Overview

The 0.3mm Zinc-Coated Galvanized Steel Coil is a versatile metallurgical product engineered for high-performance in moderate to severe environmental conditions. Composed of a cold-rolled steel core coated with a protective zinc layer (coating weights: Z60 to Z275, 60-275g/m²), this coil offers a balance of corrosion resistance, formability, and cost-efficiency. The thin 0.3mm thickness makes it ideal for applications requiring lightweight yet durable material, such as roofing, cladding, and precision fabrication.

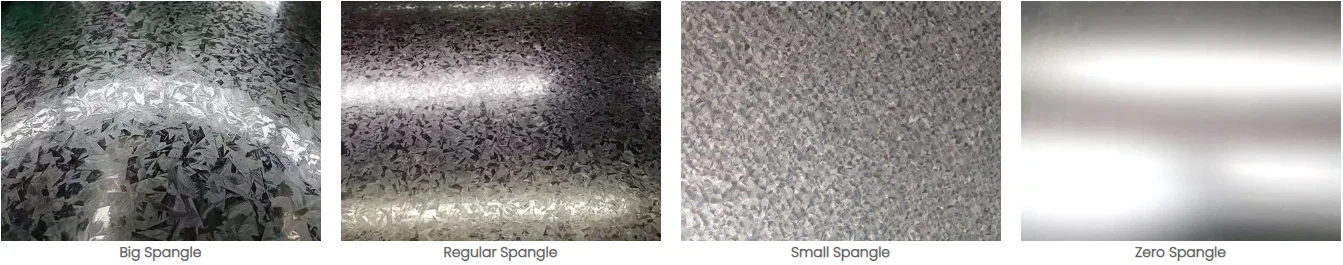

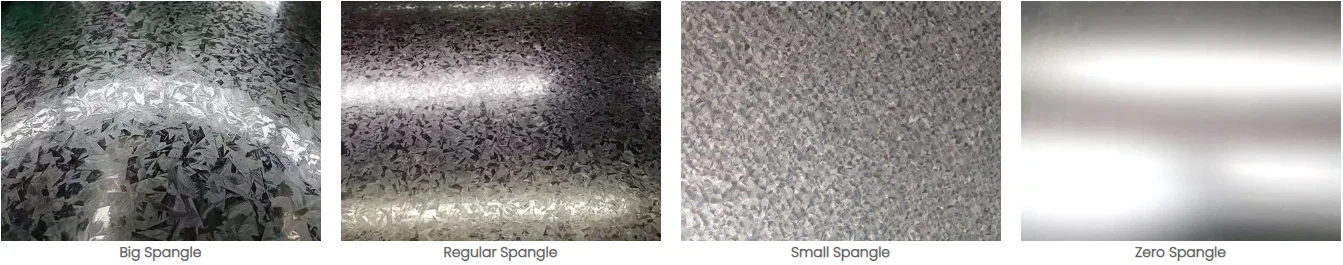

Manufactured via continuous hot-dip galvanizing, the coil features a spangle or spangle-free surface finish, suitable for direct use or as a base for secondary processing like painting or powder coating. Its standardized width (up to 1250mm) and customizable coil weight (1-10 tons) ensure compatibility with most industrial roll-forming lines.

Features

Z60-Z120: Suitable for indoor or dry outdoor environments (e.g., office buildings, furniture).

Z180-Z275: Ideal for coastal areas, industrial zones, or high-humidity settings (e.g., warehouses, marine containers).

Exceptional Formability: The 0.3mm thickness provides excellent ductility for deep drawing, bending, and embossing, making it perfect for intricate shapes in automotive parts and appliance panels.

Precision Thickness Control: Tight tolerance (+/-0.01mm) ensures uniform performance across large-scale projects, reducing material waste during fabrication.

High-Speed Processing Ready: Supplied in large coils to minimize downtime in continuous manufacturing lines, with optional slitting services to custom widths.

Economic Solution: Offers superior cost-performance compared to stainless steel or aluminum for non-critical corrosion applications, without compromising mechanical strength.

Application

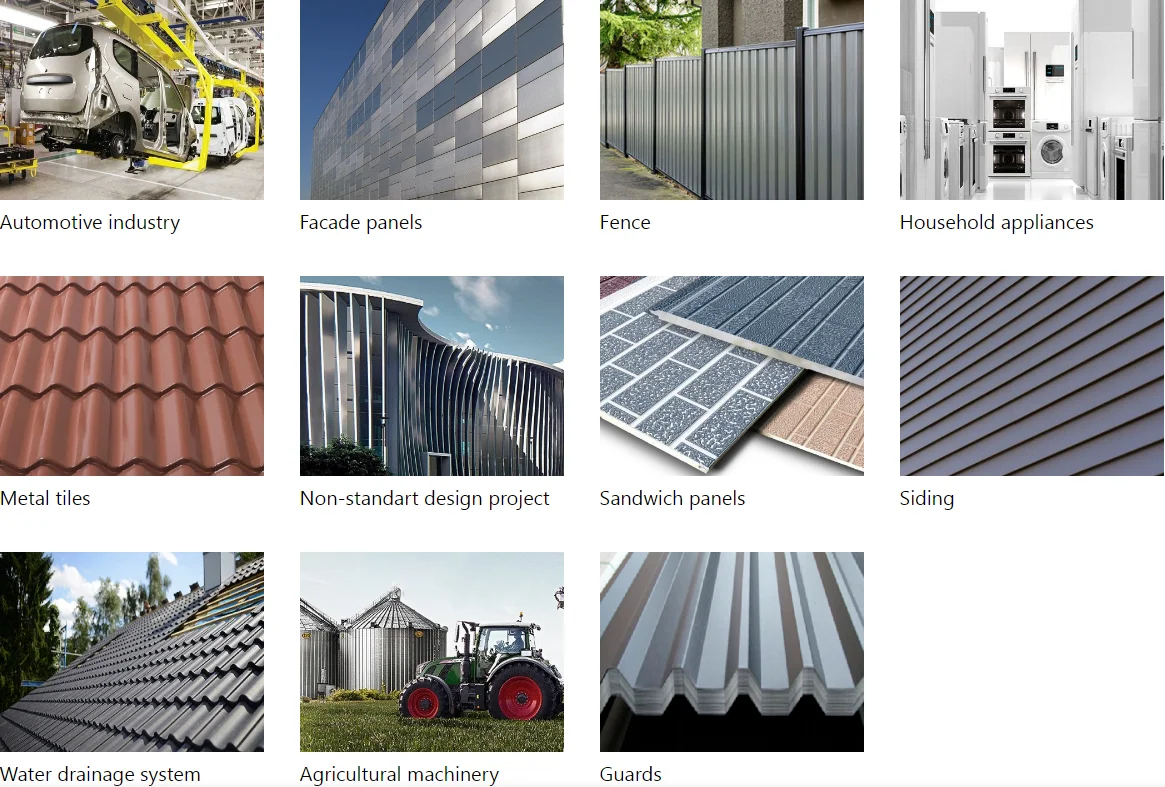

Roofing & Cladding: Used in prefab houses, temporary shelters, and industrial sheds, where lightweight material and quick installation are essential.

Appliance Manufacturing: Forms inner panels for refrigerators, washing machines, and ovens, providing a stable base for enamel or polymer coatings.

Automotive Industry: Fabricates door panels, trunk lids, and underbody components, offering protection against road debris and saltwater spray.

General Metalworking: Ideal for HVAC ductwork, cable trays, and storage racks, combining easy cutting/welding with long-term rust resistance.

FAQ

Q: What’s the difference between spangle and spangle-free surfaces?

A: Spangled surfaces have a crystalline zinc pattern for visual texture and slightly better corrosion resistance; spangle-free offer a smooth finish for painting or decorative use.

Q: Can this coil be used in direct contact with food?

A: No, galvanized steel is not food-grade. For food packaging, consider tinplate or stainless steel alternatives.

Q: How long does the zinc coating last in a coastal environment?

A: Z275 coating can last 15-20 years in coastal areas with regular maintenance; for longer life, apply a protective topcoat.

Q: What is the minimum bend radius for this thickness?

A: The 0.3mm sheet can be bent to a radius of 1.5x thickness (0.45mm) without cracking, depending on the specific alloy composition.

| Product Name | Galvanized Coil |

| Material | Dx51-54D, S220/ S250/ S280/ S350/ S350/ S550GD; SGCC, SGHC, SGCH, SGH340, 400, 440, 490 |

| Thickness | 0.12-6.00mm or customer's requirement |

| Width | 600mm-1500mm, according to customer's requirement |

| Zinc coated | 30g-275g/m2 |

| Type of Coating | Hot Dipped Galvanized Steel |

| Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

| Surface Structure | Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS) |

| Coil ID | 508mm or 610mm |

| Coil Weight | 3-20 metric ton per coil |

| Standard | JIS / ASTM /EN AISI , ASTM , JIS, BS |

| Technique | Hot Rolled / Cold Rolled |

| Product Application | 1. Fence, greenhouse, door pipe,greenhouse |

| 2. Indoor and outdoor building construction |

| 3. Widely used in scaffolding, low cost and convenient |

| Origin | Shandong China |

| Certificates | API ISO9001-2008,SGS.BV |

| Delivery Time | 7-21 days |