Understanding Zinc Coated Steel Coils

Zinc coated steel coils are among the most widely used materials in construction, manufacturing, infrastructure, and consumer goods because of their impressive resistance to corrosion and long-term durability. These coils consist of high-quality steel sheets coated with a protective layer of zinc through a controlled hot-dip process or electro-galvanizing method. This zinc coating acts as a barrier against moisture, chemicals, and environmental oxidation, making zinc coated steel coils suitable for both indoor and outdoor applications.

As industries gradually shift toward more sustainable, long-lasting materials, zinc coated steel coils have gained strong market attention. In addition to protection, the zinc layer also offers enhanced aesthetics, making these coils essential for roofing, cladding, appliances, storage systems, and many other products.

Why Zinc Is Used for Steel Protection

The Science Behind Zinc’s Anti-Corrosion Behavior

Zinc offers sacrificial protection, which means it corrodes before the underlying steel does. This provides two critical benefits:

Barrier Protection: The zinc layer shields steel from exposure to air and moisture.

Cathodic Protection: If the coating is damaged, exposed steel is still protected by nearby zinc.

This dual mechanism significantly improves steel’s corrosion resistance and lifespan, especially in humid, industrial, or coastal environments.

Hot-Dip vs. Electro-Galvanized Zinc Coated Steel Coils

Both processes produce durable zinc coated steel coils, but each serves different needs:

Hot-Dip Galvanizing:

Produces a thicker zinc layer that offers stronger corrosion protection. Common for construction materials and outdoor usage.

Electro-Galvanizing:

Coating is thinner and more uniform. Ideal for automotive panels and electronics requiring excellent surface finish.

Key Properties of Zinc Coated Steel Coils

Enhanced Durability

The zinc layer extends the service life of steel significantly. Depending on the coating thickness and environmental conditions, zinc coated steel coils can last 20–70 years with minimal maintenance.

Excellent Versatility

These coils are compatible with stamping, bending, cutting, and welding processes. As a result, they are adaptable across multiple industries.

Cost-Efficiency

Compared with stainless steel or aluminum, zinc coated steel coils provide high performance at lower cost, making them one of the most economical anti-corrosion solutions.

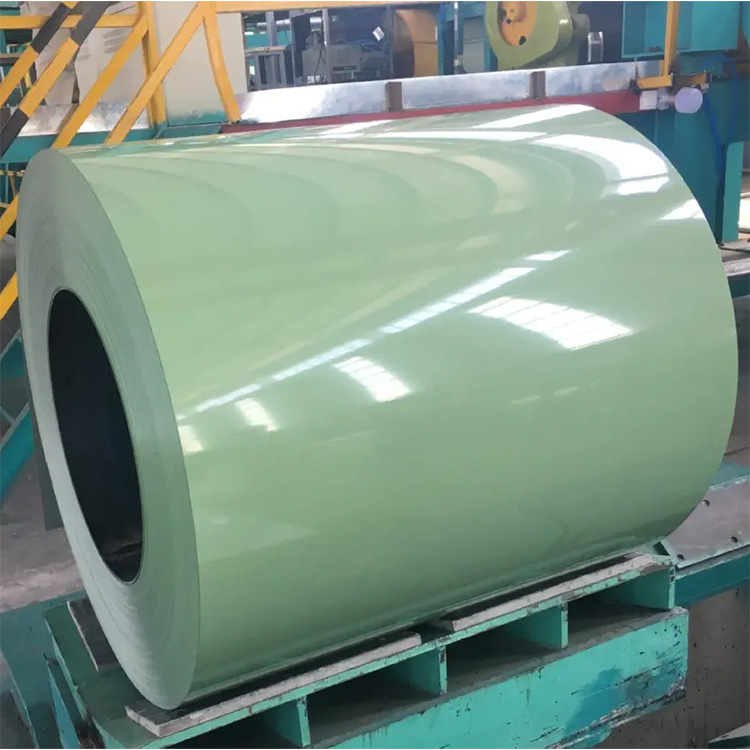

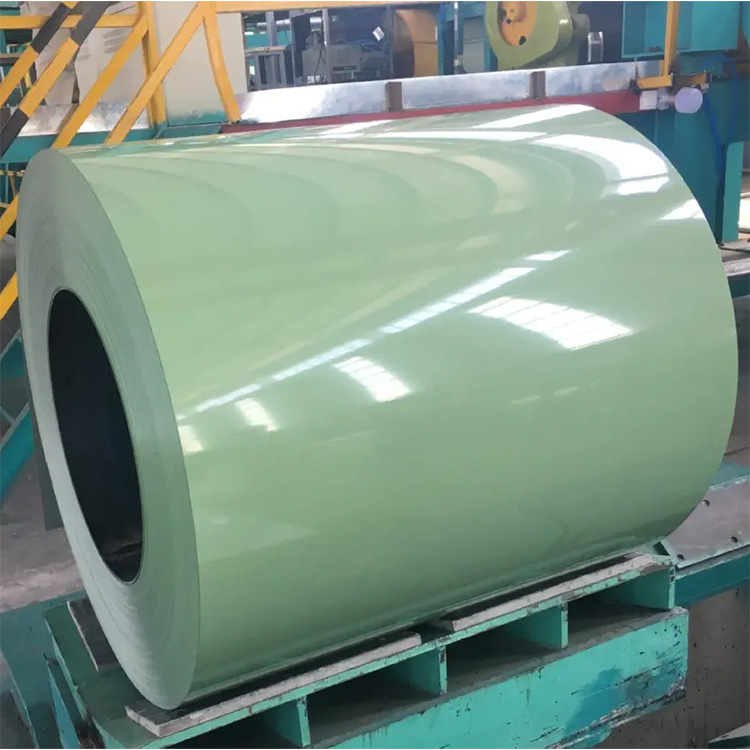

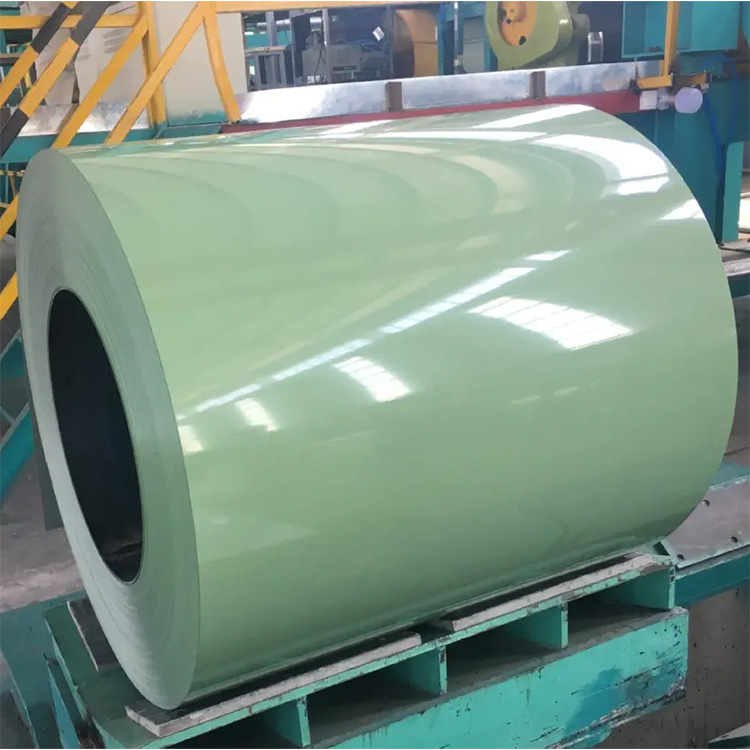

Aesthetic Benefits

Zinc coated steel coils can be further processed into color-coated products (PPGI/PPGL), textured finishes, or patterned materials to suit architectural and industrial design needs.

Why Zinc Coated Steel Coils Are in High Demand

1. Growing Infrastructure Projects Worldwide

Urbanization, transportation development, and large-scale construction have accelerated demand for corrosion-resistant building materials. Zinc coated steel coils are widely used in:

roofing and wall systems

highway guardrails

steel framing

bridges and tunnels

industrial plants

Their longevity helps reduce maintenance costs and enhances the reliability of infrastructure.

2. Expansion of Manufacturing and Automotive Applications

Manufacturers increasingly rely on zinc coated steel coils for components that must withstand friction, humidity, and environmental exposure. Automotive factories use zinc coated steel for:

body panels

chassis parts

reinforcement components

This ensures better corrosion resistance and longer vehicle lifespan.

3. Renewable Energy and Green Construction

As global industries shift toward eco-friendly materials, zinc coated steel coils meet the demand for recyclable, energy-efficient, and durable building components. Solar panel frames, wind turbine components, and green building systems often incorporate zinc coated steel.

4. Cost Advantages Compared with Other Materials

By combining the strength of steel with the corrosion resistance of zinc, these coils offer a cost-effective balance of durability and affordability. This makes them the preferred choice for budget-sensitive construction or industrial projects.

5. Versatility Across Industries

Demand is rising in sectors such as:

household appliances

agricultural facilities

HVAC systems

electrical equipment

storage tanks

marine environments

The adaptability of zinc coated steel coils contributes significantly to their global popularity.

Applications of Zinc Coated Steel Coils

Construction and Architecture

Architects favor zinc coated steel coils for roofs, façades, structural supports, and external cladding due to their visual appeal and weather resistance.

Home Appliance Manufacturing

Washing machines, refrigerators, ovens, and ventilation systems often incorporate zinc coated steel because it withstands moisture and heat.

Transportation and Logistics

Shipping containers, cargo vehicles, and railway components rely on corrosion-resistant materials to maintain structural integrity during long-term use.

Agricultural Equipment

Greenhouses, barns, fencing systems, and storage silos benefit from zinc coated steel coils because they perform well in humid or chemically active environments.

Factors Influencing the Growth of the Zinc Coated Steel Coil Market

Rising Safety and Quality Standards

Governments worldwide are enforcing stricter regulations on building materials. Zinc coated steel coils meet international corrosion-resistance standards, promoting wider adoption.

Technological Improvements in Coating Lines

Modern coating facilities produce:

These advancements boost product reliability and expand market usage.

Supply Chain Expansion

With Asia—especially China—being the world’s largest steel production hub, global availability of zinc coated steel coils continues to increase, ensuring stable supply and competitive pricing.

Growth of Pre-Painted Steel

The rising popularity of PPGI/PPGL products also drives base-material demand, as zinc coated steel coils serve as the substrate for most color-coated steel.

Future Market Outlook

The zinc coated steel coil market is expected to grow steadily over the next decade, driven by:

sustained demand from construction and automotive sectors

increasing need for long-life, low-maintenance materials

global push for sustainability and recyclable metals

development of new zinc-aluminum-magnesium coatings

Emerging markets in Africa, Southeast Asia, and Latin America are projected to experience the fastest consumption growth, fueled by large infrastructure projects and industrial upgrades.

Why High-Quality Coating Matters

Coating Thickness

A thicker zinc coating offers stronger corrosion resistance. Buyers typically evaluate coating weight (e.g., Z60, Z120, Z275) before selecting a material.

Surface Uniformity

A smooth, consistent surface reduces issues during painting, forming, or assembly.

Mechanical Properties

Strength, elongation, and processing suitability impact how easily the steel can be fabricated into final products.

Choosing certified, high-quality zinc coated steel coils is essential for long-term performance and safety.

Why Choose Our Zinc Coated Steel Coils

As a professional supplier of galvanized and zinc coated steel materials, Shandong Sino Steel Co.,Ltd provides products manufactured with advanced coating lines and strict quality control. Our coils feature stable zinc-layer thickness, excellent corrosion resistance, and consistent surface quality suitable for construction, industrial manufacturing, household appliances, and infrastructure projects. With strong production capacity, customized specifications, and reliable export services, we deliver durable and high-value metal solutions for customers worldwide.

FAQs

1. What makes zinc coated steel coils different from regular steel coils?

They include a protective zinc layer that prevents corrosion, significantly extending steel’s lifespan.

2. Are zinc coated steel coils suitable for coastal environments?

Yes. The zinc layer resists moisture, salt spray, and oxidation, making the coils ideal for coastal structures.

3. What coating thickness should I choose?

It depends on usage. Heavy-duty outdoor applications typically use Z180–Z275. Indoor or light industrial use may require thinner coatings.

4. Can zinc coated steel coils be painted or color-coated?

Absolutely. They are commonly used as substrates for PPGI and PPGL coils.

5. How long do zinc coated steel coils last?

Depending on coating weight and environmental exposure, service life can range from 20 to over 70 years.