Stainless steel has four main types. These are Austenitic, Ferritic, Martensitic, and Duplex. Austenitic

stainless steel is the most common type. It is used in most products. It makes up about 70% of all

stainless steel made in the world. Here is a quick look:

Type of Stainless Steel | Global Production Percentage |

Austenitic | 70% |

Grades 304 and 316 are used a lot. Grade 304 is found in kitchen tools and building parts. Grade 316 is good for boats and medical tools. Picking the right type and grade is important. It helps you get the best results for your project. Our Company says you should always choose the material that fits your needs.

Key Takeaways

Stainless steel comes in four main types. These are Austenitic, Ferritic, Martensitic, and Duplex. Each type has special features. These features help in different jobs.

Austenitic stainless steel is the most used type. It makes up about 70% of all stainless steel made. It works well for kitchen tools. It is also good for chemical work. This is because it does not rust easily.

Picking the right grade of stainless steel is important. For example, use 304 for kitchens. Use 316 for things near the ocean. This helps your project last longer and work better.

Ferritic stainless steel costs less. It is also magnetic. This makes it good for car parts and home machines. Martensitic stainless steel is very strong and hard. It is great for making tools and blades.

Duplex stainless steel mixes the best parts of Austenitic and Ferritic types. It is very strong and does not rust easily. This makes it good for tough places like the ocean.

What Is Stainless Steel?

Definition

Stainless steel is easy to spot. You see it in sinks, cars, and bridges. Stainless steel is a metal mix. It does not rust or stain easily. It has iron and other elements. This makes it strong and shiny. People use stainless steel because it fights corrosion. It lasts a long time in hard places.

Alloying Elements

Stainless steel is special because of its mix. You add elements to iron to make it. Each element changes how it works. Here are the main alloying elements in stainless steel:

Chromium (Cr): You need at least 10.5% chromium. It makes a thin layer that stops rust.

Nickel (Ni): You often see 8-10% nickel. It helps stainless steel stay tough and bend.

Molybdenum (Mo): Molybdenum helps stainless steel resist damage from salt and chemicals.

Carbon (C): Carbon makes stainless steel harder and stronger. Too much carbon can lower how well it fights rust.

Nitrogen (N): Nitrogen makes stainless steel stronger and helps stop pitting.

Manganese (Mn): Manganese helps stainless steel keep its shape and mix with nitrogen.

Copper (Cu): Copper helps stainless steel resist some acids.

Tungsten (W): Tungsten helps stainless steel resist pitting.

Zirconium (Zr): Zirconium makes stainless steel stronger in cold places.

Cerium (Ce): Cerium helps stainless steel resist oxidation when it gets hot.

Tip: The mix of stainless steel changes with its grade and type. Always check the elements before you pick a material.

Why Types and Grades Matter

You must pick the right stainless steel for your job. The type and grade change how well it works. You get different levels of rust resistance, strength, and shaping. Some grades work better in salty water. Others handle heat or strong chemicals. Think about where you will use stainless steel. Marine places need high rust resistance. Not every grade fits every job. Match the mix and grade to your needs. This helps you avoid trouble and get good results.

Note: Picking the right grade makes your product last longer and work better. You save money and avoid fixing things by choosing well.

Types of Stainless Steel

You see many types of stainless steel every day. Each type has its own special features. You need to know these features to pick the best one. There are four main types. They are Austenitic, Ferritic, Martensitic, and Duplex. Austenitic stainless steels are the most common type. They make up about 70% of all stainless steel made. You find them in lots of products because they are strong and do not rust easily.

Here is a quick look at the four types:

Type | Composition | Structure | Hardening Method |

Austenitic | Iron, Carbon, Chromium, at least 8% Nickel | Face-centered cubic (FCC) | Cold working only |

Martensitic | 12–18% Chromium, 0.1–1.2% Carbon | Body-centered tetragonal (BCT) | Heat treatment possible |

Ferritic | Iron, Carbon, Chromium (typically 10.5-30%) | Body-centered cubic (BCC) | Not hardenable |

Duplex | 19–32% Chromium, up to 5% Molybdenum, less Nickel | Hybrid of FCC and BCC | Not specified |

Tip: Use this table to compare what each type is made of and how it is built. This helps you pick the right stainless steel for your project.

Austenitic Stainless Steel

Austenitic stainless steels are good when you need metal that does not rust and is easy to shape. These steels have iron, carbon, chromium, and at least 8% nickel. Nickel makes them tough and bendable. You cannot make them harder with heat. You can only make them harder by bending or rolling the metal.

Austenitic stainless steel does not stick to magnets. You see it in kitchen sinks, food machines, and chemical plants. It works well where there is water or chemicals. You can weld and shape it easily. Grades like 304 and 316 are used in many things.

Here is a table with important facts:

Property | Austenitic Stainless Steel |

Corrosion Resistance | Excellent |

Ductility | High |

Weldability | Excellent |

Magnetic Response | Non-magnetic |

Hardening | Not hardenable by heat |

Formability | Excellent |

Strength | Moderate |

You see austenitic stainless steel used for:

Common Uses |

Cookware |

Food and beverage equipment |

Processing equipment |

Automotive industry |

Chemical processing |

Pulp and paper industry |

Note: Pick austenitic stainless steel if you want metal that does not rust and is easy to shape.

Ferritic Stainless Steel

Ferritic stainless steel is good if you want metal that resists rust and costs less. This type has iron, carbon, and chromium, usually between 10.5% and 30%. It does not have much nickel. Ferritic stainless steel has a body-centered cubic structure. You cannot make it harder with heat.

Ferritic stainless steel sticks to magnets. You see it in car parts, exhaust pipes, and home machines. It works well in places with less stress and cooler temperatures. You can weld it, but it is not as easy as austenitic steel.

Here is a table with important facts:

Property | Ferritic Stainless Steel |

Corrosion Resistance | Moderate |

Ductility | Good |

Weldability | Moderate |

Magnetic Response | Always magnetic |

Hardening | Not hardenable |

Formability | Good |

Strength | Moderate |

You see ferritic stainless steel used for:

Common Uses |

Exhaust systems |

Petrochemical components |

Automotive trim |

Heat exchangers |

Furnaces |

Appliances |

Food equipment |

Tip: Use ferritic stainless steel for car parts and home machines that do not need to be very strong.

Martensitic Stainless Steel

Martensitic stainless steel is good when you need metal that is very strong and hard. This type has 12–18% chromium and more carbon than other types. You can make it harder with heat. Martensitic stainless steel has a body-centered tetragonal structure.

Martensitic stainless steel sticks to magnets. You see it in knives, scissors, and medical tools. It does not resist rust as well as other types. You need to keep it away from water and chemicals.

Here is a table with important facts:

Property | Martensitic Stainless Steel |

Corrosion Resistance | Lower than austenitic |

Ductility | Lower than austenitic |

Weldability | Difficult |

Magnetic Response | Magnetic |

Hardening | Heat treatable for hardness |

Formability | Moderate |

Strength | High |

You see martensitic stainless steel used for:

Common Uses |

Cutlery |

Surgical and dental instruments |

Springs |

Scissors |

Industrial blades |

Aerospace components |

General engineering components |

Note: Pick martensitic stainless steel for tools and blades that need to be sharp and strong.

Duplex Stainless Steel

Duplex stainless steel is good when you need metal that is strong and does not rust easily. This type has 19–32% chromium, up to 5% molybdenum, and less nickel than austenitic steel. Duplex stainless steel has a mix of two structures. This makes it tough and strong.

Duplex stainless steel does not stick to magnets as much as other types. You see it in places with saltwater, like ships and water plants. It works well in pressure tanks and heat exchangers. You can weld it, and it does not crack easily.

Here is a table with important facts:

Property | Duplex Stainless Steel |

Corrosion Resistance | Better than ferritic and martensitic |

Ductility | Moderate |

Weldability | Good |

Magnetic Response | Varies (generally non-magnetic) |

Hardening | Not applicable |

Formability | Good |

Strength | High |

You see duplex stainless steel used for:

Common Uses |

Pressure vessels |

Heat exchangers |

Desalination plants |

Marine and saltwater applications |

Construction |

Paper production |

Tip: Use duplex stainless steel for tough jobs in places like ships or chemical plants.

Comparing the Different Types of Stainless Steel

You need to look at all the types before you choose one. Each type has good and bad points. Austenitic stainless steel is the most common because it does not rust and is easy to shape. Ferritic stainless steel costs less and is good for car parts. Martensitic stainless steel is best for tools and blades. Duplex stainless steel is strong and does not rust, so it is good for hard jobs.

Here is a table to help you compare:

Type | Corrosion Resistance | Strength | Magnetic | Common Uses |

Austenitic | Excellent | Moderate | No | Kitchenware, chemical plants |

Ferritic | Moderate | Moderate | Yes | Car parts, appliances |

Martensitic | Lower | High | Yes | Knives, medical tools |

Duplex | High | High | Varies | Marine, construction, pressure vessels |

Note: Always match the type of stainless steel to your project. This helps you get the best results and avoid problems.

Common Grades of Stainless Steel

Stainless steel has many grades. Each grade has its own mix of elements. Different grades are used for different jobs. Some grades are better for kitchens. Others are best for boats or factories. You should know the main grades to choose the right one.

Austenitic Grades (304, 316, 301, 302, 303, 309, 321)

Austenitic stainless steel is the most used type. You see it in sinks, cookware, and medical tools. This type has a lot of chromium and nickel. It is strong and does not rust easily. You can shape and weld it without problems.

Here are the most common austenitic grades:

304: You find this grade almost everywhere. It has 18–20% chromium and 8–10.5% nickel. It is strong and resists rust. You see it in food processing, kitchen sinks, and chemical containers.

316: This grade has more nickel and 2–3% molybdenum. It fights salt and chemicals better than 304. You use it for boats, medical devices, and pharmaceutical equipment.

301, 302, 303: These grades have small changes in nickel and chromium. You use them for springs, fasteners, and parts that need to bend.

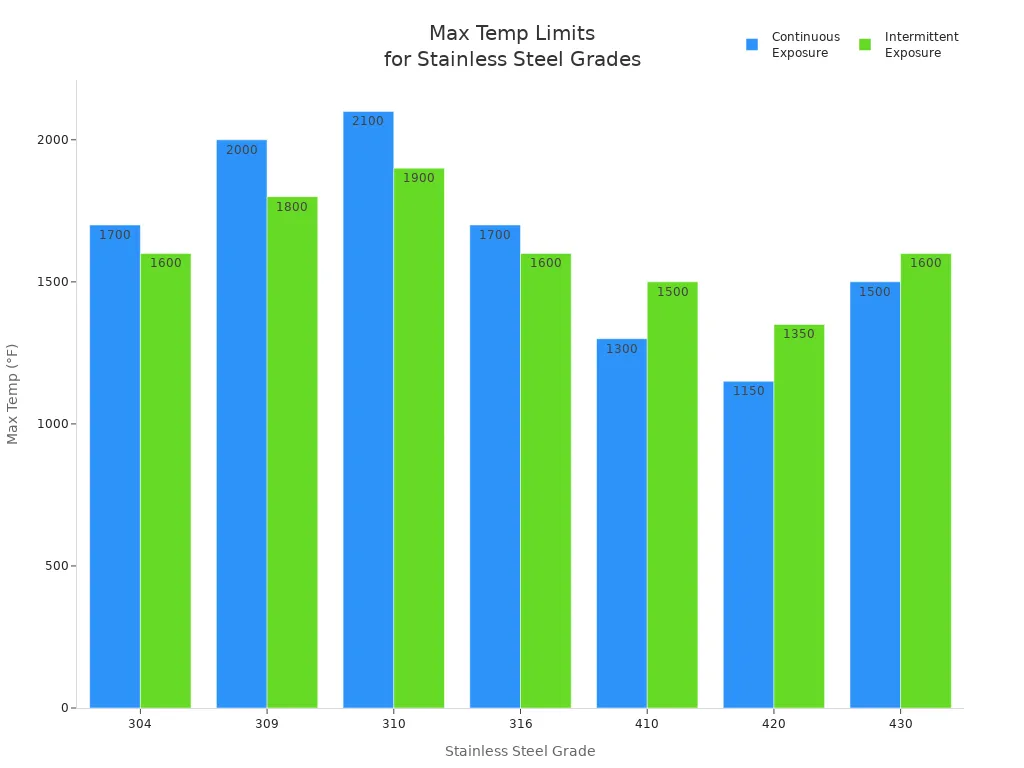

309, 321: These grades can handle high heat. You use them in ovens, furnaces, and exhaust systems.

Tip: Pick 316 for salty or chemical-rich places. Use 304 for most kitchen and food jobs.

Here is a table with the most used austenitic grades and their uses:

Grade | Description | Typical Applications |

304 | Great at resisting rust | Food processing, kitchen equipment, chemical containers |

316 | Better against chloride | Marine uses, pharmaceutical equipment, medical devices |

Austenitic stainless steel is found in many places. You see it in food factories, hospitals, and chemical plants. It is also used in cars and buildings.

Here is a table comparing the chemical makeup and uses of 304 and 316:

Grade | Composition Highlights | Key Properties | Applications |

304 | Cr: 18–20%, Ni: 8–10.5% | Strong, resists rust | Sinks, cookware, medical tools |

316 | Cr: 16–18%, Ni: 10–14%, Mo: 2–3% | Better against chloride | Marine parts, food processing |

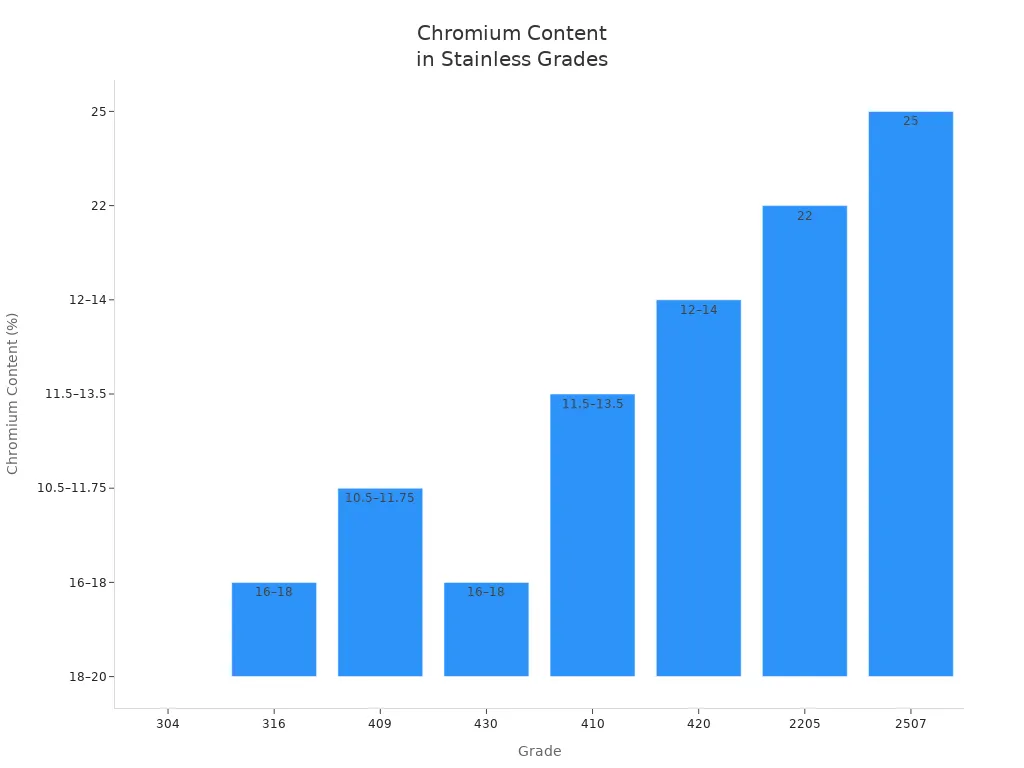

Note: The chart shows how much chromium is in each grade. Chromium helps stainless steel resist rust.

Ferritic Grades (409, 430, 446)

Ferritic stainless steels have less nickel. They cost less but still resist rust. You see ferritic stainless steels in car parts, kitchen backsplashes, and home appliances. These grades are magnetic. You cannot make them harder with heat.

Here are the main ferritic grades:

409: You use this grade for car exhaust systems. It has 10.5–11.75% chromium. It resists heat and oxidation.

430: This grade has 16–18% chromium. You find it in kitchen utensils, car trim, and home appliances. It is magnetic and resists rust well.

446: This grade can handle high heat. You use it in furnaces and heaters.

Tip: Use ferritic stainless steels for jobs that need good rust resistance but not high strength.

Here is a table with the most common ferritic grades and their uses:

Grade | Description | Typical Applications |

409 | Good at resisting oxidation | Car exhaust systems |

430 | Cheap, decent durability | Kitchen backsplashes, home appliances, car trims |

Ferritic stainless steels are found in homes and cars. You see them in trim, exhaust pipes, and kitchen tools.

Here is a table comparing the chemical makeup and uses of 409 and 430:

Grade | Composition Highlights | Key Properties | Applications |

409 | Cr: 10.5–11.75% | Good at resisting oxidation | Car exhaust systems |

430 | Cr: 16–18% | Good at resisting rust, magnetic | Kitchen utensils, car trim |

Note: Ferritic stainless steels are magnetic. You can check them with a magnet.

Martensitic Grades (410, 420, 440)

Martensitic stainless steel is very strong. You can make it harder with heat. You see martensitic stainless steel in knives, scissors, and surgical tools. This type has more carbon. It can be very hard and sharp.

Here are the main martensitic grades:

410: This grade has 11.5–13.5% chromium. You use it for cutlery, surgical instruments, and valves. It can be made harder for extra strength.

420: This grade has 12–14% chromium. You use it for knives and scissors. It gets very hard and keeps a sharp edge.

440: This grade has even more carbon. You use it for blades that need to be extra hard.

Tip: Pick martensitic stainless steel for tools and blades that need to be strong and sharp.

Here is a table with the most common martensitic grades and their uses:

Grade | Description | Typical Applications |

410 | Can be hardened, moderate rust resistance | Cutlery, surgical instruments |

420 | Very hard, moderate rust resistance | Cutlery, surgical instruments |

Martensitic stainless steels are found in kitchens, hospitals, and factories. You see them in knives, scissors, and springs.

Here is a table comparing the chemical makeup and uses of 410 and 420:

Grade | Composition Highlights | Key Properties | Applications |

410 | Cr: 11.5–13.5% | Can be hardened, moderate rust resistance | Cutlery, surgical instruments |

420 | Cr: 12–14% | Very hard, moderate rust resistance | Cutlery, surgical instruments |

Note: Martensitic stainless steel is magnetic. You can make it very hard with heat.

Duplex Grades (2205, 2507)

Duplex stainless steels have two structures mixed together. They are strong and resist rust very well. You see duplex stainless steels in ships, chemical plants, and oil rigs. These grades have more chromium and molybdenum. They fight pitting and cracking.

Here are the main duplex grades:

2205: This grade has 22% chromium, 5–6% nickel, and 3% molybdenum. You use it for marine and petrochemical jobs. It is strong and resists rust.

2507: This grade has 25% chromium, 7% nickel, and 4% molybdenum. You use it for offshore oil and gas work. It resists pitting and cracking in tough places.

Tip: Use duplex stainless steels for jobs in saltwater or chemical plants.

Here is a table comparing the chemical makeup and uses of 2205 and 2507:

Grade | Composition Highlights | Key Properties | Applications |

2205 | Cr: 22%, Ni: 5–6%, Mo: 3% | Very strong, great at resisting rust | Marine, petrochemical uses |

2507 | Cr: 25%, Ni: 7%, Mo: 4% | Super strong, great at resisting pitting | Offshore oil and gas, chemical tanks |

Duplex stainless steels are used where strong metal is needed. You find them in ships, tanks, and factories.

Note: Duplex stainless steels are not always magnetic. They work well in places with salt and chemicals.

Other Grades

You might hear about precipitation hardened stainless steel. This type uses special heat treatments. It is very strong and tough. You see it in aerospace and high-tech jobs.

Tip: Always check the grade before you pick stainless steel. Each grade works best for certain jobs.

Properties and Applications

Corrosion Resistance

It is important to know how stainless steel stops rust. Corrosion resistance is a big reason people pick stainless steel. Chromium in stainless steel makes a thin layer on top. This layer keeps the metal safe from rust and damage. Some grades stop rust better than others. Some are only good for places that are not too harsh.

Here is a table that compares some common grades:

Stainless Steel Grade | Corrosion Resistance | Key Features |

304 | Moderate | Used a lot, not great with chlorides |

316L | High | Has molybdenum, good for tough places |

You can see that 316L resists rust very well. Molybdenum in 316L helps it fight salt and chemicals. If you work with acids or saltwater, pick 316L. For hard jobs, you need better corrosion resistance. 304 is fine for kitchens, but use coated 316 or higher grades for tough places. 316L is great for boats and chemical plants because it resists rust so well.

Tip: Always check how well stainless steel resists rust before you choose it.

316L stainless steel does very well in hydrochloric and sulfuric acid.

Molybdenum in 316L helps it resist rust in salty places.

For tough jobs, use 316 or higher grades instead of 304.

Strength and Hardness

You want stainless steel to be strong and hard for many jobs. Tensile strength tells you how much force it takes to break the metal. Hardness shows how well it stands up to scratches and dents. Each grade has its own strength and hardness.

Here is a table that compares strength and hardness:

Grade | Type | Strength | Hardness | Applications |

409 | Ferritic | Moderate | Moderate | General uses, stops oxidation |

430 | Ferritic | Lower | Moderate | Handles nitric acid, many uses |

440 | Martensitic | High | High | Knives, resists wear |

410 | Martensitic | High | Moderate | Valves, pumps, heat-treated jobs |

420 | Martensitic | High | Moderate | Strong, resists impact |

Duplex | Duplex | Higher than ferritic and austenitic | Moderate | Oil jobs underwater, resists rust |

Martensitic grades like 440 and 420 are very strong and hard. You use them for knives and tools. Duplex stainless steel is strong and resists rust very well. Ferritic grades are strong enough for most jobs. Pick the grade that fits your need for strength and hardness.

Note: High strength helps stainless steel last longer in hard jobs.

Magnetic Properties

You might wonder if stainless steel sticks to magnets. The answer depends on the type and grade. Ferritic and martensitic stainless steels are magnetic. Duplex stainless steel is usually magnetic because it has ferrite. Austenitic stainless steel is not usually magnetic, but it can become a little magnetic after heating.

Here is a list of which types are magnetic:

Ferritic stainless steels like 409 and 430 are magnetic.

Martensitic stainless steels such as 410, 420, and 440 are magnetic.

Duplex stainless steels are mostly magnetic because of ferrite.

Heating can change if stainless steel is magnetic. Austenitic steels can get a bit magnetic if you heat or bend them. Ferritic and martensitic steels stay magnetic, but how strong they are can change.

Tip: Use a magnet to see if your stainless steel is ferritic or martensitic.

Typical Uses

You see stainless steel in many places because it does not rust, is strong, and is easy to clean. In food jobs, you find it in kitchen tools, appliances, and food packages. Doctors and dentists use it for tools, implants, and things that must be clean. Builders use it for roofs, tanks, handrails, and counters.

Here is a table of where stainless steel is used:

Industry | Common Applications |

Food and catering | Kitchen tools, appliances, food packages |

Medical and dental | Surgical tools, implants, equipment that can be cleaned |

Construction | Roofs, tank covers, handrails, counters |

Stainless steel lasts a long time, is easy to keep clean, and is safe for food. You pick it for places that need to fight rust and be strong. You also use it because it resists scratches and does not change when exposed to air.

Note: Stainless steel is best for places that need to fight rust, be strong, and last a long time.

Comparing Different Types of Stainless Steel

304 vs 316 Stainless Steel

You have to think about where you will use the metal. Both 304 and 316 are austenitic, so they do not rust easily. They are also simple to keep clean. 316 stainless steel has molybdenum in it. This helps it fight salt and chemicals better than 304.

Here is a table to help you compare:

Grade | Main Alloying Elements | Corrosion Resistance | Typical Uses |

304 | Chromium, Nickel | Good | Sinks, cookware, tanks |

316 | Chromium, Nickel, Molybdenum | Excellent (especially in saltwater) | Marine hardware, medical tools, chemical tanks |

Tip: Pick 316 stainless steel for boats or docks. Use 304 for kitchens or inside jobs.

You should also think about how much it costs. 316 stainless steel is more expensive than 304. It lasts longer in tough places. The higher price is because of the extra molybdenum and nickel.

Choosing the Right Stainless Steel Type

You need to pick the right type for your project. Here are some things to help you choose:

Austenitic stainless steel is best at stopping rust. It works well for food, medical, and chemical uses.

Ferritic stainless steel costs less but does not stop rust as well. Use it for car parts or home machines.

Martensitic stainless steel is very strong and hard. Pick it for knives, scissors, or tools.

Duplex stainless steel is strong and fights rust. It is good for ships and chemical plants.

When you choose a grade, think about these things:

Where you will use the metal, inside or outside

If you need it to stop rust, like in saltwater

How strong and tough it needs to be

The heat it will face

How much you want to spend

Note: Austenitic stainless steel, like 304 and 316, is the best for most jobs. It does not rust and is easy to clean. Ferritic and martensitic types are good for special jobs, like saving money or needing extra strength.

You now know about the four main types and common grades of stainless steel. Each type has its own features and uses. Look at the table below for a quick summary:

Type | Characteristics | Common Applications |

Austenitic | Has lots of chromium and nickel, not magnetic | Used for kitchen knives, airplane parts |

Ferritic | Usually sticks to magnets, low nickel, resists rust | Used in pots, pans, and car parts |

Duplex | Mix of austenitic and ferritic, can be magnetic | Used in oil jobs under the sea |

Martensitic | More carbon, very strong | Used for doctor tools and turbines |

Picking the right stainless steel keeps your project safe and working well. You should ask experts or suppliers before you decide. They can help you choose the best type and grade for your job.

FAQ

What makes stainless steel different from regular steel?

Stainless steel contains chromium. Chromium forms a protective layer that stops rust. Regular steel does not have this layer. You get better corrosion resistance with stainless steel.

Can you use stainless steel outdoors?

You can use stainless steel outside. It resists rain and sun. Grades like 316 work well near water. Always pick the right grade for your weather conditions.

Is stainless steel safe for food contact?

You can use stainless steel for food. It does not react with most foods. You see it in kitchen sinks, cookware, and food factories. It is easy to clean and keeps food safe.

How do you clean stainless steel surfaces?

Use warm water and mild soap. Wipe with a soft cloth. Avoid harsh cleaners. You keep stainless steel shiny and free from stains by cleaning regularly.

Which stainless steel grade should you choose for marine use?

Pick grade 316 for marine use. It has molybdenum. This helps fight saltwater corrosion. You see 316 stainless steel on boats and docks.