Product Overview

The G550 grade substrate offers a minimum yield strength of 550MPa, making it suitable for load-bearing applications, while the Zm450 designation refers to the metallurgical bond quality of the galvalume coating. Manufactured via continuous hot-dip process, the coil features a smooth, silvery surface with excellent heat resistance (up to 450°C) and corrosion resistance 4-6 times better than pure zinc coatings in industrial and coastal zones.

Features

Heat & Corrosion Resistance: The aluminum-rich coating forms a protective oxide layer, resisting oxidation at high temperatures and saltwater corrosion better than GI steel.

High Tensile Strength: G550 grade ensures structural integrity in heavy-duty applications, reducing material thickness requirements by 20-30% compared to lower-strength grades.

Formability & Weldability: Maintains ductility for roll-forming into complex roof profiles or wall panels, with weld points requiring minimal post-treatment due to the coating's thermal stability.

Long Service Life: Offers 20-30 years of protection in harsh environments without additional coatings, ideal for low-maintenance infrastructure.

Eco-Friendly Composition: Uses recycled aluminum and zinc, with coatings free of lead, cadmium, and other hazardous substances, compliant with EU RoHS standards.

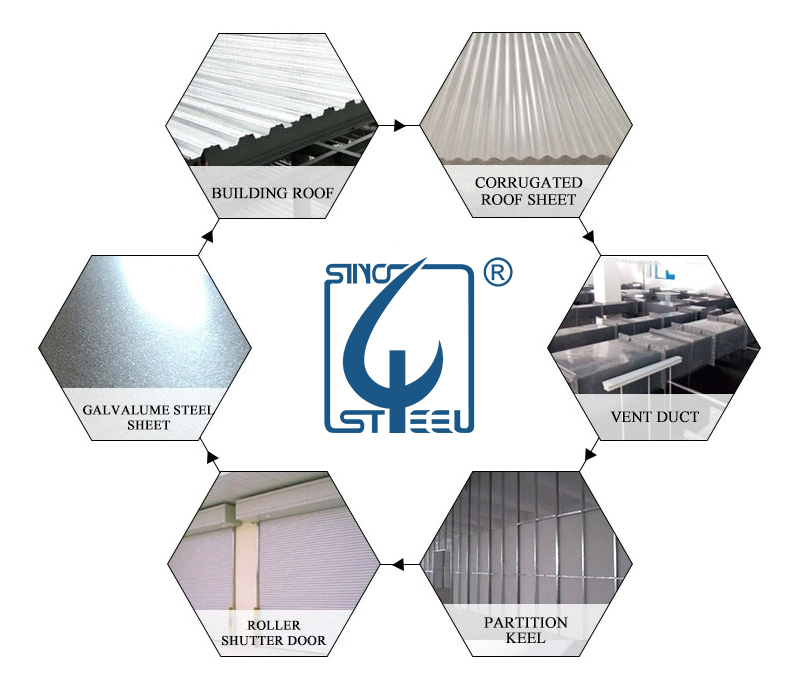

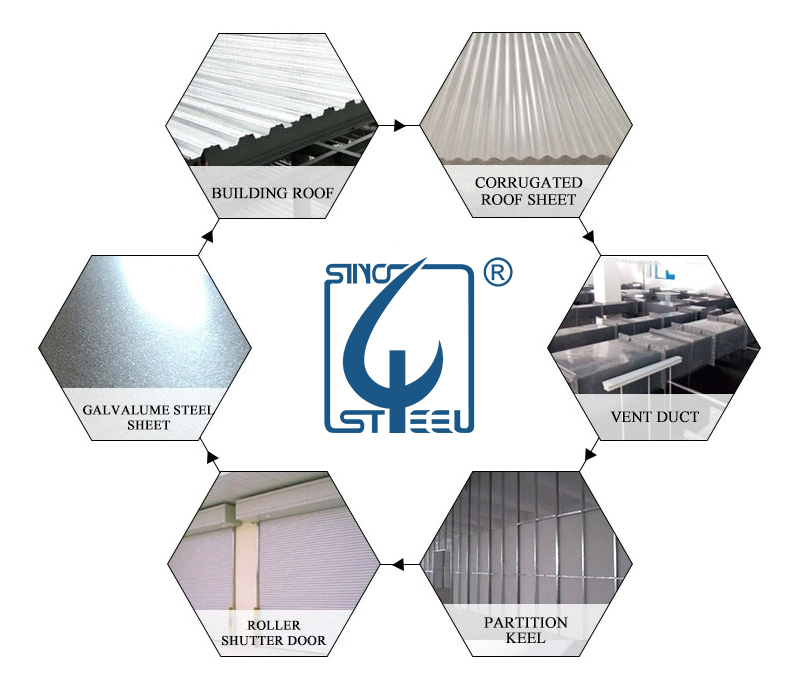

Application

High-Temperature Environments: Used for furnace linings, exhaust systems, and industrial chimneys, withstanding continuous temperatures up to 300°C.

Coastal Construction: Ideal for seawall cladding, offshore platform components, and beachfront buildings, resisting salt spray and humidity-induced corrosion.

Agricultural Machinery: Manufactures combine harvester parts, grain dryers, and livestock equipment, enduring exposure to fertilizers and moisture.

Solar & Wind Energy: Suitable for solar panel frames, wind turbine bases, and tower components, offering lightweight strength and resistance to atmospheric pollutants.

FAQ

Q: What is the difference between Galvalume (AZ150) and Galvanized (Z275)?

A: Galvalume has better heat resistance and coastal corrosion resistance, while galvanized offers better sacrificial protection in soil or freshwater environments.

Q: Can Galvalume steel be painted?

A: Yes, but requires a special adhesion promoter primer due to the smooth alloy surface; PVDF coatings are recommended for maximum longevity.

Q: How does the AZ150 coating weight compare to other grades?

A: AZ150 (150g/m²) is suitable for severe environments; lighter coatings (AZ50-AZ100) are for milder climates.

Q: Is G550 grade suitable for cold-forming?

A: Yes, its high yield strength allows cold roll-forming into complex profiles without heat treatment, though lubrication is recommended to protect the coating.

Q: Can Galvalume coils be used for potable water storage?

A: Yes, the alloy coating is non-toxic and complies with NSF/ANSI 61 for water contact, making it safe for water tank linings.

We Deliver Not Only The Goods,But Your Trust And A ffirmation.