Overview

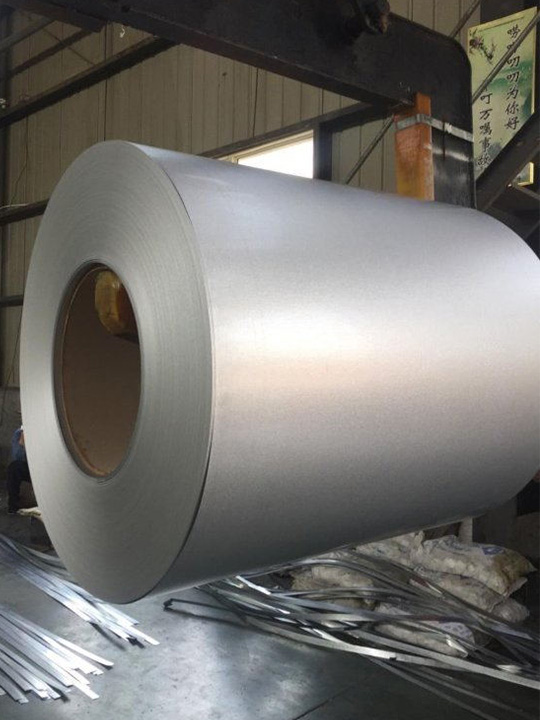

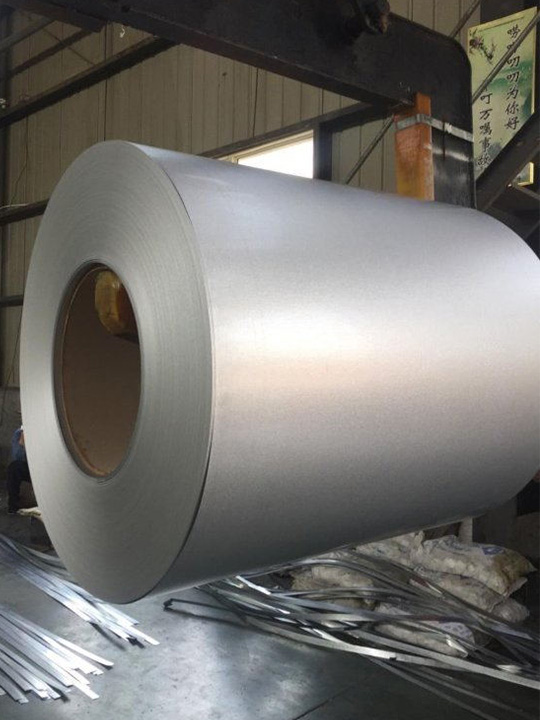

The SGS-Certified Az50/Az100/Az150 Galvalume Steel Coil is a premium metal product combining the benefits of zinc and aluminum for superior corrosion resistance and longevity. Composed of a 55% aluminum, 43.4% zinc, and 1.6% silicon alloy coating (AZ50: 50g/m², AZ100: 100g/m², AZ150: 150g/m²), this coil offers up to 4-6 times the corrosion resistance of traditional galvanized steel in harsh environments.

Manufactured to SGS international standards, the galvalume coating forms a dense oxide layer that self-heals minor scratches, protecting the steel core from rust. Supplied in coils for easy roll-forming and continuous processing, it is ideal for applications requiring both durability and aesthetic appeal.

Features

Exceptional Corrosion Resistance: The aluminum-rich coating provides superior protection against salt spray, UV radiation, and chemical pollutants, making it suitable for coastal, industrial, and tropical climates.

High Thermal Reflectivity: The metallic surface reflects up to 70% of solar radiation, reducing heat transfer and lowering cooling costs in warm regions.

Formability & Durability: Maintains excellent ductility for complex bending and profiling, while the alloy coating resists cracking during deep drawing or roll-forming.

Long Service Life: With a predicted lifespan of 25-40 years in moderate environments (up to 50 years in protected settings), it offers a low total cost of ownership.

Eco-Friendly Solution: Contains no harmful heavy metals and is 100% recyclable at the end of its life cycle, aligning with sustainable building practices.

Application

Building Cladding: Creates modern, low-maintenance facades for commercial and residential buildings, available in pre-painted or bare metal finishes.

Roofing Systems: Used in flat or pitched roofs, especially in areas with high humidity, salt exposure, or extreme temperature fluctuations.

Transportation Equipment: Manufactures truck bodies, trailer panels, and marine containers, resisting corrosion from road salts and ocean air.

Industrial Equipment: Forms storage tanks, ductwork, and heat exchangers in chemical plants and power stations, enduring harsh operational conditions.

FAQ

Q: How does Galvalume differ from galvanized steel?

A: Galvalume has a higher aluminum content, providing better corrosion resistance in outdoor environments, while galvanized steel (zinc-only) is more cost-effective for milder conditions.

Q: Can Az150 be used in coastal areas?

A: Yes, AZ150 offers the highest coating weight and is recommended for severe coastal or industrial environments with high salt or sulfur dioxide exposure.

Q: Does the coating require additional paint?

A: Bare galvalume can be used as-is for a metallic finish, but pre-painting with acrylic or polyester coatings enhances UV resistance and aesthetic options.

Q: How to handle cut edges for maximum protection?

A: Apply a zinc-rich paint or touch-up coating to cut edges to prevent rust formation at uncoated areas.

| Thickness | 0.14mm-0.8mm |

| Width | Width: 600mm-1250mm |

| Type of coating: | Galvalume or Aluminum Zinc |

| Zinc coating | 30g/m2-150g/m2 |

| Spangle | Regular Spangle or Mini Spangle or Big Spangle |

| Coil ID | 508mm |

| Coil weight: | 3--7MT |

| Price terms | FOB, CFR, CIF |

| Payment terms | 30%TT in advance+70% TT or irrevocable 80%L/C at sight |

| delivery time | 15--45 days after receipt of 30% TT |

Packaging & Shipping 1. Inside: waterproof kraft paper and plastic wrapping.

2. external: covered with steel plate and strapped to steel pallet with steel tape.

3. We can also meet other packaging suitable for sea export standard according to customers' requirements.

Payment and delivery: | Payment Terms | TT or LC at sight |

| Packing | Plastic Bag + Waterproof Paper + Steel Sheet with strip |

| Capacity | 10000MT per month |

| MOQ | 25MT/20GP |