Product Introduction

Overview

The ASTM A653 Compliant Hot-Dipped Galvanized Steel Coil is a rugged metallurgical product designed to meet the most demanding environmental and structural requirements. Manufactured to ASTM A653 standards (G90, DX51D, Z275, Z350 coatings), this coil features a thick hot-dip zinc layer (275-350g/m²) or aluminum-zinc alloy (Aluzinc AZ150) for superior corrosion resistance in severe conditions.

The substrate—available in DX51D (general purpose), DX52D (deep drawing), and DX54D (extra-deep drawing)—balances strength with formability, making it ideal for applications like marine containers, industrial roofing, and heavy machinery components. The coil’s spangle or spangle-free surface finish accommodates both functional use and secondary processing.

Features

Heavy-Duty Coating Options:

Z275/Z350: Pure zinc coatings for maximum corrosion resistance in coastal (Z275) and extreme industrial (Z350) environments, passing 2,000+ hours of salt spray testing.

Aluzinc AZ150: 55% aluminum-zinc alloy coating offering 4x longer life than pure zinc in high-temperature/high-humidity settings, resisting oxidation up to 450°C (e.g., power plant exhaust systems).

Structural Grades for Every Need:

DX51D: General-purpose grade (yield strength 270 MPa), suitable for simple bending/cutting (e.g., highway guardrails, storage racks).

DX54D: Extra-deep drawing grade (elongation ≥34%), ideal for complex shapes like automotive fuel tanks and aircraft parts.

ASTM Compliance & Testing:

Meets G90 coating weight (445g/m²) for critical applications like bridge components and offshore platforms, ensuring compliance with US DOT and Eurocode 3 standards.

Rigorous mill testing includes tensile strength, bend radius, and coating adhesion (cross-cut test: ≤5% flaking).

Surface Finish Versatility:

Spangled Surface: Natural crystalline pattern (5-10mm) enhances corrosion resistance for exposed applications (e.g., shipping containers, oil rig structures).

Spangle-Free Surface: Smooth finish (Ra ≤1.5μm) for seamless painting/powder coating, used in decorative architectural elements (e.g., museum facades).

Application

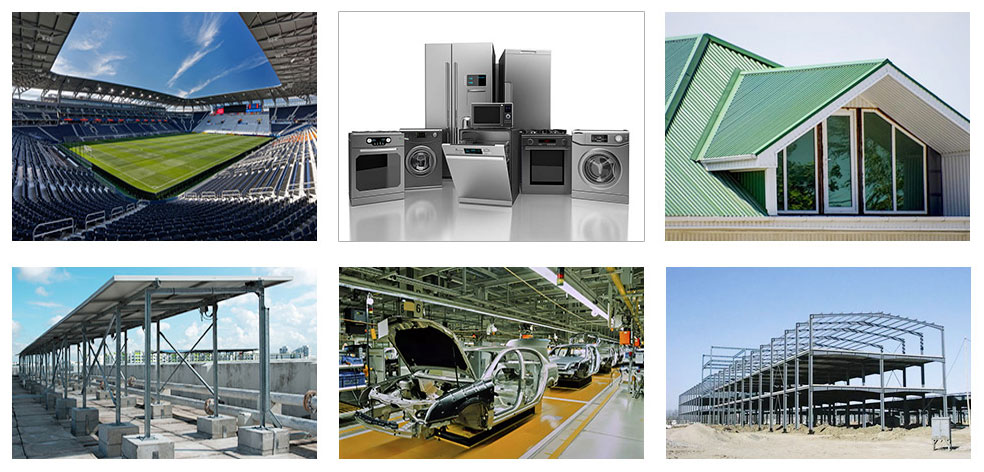

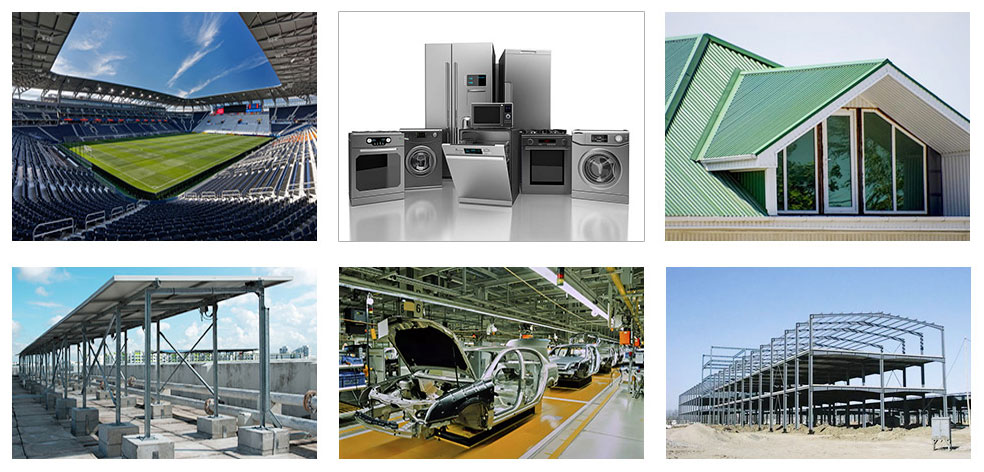

Marine & Transportation: Manufactures ISO shipping containers (e.g., Maersk cargo vessels), offshore wind turbine foundations, and railway wagons, with AZ150 coating resisting saltwater corrosion.

Industrial Infrastructure: Used in chemical plants (e.g., BASF manufacturing facilities), steel mills, and power stations for ductwork, storage tanks, and structural supports.

Heavy Machinery: Forms components for Caterpillar excavators, John Deere tractors, and mining trucks, with Z350 coating protecting against abrasion in dusty, wet environments.

Construction & Engineering: Ideal for hurricane-resistant roofing (Miami-Dade County approved), seismic steel frames (Japan’s Kanto region), and foundation piles in coastal zones.

FAQ

Q: What does "DX52D" indicate in the product code?

A: DX52D signifies a hot-dipped galvanized steel with deep drawing capability, suitable for moderate stamping (e.g., appliance panels, automotive interior brackets).

Q: Can AZ150 be used instead of stainless steel in food processing?

A: No, direct food contact requires stainless steel; AZ150 is ideal for non-food industrial applications like grain silos and fertilizer storage.

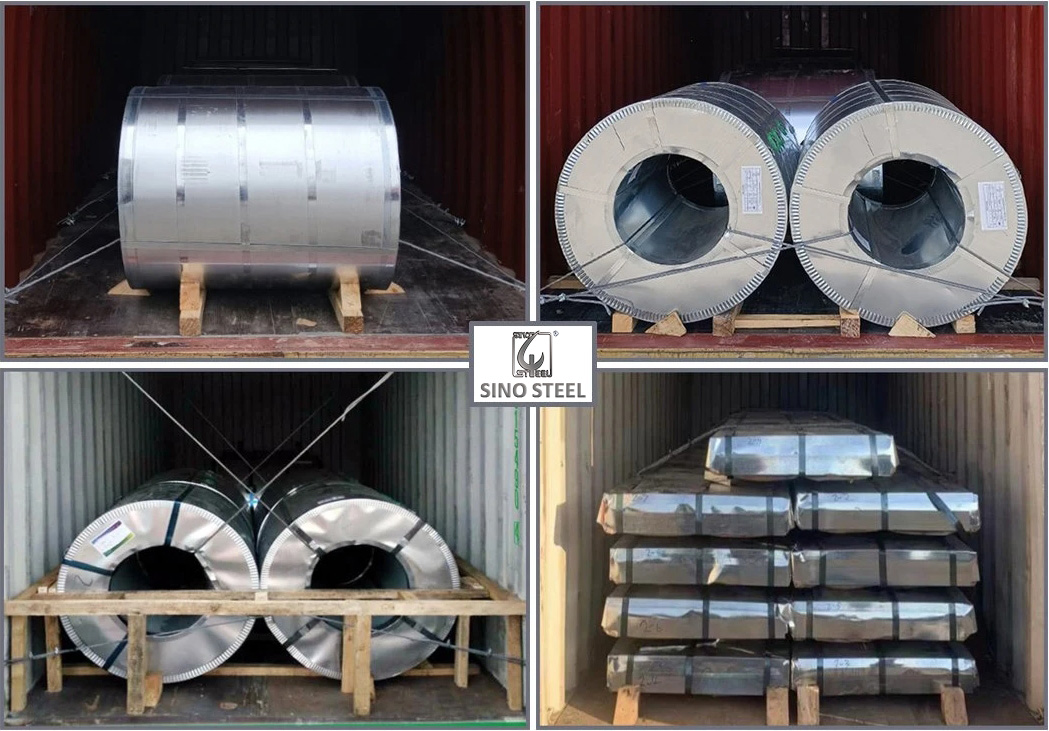

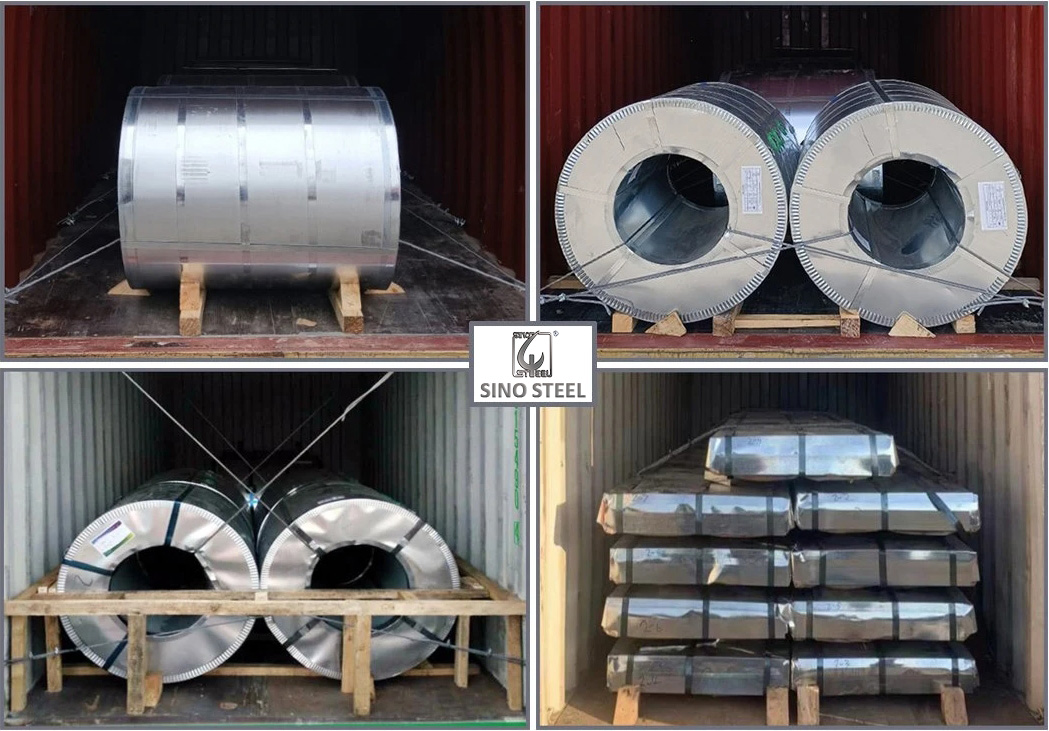

Q: How is the coil protected during overseas shipping?

A: Coils are wrapped in moisture-resistant kraft paper, sealed with polyethylene film, and strapped with steel bands to prevent sea-air corrosion during transit.

Q: What is the difference between G90 and Z350 coatings?

A: G90 (445g/m²) is an ASTM designation for heavy zinc coating, while Z350 (350g/m²) is a metric equivalent; both are used for extreme corrosion environments but G90 is thicker.

| Galvanized sheet /Galvanized coil |

Production Standard | ASTM, AISI,JIS, DIN, EN,GB, GOST |

Material | DX51D,DX52D,DX53D,Z275,G90,G350,G450,G550,SGCC,,SGCH,GECC,,SPHC,A36,E235/S235JR,Q235B,E355/S355JR,Q345A,Q345B,Q345C,Q345D,Q345E,ST35,ST37,ST45,ST52,DC01,DC02,SS400,HC340LA,HC380LA,HC420LA,B340LA,B410LA |

Size

| Thickness | 0.105-4mm |

Width | 600-1250mm |

Tolerance | +/-0.02mm |

Zinc coating | Z30-600g/㎡ |

Surface | Bright,Mill, polished, oiled, galvanized, or as required |

Payterm | Ex-work, FOB, CIF, CFR, etc |

Payment | T/T, L/C, Western Union, Alibaba Trade Assurance, etc |

Delivery Time | Within 3-5 days for our stock size, 15-20 days for our production |

Package | Dustproof kraft sheet

Iron packing

Angle protective

packing belt |

MOQ | 25 TONS (in one 20ft FCL) |

Sample | Free and available |

Quality | Mill Test Certificate, ISO9001, CE,SGS, TVE |

Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

Mechanical properties of galvanized steel

|

Usage | Grade | Yield strength(MPa) | Tensile strength(MPa) |

Punching galvnaized steel

| DC51D+Z | - | 270-500 |

DC52D+Z | 140-300 | 270-420 |

DC53D+Z | 140-260 | 270-380 |

Structure galvanized steel

| S280GD+Z | ≥280 | ≥360 |

S350GD+Z | ≥350 | ≥420 |

S550GD+Z | ≥550 | ≥560 |