Galvanized steel coils are widely used in construction, automotive, and appliance manufacturing due to their strength and affordability.

Our products feature a zinc coating applied through hot-dip galvanizing, which serves as a protective shield against moisture and other corrosive elements. Even if the coating on the galvanized steel coil gets scratched, the zinc corrodes first, safeguarding the steel beneath. You might wonder, does galvanized steel rust? The answer is yes, but it occurs very gradually. The lifespan of galvanized steel coils depends on factors like the environment, coating thickness, and maintenance.

Tip: Always inspect new galvanized steel coils for any damage. Proper care of your galvanized steel coil not only keeps it looking great but also extends the durability of your projects with our company.

Key Takeaways

Galvanized steel coils do not rust easily. This is because they have a zinc coating. The zinc acts like a shield and keeps the steel safe. The zinc layer stops water from touching

the steel. If the coating gets scratched, the zinc still helps stop rust. This makes the coil last longer. Things like salty air, pollution, and wet weather make rust happen faster. So, where you use the steel matters for how long it lasts. Cleaning the coils often helps them stay nice. Checking for damage and fixing it fast also helps. Picking the right amount of zinc coating is important. Storing the coils the right way keeps them safe. This helps them last a long time.

Does Galvanized Steel Rust?

If you ask if galvanized steel rusts, you want a simple answer. Galvanized steel coil resists corrosion well, but it can still rust. The zinc coating acts like a shield and slows down rust. Over time, things like weather and damage can wear away this shield. It is important to know how galvanizing stops rust and what to expect from good galvanized coil in different places.

Zinc Coating Protection

The zinc coating on galvanized coil makes a barrier between steel and air. This barrier keeps out water and oxygen, which cause rust. If you pick zinc-coated steel, it stands up to rain, humidity, and pollution. Hot-dip galvanizing bonds zinc to steel, so the coating lasts many years.

Studies show zinc coatings get better with special additives. These additives make the coating stronger and better at stopping rust. For example, adding ceria nanoparticles and polyaniline helps zinc protect steel from corrosion. One study tested galvanized steel coil by the sea for five years. Thicker zinc coatings lowered the risk of red rust and paint peeling, especially at the edges. The zinc layer forms films and stops oxygen from reaching steel.

You can see how the environment changes how long galvanized coil lasts in the table below:

Environment | Typical Time for Rust to Appear | Key Environmental Factors | Maintenance Recommendations |

Ordinary Outdoor | 20 to 50 years | Fresh air, low pollutants | Check coating thickness every 5 years; optional clear lacquer |

Coastal Area | 5 to 15 years | High salt content in air (salt spray) | Inspect twice a year (focus on welds/edges); clean quarterly |

Industrial Pollution | 10 years or less | Pollutants accelerate zinc wear | Frequent inspection and cleaning recommended |

Note: Cleaning and checking your galvanized coil often can make it last longer. If you do not take care of it, rust will happen faster, especially in tough places.

A galvanized steel coil can last 20 to 50 years or more outside in normal conditions. In coastal or industrial places, it does not last as long because of salt and chemicals. Quality and coating thickness are important. Thicker zinc coatings protect better and last longer.

In mild outdoor places, galvanized steel can last over 50 years before rust.

In tough places like coastal or industrial areas, it may last 20 years or less.

Galvanized steel can last 50-100 years in normal places.

In marine or industrial areas, it lasts 20-50 years with care.

Zinc coating gives both barrier and sacrificial protection from rust.

Chemicals, water, damage, and high humidity make it wear out faster.

Galvanized steel usually lasts 25 to 50 years.

In less harsh places, it can last up to 75 years.

Thicker zinc coatings protect longer.

Maintenance and extra coatings help it last longer.

GI coils can last 20 to 50 years or more in normal, non-corrosive places.

Regular care and coatings make it last longer.

Sacrificial Protection Mechanism

You may wonder why galvanized coil protects steel so well. The reason is the sacrificial protection mechanism. Zinc is less noble than steel, so it rusts first. If the zinc coating gets scratched, zinc particles act as sacrificial anodes. They give electrons to steel and stop steel from rusting. This is called cathodic protection.

When zinc rusts, it makes zinc oxide and hydroxycarbonate salts. These make a thick, self-healing film over steel. This film blocks water and oxygen, giving more protection. The zinc coating is not just a barrier. It also makes a chemical shield that traps things that cause rust and slows down rusting.

On a tiny level, zinc oxide helps move electrons at the zinc and steel edge. This helps reactions that keep steel safe. As the zinc layer wears away, protection changes from cathodic to barrier. This mix of sacrificial action and barrier effects gives galvanized coil strong corrosion resistance and long life.

Tip: Pick galvanized coil with a thick, even zinc coating for best protection. Check your coil often for scratches or damage to keep sacrificial protection working.

Causes of Rust on Galvanized Steel Coil

Environmental Factors

When you use galvanized coil outside, the weather matters a lot. If the air is very humid, water can stay on the coil. This water helps rust form faster. Salt from the sea or salty water can hurt the zinc layer. This makes rust show up sooner. Pollution in the air, like sulfur dioxide and nitrogen oxides, mixes with water. These mix to make acids that break down the zinc. Acid rain in cities also harms the protective layer. Moss and lichen can grow on the coil. They hold water close to the metal and make small wet spots. These spots help rust start.

Here are the most common causes of rust on galvanized coil:

High humidity (above 60%)

Salt in air or water (coastal areas)

Frequent wetting or soaking

Sulfur dioxide pollution

Hydrogen sulfide exposure

Contact with strong alkalis (cement, plaster)

Acid rain runoff

Moss and lichen growth

Cause/Condition | Explanation |

Humid and confined environments | Electrochemical corrosion, white rust due to moisture and poor air flow |

Breakdown of zinc carbonate | Prolonged humidity allows corrosive solutions to form |

Severe white rust areas | Zinc layer consumed, steel exposed |

Chemical reactions | Moisture, oxygen, CO2, and oxides create corrosive electrolytic solutions |

Tip: If you live near the ocean or in a city, check your galvanized coil more often. These places make rust happen faster and shorten the life of your coil.

Physical Damage

Physical damage is another big reason for rust on galvanized coil. Scratches, marks, or rough moving can break the zinc coating. If you see a scratch, the steel under it is open to air and water. Zinc can protect small scratches, but not big ones. If there is a large scratch or damage in a tough place, you need to fix it. This keeps the coil from rusting fast. You should look for damage after you put the coil in and during checks. Even tiny chips can let water in and start rust.

Note: Be gentle with galvanized steel coil when you move or install it. Use soft straps and do not drag the coil to stop scratches.

Coating Thickness

The thickness of the zinc coating is very important for stopping rust. Thicker coatings make a stronger shield and last longer in hard places. Studies show that thick zinc layers give more zinc ions. These ions help protect cut edges and weak spots. The zinc acts as a shield and slows down rust on the steel.

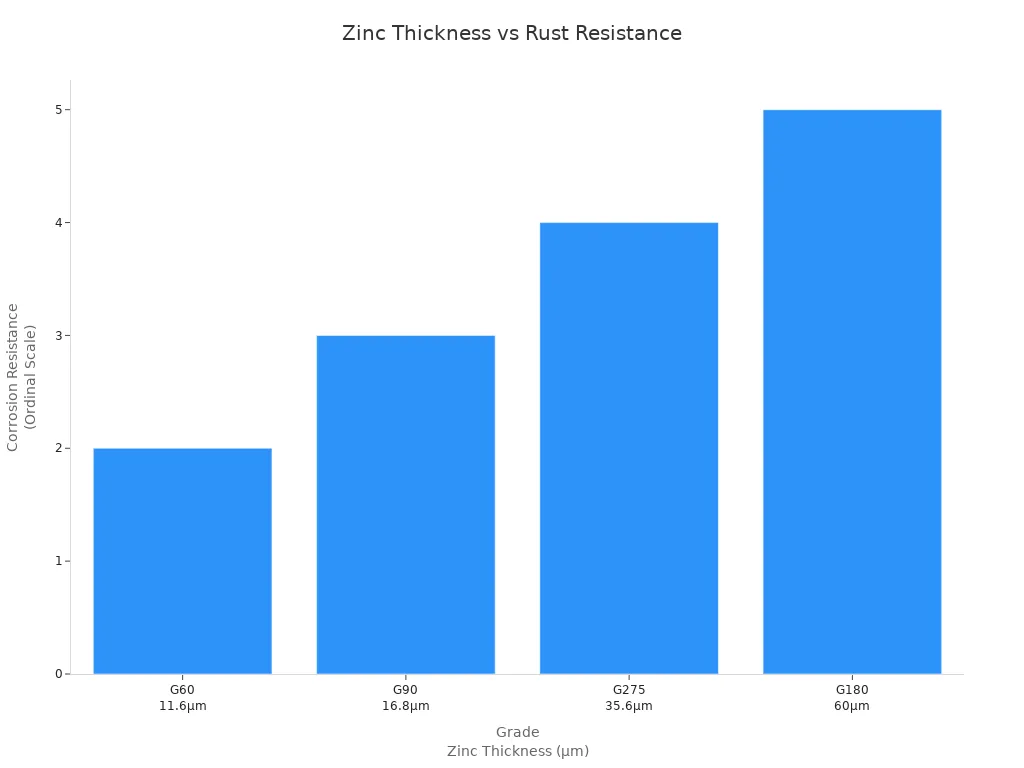

Grade | Approximate Zinc Coating Thickness (μm) | Corrosion Resistance Level | Typical Application Environment |

G60 | 11.6 | Moderate | Mildly corrosive environments |

G90 | 16.8 | Good | Most building and roofing |

G180 | 60 | Very high | Extreme corrosive environments |

G275 | 35.6 | High | Harsh environments |

Pick the zinc coating thickness that fits your project and where you use it. Thicker coatings cost more, but they protect better and last longer.

Galvanized Coil Maintenance

Taking care of your galvanized coil is the best way to prevent galvanized steel from rusting and keep its quality high. Simple steps like cleaning, inspecting, and repairing can help you get the most out of your investment. Regular maintenance also saves you money by avoiding costly replacements.

Regular Cleaning

You should clean your galvanized coil at least once a year. In coastal or industrial areas, clean every three months. Cleaning removes salt, dust, and acid rain residue that can wear down the zinc coating. Start with gentle methods and only use stronger cleaners if needed.

Use a soft plastic bristle brush for scrubbing. Avoid steel brushes, which can scratch and discolor the zinc coating.

Wash with mild soap or car wash products and low-pressure water.

For mild stains, use household ammonia cleaners. For rust stains or cement deposits, use oxalic acid, then rinse well.

Remove paint with thinners and a plastic or wooden scraper. Use non-alkaline strippers for tough paint.

Always rinse the coil after cleaning to remove any cleaner residue.

Tip: Test any new cleaning method on a small, hidden area first. This helps you avoid damaging the zinc coating.

Cleaning your galvanized coil regularly helps prevent galvanized steel from rusting and keeps the surface looking bright. It also protects the zinc layer, which is key to long-term quality.

Inspection and Repair

You should inspect your galvanized coil at least once a year. In harsh environments, check every six months. Look for early signs of rust or coating damage. Focus on these key points:

Flat areas where water can collect.

Edges and welds, which are more likely to corrode.

Spots that have been touched up before.

Areas with brown stains or white rust.

Bare spots where the zinc coating is missing.

Crevices and corners where water and dirt can build up.

Places where the coil touches other metals.

Use a magnetic thickness gauge to check the zinc coating. If you find scratches or small rust spots, repair them right away:

Clean the area with mild soap and water.

Remove rust with a brass wire brush or fine sandpaper.

Apply zinc-rich paint or cold-spray zinc to restore protection.

For bigger repairs, use a moisture-cured urethane or vinyl-based paint.

Note: Quick repairs stop rust from spreading and help maintain the quality of your galvanized coil.

Avoiding Harsh Chemicals

Certain chemicals can damage the zinc coating and speed up rust. You should avoid:

Fertilizers and garden chemicals, which can reduce zinc protection by up to 40%.

Strong acids and alkaline cleaners, which break down the zinc layer.

Saltwater and high humidity, which increase corrosion rates.

Acid rain and industrial pollutants, which wear away the coating faster.

Contact with copper or other metals, which can cause galvanic corrosion.

Store your galvanized coil in a dry, well-ventilated place. Keep it away from chemicals and other metals. If you must use a cleaner, choose one that is safe for zinc coatings, such as acetone or commercial products tested for galvanized steel.

Tip: Good storage and careful cleaning are simple ways to protect your galvanized coil and extend its life.

Cost-Effectiveness of Maintenance

Regular maintenance costs much less than replacing a rusted coil. Cleaning and small repairs keep the zinc coating strong and prevent big problems. If you skip maintenance, rust can damage the coil and force you to buy a new one. Investing a little time and money in upkeep helps you avoid expensive replacements and keeps your galvanized steel coil in top condition for years.

Environmental Impact on Galvanized Steel Coil

Outdoor vs. Coastal Areas

The place where you use galvanized coil matters a lot. In country or town areas, galvanized coil lasts many years. You may not see rust for over 70 years in these places. This happens because the air is clean and there is less water in the air.

But near the ocean, things are different. Salt in the air makes rust happen faster. If the coil faces salty wind, rust can show up in 5 to 7 years. If the coil is protected, it can last 15 to 25 years before rust starts. You should clean and check coils near the coast more often. Wash them with fresh water every few months to get rid of salt. Use extra coatings if you can. Look for rust or damage at least two times a year.

Environment Type | Average Time to First Rust Appearance | Key Conditions and Notes |

Coastal (within 1 mile, >250 ft from coast) | 5-7 years (direct exposure) | Direct exposure to salty/chloride-rich winds; sheltered areas last 15-25 years longer |

Outdoor (rural, suburban, temperate marine) | Multiple decades to over 70 years | Includes rural and suburban areas with less corrosive atmospheres; temperate marine environments included |

Tip: If you live close to the sea, clean and check your coil more often. This helps it last longer.

Industrial Pollution

Factories and busy roads make things hard for galvanized coil. They put gases like sulfur dioxide and nitrogen oxides into the air. These gases mix with rain and make acid rain. Acid rain wears away the zinc coating. In these places, galvanized coil lasts about 20 to 40 years before rust shows up. This is not as long as in clean air.

You should check galvanized coil in factory areas more often. Look for white rust, red rust, scratches, and worn coating. Clean the coil every three to six months. Pay attention to joints, welds, and places that get a lot of use. Use extra coatings if you can. Pick a thicker zinc coating for better protection in tough places.

Check surface coatings every three months.

Look at joints every month for rust.

Watch high-use spots every two months.

Clean and fix damage as soon as you see it.

Note: Checking often and using thicker zinc coatings help your coil fight pollution and last longer.

Prevent White Rust on Galvanized Coil

What Is White Rust?

Sometimes you see a white, flaky layer on galvanized steel coil. This is called white rust. It happens when the coil sits in damp places with little air. White rust looks powdery or chalky, not like red rust. It is made of zinc corrosion products. These include zinc hydroxide, zinc oxide, and zinc carbonates. Moisture reacts with the zinc coating to make these compounds. This happens more if air cannot move around the coil. People also call it "storage stain" or "wet storage stain."

White rust usually stays on the surface and does not hurt the zinc coating’s protection. Over time, zinc hydroxide changes into zinc oxide and zinc carbonate. If you leave the coil outside, white rust often goes away as it turns into stable compounds.

Note: White rust means moisture got trapped against the zinc coating. It is a sign to check how you store and handle your coil.

Prevention Methods

You can stop white rust by doing a few easy things. Always keep galvanized steel coils in dry places with good airflow. Do not put them on the ground. Use spacers so air can move between coils. Do not stack coils too close together. This traps moisture and helps white rust form.

When you move coils, wrap them with waterproof covers and protect the edges. If you see any wet coils, dry them fast. Separate wet sheets so air can reach them.

Check coils often to find white rust early. If you see it, clean the spot with mild soap and water. For tough spots, use a weak acid solution and rinse well.

Put on protective coatings like zinc-rich paint, epoxy, or powder coatings for extra protection. If you see scratches or bare spots, fix them with cold-spray zinc or zinc-rich coatings. Use a gauge to check the zinc layer and make sure it still protects well.

Keep coils away from copper, brass, or other metals that cause galvanic corrosion. Make sure the storage area stays below 60% humidity. If you must keep coils outside, cover them with waterproof tarps and lift one end for drainage.

Tip: Storing coils well and acting fast are the best ways to stop white rust and keep your galvanized steel coil strong.

Galvanized steel coils do not rust easily. The zinc coating protects the steel underneath. But no coil can stop rust forever. You need to clean your coil often. Fix any damage quickly to help the zinc last longer. If you take care of it, your coil can last 20 to 50 years. When picking galvanized steel, think about these things:

Environment: Places near the ocean or factories need extra protection.

Zinc coating thickness: Thicker coatings from hot-dip galvanizing last longer.

Maintenance: Clean and check your galvanized steel coil often.

If you make good choices and care for your coil, it can last for many years.

FAQ

How long does galvanized steel coil last outdoors?

You can expect galvanized steel coil to last 20 to 50 years outdoors. The zinc coating from hot-dip galvanizing protects the steel. In mild environments, it lasts longer. In coastal or industrial areas, you may see rust sooner.

Can you paint over galvanized steel coil?

Yes, you can paint over galvanized steel coil. Clean the surface first. Use a primer made for zinc coating. Paint helps protect the coil and can improve its appearance.

What causes white rust on galvanized steel coil?

White rust forms when moisture gets trapped on the zinc coating. This often happens during storage. You can prevent it by keeping galvanized steel coil dry and allowing air to circulate.

How do you repair scratches on galvanized steel coil?

Clean the scratch with mild soap and water. Dry the area. Apply a zinc-rich paint or cold galvanizing spray. This restores the zinc coating and protects the steel underneath.

Is galvanized steel coil safe for drinking water systems?

You can use galvanized steel coil for some water systems. The zinc coating resists corrosion. However, always check local codes and standards before using it for drinking water.