Products Name

| Hot Dipped Galvanized GI Steel Coil

|

| Grade | DX51D,SGCC,DX52D,ASTMA653,JISG3302 |

| Zinc Coating | Z40-275g/m² |

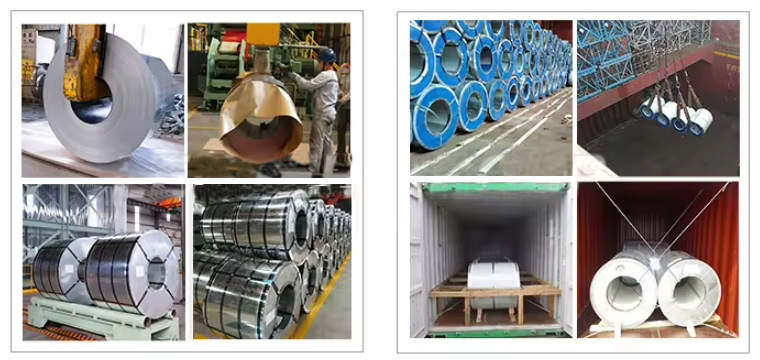

| Coil weight | 4-5tons |

| Coil id | 508/610mm |

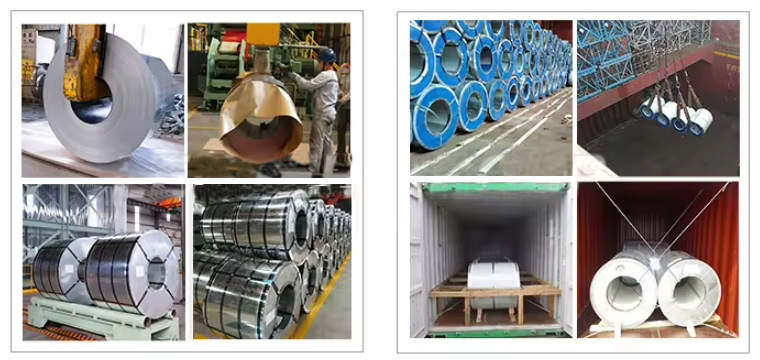

| Package | Standard Sea Worthy Package |

| MOQ | 25tons |

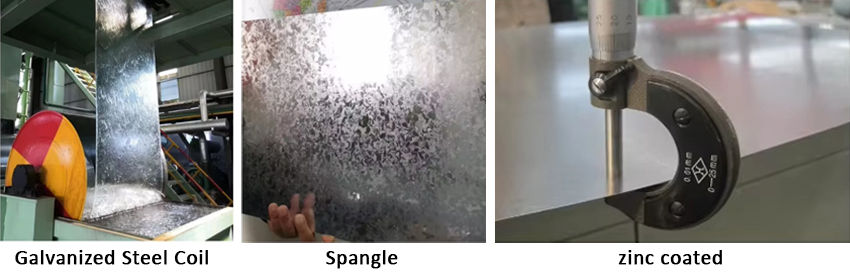

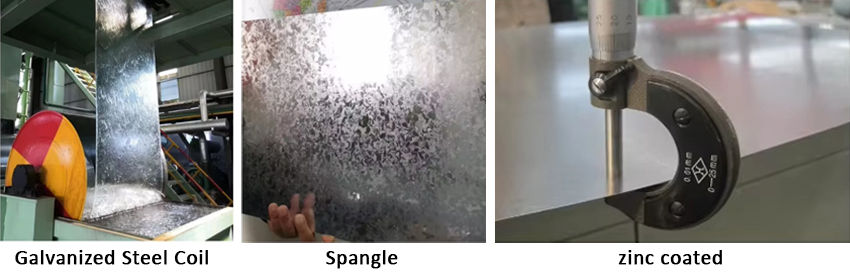

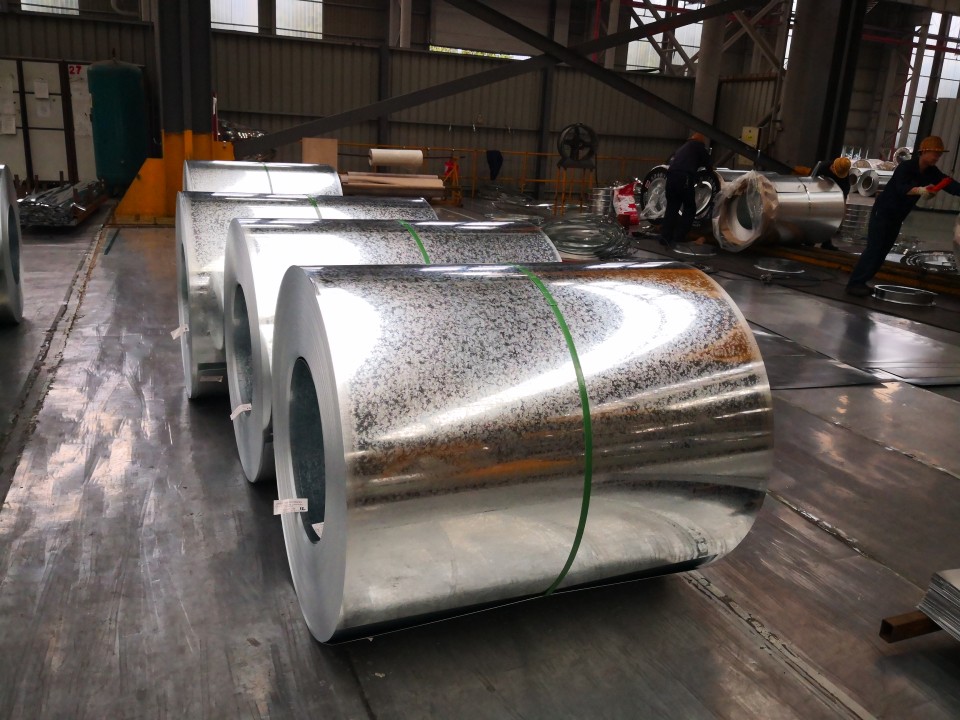

| Spangle | Normal Spangle,Mini Spangle,Big Spangle |

| Certificate | SGS |

| Application | uilding, Roofing sheet, safety fence and so on. |

| Delivery Time | within 15-20 days after receive 30% deposit or depend on Quantity |

| Payment Term | T/T, Irrevocable L/C at sight (30% deposit) |

| Trade Term | EXW, FOB, CFR, CIF |

Overview

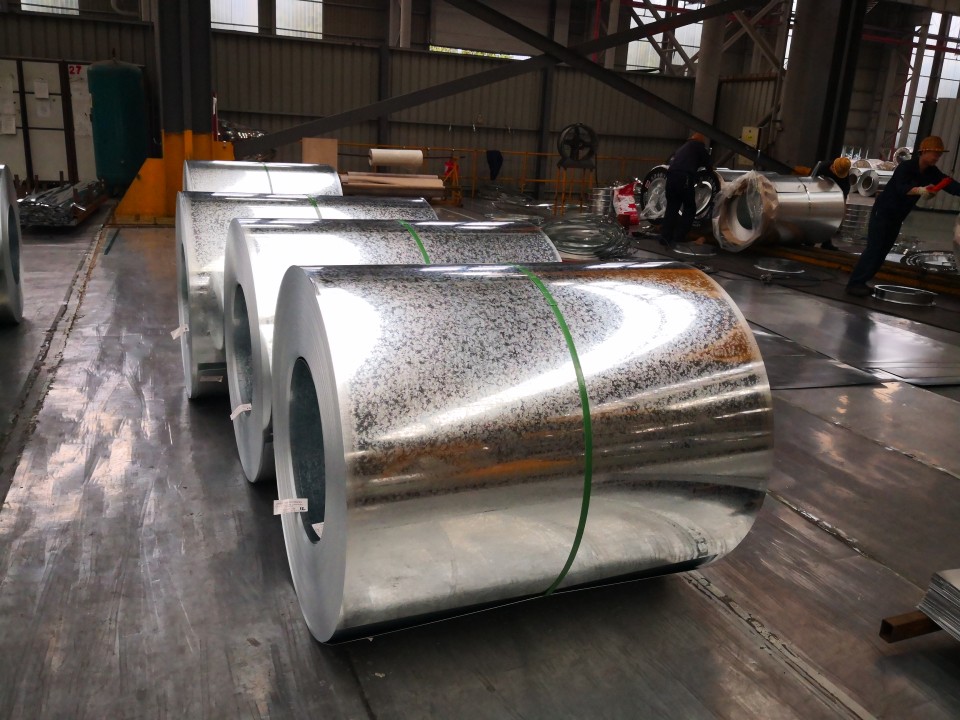

The High-Performance Hot-Dipped GI Galvanized Steel Coil is a foundational metallurgical product engineered for industrial applications requiring robust corrosion resistance, mechanical strength, and process compatibility. Manufactured via the hot-dip galvanizing process, this coil features a thick zinc coating (Z180-Z275g) on a low-carbon steel substrate (Q235, SS400 grades), providing excellent protection against moisture, UV radiation, and atmospheric pollutants.

Available in thicknesses from 0.5mm to 4.0mm and widths up to 1500mm, the coil is optimized for heavy-duty fabrication in construction, automotive, and machinery industries. The hot-dip process ensures a metallurgical bond between zinc and steel, creating a durable layer that self-heals minor scratches through sacrificial protection.

Features

Robust Corrosion Protection:

Z180-Z275 Coating: Ideal for outdoor/industrial environments (Z180: urban infrastructure, Z275: coastal/chemical plants), with a predicted lifespan of 15-30 years depending on maintenance (e.g., annual inspections).

Sacrificial Protection: Zinc layer oxidizes preferentially to steel, protecting cut edges and scratches until repaired with zinc-rich paint (e.g., International Paint’s Zincalume).

Industrial-Grade Mechanical Properties:

High yield strength (235-400 MPa) supports structural applications like steel beams, bridge components, and heavy machinery frames (e.g., Caterpillar engine mounts).

Excellent weldability (low carbon content ≤0.20%) and formability, with spangle-free surfaces enabling precise TIG/MIG welding for critical joints (e.g., offshore platform connections).

Process Compatibility:

Suitable for electroplating, powder coating, and liquid painting, with optional chromate pretreatment enhancing paint adhesion by 40% (e.g., AkzoNobel industrial coatings).

Large coil weights (10-20 tons) reduce downtime in high-speed production lines, with custom slitting available to exact widths (tolerance: +/-0.5mm for 1000mm+ widths).

Global Standards Compliance:

Meets ASTM A653 (G90), JIS G3302 (SGCC), and EN 10142 (Z275) standards, ensuring quality consistency for international procurement (e.g., UAE infrastructure projects, Brazilian mining operations).

100% recyclable at end-of-life, with zinc recovery rates exceeding 95%, aligning with circular economy principles.

Application

Construction & Infrastructure: Fabricates I-beams, channel sections, and roof trusses for commercial buildings (e.g., Dubai Mall expansion), bridges (e.g., San Francisco-Oakland Bay Bridge), and power plants (e.g., Saudi Aramco facilities).

Automotive & Transportation: Forms chassis components, truck frames, and trailer axles for heavy-duty vehicles (e.g., Volvo FH trucks), offering protection against road salt and mechanical stress.

Industrial Machinery: Used for manufacturing equipment frames, conveyor systems, and storage tanks in mining (e.g., BHP Billiton ore processing), agriculture (e.g., John Deere combine harvesters), and manufacturing sectors.

Energy Sector: Ideal for wind turbine bases (e.g., Vestas wind farms), solar panel mounts, and offshore energy structures, with AZ150 alloy coating (optional) enhancing heat resistance for solar applications.

FAQ

Q: How does hot-dip galvanizing compare to electro-galvanizing?

A: Hot-dip provides thicker, more durable coatings (30-275g/m²) for outdoor use; electro-galvanizing (10-20g/m²) is thinner and suitable for decorative indoor applications like furniture hardware.

Q: Can this coil be used for potable water storage?

A: No, direct contact with drinking water requires food-grade materials like stainless steel or epoxy-lined steel; GI steel is suitable for non-potable water tanks and irrigation systems.

Q: What is the best way to remove mill scale before painting?

A: Use abrasive blasting (sand/shot blasting) to achieve a Sa2.5 surface profile, ensuring optimal paint adhesion for long-term durability.

Q: How to verify coating weight on-site without damaging the coil?

A: Use a magnetic thickness gauge (e.g., Fischer XDL) to measure coating thickness non-destructively; values should be within 5% of the specified coating weight.