For most outdoor jobs,

Galvanized Steel Coil is the best choice. It does not rust easily and can handle bad weather. If you want a smooth look, like for furniture or appliances, cold rolled steel coil is often better. Think about what is most important for your project. You should consider rust protection, how it looks, and how much it costs. Here are some common ways people use these coils:

Construction: metal roofs, wall panels, and floor decks

Automotive: car bodies and parts

Appliances: refrigerator doors and washing machine drums

You can trust our company to help you pick the right material.

Key Takeaways

Pick galvanized steel coil for projects outside. It does not rust easily and lasts longer when it is wet.

Use cold rolled steel coil for things inside. It has a smooth surface and exact shapes. This makes it good for furniture and machines.

Think about how thick the zinc coating is on galvanized steel. Thicker coatings stop rust better and help it last longer.

Look at the price differences. Galvanized steel coil usually costs less at first. Cold rolled steel coil might save money later if it is dry.

Always put safety first with galvanized steel. Wear safety gear and make sure there is fresh air. This keeps you safe from bad fumes when cutting or welding.

Comparison Overview

Galvanized Steel Coil vs Cold Rolled Steel Coil

When you look at galvanized steel coil and cold rolled steel coil, you notice they are made in different ways. Galvanized steel coil gets put into hot, melted zinc. The zinc covers the steel and keeps it from rusting. This makes it last longer outside or in wet places. Cold rolled steel coil is made at cooler temperatures. This gives the steel a smooth surface and very exact shapes. Galvanizing helps stop rust. Cold rolling makes the steel look nicer and fit together better.

Pick galvanized steel coil if you need strong protection from rain or water. Cold rolled steel coil is better when you want a shiny, smooth finish and need parts to fit together well.

Key Differences

Here is a table to show the main differences:

Property | Galvanized Steel Coil | Cold Rolled Steel Coil |

Corrosion Resistance | Stays strong against rust | Does not fight rust as well |

Drawability | Not as easy to shape | Easier to shape |

Weldability | Harder to weld because of zinc | Easier to weld |

Tip: Use galvanized steel coil for roofs, wall panels, and guardrails. Pick cold rolled steel coil for car panels, cabinets, and furniture that need a smooth look.

Galvanized steel coil works well in building, cars, and appliances that get wet or face weather. Cold rolled steel coil is best for projects where you want a clean look and tight shapes.

Durability & Corrosion Resistance

Galvanized Steel Coil Performance

When you choose galvanized steel coil for your project, you get strong protection against rust and weather. The zinc coating on galvanized steel acts as a shield. This barrier keeps moisture and air away from the steel underneath. Because of this, galvanized steel shows excellent corrosion resistance, especially in outdoor or humid places.

In normal outdoor environments, galvanized steel coil can last between 20 and 50 years.

In salty or humid areas, you might see it last 50 to 80 years before major rust appears.

If you use a thicker zinc coating and keep up with maintenance, the lifespan gets even longer.

The thickness of the zinc coating matters a lot. Thicker coatings give you a stronger barrier against water and dirt. They slow down rust and keep the steel safe for more years. For example, a G90 coating can protect steel for 20 years or more in moderate conditions. If you use an even thicker coating, like Z120, you can double the service life compared to thinner coatings.

Zinc Coating Type | Estimated Lifespan in Moderate Environments |

G30 | 5–10 years |

G90 | 20 years or more |

Note: Thicker zinc layers delay rust and help your project last longer, even in tough weather.

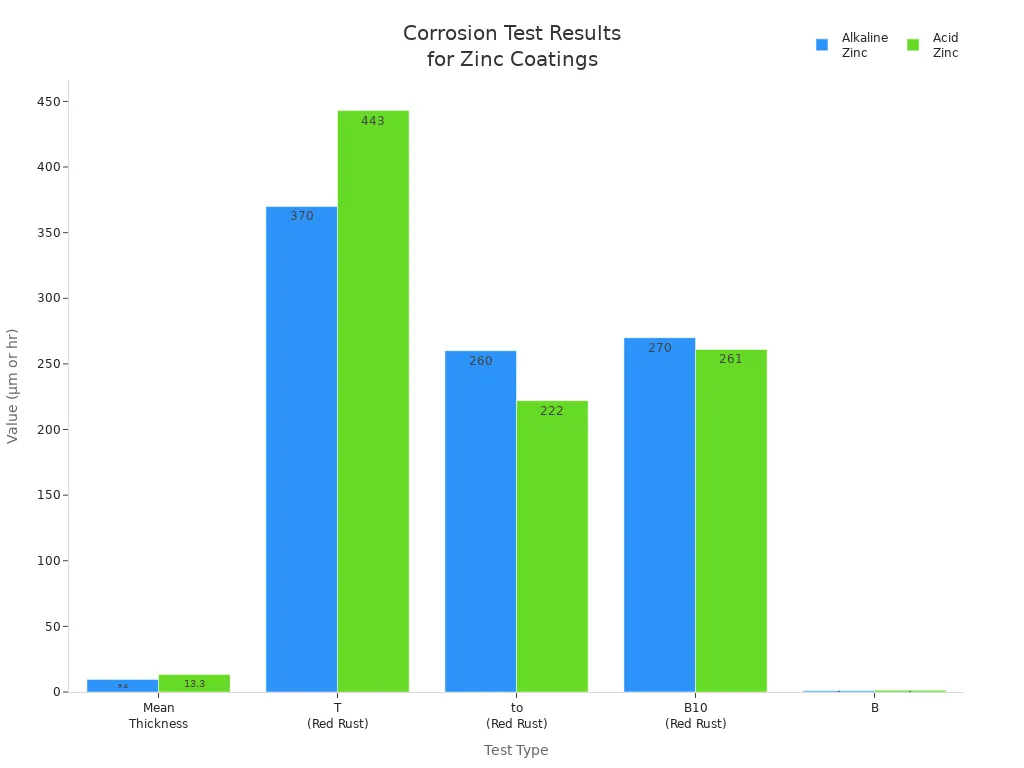

Standardized corrosion tests show how well galvanized steel stands up to harsh conditions. The table below shows how long different zinc coatings last in salt spray tests, which measure resistance to rust:

| Alkaline Zinc | Acid Zinc |

Mean Thickness | 9.6 µm | 13.3 µm |

Salt Spray Test (Red Rust) |

|

|

T | 370 hr | 443 hr |

to | 260 hr | 222 hr |

B10 | 270 hr | 261 hr |

B | 0.9 | 1.3 |

You can see that galvanized steel coil offers top-level corrosion resistance. This makes it a smart choice for roofs, fences, and any project that faces rain or humidity.

Cold Rolled Steel Coil Performance

Cold rolled steel coil gives you a smooth surface and tight shape, but it does not have the same protection as galvanized steel. Cold rolled steel does not have a zinc coating. When you use it in outdoor or wet places, it can start to rust quickly. The lack of a protective layer means moisture and air can reach the steel surface. This makes cold rolled steel less suitable for humid or corrosive environments.

If you want to use cold rolled steel outside, you need to add extra protection. You might paint it or use another coating to help with corrosion resistance. Even then, it will not match the long-term durability of galvanized steel. Cold rolled steel works best indoors or in dry places where rust is not a big problem.

Tip: Use cold rolled steel coil for indoor furniture, cabinets, or parts that will not get wet. For outdoor or humid projects, galvanized steel is the better choice.

Cost Factors

Galvanized Steel Coil Cost

You might notice that galvanized steel coil often costs less than cold rolled steel coil. The zinc coating adds some expense, but the process is not as complex as cold rolling. You get good value for outdoor projects because the coil resists rust and lasts a long time. Here is a table that shows typical price ranges:

Steel Type | Price Range (USD per ton) |

Galvanized Steel Coil | 600 - 700 |

Cold Rolled Steel Coil | 600 - 650 |

Hot Rolled Steel Coil | 500 - 600 |

Galvanized steel coil gives you a lower initial cost for most construction jobs. If the zinc coating gets damaged, you may need to pay for repairs or touch-ups. Regular inspections help you catch problems early. Over time, maintenance costs can rise if you do not protect the coating.

Note: Galvanized steel coil needs regular care to stay strong. If you keep up with inspections, you can avoid bigger repair bills later.

Cold Rolled Steel Coil Cost

Cold rolled steel coil usually costs more because the manufacturing process takes extra steps. The steel gets rolled at cooler temperatures, which makes the surface smooth and the shape precise. This extra work increases the price. Some sources show cold rolled coil prices between $1,092 and $1,240 per ton, which is higher than galvanized steel coil.

You pay more up front for cold rolled steel coil, but you get a better finish. Maintenance costs are not as well documented. If you use cold rolled steel coil indoors, you do not need to worry much about rust. For outdoor use, you may need to add paint or another coating, which increases your total cost.

Cold rolled steel coil gives you a smooth look and tight fit.

You spend more at first, but you save on maintenance if you keep it dry.

If you use it outside, plan for extra protection.

Tip: Choose cold rolled steel coil for indoor projects where you want a clean finish and do not expect much wear.

Appearance & Finish

Surface Quality of Cold Rolled Steel

When you look at cold rolled steel, you see it looks smooth and shiny. The way it is made removes most marks and gives a flat surface. You can paint or powder coat it in many colors. This makes it good for projects where looks are important.

Here is a table that compares cold rolled steel and hot rolled steel for painting and coating:

Feature | Cold Rolled Steel | Hot Rolled Steel |

Surface Quality | Smooth and uniform finish | Scale and surface imperfections |

Defects | Free from defects and impurities | Often has defects |

Suitability for Coating | Excellent adhesion for paints/coatings | More challenging for coatings |

Cold rolled steel is used in furniture, fixtures, and hardware. It is also used for cabinets and panels that look nice. You find it in car parts and machines where a clean look matters. The smooth surface helps paint stick and makes your project look polished.

Tip: Pick cold rolled steel if you want a bright and nice finish for things people will see.

Surface Quality of Galvanized Steel

Galvanized steel looks different because it has a zinc coating. The surface feels rough and may have a spangled pattern. This coating keeps the steel from rusting, but it does not look as shiny as cold rolled steel. You can paint galvanized steel, but you need special primers to help the paint stay on.

Galvanized steel is best for jobs where protection is more important than looks. You see it used for metal roofs, wall panels, and guardrails. These places need to fight rust, not look perfect. If you want something to look nice, you might choose cold rolled steel instead.

Note: If you want your project to look smooth and colorful, cold rolled steel is the best pick.

Fabrication & Workability

Working with Galvanized Steel

When you work with galvanized steel, you need to think about the zinc coating. This layer protects the steel from rust, but it can make cutting and welding more difficult. If you weld galvanized steel, the heat burns off the zinc. This releases toxic fumes that can make you feel sick. You should always use good ventilation and wear a respirator to stay safe.

You may notice that the zinc coating can cause problems with your welds. The coating can make the weld weak or create holes if you do not remove it first. Sometimes, the zinc gets trapped in the weld and causes cracks. You might also see spatter and tiny holes, called porosity, in the weld. After welding, the area loses its rust protection. You can fix this by applying a cold galvanizing compound to the welded spot.

Here are some tips for working with galvanized steel:

Use proper safety gear to avoid breathing zinc fumes.

Remove the zinc coating from the area you plan to weld.

Restore corrosion protection after welding.

Watch for weld defects like cracks or holes.

Safety first: Always work in a well-ventilated area when cutting or welding galvanized steel.

Working with Cold Rolled Steel

Cold rolled steel is easier to shape and weld than galvanized steel. You get clean edges and a smooth surface, which helps you make precise cuts. The higher strength and hardness of cold rolled steel make it great for projects that need tight tolerances. You can weld cold rolled steel without worrying about toxic fumes from coatings.

However, the hardness of cold rolled steel can make forming more challenging if you overwork it. If you bend or shape it too much, you might see cracks or stress marks. You should use the right tools and avoid working the steel too hard. Cold rolled steel is a top choice for welding because it keeps a smooth finish and needs less cleanup after you finish.

Cold rolled steel works well for furniture, cabinets, and car parts.

You can cut and weld it easily, but take care not to overwork it.

The smooth surface helps you get a clean look for your project.

Tip: Choose cold rolled steel when you want easy fabrication and a polished finish.

Application Suitability

Galvanized Steel Applications

Galvanized steel is used in many outdoor jobs. The zinc coating keeps the steel from rusting. It works well in places with rain or lots of moisture. If you need something that lasts outside, galvanized steel is a good pick.

Here are common ways people use galvanized steel in building:

Roofing and cladding

Structural parts

Framing and studs

Fencing and gates

Ductwork and HVAC systems

Floor decking

Purlins and girts

Rainwater systems

Bridge parts

Solar panel mounts

You can also use galvanized steel for guardrails and outdoor stairs. It works for farm tools too. The zinc layer helps the steel stay safe from rust, even in tough places. If your project faces rain or wet weather, galvanized steel coil is the best choice.

Note: Galvanized steel is not great for marine jobs. Saltwater can wear away the zinc coating after a while. For boats or docks, stainless steel (like SS316) is better. It fights rust in harsh marine places.

Cold Rolled Steel Applications

Cold rolled steel has a smooth surface and exact shape. You see it used in jobs where looks and tight sizes matter. If you want to make furniture, car parts, or appliances, cold rolled steel helps you get a clean look.

In cars, cold rolled steel is used for:

Body panels and frames: These need to be strong and light.

Chassis and suspension parts: Cold rolled steel helps absorb shocks.

Transmission parts: The steel handles stress and moves power.

For furniture, cold rolled steel is a top choice. You get a smooth finish and strong pieces. The sizes are exact, so it is easy to build tables, chairs, and cabinets.

Smooth surface finish

Extra strength

Exact sizes

You can also use cold rolled steel for shelves, lockers, and home appliances. If you do a DIY project inside, cold rolled steel looks nice and is easy to shape or weld.

Tip: Pick cold rolled steel for projects that need a smooth look and exact sizes, especially for indoor use.

Comparing Performance in DIY Projects

You might ask which steel coil is better for your DIY job. The answer depends on what you need. Here is a table that shows how the two types work for different uses:

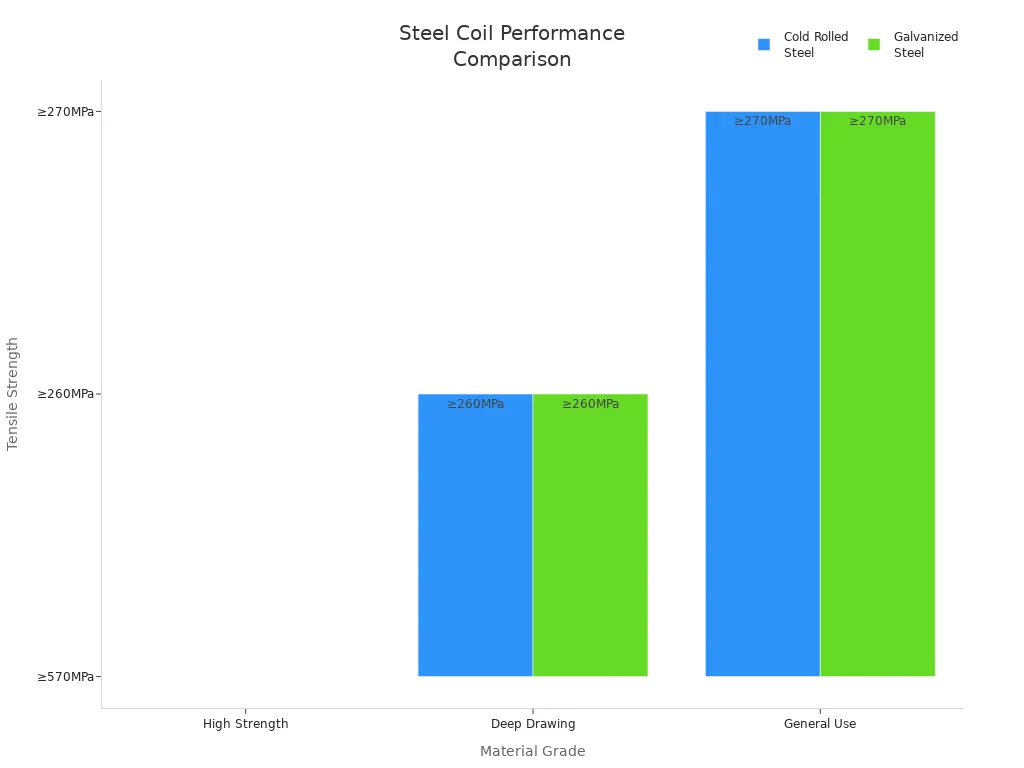

Material Grades | Cold Rolled Steel | Hot Dipped Galvanized Steel | Mechanical Properties |

High Strength | G550 | G550 | Tensile strength ≥570MPa Yield strength ≥550MPa |

Deep Drawing | SPCESPCEN | SGCE/DX52D/53D | Tensile strength≥260MPa Yield strength: 180-260MPa Elongation: 36-38% |

General Use | SPCC | SGCC/DX51D | Tensile strength ≥270MPa Yield strength ≥280MPa Elongation: 22-36% |

Remember: Use galvanized steel for outdoor building. Use cold rolled steel for indoor furniture, car parts, and appliances.

You should choose galvanized steel coil for outdoor projects that need strong rust protection and long life. Cold rolled steel coil works best for indoor jobs where you want a smooth, clean look. When you pick a steel coil, think about these factors:

Grade: Different grades offer more or less strength and corrosion resistance.

Thickness: Thicker coils last longer but may be harder to shape.

Finish: Pick polished, brushed, or matte to match your needs.

Application: Make sure the coil type fits your project.

Galvalume steel coil lasts even longer than regular galvanized steel and looks more attractive, though it costs more at first. Many builders now prefer galvanized steel for its eco-friendly qualities and use it in cars and renewable energy projects. For the best results, talk with a supplier or expert before you decide.

FAQ

What is the main difference between galvanized steel coil and cold rolled steel coil?

Galvanized steel coil has a zinc coating that protects it from rust. Cold rolled steel coil has a smooth surface and precise shape. You should pick galvanized steel for outdoor use and cold rolled steel for indoor projects.

Can you paint galvanized steel coil?

You can paint galvanized steel coil. Use a special primer first. This helps the paint stick to the zinc coating. Always clean the surface before you start painting.

Which steel coil is better for furniture?

Cold rolled steel coil works best for furniture. You get a smooth finish and sharp edges. The surface looks clean and is easy to paint or coat.

Is galvanized steel coil safe to weld?

You can weld galvanized steel coil, but you must take safety steps. The zinc coating releases fumes when heated. Always use good ventilation and wear a mask to protect yourself.