Are aluminum coils better than copper ones in HVAC systems? It's a question that sparks debate among experts. Coil material impacts efficiency, cost, and durability. In this post, you'll learn the pros and cons of aluminum coils compared to copper, helping you make an informed choice.

Historical Context of Aluminum Coils

Introduction of Aluminum Coils in the 1970s

Aluminum coils first appeared in the HVAC industry during the 1970s. General Electric, aiming to cut production costs, pioneered the use of aluminum tubes and fins for coils instead of the traditional copper. Before this shift, most air conditioning units used copper tubes with aluminum fins. This change was significant because aluminum is less expensive than copper, making cooling systems more affordable for consumers.

At that time, air conditioning was still a luxury in many homes. Only about 20% of residential buildings had central air systems. The high cost of copper coils contributed to this. Aluminum coils helped lower the price, enabling more widespread adoption.

Impact on HVAC Industry

The introduction of aluminum coils transformed the HVAC market. Other manufacturers soon followed GE's lead, producing aluminum coil systems. This development allowed companies to offer air conditioners at lower prices, boosting sales and expanding the market.

Aluminum coils provided a competitive edge to manufacturers by reducing material costs and simplifying production. This shift contributed to the rapid growth of air conditioning in residential and commercial buildings, especially during the construction boom of the late 20th century.

Evolution and Adoption Over Time

Over the decades, aluminum coils have evolved. Early aluminum coils faced challenges like corrosion and fragility compared to copper. However, manufacturers improved designs by adding protective coatings and stronger casings to increase durability.

Today, aluminum coils are common in many HVAC units, especially in budget-friendly models. They are favored for their light weight and resistance to certain types of corrosion. Despite some technical drawbacks, ongoing innovations help aluminum coils perform better and last longer.

Meanwhile, copper coils remain popular in premium systems, prized for their strength and superior heat transfer. The choice between aluminum and copper coils now depends on factors like cost, climate, and maintenance preferences.

Understanding the historical development of aluminum coils helps HVAC professionals advise clients on the best coil type based on evolving technology and market trends.

Economic Advantages of Aluminum Coils

Cost of Manufacturing

Aluminum coils cost less to make than copper coils. Aluminum is more abundant and cheaper as a raw material. It also weighs less, so it saves on transportation and handling costs during manufacturing. The production process for aluminum coils is often simpler and faster, helping manufacturers reduce labor and energy expenses. These factors combine to make aluminum coils a more affordable option for HVAC manufacturers.

Affordability for Consumers

Because aluminum coils cost less to produce, air conditioning units using aluminum coils tend to be priced lower. This makes cooling systems more accessible to a wider range of homeowners and businesses. Lower upfront costs can be especially attractive for budget-conscious buyers or those needing multiple units for large buildings. Additionally, the lighter weight of aluminum coils can reduce installation time and labor costs, which helps keep the overall expense down.

Comparison with Copper Coils

Copper coils have superior heat transfer and durability but come with a higher price tag. Copper is a more expensive metal and requires thicker tubing due to its weight and strength, increasing material costs. While copper coils may offer better performance and easier repairs, the initial investment can be significant.

In contrast, aluminum coils provide a cost-effective alternative, especially where budget constraints exist. They allow manufacturers to offer competitively priced products without sacrificing all performance aspects. However, aluminum coils may require more careful handling and maintenance, which can affect long-term costs.

| Feature | Aluminum Coils | Copper Coils |

| Raw Material Cost | Lower | Higher |

| Weight | Lighter | Heavier |

| Manufacturing Expense | Lower | Higher |

| Initial Unit Price | More Affordable | More Expensive |

| Installation Cost | Lower (due to weight) | Higher |

| Repairability | More Difficult | Easier |

Example: A residential AC unit with aluminum coils might cost 10-20% less than a similar one with copper coils, making it appealing for first-time buyers or large-scale projects where cost savings add up.

Technical Benefits of Aluminum Coils

Lightweight and Easy Installation

Aluminum coils weigh significantly less than copper coils. This lighter weight makes them easier to handle during manufacturing, transport, and installation. For HVAC technicians, this means less strain and faster setup times. A lighter coil also reduces the overall weight of the cooling system, which can be a benefit for certain building structures or portable units. The reduced weight often translates to lower labor costs during installation, making aluminum coils attractive for both manufacturers and consumers.

Resistance to Corrosion

One major advantage of aluminum coils is their natural resistance to corrosion. Aluminum forms a thin oxide layer on its surface when exposed to air, which acts as a protective barrier against rust and degradation. This quality helps aluminum coils last longer in environments where moisture or other corrosive elements are present. Unlike copper, which can suffer from specific types of corrosion if not maintained properly, aluminum's oxide layer prevents rapid deterioration. This resistance reduces the frequency of coil replacements and maintenance, especially in humid or polluted areas.

Suitability for Coastal Climates

Coastal regions present unique challenges for HVAC systems due to salty air and high humidity. Salt accelerates corrosion in metals like copper, often leading to faster coil damage and reduced system efficiency. Aluminum coils perform better in these conditions because their oxide layer protects against salt-induced corrosion. Additionally, manufacturers often apply extra protective coatings to aluminum coils, further enhancing their durability in coastal environments. This makes aluminum coils a preferred choice for homes and businesses near oceans or seas, where maintaining system longevity is critical.

Challenges Associated with Aluminum Coils

Heat Transfer Limitations

Aluminum coils generally do not transfer heat as efficiently as copper coils. Copper has a higher thermal conductivity, meaning it can absorb and release heat faster. This property allows copper coils to cool spaces more quickly and efficiently. Aluminum coils, while lighter and cheaper, require more surface area or additional design tweaks to match copper's heat transfer performance. This can sometimes lead to larger or more complex coil designs, which may not always be practical for every HVAC system.

Maintenance and Repair Difficulties

One significant challenge with aluminum coils is their maintenance and repair. Aluminum is more prone to damage during cleaning or handling because it is softer and less ductile than copper. Repairing leaks in aluminum coils can be tricky. Unlike copper, which can often be repaired on-site by brazing or soldering, aluminum coils usually require specialized welding equipment or complete replacement if damaged. This can increase downtime and repair costs for homeowners or businesses relying on aluminum coil systems.

Fragility Compared to Copper Coils

Aluminum coils are more fragile than copper coils. Copper’s strength and flexibility make it less likely to crack or break under stress. Aluminum, on the other hand, can be more brittle, especially at bends or joints. Because of this, aluminum coil systems often need to be housed in sturdier protective casings to prevent damage during transport, installation, or operation. This added protection can make cleaning and maintenance more difficult, as technicians must work around these protective layers.

Tip: When considering aluminum coils, factor in potential higher maintenance and repair complexity, and ensure HVAC technicians are experienced with aluminum-specific repair methods.

Comparative Analysis: Aluminum vs Copper Coils

Strength and Durability

Copper coils are generally stronger and more durable than aluminum coils. Copper’s natural tensile strength allows it to withstand physical stress, bending, and impacts better. This durability means copper coils are less likely to crack or break during installation or operation. Aluminum coils tend to be more fragile and can suffer damage more easily, especially at bends or joints. To protect aluminum coils, manufacturers often encase them in sturdy cabinets, which adds weight and can complicate maintenance.

However, aluminum's lighter weight is a significant advantage in reducing overall system weight. While aluminum is less tough, modern manufacturing techniques and protective coatings help improve its durability. Still, when it comes to raw strength, copper remains superior.

Ease of Maintenance

Copper coils are easier to maintain and repair than aluminum coils. Copper’s ductility allows technicians to perform on-site repairs such as brazing or soldering leaks, which can save time and money. Aluminum coils, on the other hand, are more challenging to repair. Leaks often require specialized welding equipment or complete coil replacement, increasing downtime and service costs.

Cleaning copper coils is also simpler. Copper resists corrosion longer and is less prone to damage during cleaning. Aluminum coils need careful handling to avoid dents or scratches that can lead to corrosion. Additionally, aluminum coils enclosed in protective casings may be harder to access for thorough cleaning.

Energy Efficiency and Cooling Performance

Copper has a higher thermal conductivity than aluminum, meaning it transfers heat more efficiently. This property allows copper coils to cool spaces faster and often with less energy consumption. Copper coils provide better overall cooling performance, which can translate into energy savings and increased comfort.

Aluminum coils, while less efficient in heat transfer, can still perform well when designed with larger surface areas or enhanced fin structures. Recent advances, like microchannel technology, improve aluminum coil efficiency. Still, copper coils typically maintain an edge in energy efficiency and cooling speed.

Modern Technologies Enhancing Aluminum Coils

Microchannel Technology

Microchannel technology has revolutionized aluminum coil design. Instead of traditional round tubes, microchannel coils use flat tubes with multiple small channels inside. This design increases the surface area exposed to air, improving heat transfer efficiency. It also reduces the amount of refrigerant needed, making systems more eco-friendly.

Because microchannel coils avoid joining different metals, they eliminate galvanic corrosion risks common in older aluminum-copper joints. This results in longer-lasting coils, especially in humid or coastal environments. Many modern air conditioners now feature microchannel aluminum coils to balance cost, weight, and performance.

Blue Fin Coating

Blue fin coating is a special anti-corrosive layer applied to aluminum coils. This coating protects the coil from salt, acid, and moisture damage. It is especially useful in coastal areas where salty air can quickly corrode metal surfaces.

The blue fin coating extends coil life and maintains heat transfer efficiency by preventing rust buildup. Many premium HVAC brands use this technology to enhance aluminum coil durability. The coating also makes cleaning easier, preserving system performance over time.

Impact on Longevity and Performance

Together, microchannel technology and blue fin coating significantly improve aluminum coil lifespan and efficiency. Microchannels boost heat exchange rates, narrowing the gap between aluminum and copper coils. Blue fin coating protects against corrosion, a traditional weakness of aluminum coils.

These technologies reduce maintenance frequency and repair costs. They also help aluminum coils perform reliably in harsh conditions, making them a practical choice for many applications. While copper still leads in raw thermal conductivity, modern aluminum coils offer competitive performance with added benefits like lighter weight and lower cost.

When specifying aluminum coils for HVAC projects, prioritize units featuring microchannel technology and blue fin coating to ensure enhanced durability and efficient heat transfer in challenging environments.

Conclusion

Homeowners should consider cost, climate, and maintenance preferences when choosing between aluminum and copper coils. Aluminum coils offer economic advantages like lower upfront costs and lightweight design, which can reduce installation expenses. They also provide resistance to corrosion, making them suitable for coastal climates. While copper coils excel in heat transfer and durability, aluminum coils with modern enhancements like microchannel technology and blue fin coating offer competitive performance. For value and quality, consider Sino Steel products, which leverage advanced technologies for efficient and durable aluminum coil solutions.

FAQ

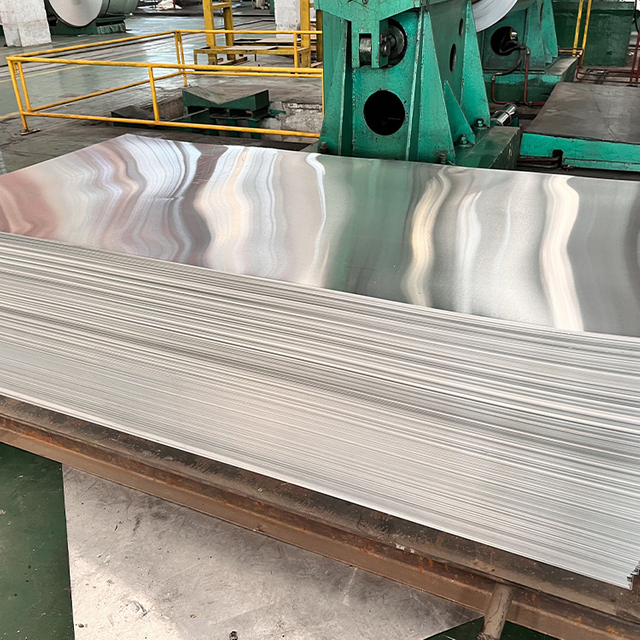

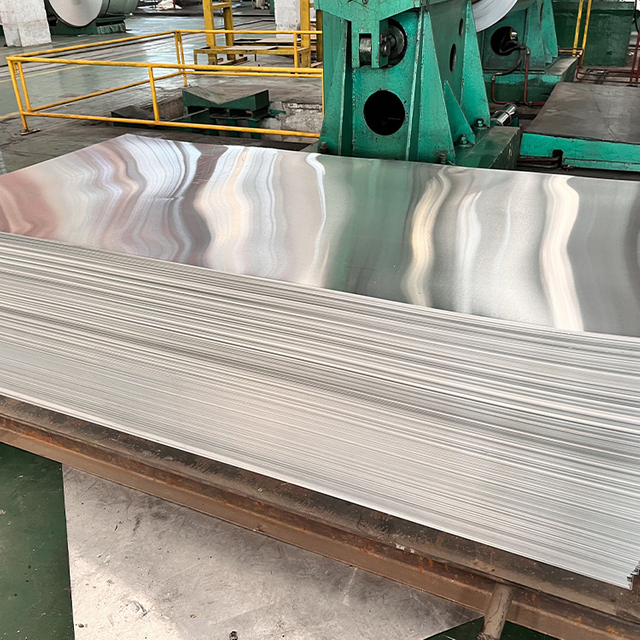

Q: What is an Aluminum Coil?

A: An Aluminum Coil is a component used in HVAC systems, made from aluminum tubes and fins, known for being lightweight and cost-effective compared to traditional copper coils.

Q: How is an Aluminum Coil used in air conditioning?

A: Aluminum Coils are used in air conditioning units to transfer heat, helping cool indoor spaces. Their lightweight nature aids in easier installation and handling.

Q: Why choose Aluminum Coil over Copper Coil?

A: Aluminum Coils are chosen over Copper Coils for their affordability, corrosion resistance, and lighter weight, making them ideal for budget-conscious projects.

Q: Are Aluminum Coils cheaper than Copper Coils?

A: Yes, Aluminum Coils are generally cheaper than Copper Coils due to lower raw material costs and simpler manufacturing processes.

Q: What are the benefits of using an Aluminum Coil?

A: Benefits of using Aluminum Coils include lower upfront costs, lighter weight, and resistance to certain types of corrosion, especially in humid or coastal environments.

Q: Can Aluminum Coils be repaired easily?

A: Aluminum Coils are more challenging to repair than Copper Coils, often requiring specialized equipment or replacement, due to their softer nature.