| Material | SGCC, SGCH, G350, G450, G550, DX51D, DX52D, DX53D |

| Thickness | 0.12-4.0mm |

| Width | 20-1500mm |

| Zinc coating | AZ30-200G/M2 |

| Coil ID | 508 / 610mm |

| Coil Weight | 3-5Tons |

| Monthly Output | 50000 tons |

| Payment | T/T, L/C, Paypal, O/A, D/P |

| Hardness | Full hard(HRB85-95) |

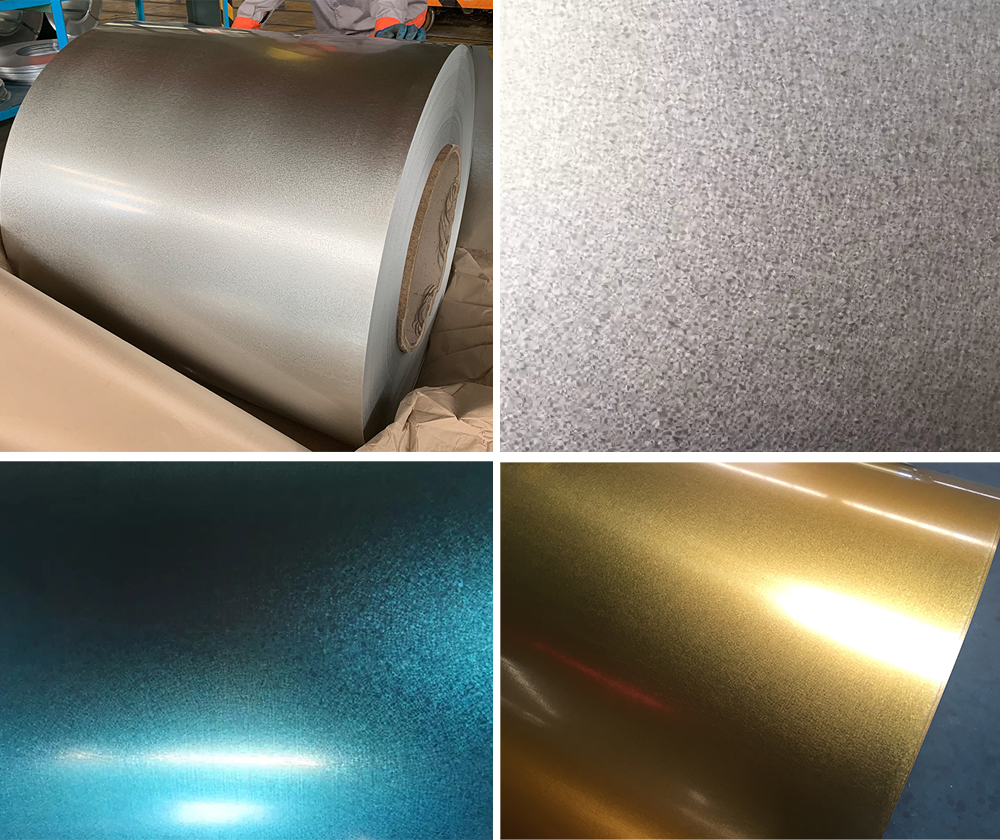

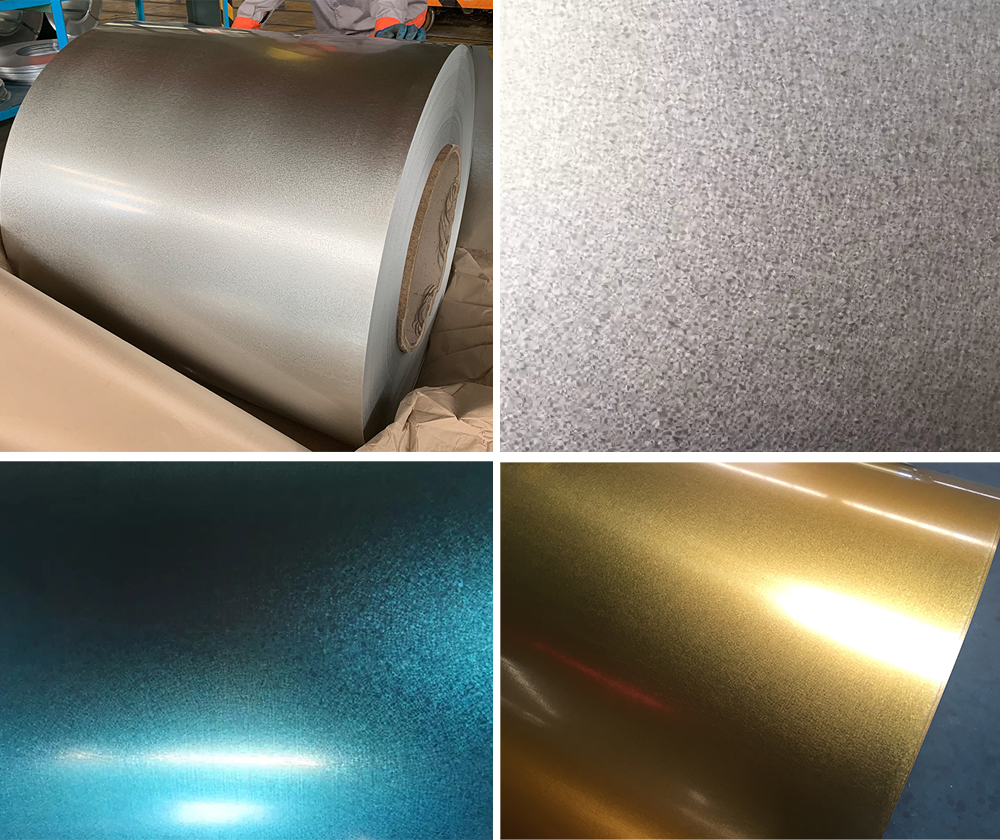

| Surface structure | Regular, Minimum, Zero, Big spangle |

| Surface | Choose between our sophisticated Anti-finger and classic Regular Surface finishes, tailored to meet diverse aesthetic and functional needs. |

Overview

The S350GD Galvalume Steel Coil is a high-performance building material engineered to meet the rigorous demands of modern construction, offering a combination of structural strength, weather resistance, and design flexibility. Composed of a 55% aluminum-zinc alloy (Aluzinc) coating (AZ50-AZ150g) on an S350GD high-strength steel substrate, this coil is ideal for load-bearing roofing, cladding, and structural components in commercial, industrial, and residential projects.

Available in thicknesses from 0.3mm to 1.5mm and widths up to 1250mm, the coil features a spangle or spangle-free surface finish, compatible with roll-forming, cutting, and welding processes. The S350GD designation (yield strength ≥350 MPa) ensures reliable performance in high-wind and seismic zones, while the galvalume coating provides long-lasting protection against corrosion and UV degradation.

Features

Structural Grade Performance:

S350GD Steel Substrate: Offers superior yield strength compared to standard grades, reducing material thickness requirements for large-span roofs and saving 15%+ in framework costs.

High Wind Resistance: Tested to withstand 160 km/h (100 mph) wind loads when properly fastened, meeting building codes in hurricane-prone regions (e.g., Florida, Japan).

Enhanced Corrosion Protection:

Aluzinc Coating Options:

AZ50: For indoor/storage applications (50g/m², 10-year life).

AZ150: For coastal/industrial zones (150g/m², 30+ year life with maintenance).

Self-Healing Oxide Layer: Aluminum-rich coating forms a protective film that repairs minor damage, delaying rust formation on cut edges and fastener holes.

Construction-Friendly Design:

Lightweight: 0.5mm thickness weighs 3.9kg/m², 50% lighter than concrete tiles, reducing transportation and installation costs.

Interlocking Profile Compatibility: Works with standard trapezoidal, corrugated, and standing seam roofing systems, enabling quick installation with clip-lock or screw-down methods.

Design & Sustainability:

Pre-Paint Ready: Smooth surface accepts polyester, PVDF, or silicone coatings for color customization (RAL/Pantone matching available).

100% Recyclable: Steel and Aluzinc layers are fully recyclable at end-of-life, contributing to LEED credits for green building projects.

Application

Commercial Roofing: Used in office complexes, shopping malls, and sports arenas, with AZ100 coating resisting urban pollution and UV exposure in high-rise environments.

Industrial Cladding: Protects factories, warehouses, and power plants from chemical emissions and heavy rainfall, with darker colors (e.g., RAL 7016) hiding dirt in polluted areas.

Residential Construction: Ideal for villa roofs and townhouse cladding, offering a low-maintenance alternative to clay tiles with customizable colors to match architectural styles.

Infrastructure Projects: Forms roofing for airports, train stations, and bridges, combining S350GD strength with AZ150 corrosion resistance in harsh outdoor conditions.

FAQ

Q: What is the recommended coating weight for a coastal villa?

A: AZ150g/m² is ideal for coastal areas, providing maximum protection against salt spray; pair with a PVDF topcoat for 20+ years of color retention.

Q: Can this coil be used for load-bearing wall frames?

A: Yes, the S350GD substrate meets EN 10143 structural standards for cold-formed steel framing, suitable for load-bearing walls in multi-story buildings.

Q: How does galvalume perform in high-temperature regions?

A: Aluzinc coating withstands up to 450°C, making it suitable for regions with extreme heat (e.g., deserts) without compromising corrosion resistance.

Q: What is the difference between spangle and spangle-free for construction?

A: Spangled surfaces have better corrosion resistance for exposed roofing, while spangle-free offers a smoother finish for painted cladding requiring uniform appearance.