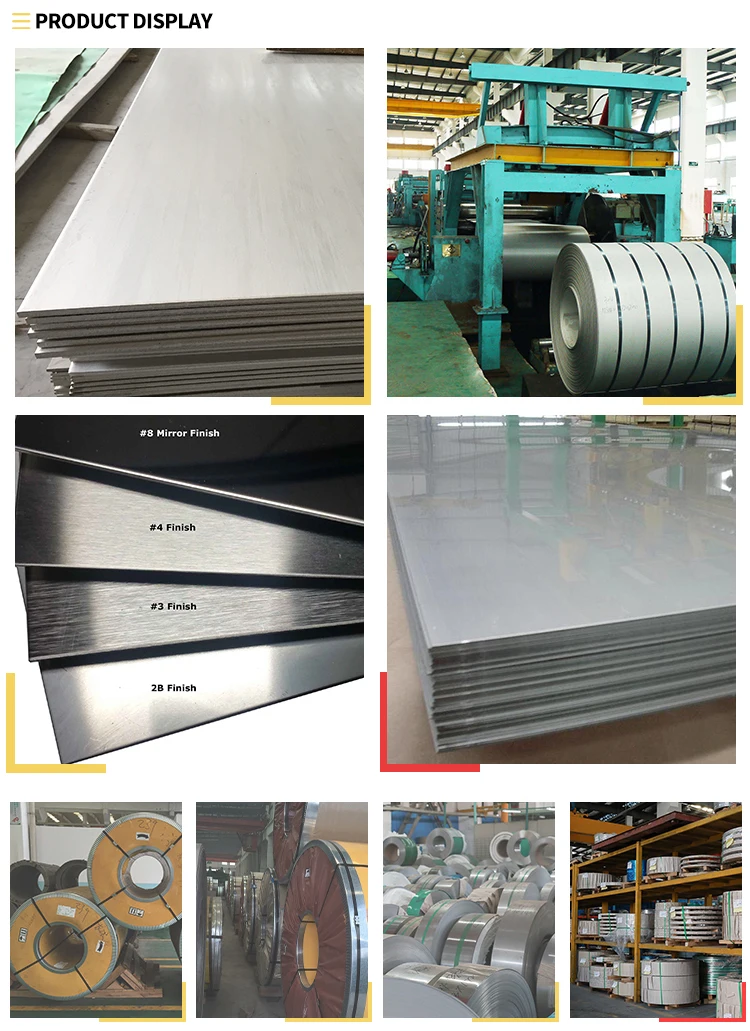

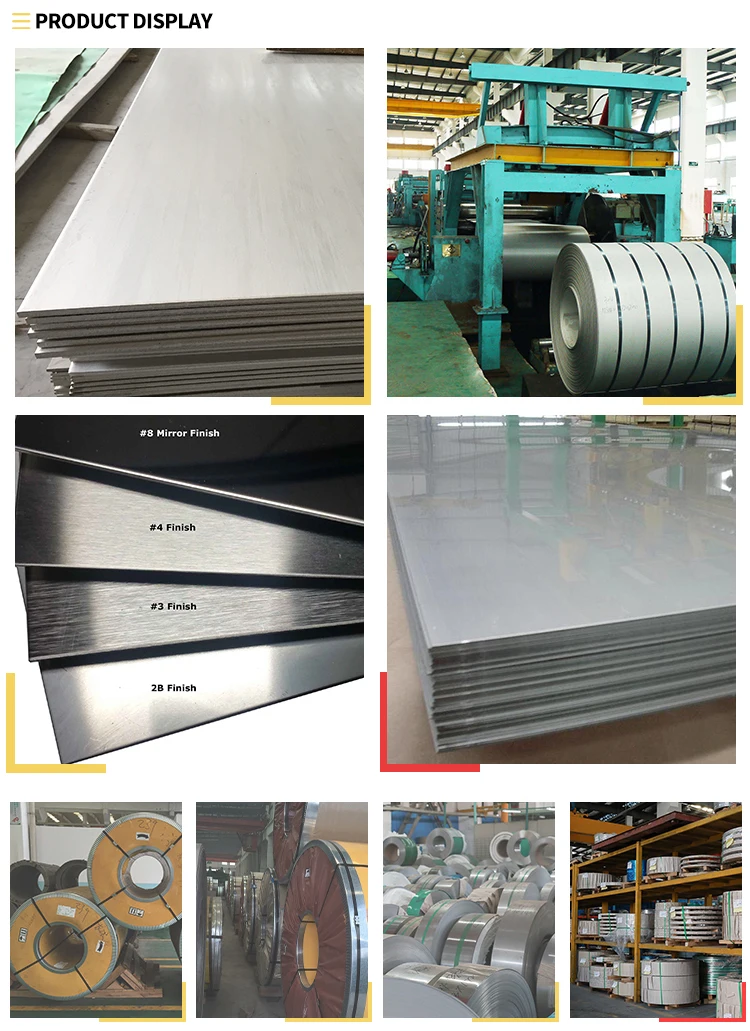

Product Description

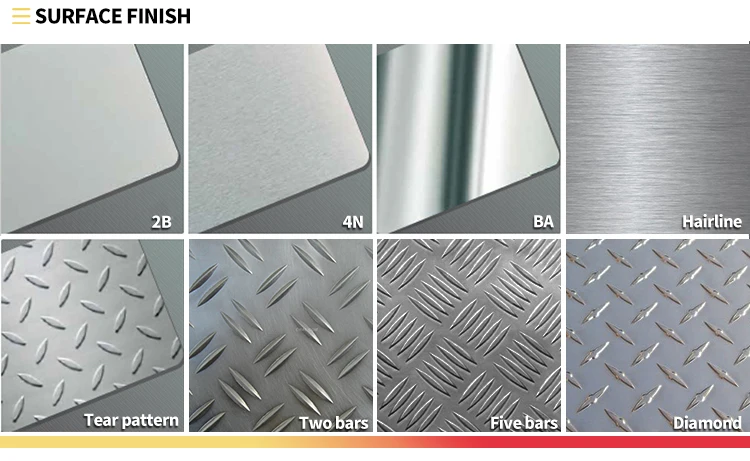

The Stainless Steel Coil Sheet is a premium corrosion-resistant material manufactured from austenitic, ferritic, or martensitic alloys, with common grades including 304 (18Cr-8Ni), 316 (16Cr-10Ni-2Mo), and 430 (17Cr). Produced via cold-rolling for precision thickness (0.3-3.0mm) and hot-rolling for thicker plates (4.0-20mm), the coil features a mill finish (2B: smooth, reflective) or surface treatments like BA (bright annealed), No.4 (brushed), or embossed textures. Meeting standards such as ASTM A240 and EN 10088, it offers excellent resistance to acids, alkalis, and chloride environments, with mechanical properties ranging from yield strength 205MPa (304) to 415MPa (316H).

Features

Exceptional Corrosion Resistance: Chromium-rich oxide layer (≥10.5% Cr) provides passive protection against rust, with 316 grade resisting chloride pitting in marine environments.

High Temperature Performance: Maintains strength from -200°C to 800°C (304 grade), making it suitable for cryogenic storage and high-temperature furnaces.

Hygienic & Non-Reactive: Smooth surface resists bacterial growth and chemical contamination, ideal for food, pharmaceutical, and medical applications.

Design Versatility: Available in polished, brushed, or colored finishes (via PVD coating), combining functionality with aesthetic appeal in architectural projects.

Long Lifecycle: Requires minimal maintenance, with a service life exceeding 50 years in most environments, reducing total cost of ownership.

Application

Food & Beverage Industry: Used for processing equipment, storage tanks, and conveyor belts, complying with FDA and 3A sanitary standards.

Medical Equipment: Manufactures surgical instruments, hospital furniture, and sterilization trays, ensuring biocompatibility and easy cleaning.

Architectural Facades: Ideal for curtain walls, canopies, and decorative panels in high-end buildings, offering corrosion resistance and modern aesthetics.

Chemical Processing: Suitable for reactor vessels, pipelines, and heat exchangers in petrochemical plants, resisting harsh chemical corrosion (316 grade).

FAQ

Q: What's the difference between 304 and 316 stainless steel?

A: 316 contains molybdenum, providing superior resistance to chlorides and pitting, making it ideal for marine or saltwater applications.

Q: Can stainless steel coils be welded without discoloration?

A: Use TIG welding with argon shielding and post-weld passivation to remove heat-tinted (blue) areas and restore corrosion resistance.

Q: How do I clean a brushed stainless steel surface?

A: Wipe with a soft cloth and neutral detergent; avoid abrasive pads that may scratch the surface.

Q: Is stainless steel magnetic?

A: Austenitic grades (304, 316) are non-magnetic, while ferritic/martensitic grades (430, 410) are magnetic.