Product Description

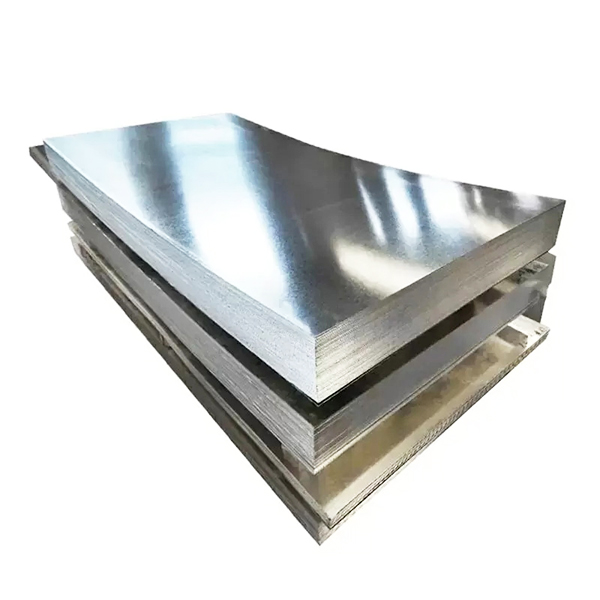

Our Hot Rolled Galvanized Plate is designed for demanding industrial and structural applications where strength and longevity matter most. Manufactured under JIS S335J2 and other international standards, these plates are hot-rolled for robustness and then zinc-coated through advanced galvanizing processes to ensure long-lasting corrosion resistance.

The surface carries a clean metallic sheen, sometimes with a delicate crystallized pattern known as spangle, giving the plate both aesthetic value and protective qualities. Unlike ordinary steel sheets, this product combines the toughness of hot rolling with the reliability of a zinc barrier, ensuring that even in humid, coastal, or chemically aggressive environments, the steel remains protected.

Engineers, contractors, and fabricators trust this material for projects where failure is not an option—from skyscraper frameworks to heavy equipment bases. Its durability translates to lower maintenance, fewer replacements, and ultimately, long-term cost savings.

Product Parameters

| Product Name | Galvanized steel sheet |

| Grade

| SGSS/SGCD1/SGCD2/SGCD3/SGC340,400,440,490,570/

CS TypeA,B,C/FS TypeA/FS TypeB/DDS TypeA,C/EDDS/DX51D+Z |

|

|

| Zinc Coating

| 30-275g/m2,double side |

|

|

|

|

| Thickness | 0.12mm-4.0mm, all available |

| Width

| 500mm,1000mm,1200mm,1219mm,1250mm,1220mm, 1500mm, 2000mm.Or According To Customer's Requirement |

| Length

| 1000mm,3000mm,6000mm,12000mmm.Or According To Customer's Requirement |

| Spangle

| Big spangle, normal spangle, small spangle, non-spangle |

| Technology

| Hot Dipped |

Key Features and Highlights

Exceptional Strength – Hot rolled for superior load-bearing capacity in demanding structural work.

Corrosion Protection – Zinc coating (40–275 g/m²) provides a long-lasting shield against rust.

Versatile Applications – Suitable for construction, automotive, bridges, shipbuilding, and industrial machinery.

Customizable Dimensions – Available in widths up to 2000 mm and cut-to-length options.

Surface Options – Zero or regular spangle, with chromated or oiled finishes to suit project needs.

Easy Fabrication – Can be welded, cut, and shaped without compromising protective coating.

Standards Compliance – Manufactured according to JIS S335J2, ASTM, and EN specifications.

Applications

Construction & Infrastructure: Used in beams, columns, and reinforcement plates for commercial and residential buildings.

Bridges & Transportation: Provides the load-bearing strength needed in bridges and highways.

Automotive & Heavy Equipment: Suitable for chassis, frames, and protective panels.

Shipbuilding: Withstands marine environments thanks to its corrosion-resistant galvanized coating.

Machinery & Industrial Fabrication: Ensures equipment longevity even under high wear conditions.

Advantages of Hot Rolled Galvanized Plate

Longer Service Life – Reduced risk of rust and premature failure in harsh conditions.

Lower Maintenance Costs – Zinc coating minimizes repair and repaint cycles.

Enhanced Safety – Strong structural integrity ensures stability in critical applications.

Aesthetic Appeal – Uniform surface finish enhances appearance in exposed structures.

Sustainability – Fully recyclable steel with eco-friendly protective coating.

Why Choose Us

Proven Manufacturing Expertise – Years of experience in steel processing and galvanization.

International Certifications – Compliance with JIS, ASTM, and EN standards.

Strict Quality Control – Every plate undergoes rigorous inspection for thickness, coating, and surface quality.

Global Supply Capability – Reliable export services to over 80 countries.

Flexible Customization – Dimensions, coatings, and finishes tailored to customer needs.

B2B-Focused Service – Dedicated support for contractors, fabricators, and distributors.

FAQ

Q1: What is the minimum order quantity (MOQ)?

A1: Typically 25 MT per size, but flexible depending on order mix.

Q2: Can you provide samples?

A2: Yes, small samples are available free of charge; shipping costs are covered by the buyer.

Q3: How do you ensure consistent quality?

A3: Each batch is tested for coating weight, mechanical properties, and dimensional accuracy before shipment.

Q4: What surface finishes are available?

A4: Regular or zero spangle, chromated, oiled, or dry finish options.

Q5: Do you accept OEM/ODM orders?

A5: Yes, custom branding, packaging, and specifications are supported.

Q6: What is your delivery time?

A6: Normally 15–25 days after receiving the deposit, depending on order volume.