days after receiving deposit, depending on order volume.

Q6: Do you support OEM or customized branding?

A6: Yes, OEM/ODM is supported with flexible packaging and labeling options.