Did you know that mechanical engineering, electrical machinery, and transportation use most of the world’s

stainless steel?

You see stainless steel types everywhere because they are strong. The corrosion resistance keeps things safe from rust and chemicals. Many stainless steel types are strong enough for heavy loads. The non-porous surface helps keep food and medical places clean. Corrosion resistance also helps the environment because it is fully recyclable. These stainless steel properties make this metal popular in every industry. Our Company trusts stainless steel because it is reliable and lasts a long time.

Key Takeaways

Stainless steel is tough and does not rust easily. This makes it great for building things. It is used in food, medical, and transport industries.

Its smooth surface helps keep things clean. This is why it is used in kitchens and medical tools.

Stainless steel can be recycled. This helps the environment and cuts down on trash.

Using stainless steel in buildings makes them last longer. It also lowers repair costs over time.

Things we use every day, like pots and appliances, use stainless steel. It is safe and strong, so many people pick it for their homes.

Stainless Steel Applications in Construction

Structural Uses

Stainless steel is used in many new buildings. Builders pick it for beams, columns, and frames. These parts help hold up big buildings. Stainless steel does not rust and is very strong. That is why it is good for civil engineering. You can find it in water plants and nuclear sites. It is also in chemical industry buildings. Stainless steel is used for elevator shafts and swimming pools too. These places have a lot of water. The smooth surface keeps things clean and safe.

Here is a table that lists where stainless steel is used:

Application Type | Description |

Beams and Columns | Support for plants and industrial buildings |

Bridges | Main beams, columns, and railings for harsh environments |

Coastal Structures | Seawalls and piers that face saltwater |

Reinforcement | Rebar in concrete for extra strength |

Curtain Walling | Facades and roofing for both looks and function |

Security Features | Barriers and hand railings in public spaces |

Fasteners | Secure assembly of construction materials |

Swimming Pools | Structural parts that resist corrosion |

Offshore Platforms | Fire-resistant walkways and structures |

Architectural Features

Stainless steel is not just for strength. It is used on building outsides and roofs. It is also used for decorations. Architects like it because they can make cool shapes. It does not make buildings heavy. The shiny look makes buildings look new. Stainless steel is good for the planet. Most of it gets recycled. It lasts a long time, so you do not need to fix or clean it much. This saves money and cuts down on trash.

Stainless steel does not rust or get damaged by weather.

It is strong and helps make new designs.

It is easy to recycle, so it is good for the earth.

It lasts long, so you fix and clean it less.

Infrastructure

Stainless steel is used in bridges and trains. It is also used in buildings near the ocean. These places need strong materials. Stainless steel can handle chemicals and saltwater. It also works in hot or cold places. You see it in bridge rails and subway stations. It is in airport buildings too. It lasts long and does not need much care. That is why it is good for busy places.

Because stainless steel is tough, it is important for transportation projects. For example, stainless steel rebar is great for highways and bridges. It is also good for other buildings in places with lots of salt.

When you use stainless steel, you help make better buildings and cities.

Uses of Stainless Steel in Food Industry

Stainless steel plays a key role in the food industry. You see it in kitchens, factories, and even in how food gets stored and moved. The uses of stainless steel in this industry come from its special properties. It does not react with food, so it keeps flavors pure. Its smooth surface makes cleaning easy and stops bacteria from growing. These stainless steel properties help you meet strict hygiene rules.

Kitchen Equipment

You find stainless steel in almost every commercial kitchen. Sinks, countertops, utensils, and appliances use this material because it is strong and easy to clean. Most kitchen equipment must meet high hygiene standards. Stainless steel helps you do this. The table below shows how stainless steel meets these needs:

Evidence | Description |

Cleanliness | Stainless steel is one of the most sanitary materials for kitchens. |

Compliance | It helps you meet health codes and hygiene rules. |

Non-porous Surface | The smooth surface stops bacteria from hiding or growing. |

Material Properties | Food grade stainless steel is safe and non-reactive for food contact. |

Corrosion Resistance | Grades like 304 and 316 resist rust and keep food safe. |

Cleaning Ease | You can clean stainless steel quickly and well, as rules require. |

You also see stainless steel in beverage machines and ovens. Its durability means it lasts a long time, even with heavy use.

Food Processing

Stainless steel in food processing keeps your food safe. The non-reactive surface does not change the taste or smell of food. This is important when you work with acids or salty foods. You can clean and sanitize equipment easily, which lowers the risk of cross-contamination. Here are some key benefits:

Stainless steel is non-porous and non-reactive, so bacteria cannot hide.

It keeps food safe and does not change flavors.

You can clean it fast, which helps you follow safety rules.

It resists corrosion, even with strong cleaners or food acids.

Storage & Transport

You use stainless steel containers to store and move food. These containers keep food safe from germs and chemicals. The most common types are 304 and 316 stainless steel. Grade 304 is used for dairy and beer, while 316 is better for salty or harsh foods. The table below shows the main types:

Type | Description |

304 | Used for dairy, beer, and sanitation. |

316 | Best for commercial food production, resists salt. |

430 | Cheaper, but needs drying after getting wet. |

You must store food in clean, dry places. Containers should stay off the floor. Many food safety rules require you to use stainless steel for these reasons. The uses of stainless steel in storage and transport help you keep food fresh and safe.

Stainless Steel in Medical & Pharmaceutical Applications

Stainless steel is very important in the medical field. You see it in many places because it is strong and safe. It is also easy to keep clean. Hospitals and pharmaceutical companies use it a lot. Stainless steel does not rust, so it keeps patients safe. It also helps equipment work well for a long time.

Surgical Instruments

Doctors use stainless steel tools every day. These tools stay clean and do not rust. You can clean them many times without damage. The table below shows why stainless steel is great for these tools:

Advantage | Description |

Hygienic properties | The passive oxide layer stops rust and blocks germs. |

Supports repeated sterilization | You can sterilize tools many times and keep them free from contaminants. |

Durability | Stainless steel is strong and does not break or wear out easily. |

Surgical tools must be sharp and safe. Stainless steel helps meet strict safety rules. These tools last for years because they are tough and reliable.

Hospital Equipment

You find stainless steel all over hospitals. It is in beds, trays, carts, and cabinets. This metal does not break easily. You can clean it fast because it is smooth. Germs cannot hide on the surface. Here are some reasons hospitals pick stainless steel:

The smooth surface is easy to clean.

There are no cracks for germs to hide.

You can clean it with high heat.

Stainless steel keeps its shape after many cleanings.

Stainless steel does not rust, so it keeps equipment safe. You can trust it to last a long time.

The table below shows important features:

Property | Explanation |

Strength | Resists breaking or cracking from drops or tossed instruments. |

Corrosion Resistance | Forms a passive film that resists rust and corrosion. |

Self-Healing Properties | Scratches fill in with chromium oxide, keeping surfaces intact. |

Ease of Cleaning | Smooth surface prevents pathogen harboring, improving hygiene. |

High Heat Tolerance | Handles high temperatures for sterilization without melting or warping. |

Cleanroom Uses

Pharmaceutical companies use stainless steel in cleanrooms. You need very clean surfaces to make safe medicine. Stainless steel does not react with chemicals. It is also easy to clean. You see different grades in cleanrooms:

304 Stainless Steel: Good for stopping rust and easy to clean.

316 Stainless Steel: Better for strong chemicals and salt.

316L Stainless Steel: Low carbon, very clean, and resists pitting.

316Ti Stainless Steel: Handles high heat and resists rust.

904L Stainless Steel: Works well with strong chemicals.

You use these grades for tables, tanks, and tools. Stainless steel helps keep cleanrooms safe and germ-free. These uses show why stainless steel is so important for health and safety.

Applications for Stainless Steel in Automotive & Transportation

Vehicle Parts

Stainless steel is used in many car parts. Car makers pick it because it does not rust. It also looks nice and shiny. You see it in exhausts, trims, and engine parts. Stainless steel has at least 10.5 percent chromium. This stops rust and stains. The metal is strong and lasts a long time. Here are some stainless steel parts in cars:

Grade 409 stainless steel is in exhausts. It resists heat and rust.

Decorative trims look good and protect from weather.

Fasteners and brackets hold parts together and stay strong.

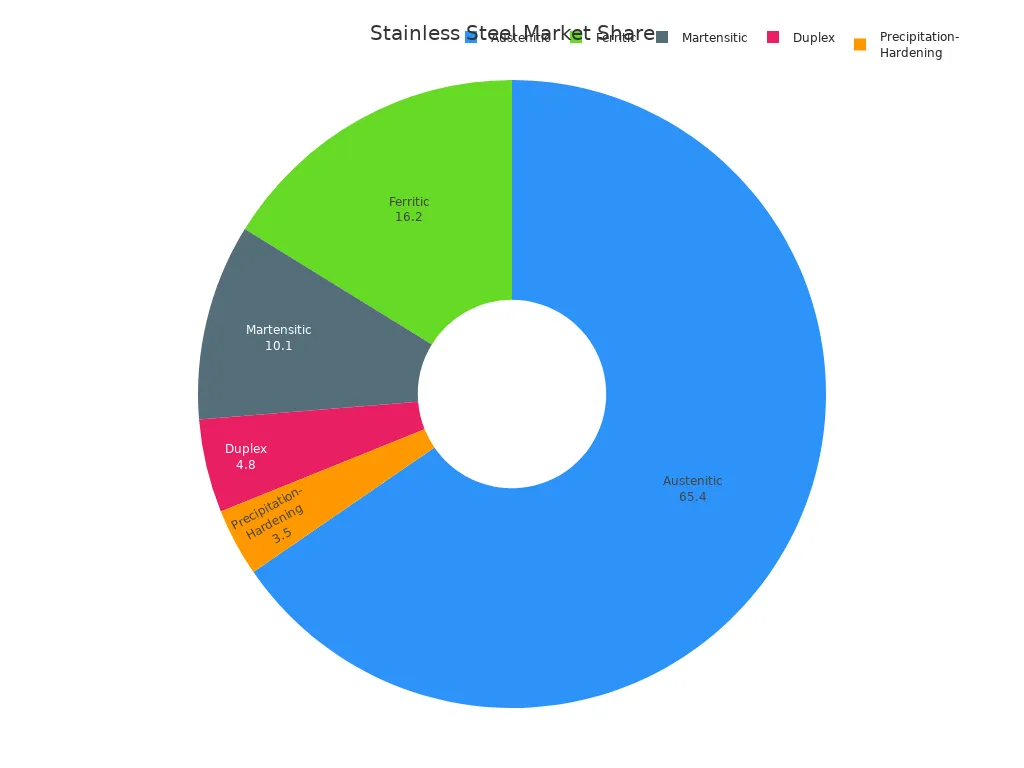

Stainless steel helps cars meet safety rules. It keeps cars looking new for years. The chart shows how much each stainless steel type is used:

Stainless Steel Type | Market Share (%) |

Austenitic | 65.4 |

Ferritic | 16.2 |

Martensitic | 10.1 |

Duplex | 4.8 |

Precipitation-Hardening | 3.5 |

Aircraft

Stainless steel is used in many airplane parts. It gives strength and keeps people safe. Airplanes need tough materials for heat and stress. Stainless steel works for engines, exhausts, landing gear, and joints. These parts last longer and work better.

Engine and exhaust parts use stainless steel for heat and rust.

Landing gear is strong and takes hard landings.

Joints in the plane are durable and do not break easily.

The table shows how strong stainless steel is:

Mechanical Property | 304 Stainless Steel | 316 Stainless Steel |

Ultimate Tensile Strength | 505 MPa (73,200 psi) | 580 MPa (84,100 psi) |

Melting Point | 1,400-1,455˚C (2,550-2,650˚F) | 1,370-1,400˚C (2,500-2,550˚F) |

Stainless steel makes airplane parts strong and safe.

Marine

Stainless steel is important for ships and platforms. It is used in shipbuilding and offshore places. Ships need metal that does not rust in water. Stainless steel works in saltwater and freshwater. You see it in fasteners, trims, floors, and rails. Marine grade stainless steel lasts longer and is safer.

Stainless steel does not rust in tough marine places.

Special grades are used for ships and offshore jobs.

Ships and platforms last longer and are safer.

Stainless steel helps build strong ships and platforms. It works well even in hard conditions.

Stainless Steel Applications in Energy & Chemical Industries

Power Generation

Stainless steel is used in almost every power plant. It helps keep turbines, boilers, and heat exchangers safe. This metal can handle high heat and pressure. It does not rust, even in tough places. Here are some ways it helps power plants:

Corrosion resistance keeps equipment from rusting, which is very important.

Heat transfer lets boilers and heat exchangers work at high temperatures.

Mechanical properties make parts strong and last a long time.

You also see stainless steel in seawater desalination plants. These plants need materials that can handle saltwater and high pressure. Stainless steel makes these plants work well and last longer. Its strength and toughness help save money over time.

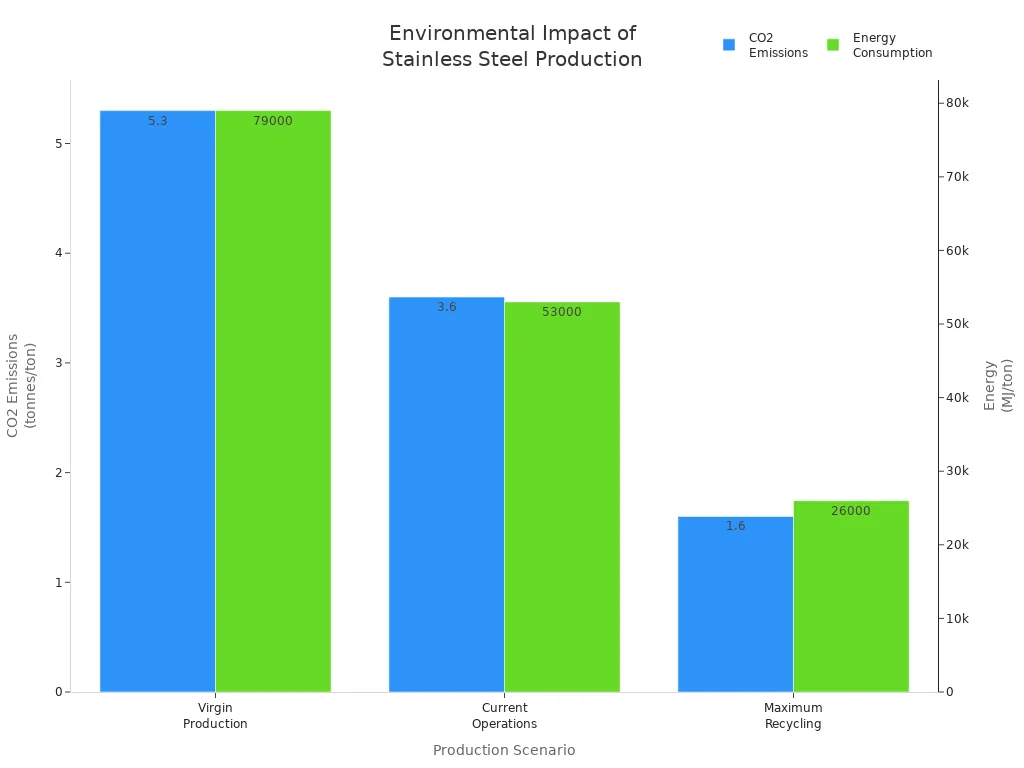

Tip: Stainless steel is good for the environment because you can recycle it after using it for many years.

Chemical Processing

The chemical industry needs safe and efficient equipment. Stainless steel is important for storing and moving caustic materials. Its smooth surface keeps bacteria away and makes cleaning easy. You use stainless steel for tanks, pumps, and pipes. This metal can handle strong chemicals and high heat.

Stainless steel tanks keep dangerous materials safe.

Pumps and pipes made from stainless steel last longer and leak less.

You can clean and sterilize these surfaces quickly, which helps you follow safety rules.

Stainless steel lasts a long time and can be recycled, which is good for the planet.

Stainless steel in chemical processing helps stop accidents and saves money.

Oil & Gas

The oil and gas industry uses stainless steel in many ways. You see it in pipelines, storage tanks, and offshore rigs. Stainless steel types like 304 and 316 do not rust during crude distillation. Grades 321 and 347 work well in hot areas, like fluid catalytic cracking.

Application Type | Description |

Stainless Steel Pipelines | Used for oil, heat exchangers, offshore rigs, and gas plant equipment. |

Stainless Steel Storage | Includes storage tanks, separators, and pumps. |

Stainless Steel Components | Used in coastal and harbor parts, and ship propellers. |

Stainless steel keeps your equipment safe and working well, even in hard places.

Everyday Applications of Stainless Steel

Household Items

You see stainless steel every day in your home. This material makes your kitchen safer and cleaner. Many people choose stainless steel cookware because it does not release toxins when you cook. You can use pots and pans at high temperatures without worrying about damage. Stainless steel lasts for years, even with heavy use.

Health and safety matter to you. Stainless steel does not react with food, so you keep your meals pure.

Durability stands out. You can drop or scrape stainless steel cookware, and it still works well.

The sleek look fits modern kitchens. Many people want their kitchen to look stylish, and stainless steel helps you achieve that.

Restaurants and catering services use stainless steel because it handles busy kitchens.

More people cook at home now. You want reliable cookware, and stainless steel meets your needs.

Here is a table showing popular household applications:

Item Type | Why You Choose Stainless Steel |

Cookware | Safe, durable, and easy to clean |

Sinks | Resists stains and keeps germs away |

Utensils | Non-toxic and long-lasting |

Appliances | Modern look and strong performance |

Storage Containers | Keeps food fresh and safe |

Stainless steel helps you keep your home clean and stylish. You invest in quality that lasts.

Art & Design

Stainless steel inspires artists and designers. You see sculptures and decorations made from this material in parks and buildings. Artists shape stainless steel into many forms. The reflective surface catches light and changes with the environment. You notice how it adds a modern touch to public spaces.

You find stainless steel in intricate designs. Artists bend and mold it to create unique pieces.

The shiny surface reflects light, making art come alive.

Stainless steel fits with modern architecture. You see it in city centers and new buildings.

Outdoor art lasts longer because stainless steel resists rust and weather.

You clean stainless steel art easily. It stays beautiful with little effort.

Stainless steel supports eco-friendly design. You can recycle it, so it helps the planet.

When you walk through a city, you see how stainless steel transforms spaces. It brings art and design together with strength and beauty.

You see stainless steel in many places around you. It is strong and does not rust. You can clean it easily. This makes it important for many jobs. In the last ten years, it has helped make new things in cars, energy, medicine, and design.

Car makers use it because it lasts and can be recycled.

It is needed for clean energy and medical tools.

People pick it for safe food and cool buildings.

People now care more about recycling and saving energy. New stainless steel types help make things better. In the future, stainless steel will help make life safer, cleaner, and smarter.

FAQ

What makes stainless steel different from regular steel?

Stainless steel contains chromium. This element forms a thin layer on the surface. The layer stops rust and stains. Regular steel does not have this protection. You get better durability and hygiene with stainless steel.

Can you recycle stainless steel?

Yes, you can recycle stainless steel many times. The metal keeps its strength and quality. Recycling helps save resources and energy. You help the environment when you choose recycled stainless steel.

Why do hospitals use stainless steel equipment?

Hospitals use stainless steel because it is easy to clean. The smooth surface stops germs from hiding. Stainless steel does not rust. You get safe and long-lasting equipment.

Is stainless steel safe for cooking and food storage?

Stainless steel is safe for cooking and storing food. It does not react with food or change flavors. You can clean it easily. Many chefs and food companies trust stainless steel for safety.

How do you keep stainless steel looking new?

You can wipe stainless steel with a soft cloth. Use mild soap and water. Dry the surface to stop water spots. Avoid harsh cleaners. Regular care keeps your stainless steel shiny and clean.