You can find

aluminum sheet grades like 1100, 2024, 3003, 5052, 6061, 6063, and 7075 in many places. Each grade has special features. These features make them good for different jobs. For example, 5052 is great for fuel tanks. 6061 is good for building frames. Picking the right grade helps things work better and last longer. If you know about the grades, you can choose wisely for your project. This is true if you need

Aluminum Coil or material for your company’s work.

Knowing how aluminum grades are different helps you choose the best one for your needs.

Key Takeaways

Aluminum Sheet Grades Overview

Different Grades of Aluminum

There are many kinds of aluminum sheets. These kinds are called grades. Each grade has a special mix of metals. Each one has its own features. You can find grades like 1100, 2024, 3003, 5052, 6061, 6063, and 7075 in things you use every day. These grades help you pick the best sheet for your project.

Aluminum sheet grades come from two main groups. One group is wrought aluminum. The other group is cast aluminum. Wrought aluminum is made by rolling or pressing. Cast aluminum is made by pouring melted metal into a mold. Most sheets use wrought aluminum. It is strong and easy to shape.

Here are the main series of aluminum alloys you will see:

Series | Major Alloying Element(s) |

1xx.x | Minimum 99% aluminum |

2xx.x | Copper |

3xx.x | Silicon, with added copper and/or magnesium |

4xx.x | Silicon |

5xx.x | Magnesium |

6xx.x | Unused series |

7xx.x | Zinc |

8xx.x | Tin |

9xx.x | Other elements |

You can use this table to match the series with the main metal added. For example, 1000 series aluminum is almost pure aluminum. 2000 series aluminum uses copper to make it stronger. 3000 series aluminum adds manganese. 5000 series aluminum uses magnesium to stop rust. 6000 series aluminum mixes magnesium and silicon for strength and easy welding. 7000 series aluminum uses zinc for high strength. 8000 series aluminum uses tin for special jobs.

Classification

Aluminum grades have four numbers, like 6061 or 3003. The first number shows the main metal mixed with aluminum. This naming system comes from the Aluminum Association. It helps you know what each grade is like.

International standards use alloy mix and strength to sort aluminum sheet grades. These standards check how strong the metal is and how well it fights rust. They make sure you get the right sheet for your job. The grade you pick affects how long your product lasts and how well it works.

Aluminum grades are set by rules that test how they work.

The first number in the grade name shows the main metal added.

Standards help you pick the best grade for your needs.

You will see different grades of aluminum in many things. For example, 1100 is good for chemical equipment. 2024 is used in airplanes. 3003 is found in cooking tools. 5052 is great for boat parts. 6061 and 6063 work well in building frames. 7075 is strong enough for planes and rockets. 8000 series aluminum is used for electrical wires.

When you know the types of aluminum and how they are sorted, you can pick the best aluminum sheet for your project.

1100 Aluminum Sheet

Properties

1100 aluminum is known for being very pure. It has at least 99% aluminum in it. This makes it one of the purest types you can use. Because it is so pure, it does not rust easily. It stays strong even when it touches water or salt. You can bend and weld this sheet without much trouble. That is why many people like to use it for projects. If you need a sheet that bends without breaking, 1100 aluminum is a good pick.

Let’s see how 1100 aluminum is different from 3003 aluminum:

Property | 1100 Aluminum | 3003 Aluminum |

Aluminum Content (%) | 99.0 minimum | ~98.8 |

Tensile Strength (MPa) | 90–130 | 130–200 |

Yield Strength (MPa) | 30–95 | 115–145 |

Elongation (%) | Up to 35% | Up to 30% |

Formability | Excellent | Excellent |

Corrosion Resistance | Excellent | Very Good |

Machinability | Marine, structural, tanks | Fair |

Weldability | Excellent | Excellent |

Cost | Slightly lower | Slightly higher |

1100 aluminum is not as strong as 3003. But you can stretch or bend it more before it breaks. This makes it great for jobs where you need it to bend and not rust. You do not use it when you need something very strong.

1100 aluminum is made by rolling or pressing. It is not poured into a mold. This way, you get a sheet that is easy to shape.

Tip: Pick 1100 aluminum for chemical tools or food machines. Its purity and rust resistance make it a smart choice.

Uses

Many industries use 1100 aluminum because it has special features. Here are some ways people use it:

Food processing equipment

Chemical industries

HVAC systems

Signage and nameplates

Cookware and kitchen utensils

Reflectors for lighting

Electrical bus bars and transformers

Decorative trim and panels

You might also see 1100 aluminum in car parts, building materials, and strong tools. It does not rust and you can shape it in many ways. That is why it is picked for these jobs.

If you choose 1100 aluminum, you get a sheet that is pure, easy to bend, and does not rust. You can trust it for both normal and special uses.

2024 Aluminum Sheet

Properties

2024 aluminum sheet is known for being very strong. It is a type of wrought aluminum alloy. This means it is rolled or pressed, not poured into a mold. The main metals mixed in are copper, magnesium, and manganese. Copper makes the sheet harder and stronger. Magnesium also helps make it stronger, especially after heating. Manganese helps stop rust and adds more strength.

Here is a table that shows what is in 2024 aluminum sheet:

Element | Percentage Composition (%) |

Aluminum (Al) | Balance (approx. 90.7–94.7) |

Copper (Cu) | 3.8–4.9 |

Magnesium (Mg) | 1.2–1.8 |

Manganese (Mn) | 0.3–0.9 |

Iron (Fe) | Max 0.5 |

Silicon (Si) | Max 0.5 |

Zinc (Zn) | Max 0.25 |

Chromium (Cr) | Max 0.1 |

Titanium (Ti) | Max 0.15 |

Other elements (each) | Max 0.05 |

Other elements (total) | Max 0.15 |

This mix makes the sheet strong, light, and tough. It has a high strength-to-weight ratio. This means it is strong but does not weigh much. You can use it when you need both strength and low weight. The sheet does not break easily when bent or moved a lot.

Tip: Pick 2024 aluminum sheet if you need something strong that lasts a long time.

Uses

2024 aluminum sheet is used for important jobs. The aerospace industry uses it because it is strong and light. You see it in airplane parts like the body and wings. It is also used for airplane fittings and hydraulic manifolds. Other vehicles use it too.

Here are some ways people use 2024 aluminum sheet:

Airplane bodies and wings

Making airplane parts and fittings

Hydraulic manifolds

Military and commercial airplane skin

Other vehicle parts

You can trust 2024 aluminum sheet for jobs that need to be strong and last long. Its features make it great for important parts in planes and vehicles. It is light, strong, and works well. If you work with airplanes or vehicles, you will see this grade a lot.

Note: 2024 aluminum sheet is not the best if you need something that does not rust. Use it when you need strength the most.

3003 Aluminum Sheet

Properties

3003 aluminum is strong and easy to work with. It is part of the wrought aluminum group. This means it is rolled or pressed, not poured. Manganese is the main added metal. Manganese makes it stronger but still easy to bend.

You can shape and weld 3003 aluminum without trouble. It does not crack when you bend it. You can make many shapes with it. It also does not rust fast when it gets wet or touches chemicals. But 5052 aluminum is even stronger and resists rust better.

Here is a table that compares 3003 and 5052 aluminum:

Aluminum Grade | Corrosion Resistance | Strength | Workability |

3003 | Good | Moderate | Excellent |

5052 | Superior | Stronger | Good |

Tip: Pick 3003 aluminum if you need a sheet that bends well and does not rust in most places.

This grade is good for jobs that need to bend and last. It is not as strong as some other grades. But it is easy to use and works for many things.

Uses

Many industries use 3003 aluminum because it has special features. Food and chemical companies like it because it does not rust and can take heat. You can use it for storage boxes, pipes, and metal parts. These things must stay strong and clean, especially with food or chemicals.

Here are some ways people use 3003 aluminum:

Storage boxes

Metal parts

Pipes

Cooking tools

Refrigerator panels

Ice cube trays

Appliance parts

You also see this grade in food boxes and cooking tools. It can take high heat without melting or changing shape. Chemical tools use 3003 aluminum because it does not rust with many chemicals.

Here is a table that shows common uses:

Application Type | Description |

Food Containers | Made from 3003 aluminum because it resists heat and rust. |

Cooking Utensils | Used because they can take high heat without melting. |

Chemical Handling Equipment | Used because it does not rust with many chemicals. |

Note: If you need a sheet for food or chemical storage, 3003 aluminum is safe and lasts a long time.

You can trust 3003 aluminum for jobs that need to bend, not rust, and work well. It is good for home and factory use.

5052 Aluminum Sheet

Properties

5052 aluminum sheet is strong and bends easily. It is made by rolling or pressing, not pouring. Magnesium is the main metal added. This helps the sheet fight rust, even in wet or salty places.

You can bend and shape 5052 aluminum sheet without cracks. It is easy to work with because it stretches well and does not break quickly. The way the sheet is rolled can change how it acts when you shape it.

Here is a table that shows important facts about 5052 aluminum sheet:

Property | Value |

Tensile Strength | 31,000 to 38,000 psi |

Yield Strength | 28,000 to 33,000 psi |

Elongation | 12% to 20% |

5052 aluminum sheet is good for jobs that need strength and bending. It does not rust or get damaged by chemicals. You can weld and finish it easily. Many people use it for different projects.

Tip: Pick 5052 aluminum sheet if you need something strong and flexible that does not rust outside or near water.

Uses

5052 aluminum sheet is used in many places because it is strong and does not rust. Boat and car companies use it for important parts. It works well in tough places.

Here are some ways people use 5052 aluminum sheet:

Fuel tanks for boats

Main parts of boat bodies

Road and highway signs

Walls and bulkheads in cabins

Ladders and handrails on ships

Brackets inside and outside cars

You also see 5052 aluminum sheet in other jobs. It is used for road signs because it lasts outside. Boat makers use it for walls and bulkheads. Ship builders use it for ladders and handrails to keep people safe. Car makers use it for brackets in cars.

Here is a table that shows common uses:

Application Type | Description |

Fuel Tanks | Holds boat fuel, oil, and other liquids. |

Marine Boats | Used to build boat parts. |

Highway and Road Signs | Makes strong signs for roads. |

Hull Structures | Main parts of boat bodies, like walls and bulkheads. |

Ladders and Handrails | Keeps people safe on ships. |

Automotive Bracketry | Used for brackets in cars, inside and outside. |

5052 aluminum sheet is great for places that need strength and no rust. It bends easily and lasts a long time. Many people pick it for outdoor and boat projects.

Note: If you want a material that is easy to shape and lasts in hard places, 5052 aluminum sheet is a good choice.

6061 Aluminum Sheet

Properties

6061 aluminum is strong and useful for many things. It is a wrought aluminum, so it is rolled or pressed into sheets. It is not poured into molds like cast aluminum. This makes it easy to shape and gives it good strength.

6061 aluminum has magnesium and silicon in it. These metals help it fight rust and make it tough. You can use this sheet when you need it to last and bend without breaking. It keeps its shape and does not crack when bent.

6061 aluminum is easy to cut and weld. Here are some facts about how it works:

You can cut 6061 T6 and 6061 T651 easily. These types keep their shape well.

It is easy to weld, but you must pick the right way and filler. Filler like 4043 or 5356 aluminum alloy helps stop cracks.

Welding can make the area near the weld softer. You may need to heat it after welding to make it strong again.

6061 aluminum is stronger than 3003. It also fights rust better than many other grades.

It is easier to weld than 2xxx or 7xxx series aluminum. It keeps its shape if you work with it the right way.

Tip: Pick 6061 aluminum if you want a sheet you can cut, weld, and shape for many jobs.

Uses

6061 aluminum sheet is used in many jobs. It is popular in transportation and building. You see it in railroad cars, trucks, and trailers. Truck frames and rail coaches use it because it is strong and light.

People use 6061 aluminum for bridges in the military and for business. Shipbuilders use it for ship parts. Towers and pylons use it because it stands up to weather and stress.

Here are some ways people use 6061 aluminum sheet:

Railroad cars and truck frames

Trailers and rail coaches

Military and business bridges

Ship building

Towers and pylons

Food processing machines

Sporting goods and solar panel frames

Aircraft and building parts

Plastic structures with fiberglass

You also see this sheet in ships and food machines. Sports gear makers use it for strong, light items. Solar panel frames and airplane parts use it because it lasts a long time.

Note: You can trust 6061 aluminum sheet for jobs that need strength, rust resistance, and easy shaping. Builders and makers like it because it works for many things.

6063 Aluminum Sheet

Properties

6063 aluminum sheet has a smooth and shiny surface. People call it the "architectural alloy" because it looks nice. It is good for decoration and design projects. This sheet comes from the wrought aluminum group. Makers roll or press it, not pour it. That makes it easy to bend and shape.

6063 aluminum sheet has magnesium and silicon in it. These metals help stop rust and keep it shiny. You can polish or anodize it to make it look even better. The sheet does not crack when you bend it for frames or trim. It is easier to shape than some other aluminum alloys.

Here is a table that compares 6063 and 6061 aluminum sheets:

Feature | 6061 | 6063 |

Strength | Higher yield strength | Lower yield strength |

Corrosion Resistance | Good | Slightly better |

Surface Finish | Less aesthetic | Better aesthetic qualities |

Primary Use | Industrial applications | Architectural and decorative uses |

6063 aluminum sheet looks better and resists rust a bit more. It is not as strong as 6061, but it is prettier for parts you can see.

Tip: Pick 6063 aluminum sheet if you want a nice finish and need to shape metal for design work.

Uses

6063 aluminum sheet is used in many building products. Builders and designers use it for parts people see every day. You can make window frames, door frames, and curtain walls with it. It works well for trim and roofing systems. You also use it for framing and strong supports.

Here are common ways to use 6063 aluminum sheet:

6063 aluminum sheet is good for jobs that need to look nice and work well. It stays shiny outside and lasts a long time. You see it in railings and balustrades that must look good and be strong. Sign frames and shop fittings use this sheet because it is easy to shape and finish.

If you use aluminum alloys for building or decorating, you will often pick 6063. It has a smooth look and is easy to shape. It does not rust and keeps its color. You can use it for many design jobs where looks matter.

Note: 6063 aluminum sheet gives you beauty, rust resistance, and easy shaping. You can trust it for building and decorating projects.

7075 Aluminum Sheet

Properties

7075 aluminum sheet is known for being very strong. It is part of the wrought aluminum group. This means it is rolled or pressed into sheets. The main metals in it are zinc, magnesium, and copper. These metals make the sheet tough and strong.

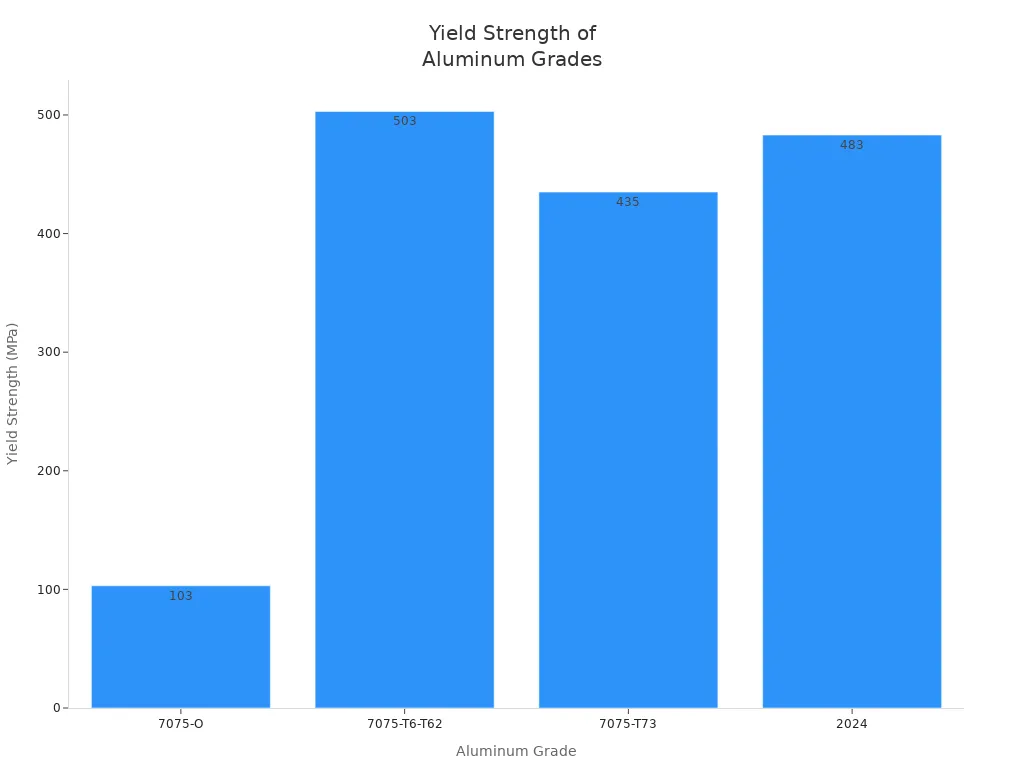

7075 aluminum can take hard hits and lots of pressure. It does not bend easily. Its yield strength is higher than most other grades. For example, 7075-T6 has a yield strength of 503 MPa. This is more than 2024 aluminum, which is 483 MPa. You can see how strong 7075 is in the table below:

Aluminum Grade | Yield Strength (MPa) |

7075-O | 103 |

7075-T6-T62 | 503 |

7075-T73 | 435 |

2024 | 483 |

5052 | < 483 |

7075 aluminum sheet does not get tired or break from stress. It is light, so it is good for jobs where weight matters. Cast aluminum is made by pouring metal into molds. 7075 aluminum gets its strength from rolling and pressing.

Tip: Pick 7075 aluminum sheet if you need something very strong and tough.

Uses

7075 aluminum sheet is used in the military and space fields. It is picked when strength and trust are most important. The first big use was in the Mitsubishi A6M Zero fighter plane. This plane was famous for being light and easy to move because of its strong frame.

You can find 7075 aluminum in many important parts, such as:

Aircraft bodies and wings

Space Shuttle SRB nozzles that face heat and pressure

M16 rifles, in the lower and upper receivers

High-stress parts in airplanes and rockets

Here is a table that shows some main uses:

Application | Description |

Mitsubishi A6M Zero | First big use, made the plane strong and easy to fly. |

M16 rifles | Used for making strong gun parts. |

Space Shuttle SRB nozzles | Used in space parts that need to be very strong. |

Aircraft structures | Used a lot in airplane bodies and wings. |

You also see 7075 aluminum in sports gear and bike frames. It is used for things that must be strong and light. This alloy is chosen for parts that get a lot of stress. It does not break or wear out fast.

Note: If you need a material for hard jobs that keeps its shape, 7075 aluminum sheet is a good choice. Its uses show why it is trusted for the toughest work.

Aluminum Sheet Grades Comparison

Table

This table helps you compare the main aluminum sheet grades. It shows what each grade is made of, how strong it is, how well it fights rust, and how easy it is to shape. You can also see what each grade is used for. This makes it easy to spot the differences quickly.

Grade | Main Alloying Element(s) | Strength | Corrosion Resistance | Formability | Common Uses |

1100 | Pure Aluminum | Low | Excellent | Excellent | Food equipment, chemical tanks |

2024 | Copper | High | Poor | Fair | Aircraft, military vehicles |

3003 | Manganese | Moderate | Good | Excellent | Cooking tools, storage boxes |

5052 | Magnesium | High | Superior | Good | Marine parts, fuel tanks, road signs |

6061 | Magnesium, Silicon | High | Good | Good | Truck frames, bridges, sports gear |

6063 | Magnesium, Silicon | Moderate | Slightly Better | Excellent | Window frames, decorative trim |

7075 | Zinc, Magnesium, Copper | Very High | Fair | Poor | Aircraft, rifles, space shuttle |

Tip: Look at this table when you need to choose an aluminum sheet. Match the grade to the job you want to do.

How to Use

The comparison table helps you pick the best aluminum sheet. First, think about what you need the sheet to do. If you want a sheet that bends easily and does not rust, try 1100 or 3003. If you need something strong, look at 2024, 6061, or 7075.

Think about where you will use the sheet. For outdoor or water jobs, pick a grade that fights rust well, like 5052. If you want a nice look for building or design, 6063 is a good choice. For hard jobs in planes or the military, 7075 is the strongest.

Here are some steps to help you choose:

Decide which features matter most for your project, like strength or rust resistance.

Check the table for grades that match what you need.

Look at the uses listed for each grade.

Pick the grade that fits your project best.

Note: Aluminum grades are different because of the metals mixed in. You can find the right grade by matching your needs to the table.

Aluminum alloys give you many choices for different jobs. Use the table as a quick guide when you need to pick a sheet. This makes choosing easier and helps you get good results.

Choosing Aluminum Sheet Grades

Factors

When you pick an aluminum sheet, you must think about some key things. Each thing changes how well the sheet works for your project.

Here is a table that shows what to look at:

Factor | Description |

Strength | Tells how much force the sheet can take before it bends or breaks. |

Machining | Shows how simple it is to cut and shape the sheet. |

Weldability | Tells how easy it is to join pieces by welding. |

Corrosion Resistance | Shows how well the sheet fights rust and chemical harm. |

Workability/Formability | Tells how easy it is to bend or shape the sheet without cracks. |

Heat Treatment | Lets you change strength and flexibility by heating the sheet. |

Tip: Always check strength and corrosion resistance first if you need a sheet for outside or for building things.

Corrosion resistance is very important for things used outside. Aluminum alloys make a special oxide layer. This layer helps stop rust and keeps water or chemicals from hurting the sheet. You should use aluminum grades with high corrosion resistance for boats or buildings.

Here is a table that shows how different alloys fight rust:

Alloy | Corrosion Resistance | Application |

5052 | High (saltwater) | Marine |

6061 | Moderate | General |

7075 | Low | Aerospace |

You also need to think about how easy it is to bend or weld the sheet. Some grades bend without breaking, while others are better for cutting or shaping. Heating the sheet can make it stronger or more bendy, based on what you need.

Knowing about the different grades of aluminum sheet helps you pick the right one. If you choose the best grade for your project, you get better results. You can also save money by picking the right grade. For example, the right grade can stop rust or lower your costs. Always look at the comparison table and grade details before you choose. This helps you avoid mistakes and makes your project last longer and work better.

FAQ

What is the difference between 6061 and 6063 aluminum sheets?

6061 aluminum sheet is stronger and used for structural parts. 6063 aluminum sheet has a smoother finish and works best for decorative or architectural uses.

Can you weld all grades of aluminum sheet?

You can weld most grades, like 1100, 3003, 5052, and 6061. Grades like 2024 and 7075 do not weld well. Always check the grade before welding.

Which aluminum sheet grade resists corrosion best?

5052 aluminum sheet resists corrosion best, especially in saltwater. You can use it for marine and outdoor projects.

Is aluminum sheet safe for food contact?

Yes, grades like 1100 and 3003 are safe for food contact. You often see them in cookware and food processing equipment.

How do you choose the right aluminum sheet grade?

Think about strength, corrosion resistance, and how you will shape the sheet. Use the comparison table to match your needs to the right grade.

Can you bend aluminum sheets without cracking them?

You can bend grades like 1100, 3003, and 5052 easily. These grades have high formability and do not crack when you shape them.

What is the strongest aluminum sheet grade?

7075 aluminum sheet is the strongest. You find it in aircraft, military, and high-stress parts.