Wɔde galvanized steel coils di dwuma kɛse wɔ adansi, kar, ne mfiri a wɔyɛ mu esiane sɛ ɛyɛ den na ne bo yɛ den nti.

Yɛn nneɛma no wɔ zinc coating a wɔde di dwuma denam hot-dip galvanizing so, a ɛyɛ kyɛm a ɛbɔ ho ban fi nsu ne nneɛma afoforo a ɛyɛ mmerɛw ho. Sɛ mpo galvanized steel coil no so ade a wɔde kata so no twetwe a, zinc no di kan sɛe, na ɛbɔ dade a ɛwɔ ase no ho ban. Ebia wubebisa sɛ, so galvanized steel rust? Mmuae no yɛ yiw, nanso ɛba nkakrankakra yiye. Dade a wɔde galvanized ayɛ no nkwa nna gyina nneɛma te sɛ nneɛma a atwa yɛn ho ahyia, nea ɛkata so kɛse, ne sɛnea wosiesie so.

Afotu: Bere nyinaa hwɛ dade a wɔde galvanized ayɛ foforo no mu hwɛ sɛ biribiara asɛe anaa. Ɛnyɛ sɛ wo galvanized steel coil no sohwɛ a ɛfata no ma ɛyɛ fɛ yiye nko, na mmom ɛtrɛw wo nnwuma a ɛbɛtra hɔ akyɛ no mu . Yɛn adwumakuw no ..

Key Takeaways .

galvanized steel coils no ntumi nsɛe ntɛmntɛm. Eyi te saa efisɛ wɔwɔ zinc coating. zinc no yɛ adwuma te sɛ kyɛm na ɛma dade no yɛ nea ahobammɔ wom. Zinc layer no siw nsu ano ma ɛka .

dade no. Sɛ ade a wɔde kata so no yɛ mmerɛw a, zinc no da so ara boa ma rust gyae. Eyi ma coil no kyɛ. Nneɛma te sɛ nkyene mframa, efĩ, ne wim tebea a ɛyɛ nsu ma nkannare sisi ntɛmntɛm. Enti, baabi a wode dade no bedi dwuma no ho hia bere tenten a ɛtra hɔ kyɛ. Mpɛn pii no, coil ahorow a wosiesie no boa wɔn ma wɔyɛ fɛ. Sɛ wohwɛ sɛ nneɛma asɛe na woasiesie no ntɛmntɛm a, ɛboa nso. Sɛ́ wobɛpaw zinc a wɔde kata so dodow a ɛfata no ho hia. Sɛ wɔde coils no sie ɔkwan pa so a, ɛma wonya ahobammɔ. Eyi boa wɔn ma wɔtra hɔ kyɛ.

So dade a wɔde galvanized ayɛ no yɛ rust?

Sɛ wubisa sɛ galvanized steel rusts a, wopɛ mmuae a ɛyɛ mmerɛw. Galvanized steel coil no gyina corrosion no ano yiye, nanso ɛda so ara tumi yɛ rust. Zinc a wɔde kata so no yɛ adwuma te sɛ kyɛm na ɛma nkannare no brɛ ase. Bere kɔ so no, nneɛma te sɛ wim tebea ne nneɛma a ɛsɛe betumi asɛe saa kyɛm yi. Ɛho hia sɛ wuhu sɛnea galvanizing gyae rust ne nea wobɛhwɛ kwan afi galvanized coil pa mu wɔ mmeae ahorow.

Zinc a wɔde kata so ho banbɔ .

Zinc a wɔde kata galvanized coil so no yɛ akwanside wɔ dade ne mframa ntam. Saa akwanside yi ma nsu ne mframa pa ba, na ɛma ɛyɛ mmerɛw. Sɛ wopaw dade a wɔde zinc adura ho a, osu, nsu a ɛyɛ nwini, ne efĩ gyina hɔ ma. Hot-dip galvanizing bonds zinc to steel, enti ade a wɔde kata so no di mfe pii.

Nhwehwɛmu ahorow kyerɛ sɛ zinc coatings no nya nkɔso wɔ nneɛma titiriw a wɔde ka ho mu. Saa nneɛma a wɔde ka ho yi ma ade a wɔde kata so no yɛ den na eye wɔ nkannare a wosiw ano no mu. Sɛ nhwɛso no, sɛ wode ceria nanoparticles ne polyaniline ka ho a, ɛboa ma zinc bɔ dade ho ban fi nsu a ɛbɛporɔw ho. Nhwehwɛmu biako sɔɔ galvanized steel coil hwɛe wɔ po no ho mfe anum. Zinc a ɛyɛ den a wɔde kataa so no maa asiane a ɛwɔ hɔ sɛ wɔde rust kɔkɔɔ ne paint bɛpae no so tew, titiriw wɔ anoano. Zinc layer no yɛ films na egyae oxygen a ɛrenkɔ dade mu.

Wubetumi ahu sɛnea nneɛma a atwa yɛn ho ahyia no sesa bere tenten a galvanized coil kyɛ wɔ pon a ɛwɔ ase hɔ no so:

Atenaeɛ |

Bere a wɔtaa de yɛ rust . |

Nneɛma atitiriw a atwa yɛn ho ahyia . |

Nsiesiei ho nyansahyɛ ahorow . |

Abɔnten a ɛyɛ ɔkwan biara so . |

Mfe 20 kosi 50 . |

Mframa pa, efĩ a ɛba fam . |

Hwɛ coating thickness mfe 5 biara; Optional clear lacquer . |

mpoano beae . |

Mfe 5 kosi 15 . |

Nkyene a ɛdɔɔso wɔ mframa mu (nkyene a wɔde petepete so) . |

Hwɛ mprenu afe biara (fa w’adwene si welds/edges so); Ɛho tew wɔ asram abiɛsa biara mu . |

Mfiridwuma mu efĩ . |

Mfe 10 anaa nea ennu saa . |

Efĩ a ɛwɔ hɔ ntɛmntɛm . |

Wɔkamfo kyerɛ sɛ wɔnyɛ nhwehwɛmu na wosiesie . |

Hyɛ no nsow: Wo galvanized coil a wobɛhohoro mu na woahwɛ no taa betumi ama akyɛ. Sɛ woanhwɛ so a, nkannare bɛba ntɛmntɛm, titiriw wɔ mmeae a emu yɛ den.

Dade a wɔde galvanized ayɛ no betumi adi mfe 20 kosi 50 anaa nea ɛboro saa wɔ abɔnten wɔ tebea horow a ɛfata mu. Wɔ mpoano anaa mfiridwuma mu no, ɛnyɛ bere tenten esiane nkyene ne nnuru nti. Quality ne coating thickness ho hia. Zinc a ɛyɛ den a wɔde kata so no bɔ ho ban yiye na ɛtra hɔ kyɛ.

Wɔ mmeae a ɛhɔ yɛ mmerɛw wɔ abɔnten no, dade a wɔde galvanized ayɛ no tumi di bɛboro mfe 50 ansa na ayɛ rust.

Wɔ mmeae a ɛyɛ den te sɛ mpoano anaa mfiridwuma mu no, ebetumi adi mfe 20 anaa nea ennu saa.

galvanized steel tumi di mfe 50-100 wɔ mmeae a ɛfata.

Wɔ po so anaa mfiridwuma mu no, ɛkyɛ mfe 20-50 bere a wɔhwɛ wɔn no.

Zinc coating ma akwanside ne afɔrebɔ ahobammɔ nyinaa fi nkannare ho.

Nnuru, nsu, nneɛma a ɛsɛe, ne nsu a ɛyɛ hyew kɛse ma ɛyɛ mmerɛw ntɛmntɛm.

Dade a wɔde galvanized ayɛ no taa di mfe 25 kosi 50.

Wɔ mmeae a ɛnyɛ den pii no, ebetumi adi mfe 75.

Zinc a ɛyɛ den a wɔde kata so no bɔ ho ban kyɛ.

Nsiesiei ne nneɛma foforo a wɔde kata so boa ma ɛtra hɔ kyɛ.

GI coils tumi di mfe 20 kosi 50 anaa nea ɛboro saa wɔ mmeae a ɛfata, a ɛnyɛ nea ɛyɛ mmerɛw.

Ɔhwɛ ne nneɛma a wɔde kata so daa no ma ɛtra hɔ kyɛ.

Afɔrebɔ ho banbɔ ho nhyehyɛe .

Ebia wubesusuw nea enti a galvanized coil bɔ dade ho ban yiye saa no ho. Nea enti a ɛte saa ne ɔkwan a wɔfa so bɔ afɔre wɔ afɔrebɔ ho no. Zinc nyɛ ade a ɛkorɔn sen dade, enti edi kan yɛ nwunu. Sɛ zinc a wɔde kata so no yɛ mmerɛw a, zinc no mu nneɛma nketenkete yɛ adwuma sɛ afɔrebɔ anode. Wɔma dade ma ɛlɛtrɔnik na esiw dade ano na ama ayɛ mmerɛw. Wɔfrɛ eyi cathodic ahobammɔ.

Sɛ zinc yɛ nwunu a, ɛma zinc oxide ne hydroxycarbonate nkyene. Eyinom yɛ sini a ɛyɛ den a ɛsa ne ho yare wɔ dade so. Saa sini yi siw nsu ne mframa pa ano, na ɛma ahobammɔ kɛse. Zinc a wɔde kata so no nyɛ akwanside ara kwa. Ɛsan nso yɛ nnuru kyɛm a ɛkyere nneɛma a ɛma nkekae ba na ɛma nsu a ɛyɛ mmerɛw no brɛ ase.

Wɔ ɔkwan ketewaa bi so no, zinc oxide boa ma ɛlɛtrɔnik kɔ zinc ne dade ano. Eyi boa nneyɛe a ɛma dade yɛ nea ahobammɔ wom. Bere a zinc layer no resɛe no, ahobammɔ sesa fi cathodic kɔ akwanside so. Saa afrafra a ɛyɛ afɔrebɔ adeyɛ ne akwanside nsunsuanso ma galvanized coil strong corrosion resistance ne nkwa tenten.

Afotu: Paw galvanized coil a ɛwɔ zinc a ɛyɛ den, mpo a wɔde kata so na ama woanya ahobammɔ a eye sen biara. Hwɛ wo coil no mpɛn pii sɛ nsensanee anaasɛ asɛe na ama afɔrebɔ ho banbɔ akɔ so ayɛ adwuma anaa.

Nneɛma a ɛde nkannare ba wɔ galvanized steel coil so .

Nneɛma a atwa yɛn ho ahyia .

Sɛ wode galvanized coil di dwuma wɔ abɔnten a, wim tebea ho hia kɛse. Sɛ mframa no yɛ nwini paa a, nsu tumi tra coil no so. Saa nsu yi boa ma nkannare yɛ ntɛmntɛm. Nkyene a efi po anaa nsu a nkyene wom mu no betumi apira zinc no. Eyi ma rust da adi ntɛm. Efĩ a ɛwɔ mframa mu, te sɛ sulfur dioxide ne nitrogen oxides no ne nsu fra. Eyinom frafra ma ɛyɛ acid a ɛpaapae zinc no mu. Acid osu a ɛtɔ wɔ nkurow akɛse mu nso pira ahobammɔ a ɛwɔ hɔ no. Nsɔe ne lichen tumi nyin wɔ coil no so. Wokura nsu a ɛbɛn dade no na wɔyɛ mmeae nketenkete a ɛyɛ nsu. Saa mmeae yi boa ma rust fi ase.

Nneɛma a ɛtaa ma rust ba galvanized coil so no ni:

Nsuo a ɛyɛ nwini a ɛkorɔn (ɛboro 60%) .

Nkyene a ɛwɔ mframa anaa nsu mu (mpoano mmeae) .

Nsu a ɛtaa yɛ nsu anaasɛ ɛma ɛyɛ nwini .

Sulfur dioxide a ɛyɛ fĩ .

Hydrogen sulfide a wɔde di dwuma .

Nkitahodi a ɛda alkali a ano yɛ den di nkitaho (cement, plaster) .

Acid osu a ɛtɔ gu fam .

Nsɔe ne lichen nyin .

Nea ɛde ba/tebea . |

Nkyerɛmu |

Nneɛma a atwa yɛn ho ahyia a ɛhɔ yɛ nwini na ɛyɛ mmerɛw . |

Electrochemical corrosion, rust fitaa esiane nsu ne mframa a ɛsen yiye nti . |

Zinc carbonate a ɛpaapae . |

Nsu a ɛtɔ bere tenten no ma ano aduru a ɛporɔw ma ɛyɛ yiye . |

Mmeae a ɛyɛ fitaa a ɛyɛ fitaa a emu yɛ den . |

Zinc layer a wɔde di dwuma, dade a ɛda adi . |

Nnuru a ɛma nipadua no yɛ adwuma . |

Nsu, oxygen, CO2, ne oxide ahorow no ma anyinam ahoɔden a ɛyɛ mmerɛw sɛ ɛbɛhyew . |

Afotu: Sɛ wote bɛn po no anaa kurow bi mu a, hwɛ wo galvanized coil no mu mpɛn pii. Saa mmeae yi ma nkannare si ntɛmntɛm na ɛma wo coil no nkwa yɛ tiaa.

honam fam nneɛma a wɔsɛe no .

Nipadua mu ɔsɛe yɛ ade kɛse foforo nti a ɛyɛ rust wɔ galvanized coil so. Scratches, marks, anaasɛ rough moving betumi abubu zinc coating no. Sɛ wuhu sɛ biribi ayɛ mmerɛw a, dade a ɛwɔ ase no bue ma mframa ne nsu. Zinc betumi abɔ nsensanee nketenkete ho ban, nanso ɛnyɛ akɛse. Sɛ scratch kɛse bi wɔ hɔ anaasɛ ɛsɛe wɔ baabi a ɛyɛ den a, ɛsɛ sɛ wusiesie. Eyi mma coil no ntumi nsɛe ntɛmntɛm. Ɛsɛ sɛ wohwehwɛ nneɛma a asɛe bere a wode coil no ahyɛ mu ne bere a woreyɛ check no akyi. Nnua nketenkete mpo betumi ama nsu akɔ mu na afi ase ayɛ nwunu.

Hyɛ no nsow: Yɛ brɛoo wɔ galvanized steel coil ho bere a worekɔ anaa wode ahyɛ mu no. Fa ahama a ɛyɛ mmerɛw di dwuma na twetwe coil no na ɛmma nsensanee no nsiw.

Coating a ɛyɛ den .

Zinc coating no mu duru ho hia yiye ma rust a wogyina. Nneɛma a wɔde kata so a ɛyɛ den no yɛ kyɛm a ɛyɛ den na ɛtra hɔ kyɛ wɔ mmeae a ɛyɛ den. Nhwehwɛmu ahorow kyerɛ sɛ zinc a ɛyɛ den no ma zinc ions pii. Saa ions yi boa ma wɔbɔ anoano a wɔatwa ne mmeae a ɛyɛ mmerɛw ho ban. Zinc no yɛ adwuma sɛ kyɛm na ɛma nkannare a ɛwɔ dade no so no brɛ ase.

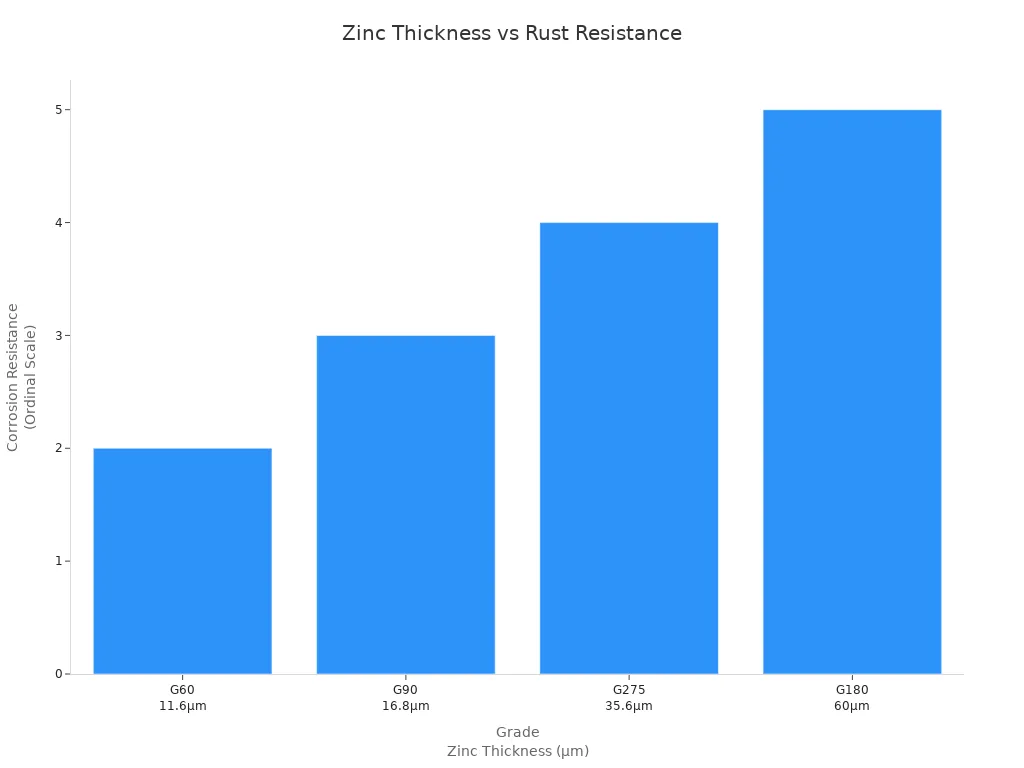

Aba |

bɛyɛ sɛ zinc a wɔde kata so no mu duru (μm) . |

Nneɛma a ɛko tia corrosion level . |

Application tebea a ɛtaa ba . |

G60. |

11.6 |

Kakra |

Nneɛma a atwa yɛn ho ahyia a ɛyɛ mmerɛw kakra . |

G90 . |

16.8 |

Papa |

Ɔdan ne ɔdan atifi dodow no ara . |

G180 . |

60 |

Ɛkorɔn paa . |

Nneɛma a atwa yɛn ho ahyia a ɛyɛ mmerɛw kɛse . |

G275 na ɛwɔ hɔ. |

35.6 |

Soro |

Nneɛma a atwa yɛn ho ahyia a emu yɛ den . |

Paw zinc coating thickness a ɛfata wo project no ne baabi a wode bedi dwuma. Nneɛma a wɔde kata so a ɛyɛ den no bo yɛ den, nanso ɛbɔ ho ban yiye na ɛtra hɔ kyɛ.

Galvanized coil a wɔde siesie .

Wo galvanized coil a wobɛhwɛ so no ne ɔkwan a eye sen biara a wobɛfa so asiw galvanized steel ano na ama ne su akɔ soro. Anamɔn a ɛyɛ mmerɛw te sɛ ahotew, nhwehwɛmu, ne nsiesie betumi aboa wo ma woanya sika a wode asie no so mfaso kɛse. Nsiesiei a wɔyɛ no daa no nso ma wunya sika denam kwati a wobɛkwati sɛ wode nneɛma a ɛho ka yɛ den besi ananmu no so.

Ahotew a wɔyɛ no daa .

Ɛsɛ sɛ wosiesie wo galvanized coil no anyɛ yiye koraa no pɛnkoro afe biara. Wɔ mpoano anaa mfiridwuma mu no, tew ho asram abiɛsa biara. Ahotew yi nkyene, mfutuma, ne osu a ɛyɛ asikre a aka a ebetumi ama zinc a wɔde kata so no ayɛ mmerɛw no fi hɔ. Fi ase fa akwan a ɛyɛ brɛoo so na sɛ ɛho hia a, fa nneɛma a ɛho tew nkutoo di dwuma.

Fa plastic bristle brɔs a ɛyɛ mmerɛw di dwuma de hohoro mu. Kwati dade brɔs a ebetumi atwetwe zinc a wɔde akata so no na ayɛ kɔla no.

Fa samina anaa kar hohoro nneɛma a ɛnyɛ den ne nsu a ɛnyɛ den pii hohoro ho.

Sɛ wopɛ nkekae a ɛnyɛ den a, fa afie mu ammonia a wɔde tew nneɛma ho di dwuma. Sɛ wopɛ nkannare anaa semɛnte a ɛwɔ hɔ a, fa oxalic acid di dwuma, afei hohoro mu yiye.

Fa nneɛma a ɛyɛ tratraa ne plastic anaa nnua a wɔde twitwiw nneɛma fi hɔ. Fa nneɛma a ɛnyɛ alkaline a wɔde yiyi nneɛma mu di dwuma ma aduru a ɛyɛ den.

Bere nyinaa hohoro coil no mu bere a woahohoro mu awie no na yi nkae biara a ɛho tew no afi hɔ.

Afotu: Sɔ ɔkwan foforo biara a wɔfa so siesie nneɛma no hwɛ wɔ beae ketewaa bi a ahintaw kan. Eyi boa ma wokwati sɛ wobɛsɛe zinc a wɔde kata so no.

Wo galvanized coil a wobɛhohoro ho daa no boa ma dade a wɔde galvanized ayɛ no ntumi nsɛe na ɛma ne soro no yɛ fɛ. Ɛsan nso bɔ zinc layer no ho ban, a ɛyɛ ade titiriw a ɛma bere tenten yɛ papa.

Nhwehwɛmu ne nsiesie .

Ɛsɛ sɛ wohwehwɛ wo galvanized coil no mu anyɛ yiye koraa no pɛnkoro afe biara. Wɔ mmeae a emu yɛ den no, hwɛ asram asia biara. Hwehwɛ nsɛnkyerɛnne a edi kan a ɛkyerɛ sɛ nkannare anaasɛ ade a wɔde kata so asɛe. Fa w’adwene si nsɛm atitiriw yi so:

Mmeae a ɛyɛ petee a nsu tumi boaboa ano.

edges ne welds, a ɛda adi sɛ ɛbɛsɛe.

nsensanee a wɔaka ho asɛm pɛn.

Mmeae a nkekae a ɛyɛ bruu anaasɛ nkannare fitaa wɔ hɔ.

mmeae a ɛda hɔ kwa a zinc coating no nni hɔ.

mpaapaemu ne ntwea so baabi a nsu ne efĩ betumi ayɛ kɛse.

Mmeae a coil no ka dade afoforo.

Fa magnetic thickness gauge di dwuma fa hwɛ sɛnea zinc no akata so. Sɛ wuhu nsensanee anaa mmeae nketenkete a ɛyɛ nwunu a, siesie no ntɛm ara:

Fa samina ne nsu a ɛyɛ mmerɛw hohoro baabi a ɛwɔ no.

Fa kɔbere wire brush anaa sandpaper a ɛyɛ fɛ yi rust fi hɔ.

Fa zinc-rich paint anaasɛ cold-spray zinc gu so na ama ahobammɔ asan aba.

Sɛ wopɛ sɛ wosiesie nneɛma akɛse a, fa urethane a wɔde nsu ayɛ anaasɛ vinyl a wɔde ayɛ aduru di dwuma.

Hyɛ no nsow: Ntɛmntɛm a wosiesie no ma rust no ntrɛw na ɛboa ma wo galvanized coil no yɛ papa.

Nnuru a emu yɛ den a wɔkwati .

Nnuru bi betumi asɛe zinc a wɔde kata so no na ayɛ mmerɛw ntɛmntɛm. Ɛsɛ sɛ wokwati:

Nnuadewa ne turo mu nnuru, a ebetumi atew zinc ahobammɔ so akodu 40%.

Acid a ano yɛ den ne alkaline cleaners, a ɛpaapae zinc layer no mu.

nkyene nsu ne nsu a ɛyɛ hyew kɛse, a ɛma nsu a ɛyɛ hyew no kɔ soro.

Acid osu ne mfiridwuma mu efĩ, a ɛma ade a wɔde kata so no gyae ntɛmntɛm.

Kɔbere anaa dade afoforo a ɛne no di nkitaho, a ebetumi ama galvanic corrosion aba.

Fa wo galvanized coil no sie baabi a ɛhɔ yɛ kusuu na mframa pa fa mu. Ma ɛntwe mfi nnuru ne dade afoforo ho. Sɛ ɛsɛ sɛ wode aduru a wɔde tew nneɛma ho di dwuma a, paw nea ahobammɔ wom ma zinc a wɔde kata so, te sɛ acetone anaa aguadi mu nneɛma a wɔasɔ ahwɛ sɛ ebia wɔde dade a wɔde ayɛ galvanized ayɛ.

Afotu: Nneɛma a wode sie yiye ne ahotew a wɔde ahwɛyiye yɛ no yɛ akwan a ɛyɛ mmerɛw a wobɛfa so abɔ wo galvanized coil no ho ban na ama ne nkwa nna atrɛw.

Ɛka a wɔbɔ wɔ nsiesie ho .

Ɛka a wosiesie no daa no ho ka sua koraa sen sɛ wɔde coil a ayɛ mmerɛw besi ananmu. Ahotew ne nneɛma nketenkete a wosiesie no ma zinc a wɔde kata so no yɛ den na esiw ɔhaw akɛse ano. Sɛ wuhuruw maintenance a, rust betumi asɛe coil no na ahyɛ wo ma woatɔ foforo. Sɛ wode bere ne sika kakra gu so wɔ ɔhwɛ a, ɛboa ma wokwati nneɛma a ne bo yɛ den a wode besi ananmu na ɛma wo galvanized steel coil no kɔ so yɛ adwuma mfe pii.

Nneɛma a atwa yɛn ho ahyia so nkɛntɛnso wɔ galvanized steel coil so .

Outdoor vs. mpoano mmeae ahorow .

Beae a wode galvanized coil di dwuma no ho hia kɛse. Wɔ ɔman anaa kurow mu mmeae no, galvanized coil di mfe pii. Ebia worenhu rust bɛboro mfe 70 wɔ mmeae yi. Eyi ba efisɛ mframa no ho tew na nsu kakraa bi na ɛwɔ mframa mu.

Nanso ɛbɛn po no, nneɛma yɛ soronko. Nkyene a ɛwɔ mframa mu no ma nkannare si ntɛmntɛm. Sɛ coil no hyia mframa a ɛyɛ nkyene a, rust betumi ada adi wɔ mfe 5 kosi 7 mu. Sɛ wɔbɔ coil no ho ban a, ebetumi adi mfe 15 kosi 25 ansa na Rust afi ase. Ɛsɛ sɛ wo ho tew na wohwɛ coils a ɛbɛn mpoano no mpɛn pii. Fa nsu pa hohoro wɔn ho asram kakraa biara na ama nkyene afi hɔ. Fa coatings foforo di dwuma sɛ wubetumi a. Anyɛ yiye koraa no, hwehwɛ nkannare anaasɛ nneɛma a asɛe no mprenu afe biara.

Nneɛma a atwa yɛn ho ahyia no su . |

Sɛ wɔkyekyem pɛpɛɛpɛ a, bere a wɔde yɛ rust a edi kan . |

Tebea titiriw ne nsɛm a wɔakyerɛw . |

Mpoano (a ɛwɔ akwansin 1 ntam, >250 ft fi mpoano) . |

Mfe 5-7 (a ɛda adi tẽẽ) . |

mframa a ɛyɛ nkyene/chloride a ɛwɔ mu no tẽẽ; Mmeae a wɔabɔ ho ban no di mfe 15-25 sen . |

Abɔnten (nkuraase, kurow no akyi, po so hyɛn a ɛyɛ hyew) . |

Mfe du du pii kosi bɛboro mfe 70 . |

Nea ɛka ho ne nkuraase ne nkurow nketewa mu mmeae a ɛhɔ yɛ hyew kɛse; Po mu nneɛma a atwa yɛn ho ahyia a ɛhɔ yɛ hyew ka ho . |

Afotuo: Sɛ wote bɛn po no a, wo ho tew na hwɛ wo coil no mpɛn pii. Eyi boa ma ɛtra hɔ kyɛ.

Mfiridwuma mu efĩ .

Nnwumayɛbea ne akwan a nnipa pii fa so no ma nneɛma yɛ den ma galvanized coil. Wɔde mframa te sɛ sulfur dioxide ne nitrogen oxides gu mframa mu. Saa mframa yi ne osu frafra na ɛma osu tɔ acid. Acid osu tɔ zinc a wɔde kata so no fi hɔ. Wɔ mmeae yi no, galvanized coil di bɛyɛ mfe 20 kosi 40 ansa na Rust ada ne ho adi. Eyi nkyɛ te sɛ nea ɛwɔ mframa a ɛho tew mu.

Ɛsɛ sɛ wohwɛ galvanized coil wɔ adwumayɛbea mmeae mpɛn pii. Hwehwɛ nkannare fitaa, nkannare kɔkɔɔ, nsensanee, ne ade a wɔde akata so a asɛe. Siesie coil no asram abiɛsa kosi asia biara. Hwɛ nkwaa, weld, ne mmeae a wɔde di dwuma kɛse. Fa coatings foforo di dwuma sɛ wubetumi a. Paw zinc coating a ɛyɛ den ma ahobammɔ a eye wɔ mmeae a ɛyɛ den.

Hwɛ nneɛma a wɔde kata so no asram abiɛsa biara.

Hwɛ joints ɔsram biara sɛ rust anaa.

Hwɛ mmeae a wɔde di dwuma kɛse asram abien biara.

Siesie na siesie nneɛma a asɛe no bere a woahu no ara pɛ.

Hyɛ no nsow: Sɛ wohwɛ mpɛn pii na wode zinc coatings a ɛyɛ den di dwuma a, ɛboa ma wo coil ko tia efĩ na ɛkyɛ.

Siw rust fitaa ano wɔ galvanized coil so .

Dɛn ne rust fitaa?

Ɛtɔ mmere bi a wuhu ade fitaa a ɛyɛ mmerɛw wɔ dade a wɔde galvanized ayɛ so. Wɔfrɛ eyi sɛ White Rust. Ɛba bere a coil no te mmeae a ɛhɔ yɛ nwini a mframa kakraa bi na ɛwɔ mu no. White rust hwɛ powdery anaa chalky, ɛnyɛ sɛ red rust. Wɔde zinc corrosion products na ɛyɛ. Eyinom bi ne zinc hydroxide, zinc oxide, ne zinc carbonates. Nsu a ɛwɔ mu no ne zinc a wɔde kata so no yɛ adwuma ma ɛyɛ saa nneɛma yi. Eyi ba kɛse sɛ mframa ntumi nkɔ coil no mu a. Nkurɔfo nso frɛ no 'storage stain' anaa 'wet storage stain.'

White rust taa tra soro na ɛnhaw zinc coating no ahobammɔ. Bere kɔ so no, zinc hydroxide sesa yɛ zinc oxide ne zinc carbonate. Sɛ wugyae coil no wɔ abɔnten a, rust fitaa taa kɔ bere a ɛdan nneɛma a ɛyɛ den no.

Hyɛ no nsow: Rust fitaa kyerɛ sɛ nsu a ɛwɔ zinc coating no mu. Ɛyɛ sɛnkyerɛnne a ɛkyerɛ sɛnea wode wo coil no sie na wudi ho dwuma.

Akwan a wɔfa so siw ano .

Wubetumi asiw rust fitaa ano denam nneɛma kakraa bi a ɛnyɛ den a wobɛyɛ so. Bere nyinaa fa galvanized steel coils sie mmeae a ɛhɔ yɛ kusuu a mframa pa fa mu. Mfa nhyɛ fam. Fa spacers di dwuma sɛnea ɛbɛyɛ a mframa betumi akɔ coils ntam. Mfa coils nbɛn ho dodo. Eyi kyere nsu na ɛboa ma rust yɛ fitaa.

Sɛ wode coils tu a, fa nkataso a nsu ntumi nkɔ mu kyekyere ho na bɔ anoano no ho ban. Sɛ wuhu coils biara a ɛyɛ nsu a, fa no ma ɛyɛ ntɛmntɛm. Tew wet sheets so sɛnea ɛbɛyɛ a mframa betumi adu hɔ.

Hwɛ coils mpɛn pii na woahu rust fitaa ntɛm. Sɛ wuhu a, fa samina ne nsu a ɛyɛ mmerɛw hohoro baabi a ɛwɔ no. Sɛ wopɛ mmeae a ɛyɛ den a, fa acid aduru a ɛyɛ mmerɛw di dwuma na hohoro mu yiye.

Fa nneɛma a ɛbɔ ho ban te sɛ zinc-rich paint, epoxy, anaa powder coatings gu so na ama wɔabɔ ho ban kɛse. Sɛ wuhu nsensanee anaasɛ nsensanee a ɛda hɔ kwa a, fa zinc a ɛyɛ nwini anaa zinc a ɛwɔ mu no siesie. Fa gauge hwɛ zinc layer no na hwɛ sɛ ɛda so ara bɔ ho ban yiye.

Ma coils nkɔ akyiri mfi kɔbere, kɔbere, anaa dade afoforo a ɛma galvanic nsɛe ho. Hwɛ sɛ baabi a wɔkora nneɛma so no bɛtra ase wɔ 60% nsu ase. Sɛ ɛsɛ sɛ wode coils to abɔnten a, fa tarps a nsu ntumi nkɔ mu kata so na ma ano biako so ma nsu no nkɔ mu.

Afotu: Sɛ wode coils sie yiye na woyɛ w’ade ntɛmntɛm a, ɛyɛ akwan a eye sen biara a wobɛfa so asiw rust fitaa ano na ama wo galvanized steel coil no ayɛ den.

galvanized steel coils no ntumi nsɛe ntɛmntɛm. Zinc a wɔde kata so no bɔ dade a ɛwɔ ase no ho ban. Nanso coil biara ntumi nsiw rust ano daa. Ɛsɛ sɛ wotaa siesie wo coil no. Siesie ɔsɛe biara ntɛm ara na aboa ma zinc no atra hɔ akyɛ. Sɛ wohwɛ so a, wo coil no betumi adi mfe 20 kosi 50. Sɛ worepaw galvanized steel a, susuw nneɛma yi ho:

Nneɛma a atwa yɛn ho ahyia: Mmeae a ɛbɛn po anaa adwumayɛbea ahorow no hia ahobammɔ foforo.

Zinc coating thickness: Nneɛma a wɔde kata so a ɛyɛ den a efi hot-dip galvanizing mu no kyɛ.

Nsiesiei: Hohoro na hwɛ wo galvanized steel coil no mpɛn pii.

Sɛ wopaw nneɛma pa na wohwɛ wo coil no so a, ebetumi atra hɔ mfe pii.

FAQ .

Bere tenten ahe na galvanized steel coil di abɔnten?

Wubetumi ahwɛ kwan sɛ galvanized steel coil bɛtra abɔnten mfe 20 kosi 50. Zinc a wɔde kata so a efi hot-dip galvanizing no bɔ dade no ho ban. Wɔ mmeae a ɛhɔ yɛ mmerɛw no, ɛtra hɔ kyɛ. Wɔ mpoano anaa mfiridwuma mu no, ebia wubehu Rust ntɛm.

So wubetumi ayɛ mfonini wɔ galvanized steel coil so?

Yiw, wubetumi ayɛ mfonini wɔ galvanized steel coil so. Di kan hohoro asase ani. Fa primer a wɔayɛ ama zinc coating di dwuma. Paint boa ma wɔbɔ coil no ho ban na ebetumi ama ne hwɛbea atu mpɔn.

Dɛn na ɛde rust fitaa ba galvanized steel coil so?

Rust fitaa ba bere a nsu no kɔhyɛ zinc a wɔde kata so no so no. Eyi taa ba bere a wɔde nneɛma gu mu no. Wubetumi asiw ano denam galvanized steel coil a wobɛma ayɛ kusuu na ama mframa akɔ so no so.

Ɔkwan bɛn so na wusiesie scratches wɔ galvanized steel coil so?

Fa samina ne nsu a ɛyɛ mmerɛw hohoro scratch no ho. Dry mpɔtam hɔ. Fa aduru a wɔde zinc pii ayɛ anaasɛ aduru a wɔde petepete galvanizing so a ɛyɛ nwini gu so. Eyi ma zinc a wɔde kata so no san ba na ɛbɔ dade a ɛwɔ ase no ho ban.

So galvanized steel coil yɛ nea asiane biara nni ho ma nsu a wɔnom ho nhyehyɛe?

Wubetumi de galvanized steel coil adi dwuma ama nsu nhyehyɛe ahorow bi. Zinc a wɔde kata so no gyina nsɛe ano. Nanso, hwɛ mpɔtam hɔ mmara ne gyinapɛn ahorow bere nyinaa ansa na wode adi dwuma de ayɛ nsu a wɔnom.