Aluminum sheet metal means thin, flat pieces of aluminum. You can use it for building, crafts, or fixing things. Aluminum sheet is easy to spot because it is light. It does not rust easily. It is also strong for its weight. In 2024, people used about 18 million tonnes of aluminum sheet worldwide. This shows that many people pick it for lots of projects.

Material | Strength-to-Weight Ratio |

Aluminum | 1/8 |

Steel | 1/16 |

If you choose aluminum sheet, it can weigh half as much as steel. It can still hold the same amount of weight. These features help you make strong and lasting things without making them heavy. If you want Aluminum Coil or more info, our company can help you start.

Key Takeaways

Aluminum sheet metal is light but also strong. This makes it good for many projects like building and crafts. It does not rust fast because it has a special oxide layer. You can use it outside without worry. Pick the right thickness for your project. Thicker sheets are stronger and last longer. Different aluminum alloys have special features. Choose one that fits your project, like if you need it to resist rust or be very strong. Aluminum sheet is useful for many things. You can cut, bend, and shape it for lots of DIY projects. This makes it a great pick for creative work.

Aluminum Sheet Metal Properties

Physical Properties of Aluminum Sheet

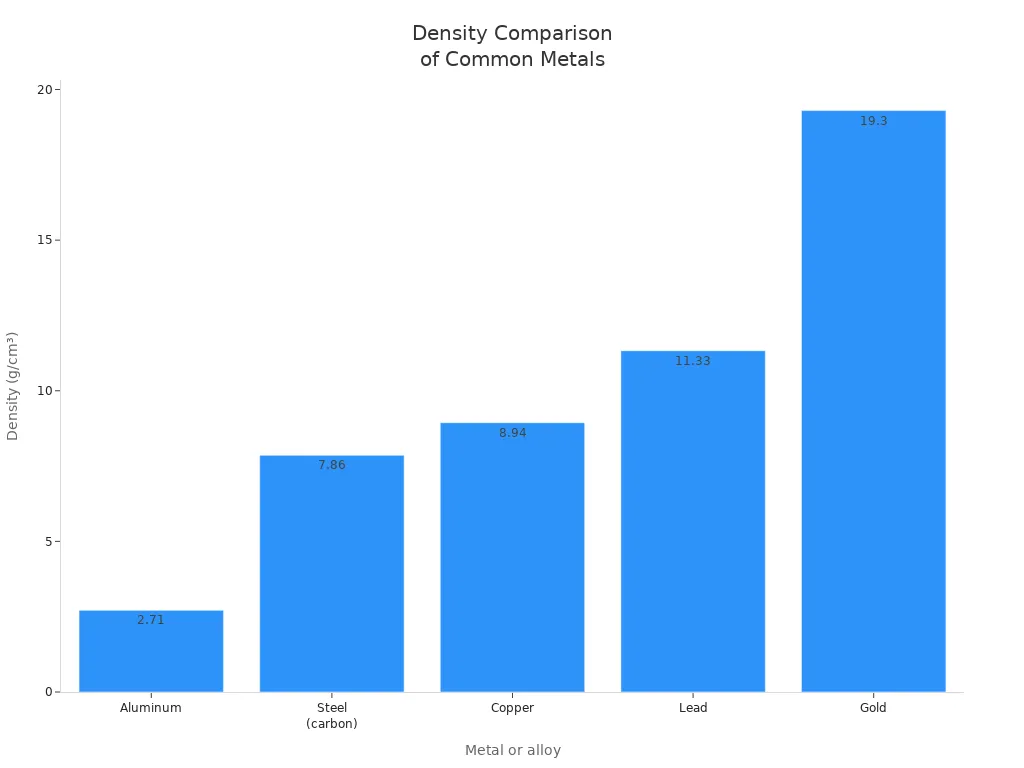

Aluminum sheet metal is light and easy to carry. It has low density, so you can move big pieces without trouble. Aluminum is much lighter than other metals. Look at this table:

Metal or alloy | Density (g/cm³) |

Aluminum | 2.71 |

Steel (carbon) | 7.86 |

Copper | 8.94 |

Lead | 11.33 |

Gold | 19.30 |

Aluminum is about three times lighter than steel. It is even lighter than copper or lead. This low density gives aluminum sheet a high strength-to-weight ratio. You get strong material that does not add much weight.

Aluminum sheet metal does not rust or corrode easily. It forms a thin oxide layer that keeps out water and chemicals. This means you can use it outside or in wet places without worry.

Aluminum also moves heat very well. Its thermal conductivity is 237 W/mK. This helps when you need to get rid of heat fast, like in heat sinks or radiators.

Aluminum sheet metal bends and shapes without breaking. You can cut, bend, or form it into many designs. This makes it easy to use for different projects. Copper and mild steel are also malleable and ductile, but aluminum is lighter.

Here are some other important physical properties:

Property | Description |

Strength | Aluminum alloys are stronger than pure aluminum. They work well for building things. |

Corrosion Resistance | They make a layer that protects them from rust. This helps them last longer. |

Electrical Conductivity | Aluminum carries electricity very well. It is second only to copper. |

Thermal Conductivity | Aluminum alloys move heat well. This is good for heat sinks and radiators. |

Lightweight | Aluminum alloys are strong but light. This is why they are used in planes and cars. |

Non-magnetic | Aluminum does not attract magnets. This helps in places where magnets are a problem. |

Non-sparking | Aluminum does not spark. This is safer in places with flammable stuff. |

Tip: Thicker aluminum sheet metal is stronger and resists rust better. Thicker sheets also carry more electricity and last longer outside.

Mechanical Properties of Aluminum

You may want to know how strong aluminum sheet is. Mechanical properties tell you how much force it can take before bending or breaking. Aluminum sheet metal comes in many alloys. Each alloy has its own strength.

Here is a table with yield strength and tensile strength for some alloys:

Aluminum Alloy | Temper | Yield Strength (ksi) | Tensile Strength (ksi) |

6061 | T6 | 35 | 45 |

2024 | T3 | 42 | 64 |

5052 | H32 | 23 | 31 |

For example, 6061-T6 alloy has a yield strength of at least 35 ksi. Its tensile strength is at least 45 ksi. Some alloys, like 2024-T3, are even stronger because of their mix of metals.

Thicker aluminum sheet metal is stronger. It can hold more weight and does not bend as easily. Even a small increase in thickness helps the sheet support more load.

Aluminum sheet metal is also very ductile. You can stretch or bend it into many shapes. It will not crack. This is good for projects that need both strength and flexibility.

Surface Finishes

There are many surface finishes for aluminum sheet metal. Each finish changes how it looks and how well it resists rust.

Anodizing makes a hard, rust-resistant layer. It also adds color and shine.

Powder coating puts on a strong, colorful layer. It protects and looks nice.

Alodine finish (chem film) gives good rust protection. It costs less than anodizing.

Bead blasting cleans and smooths the surface. It gives a matte look.

Electroplating adds a thin metal layer to improve the sheet.

Polishing makes the surface shiny and stops oxidation.

Brushing gives a textured look and hides scratches.

Note: Anodizing and powder coating both help stop rust and make the sheet look better. Brushed finishes hide scratches. Alodine is a good choice if you want protection for less money.

Pick the finish that fits your project. Some finishes help the sheet last longer outside. Others make it look better or easier to clean.

Common Uses of Aluminum Sheet

Automotive Applications

Aluminum sheet metal is used in lots of cars and trucks. Car makers pick it because it is light and strong. This helps cars use less gas and drive better. Aluminum also makes cars safer in crashes. It absorbs impact well. Look at this table to see why car makers like aluminum sheet:

Advantage | Description |

Lightweight Nature | Makes cars lighter, saves gas, and helps driving. |

Strength-to-Weight Ratio | Better than mild steel, helps make safer cars. |

Corrosion Resistance | Makes a shield, so it lasts longer. |

Recyclability | Can be recycled over and over, saves money and helps nature. |

Thermal Conductivity | Moves heat away fast, good for engines. |

You can find aluminum sheet in car doors, hoods, and frames. Lighter doors make cars easier to open and safer in crashes. Aluminum helps people get out fast in emergencies. Car makers like that aluminum can be recycled many times. This saves money and helps the earth.

Construction Uses

Aluminum sheet metal is used in lots of buildings. Builders use it because it lasts long and does not rust. You see it in roofs, window frames, and siding. Many experts think aluminum will be used even more soon. Here are some common ways it is used:

Roofing and wall coverings

Doors, window frames, and big glass walls

Ceiling panels and decorations

Aluminum sheet is light but strong. It is easy to shape into many designs. Builders like it because it needs little care and looks good for years. A survey found that 62% of building experts plan to use more aluminum soon.

DIY and Everyday Projects

Aluminum sheet is great for home projects and crafts. You can cut, bend, and shape it easily. This makes it perfect for DIY fans. Here are some fun things you can make:

Curved marquee letters

Custom magnet boards for herbs

Sheet metal dragonflies

Textured earrings

Sheet metal American flags

Simple sheet metal boxes

Aluminum sheet metal is light, so you can carry it easily. It does not rust, so your projects last longer. You can bend it into many shapes, so you have lots of choices.

Tip: Use aluminum sheet for your next craft or fix. It is easy to work with and strong enough for most jobs.

Choosing Aluminum Sheet Metal Alloys

When you pick aluminum sheet metal alloys for your project, you need to think about both thickness and alloy type. These choices decide how well your project will work and how long it will last.

Thickness and Gauge

Thickness and gauge tell you how strong and flexible your aluminum sheet will be. Gauge is a number that shows how thick the metal is, but it can mean different things for different metals. For example:

Gauge size shows metal thickness, but it is not the same for all metals.

16-gauge aluminum measures 0.062 inches thick.

16-gauge steel measures 0.059 inches thick.

You should consider these factors when choosing the right thickness:

If you need your aluminum sheet to hold weight or resist dents, pick a thicker gauge. Thicker aluminum sheets, like 0.125 inches, give you more durability and strength. These work well for load-bearing uses. Thinner sheets, such as 0.040 inches, bend and shape easily. They are good for crafts or parts that do not need much strength. Using the wrong thickness can make your project weak or hard to use.

Alloy Types

Aluminum sheet metal alloys come in many types. Each alloy has its own mix of properties. Some alloys are easy to bend, while others are strong or resist rust better. Here are some common types of aluminum sheet:

1100: Good for electrical work, food, and chemical handling.

3003: Used in cooking utensils and general sheet metal jobs.

3004: Works well for storage tanks and cookware.

3105: Chosen for roofing and siding.

5052: Great for marine uses and kitchenware.

Alloy type changes how your aluminum sheet metal behaves. For example, 5052 resists saltwater corrosion, so it is perfect for boats. 6061 is strong and resists rust, making it a top pick for building frames. 7075 stands up to harsh weather and chemicals. Some aluminum grades, like 5052, are stronger than others such as 1100 or 3003. You should also know that alloys from the 2XXX and 7XXX series have lower corrosion resistance than pure aluminum.

Here is a table to help you choose the right alloy:

Key Criteria | Description |

Strength | The ability to withstand forces without breaking. |

Stiffness | How well the sheet keeps its shape under load. |

Corrosion Resistance | How well the alloy stands up to rust and weather. |

Weight | Lighter sheets are better for projects where weight matters. |

Manufacturability | How easy it is to cut, bend, or shape the sheet. |

You will find that aluminum sheet metal alloys are used in ships, trains, cars, and even fireproof panels. The right combination of thickness and alloy type lets you match your project’s needs. Some aluminum grades, like 5052 and 6061, give you both strength and corrosion resistance. Always check the types of aluminum sheet available for your job.

Tip: Pick your aluminum sheet metal alloys based on where you will use them. For outdoor or marine projects, choose an alloy with high corrosion resistance and the right thickness for strength.

Aluminum sheet metal is thin and flat. You can use it for many things. Aluminum is much lighter than steel. It does not rust easily. You can bend, cut, and join it in many ways. Aluminum is strong and useful for lots of jobs. It helps you pick the best material for your project.

Property | Benefit |

Lightweight | About three times lighter than steel |

Corrosion Resistance | Resists rust better than steel |

Versatility | Can be shaped, cast, cut, joined, melted, machined, and extruded |

Mechanical Properties | Has a great strength-to-weight ratio |

If you know these facts, you can avoid mistakes. Do not pick the wrong finish or forget about bend radii. Use 5053 aluminum for boats because it is strong and easy to weld. This helps your project last longer and saves money.

Tip: Always check the alloy and thickness before you start. Planning well gives you better results.

FAQ

What tools do you need to cut aluminum sheet?

You can use tin snips for thin sheets. For thicker aluminum, try a jigsaw or circular saw with a metal-cutting blade. Always wear safety glasses and gloves.

Can you paint aluminum sheet metal?

Yes, you can paint aluminum. Clean the surface first. Use a primer made for metal. Then, apply spray paint or brush-on paint for a smooth finish.

How do you prevent aluminum from rusting?

Aluminum does not rust like iron. It forms a thin oxide layer that protects it. You can add extra protection with anodizing or powder coating.

Is aluminum safe for food projects?

You can use aluminum for food trays, pans, and containers. It is safe for most foods. Avoid using it with acidic foods, which may react with the metal.

Can you weld aluminum sheet at home?

Yes, you can weld aluminum at home. Use a MIG or TIG welder. Clean the metal before welding. Practice on scrap pieces to get the best results.