Raw material costs play the biggest role in the price you pay for Galvanized Coil. Steel and zinc make up most of the total cost. You should know that about 62% of the cost comes from these two materials. When zinc prices jump because of mining issues or steel costs rise due to iron ore and energy changes, you see this reflected in the final price. Companies like Sino Steel must respond quickly to these changes to keep products affordable.

Key Takeaways

Steel and zinc are the biggest costs for galvanized coil. They make up about 62% of the total price. Watch these prices to know if costs will change.

Thicker zinc coatings protect coils better. They also make coils last longer. Pick the coating thickness that fits your project.

Supply and demand affect galvanized coil prices a lot. Keep up with market trends to buy at the right time.

Pick suppliers who use good manufacturing methods. This can help keep prices steady even if raw material costs go up or down.

Long-term contracts or buying in bulk can help you avoid sudden price jumps. Plan ahead to get better deals.

Key Raw Materials for Galvanized Coil

Steel Base and Its Market Drivers

Steel is the main part of galvanized coil. The price of steel changes a lot. Iron ore and coking coal affect steel prices. If iron ore costs more, making steel costs more. Coking coal helps turn iron ore into steel. When coking coal prices go up, steel makers earn less. Shipping problems with iron ore can make prices rise fast. Coil thickness is important too. Thicker coils need more steel and energy. This makes them cost more.

How you make galvanized coil changes the price. Hot-dip gives a thicker, stronger coating. It usually costs more than other ways.

Here is a table that shows what affects steel prices:

Factor | Description |

Cost of Raw Materials | Iron ore, zinc, and other materials set the base cost. |

Manufacturing Process | Hot-dip or electro-galvanizing changes the price. |

Thickness of the Coil | More thickness means higher cost. |

Demand from Industries | High demand from construction or cars can push prices up. |

Zinc Coating and Price Fluctuations

Zinc is the second main material in galvanized coil. Zinc prices change because of supply and demand. World economics and trading also affect zinc prices. If there is less zinc or more people want it, prices go up. New mining or environment rules can make zinc harder to get.

Zinc coating thickness is very important. Thicker coatings protect better and last longer.

Every extra 10 grams of zinc coating can cost $5 to $15 more.

Zinc coating thickness goes from z30 to z350g. This changes how long your coil lasts. It can last from 7 to 50 years.

Impact of Raw Material Quality

The quality of steel and zinc matters a lot. Good coils use better steel grades. These grades are stronger and bend easier. They cost more but work better. Thicker zinc coatings protect more and lower repair costs.

Zinc Content (g/㎡) | Corrosion Resistance | Product Life Extension | Maintenance Cost Reduction |

275 | Superior | Significant | Reduced |

Always check the quality and thickness of steel and zinc. This helps you get the best coil for your needs.

Market and Production Factors Affecting Pricing

Supply and Demand Trends

Galvanized coil prices change when supply or demand changes. In January 2023, zinc prices went up to $3,486.5. This made it cost more to make each coil. By May 2023, zinc prices dropped to $2,248.50. Some companies then lowered prices or made more profit. These price swings show how fast the market can react.

Problems in the supply chain also raise prices. Delays and shipping issues make it hard to get raw materials. Trade problems can also push costs higher for everyone.

Evidence Source | Key Points |

North America Galvanized Steel Coil Market | Global disruptions threaten steady supply. |

Cold Rolled Coil Price Trend | Logistics and geopolitical tensions raise costs. |

Market Insights 2025 | Supply chain problems cause delays and price changes. |

Labor and Energy Costs

Labor and energy are a smaller part of the total cost. They still matter for the final price. Usually, energy and labor make up 5–10% of the price. If wages or energy costs go up in big steel countries, coil prices may rise.

Cost Component | Percentage Contribution |

Base steel substrate | 60–70% |

Zinc coating materials | 15–20% |

Energy and labor | 5–10% |

Logistics, packaging, admin | 5–10% |

Manufacturing Technology Advances

New technology helps companies make coils faster and cheaper. You get better products from things like nanotechnology coatings. These coatings last longer and need less care. Eco-friendly coatings help lower pollution and meet green rules. Digital tools like AI and IoT help factories watch and control the process. This means better quality and less waste.

Nanotechnology coatings make coils last longer.

Waterborne and powder coatings lower pollution.

AI and IoT help factories work better.

Companies using new technology can keep prices lower and compete better.

Opportunity/Advancement | Description |

Cost Optimization | Advanced technology helps companies stay competitive. |

Technological Advancements | New processes improve quality and lower costs. |

Macroeconomic and Trade Impacts

Big economic changes also affect prices. Things like inflation, currency rates, and trade rules matter. A strong US dollar can make coil prices lower in some places. High inflation or a recession can make prices go up or down.

Factor | Impact on Prices |

US Dollar Strength | Can lower prices |

Interest Rate Hikes | Make the dollar stronger |

Inflation Rate (US) | Raises costs |

Risk of Recession | Changes demand |

Trade rules and tariffs change prices around the world. Tariffs between China and the US make things uncertain. In Europe, tax breaks and competition from other countries change local prices. US buyers watch for new tariffs before buying a lot.

Region | Impact of Trade Policies and Tariffs |

East Asia | Tariff agreements create uncertainty. |

Europe | Tax exemptions and competition affect prices. |

US | Buyers react to possible antidumping duties. |

Tip: Keep an eye on news about trade deals and the economy. These things can quickly change the price you pay for galvanized coil.

How Raw Material Costs Shape Galvanized Coil Prices

Cost Pass-Through to Buyers

If steel or zinc costs go up, you pay more. Companies use different ways to set prices. Some give you better deals if you buy a lot. Others use contracts to keep prices steady for you. Many companies watch the market to set prices. This helps you guess when prices will change.

Pricing Model | Description |

Bulk Purchasing Advantages | Manufacturers give better prices for bigger orders. |

Long-term Supply Contracts | Contracts help keep prices steady over time. |

Market Stability | Prices follow the market, so buyers can plan ahead. |

Tip: For big projects, think about a long-term contract. This can help you avoid sudden price jumps for Galvanized Coil.

Manufacturers and buyers watch raw material costs closely. They use this to guess future prices. Many buyers want vendors who use new ideas and follow rules. Some buyers buy over longer times to handle price changes and new rules.

Recent Price Trends and Examples

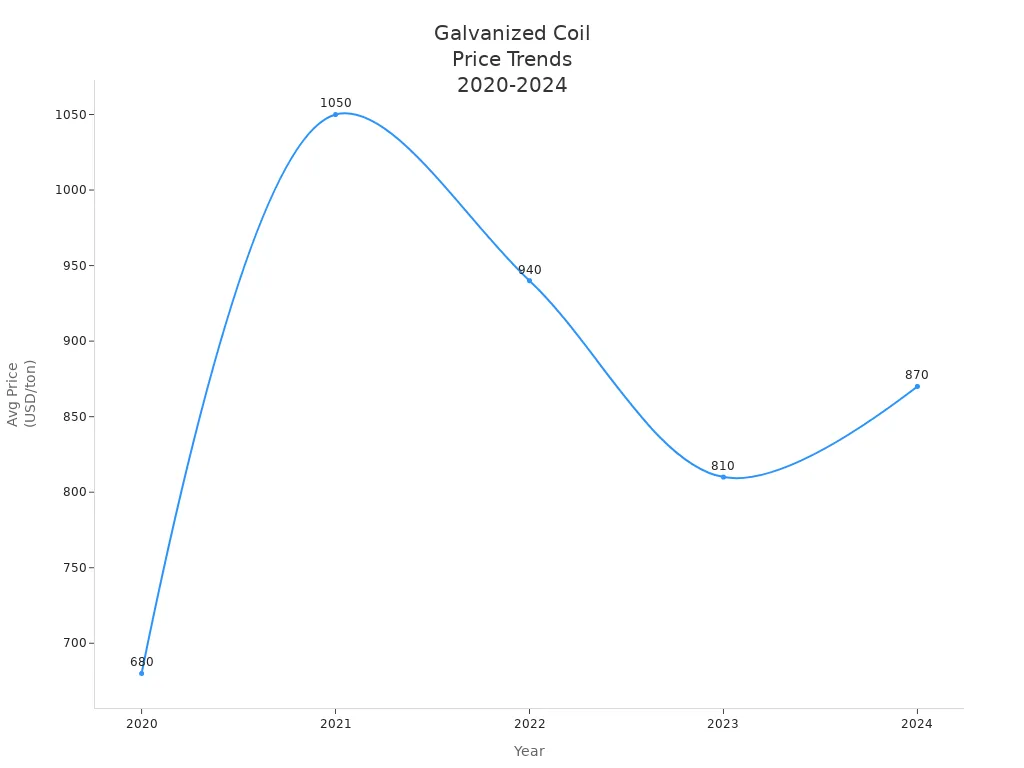

Galvanized Coil prices have changed a lot in five years. The main reasons are raw material costs, supply chain problems, and world events. In 2020, prices dropped because of COVID-19 and low demand. In 2021, prices went up when the economy got better and raw material costs rose. Prices fell again in 2022 as demand slowed and China had lockdowns. In 2023, energy costs and less production made prices go down. By 2024, supply chains got better and green manufacturing grew, so prices went up a little.

Year | Average Global Price (USD/ton) | Key Influences |

2020 | $680 | COVID-19 disruptions, low demand |

2021 | $1,050 | Stimulus-driven recovery, raw material surge |

2022 | $940 | Demand normalization, China lockdowns |

2023 | $810 | Energy crisis impact, production cutbacks |

2024 | $870 | Stabilized supply chains, green manufacturing trends |

Hot-rolled coil and zinc prices change the cost a lot. If zinc or steel prices go up, Galvanized Coil costs more.

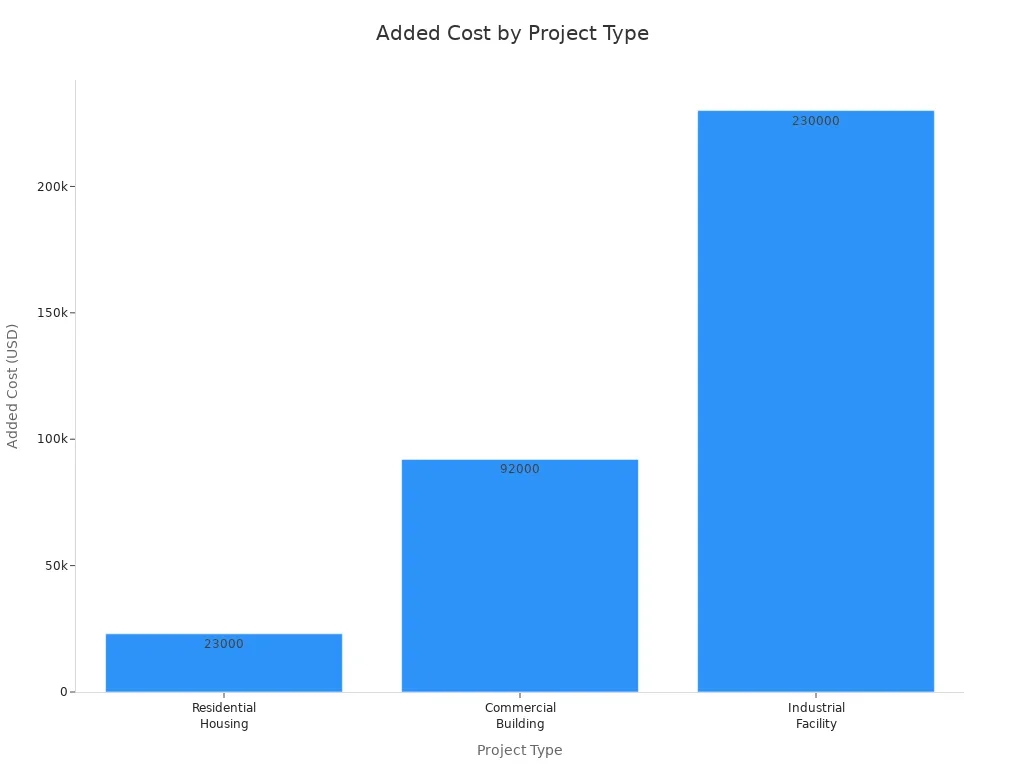

Here are some examples of how price changes affect projects:

Project Type | Average Galvalume Consumption (tons) | Added Cost per 5% Price Increase (USD) |

Residential Housing | 500 | $23,000 |

Commercial Building | 2,000 | $92,000 |

Industrial Facility | 5,000 | $230,000 |

If you work on a big project, even small price changes can cost a lot.

Role of Manufacturing Efficiency

Good manufacturing helps companies deal with price changes. If a factory runs well, it can handle cost jumps without raising your price. When aluminum and zinc prices change, companies must choose to earn less or charge more. Changing prices often can make customers worry and make planning hard.

You can pick suppliers who work efficiently. Here are ways companies get better at making coils:

Fix problems in the production process.

Use better machines and technology for faster work.

Train workers to do their jobs better.

Manage the supply chain to keep materials coming.

Check quality early to catch mistakes.

Note: Efficient companies can keep Galvanized Coil prices steady, even when raw material costs change fast.

If you want to save money, choose suppliers who use new technology and strong quality checks. This helps you get good value and steady prices.

Steel and zinc prices are the biggest reason Galvanized Coil costs change. If you watch the market and check your suppliers, you can plan better. This helps you not get surprised by price jumps. Good suppliers give you more value and help you handle price changes.

Keep an eye on steel and zinc prices to see changes early.

Pick suppliers with good ratings and who deliver on time.

Use long-term deals or smart buying to keep costs steady.

Source for Price Tracking | Benefit |

ChemAnalyst | Gives market news and future price ideas |

When you know these things, you can make better choices. This keeps your projects safe from sudden price increases.

FAQ

What is galvanized coil used for?

You use galvanized coil in roofing, wall panels, appliances, and car parts. It resists rust and lasts longer than plain steel. Many builders choose it for outdoor projects.

How do steel and zinc prices affect what I pay?

When steel or zinc prices rise, you pay more for galvanized coil. These materials make up most of the cost. Watch market trends to plan your purchases.

Can I save money by choosing a thinner zinc coating?

You can save money with a thinner coating, but the coil may not last as long. Thicker coatings protect better against rust. Think about your project’s needs before choosing.

Why do prices change so often?

Prices change because of supply, demand, and world events. Shipping delays, new rules, or higher energy costs can all make prices go up or down quickly.

How can I get the best price for galvanized coil?

You get better prices by buying in bulk or signing long-term contracts. Compare suppliers and check their quality. Ask about discounts for large orders.