Galvanized steel coil te hi an chakna leh an man tlawmna avang hian sakna, motor leh hmanrua siamnaah an hmang nasa hle a ni.

Kan thil siamte hian hot-dip galvanizing hmanga hnawih zinc coating a hmang a, chu chu tui leh thil dang eiral loh laka invenna shield atan hman a ni. Galvanized steel coil-a coating chu a hrual a nih pawhin, Zinc chuan a corrode hmasa a, a hnuaia steel chu a humhim a ni. I ngaihtuah mai thei, galvanized steel rust a ni em? A chhanna chu a ni a, mahse a thleng zauh zauh nasa hle. Galvanized steel coils dam chhung hi boruak, coating thickness, leh maintenance ang chi thilteah a innghat a ni.

Tip: Galvanized steel coil tharte chu a chhiatna a awm leh awm loh enfiah fo ang che. I galvanized steel coil enkawl dan dik chuan a mawi hle mai bakah i project-te a rei theihna a tizau bawk Kan company ..

Key takeaways 1000 a ni.

Galvanized steel coil te chu awlsam takin an rust lo. Hei hi zinc coating an neih vang a ni. Zinc hian shield angin hna a thawk a, steel chu a him reng bawk. Zinc layer hian tui a khawih loh nan a titawp a ni .

A steel chu a rawn lang a. Coating a scratch a nih chuan zinc hian rust tihtawp nan a la pui tho. Hei hian coil chu a rei zawk a ni. Thil chi hrang hrang boruak, boruak bawlhhlawh leh khaw lum ang chi thilte hian rust a ti rang zawk a ni. Chuvangin, steel i hmanna hmunah chuan eng chen nge a daih tih a pawimawh. Coil-te tihfai hian an awm ṭhat theih nân a ṭanpui fo ṭhîn. A chhiat leh chhiat leh nih loh endik leh rang taka enfiah hian a pui bawk. Zinc coating dik tak thlan a pawimawh. Coil-te chu a dik taka dah chuan a him reng a ni. Hei hian hun rei tak chhung an awm theih nan a pui a ni.

Galvanized steel rust a awm em?

Galvanized steel rusts i zawh chuan chhanna awlsam tak i duh a ni. Galvanized steel coil hian corrosion a do tha hle a, mahse a la rust thei tho. Zinc coating hian shield angin hna a thawk a, rust a ti slow bawk. Hun a kal zel a, khaw lum leh chhiatna ang chi thilte hian he shield hi a ti chhe thei a ni. Galvanizing hian rust a tihtawp dan leh hmun hrang hranga galvanized coil tha tak atanga beisei tur hriat a pawimawh.

Zinc coating laka invenna .

Galvanized coil-a zinc coating hian steel leh boruak inkarah barrier a siam a. He barrier hian tui leh oxygen a chhuah tir a, chu chuan rust a thlen thin. Zinc-a khuh steel i pick chuan ruah, humidity leh pollution thlengin a ding a ni. Hot-dip galvanizing bonds zinc to steel, chuvangin coating hi kum tam tak a daih a ni.

Zirna hrang hrangah Zinc coatings te chu special additives hmangin an tha zawk tih hmuhchhuah a ni. Heng additives te hian coating chu a tichak zawk a, rust tihtawp nan a ti tha zawk bawk. Entirnan, Ceria nanoparticles leh polyaniline te dah belh hian zinc hian steel chu corrosion lakah a veng thei a ni. Zirna pakhat chuan tuipui kama galvanized steel coil chu kum nga chhung an test a. Thicker zinc coatings chuan red rust leh paint peeling risk a ti hniam a, a bik takin a sir lamah chuan. Zinc layer hian film a siam a, oxygen chu steel-a a thlen loh nan a titawp bawk.

Galvanized coil hi a hnuaia table-ah hian environment a inthlak danglam dan chu i hmu thei ang:

Chenna khawvel |

Rust a lo lang tur hun tlangpui . |

Environment thil pawimawh tak tak . |

Enkawlna atana rawtna siam . |

Pawn lam thil pangngai . |

Kum 20 atanga kum 50 thleng . |

Thli thianghlim, boruak bawlhhlawh hniam . |

Kum 5 danah coating thickness enfiah thin ang che; A duh chuan clear lacquer . |

Coastal area . |

Kum 5 atanga kum 15 thleng . |

Thlipui (salt spray) a chi tam tak awmna . |

kum khatah vawi hnih enfiah (welds/edges-ah ngaihtuah rawh); Quarterly 1000 vel a ni. |

Industrial pollution 1.1. |

Kum 10 emaw a aia tlem emaw . |

Pollutants te chu zinc wear a ti chak hle. |

Enfiah fo leh tihfai fo tura rawtna siam . |

Note: I galvanized coil tihfai leh check fo hian a rei thei fo. I enkawl loh chuan rust hi a thleng rang zawk ang, a bik takin hmun harsa takah chuan.

Galvanized steel coil hi a tlangpuiin kum 20 atanga kum 50 emaw a aia rei emaw a daih thei. Coastal emaw industry emaw hmunah chuan chi leh chemical vangin a rei lo hle. Quality leh coating thickness hi a pawimawh hle. Thicker zinc coatings hian a veng tha zawk a, a rei zawk bawk.

Pawn lam hmun lum takah chuan galvanized steel hi rust hma kum 50 chuang a awm thei.

Coastal emaw industrial area ang chi hmun harsa takah chuan kum 20 emaw a aia rei lo pawh a daih thei.

Galvanized steel hi hmun pangngaiah chuan kum 50-100 chhung a daih thei.

Tuipui emaw, industry lamah emaw chuan kum 20-50 chhung chu fimkhur takin a hmang thin.

Zinc coating hian rust laka invenna leh inthawina venhimna a pe vek a ni.

Chemical, tui, chhiatna leh humidity sang tak hian a ti chhe rang zawk.

Galvanized steel hi kum 25 atanga kum 50 chhung a ni tlangpui.

Hmun harsa lo zawkah chuan kum 75 thleng a daih thei.

Thicker zinc coatings hian a veng rei zawk.

Maintenance leh extra coatings te hian a rei zawk nan a pui bawk.

GI coil hi kum 20 atanga kum 50 emaw a aia rei emaw chhung chu hmun pangngai, corrosive lo hmunah a awm thei.

Regular care leh coatings hian a rei zawk nan a hmang thin.

Inthawinaa invenna hmanrua .

Engvangin nge galvanized coil hian steel a humhim tha em em tih i ngaihtuah mai thei. A chhan chu inthawina humhalhna kawng a nih vang a ni. Zinc hi steel aiin a noble lo zawk a, chuvang chuan a rust hmasa ber a ni. Zinc coating chu a hrual a nih chuan zinc particle te chu sacrificial anode angin an thawk a ni. Steel-ah electron an pe a, steel rust an titawp bawk. Hei hi cathodic protection an ti a.

Zinc a rust hian zinc oxide leh hydroxycarbonate salt a siam thin. Hengte hian steel aiin film thick, self-healing tak an siam a ni. He film hian tui leh oxygen a block a, venhimna tam zawk a pe bawk. Zinc coating hi a daltu mai a ni lo. Tin, chemical shield a siam a, chu chuan rust thlentu thil a man a, rusting a ti hniam bawk.

Level tenau takah chuan zinc oxide hian electron te chu zinc leh steel edge-ah a sawn thei a ni. Hei hian steel him taka awm theihna tur reaction a pui thin. Zinc layer a chhe deuh deuh chuan cathodic atanga barrier thlengin venhimna a inthlak thin. Hetianga inthawina action leh barrier effects inzawmkhawm hian galvanized coil chu corrosion resistance chak tak leh dam rei tak a pe a ni.

Tip: Galvanized coil chu a thick a, zinc coating thlengin pick la, a tha ber tur a ni. Inthawina humhimna a thawh theih nan i coil chu a hliam emaw, a chhiatna emaw a awm leh awm loh enfiah fo rawh.

Galvanized steel coil-a rust awm chhan

Environment lam thil 1.1.

Pawn lama galvanized coil i hman hian khaw lum a pawimawh hle. Thli a lum hle a nih chuan tui chu coil-ah a awm thei. He tui hian rust form a ti rang zawk. Tuipui atanga chi emaw tui chi emaw hian zinc layer a ti na thei a ni. Hei hian Rust chu a lantir hma zawk. boruak bawlhhlawh, sulphur dioxide leh nitrogen oxide ang chi te chu tui nen a inhmeh hle. Heng mix te hian Zinc ti chhe thei acid siam nan an hmang thin. Khawpui hrang hranga acid ruah sur hian venhimna layer a tichhe bawk. Moss leh Lichen te hi coil ah hian an thang lian thei. Tui chu metal bulah an dah a, hnim hring hring te te an siam bawk. Heng spot te hian rust start a pui a ni.

Galvanized coil-a rust awm chhan tam ber chu hetiang hi a ni:

Humidity sang (60% aia sang) .

Thli emaw tui emaw a chi (coastal area) .

Wetting emaw soaking emaw a awm fo thin .

Sulfur dioxide bawlhhlawh paihna hmun .

Hydrogen sulfide hmanga inhnimhnawihna .

Alkalis chak tak (cement, plaster) nena inzawmna nei.

Acid ruah sur tur .

Moss leh Lichen te thanlenna .

A chhan/condition . |

Hrilhfiahna |

Humid leh confined environment te . |

Electrochemical corrosion, a tui leh boruak a tha lo avangin rust dum a awm bawk. |

Zinc carbonate a inhen darh dan. |

Hun rei tak humidity hmangin corrosive solutions a lo awm theih nan . |

White rust na tak tak awmna hmun . |

Zinc layer ei a, steel exposed . |

Chemical hmanga thil tih dan . |

Moisture, oxygen, CO2, leh oxide te hian electrolytic solutions tichhe thei tak tak an siam thei a ni. |

Tip: Tuipui kamah emaw, khawpuiah emaw i awm chuan i galvanized coil kha en fo ang che. Heng hmunte hian rust a ti rang a, i coil nun a ti tawi bawk.

Taksa chhiatna .

Taksa lama chhiatna hi galvanized coil-a rust awm chhan lian tak dang a ni bawk. Scratch, marks, rough moving te hian zinc coating chu a tichhia thei a ni. Scratch i hmuh chuan a hnuaia steel chu boruak leh tui atan hawn a ni. Zinc hian scratch te te a veng thei a, mahse lian tak tak erawh a veng thei lo. Hmun harsa takah scratch lian tak emaw, chhiatna emaw a awm chuan i siam that a ngai a ni. Hei hian coil chu a rust nghal vat lo. Coil i dah hnuah leh check laiin damage i zawng tur a ni. Chip te te pawh hian tui a luh tir thei a, rust a tan tir thei bawk.

Note: Galvanized steel coil hmangin i kal emaw, i install emaw chuan gentle rawh. Strap soft hmang la, coil chu drag suh, scratchs tihtawp nan.

coating thickness .

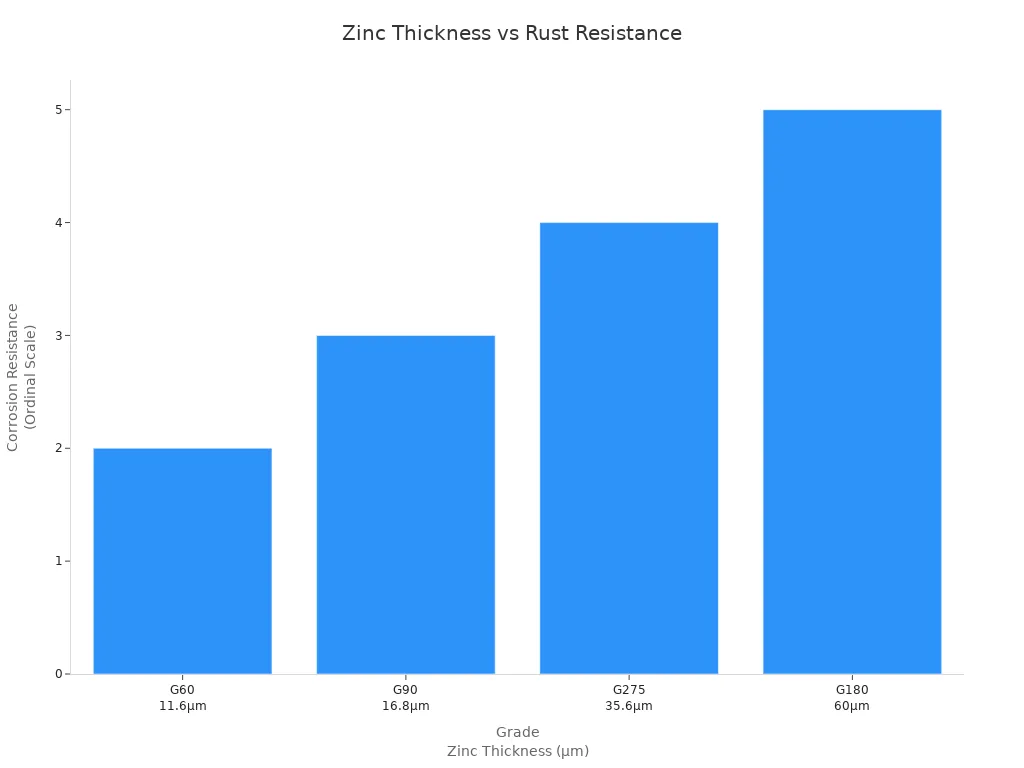

Zinc coating thickness hi rust tihtawp nan a pawimawh hle. Thicker coatings hian shield chak zawk a siam a, hmun harsa takah a awm rei zawk. Zirna hrang hrangah chuan thick zinc layers hian zinc ion a pe tam zawk tih hmuhchhuah a ni. Heng ion te hian cut edge leh weak spot te a venghim thei a ni. Zinc hian shield angin hna a thawk a, steel-a rust a ti hniam bawk.

Pawl |

Zinc coating thickness (μm) vel a ni. |

Corrosion resistance level a awm em? |

A hman dan tlangpui . |

G60 a ni. |

11.6 |

Thunun |

Mildly corrosive environments . |

G90 a ni. |

16.8 |

Tha |

Building leh roofing tam zawk . |

G180 a ni. |

60 |

A sang hle mai . |

Environment tichhe nasa lutuk . |

G275 a ni. |

35.6 |

Sang |

Environment harsa tak tak te . |

I project leh i hmanna hmun nena inmil Zinc coating thickness chu thlang rawh. Thicker coatings man a to zawk a, mahse a veng tha zawk a, a rei zawk bawk.

Galvanized coil enkawl dan .

I galvanized coil enkawl hi galvanized steel rust a awm loh nan leh a quality sang taka dah theihna kawng tha ber a ni. Step awlsam tak tak, tihfai, enfiah leh siam that ang chi te hian i investment atanga hlawkna tam ber i hmuh theih nan a pui thei che a ni. Regular maintenance hian a thlakna man to tak tak a pumpelh avangin sum a humhim bawk.

A tihfai dan pangngai .

I galvanized coil chu kum khatah vawi khat tal i tifai tur a ni. Coastal emaw industrial area-ah chuan thla thum danah tihfai thin tur a ni. Thianghlimna chuan Zinc coating a tihchhiat theihna tur chi, leivut leh acid ruahtui tla te a paih chhuak thin. Thil tih dan nem tak hmangin tan la la, a tul hunah chauh cleaner chak zawk hmang ang che.

Scrubbing atan plastic bristle brush nem tak hmang la. Steel brush ei loh tur a ni a, chu chuan zinc coating chu a hrual thei a, a ti danglam thei bawk.

Savun emaw car wash emaw, mild takin silfai a, low-pressure water hmangin silfai bawk ang che.

Mild stains tan chuan in chhunga ammonia cleaner hmang thin ang che. Rust stain emaw cement deposit emaw atan chuan oxalic acid hmang la, chutah chuan silfai tha ang che.

Paint chu thinners leh plastic emaw thing emaw scraper hmangin la chhuak rawh. Paint tough tak tak atan chuan non-alkaline stripper hmang rawh.

Coil chu tihfai zawhah silfai fo la, a chhunga thil awm zawng zawng chu paih chhuah theih a ni ang.

Tip: Hmun tlemte, thup takah tihfai dan thar eng pawh test hmasa phawt ang che. Hei hian zinc coating tihchhiat loh nan a pui che a ni.

I galvanized coil tihfai fo hian galvanized steel a rust loh nan a pui a, a chung lam chu a ti eng reng bawk. Zinc layer pawh a venghim bawk a, hei hi hun rei tak chhunga quality tha tak a nih theihna tur key a ni.

Inspection leh siamthat .

Kum khatah vawi khat tal i galvanized coil chu i enfiah tur a ni. Environment harsa takah chuan thla ruk danah check thin ang che. Rust emaw coating emaw chhiatna chhinchhiahna hmasa ber zawng rawh. Heng thu pawimawh tak takte hi ngaihtuah rawh:

tui a khawlkhawm theihna hmun zau tak.

Edges leh welds, chu chu a corrode tam zawk.

spot a hmaa khawih tawh te.

Brown stain emaw white rust emaw awmna hmun.

Zinc coating awm lohna hmunah bare spot a awm.

tui leh bawlhhlawh a lo awm theihna tur crevice leh corner te.

coil-in metal dang a khawih na hmunte.

Zinc coating enfiah nan magnetic thickness gauge hmang la. Scratch emaw rust spot te emaw i hmuh chuan siam tha nghal rawh:

A hmun chu sahbawn leh tui nem tak hmangin tifai rawh.

Rust chu brass wire brush emaw sandpaper tha tak emaw hmangin la chhuak rawh.

Zinc-rich paint emaw cold-spray zinc emaw hmangin a venhim leh theih nan hnawih rawh.

Repairing lian zawk atan chuan moisture-cured urethane emaw vinyl-based paint emaw hmang la.

Note: Quick repairs hian rust a darh tawh loh nan a titawp a, i galvanized coil quality vawng reng turin a pui bawk.

Chemical na tak tak pumpelh .

Chemical thenkhat chuan zinc coating a tichhia thei a, rust a ti chak thei bawk. I pumpelh tur a ni:

Fertilizer leh garden chemicals, zinc laka invenna 40% thlenga tihtlem thei a ni.

Acid chak tak tak leh alkaline cleaner te, zinc layer ti chhe thei.

Saltwater leh humidity sang tak, corrosion rates tisangtu.

Acid ruah leh industrial pollutants, a coating a ti chhe rang zawk.

Copper emaw metal dang emaw nena inzawmna, chu chuan galvanic corrosion a thlen thei.

I galvanized coil chu hmun lum leh boruak tha takah dah la. Chemical leh metal dang atanga hla takah dah thin ang che. Cleaner i hman a ngai a nih chuan zinc coatings atan a him tur thlang la, chu chu acetone emaw commercial products tested for galvanized steel emaw a ni.

Tip: Storage tha leh uluk taka tihfai hi i galvanized coil humhimna tur leh a dam chhung tihzauh dan awlsam tak a ni.

Maintenance man tlawm zawka siam theih a ni .

Regular maintenance man chu rusted coil thlak ai chuan a man a tlawm zawk hle. Thianghlimna leh siamthatna tenau te hian zinc coating chu a tichak a, harsatna lian tak tak a veng thei bawk. Maintenance i skip chuan rust hian coil a tichhia thei a, a thar lei turin a nawr thei che a ni. Upkeep-a hun leh sum tlem tal invest hian a thlakna man to tak tak a awm loh nan a pui a, i galvanized steel coil chu kum tam tak chhung top condition-ah a dah bawk.

Galvanized steel coil-a boruak a nghawng dan

Outdoor leh tuipui kama awmte .

Galvanized coil i hmanna hmun hi a pawimawh hle. Ram emaw khawpui emaw-ah chuan galvanized coil hi kum tam tak a daih a ni. Heng hmunah te hian kum 70 chuang zet rust i hmu lo mai thei. Hei hi boruak a thianghlim a, boruakah tui a tlem avangin a thleng thin.

Mahse tuifinriat bulah chuan thil a danglam. Thli chhunga chi (salt in the air) chuan rust a ti rang zawk. Coil hian thli tui tak a hmachhawn chuan rust hi kum 5 atanga kum 7 chhungin a rawn lang thei a ni. Coil hi venhim a nih chuan rust a tan hma kum 15 atanga 25 chhung a daih thei. Coils bulah coil i tifai a, i check fo tur a ni. Thla engemaw zat hnuah tui thianghlim hmangin silfai thin ang che. I theih chuan extra coatings hmang la. Kum khatah vawi hnih tal rust emaw damage emaw zawng rawh.

Environment chi hrang hrang . |

Rust hmel hmasa ber atanga a lan dan average . |

Key Conditions leh Notes . |

Coastal (mile 1 vel, tuipui kam atanga ft >250) |

Kum 5-7 (direct exposure) . |

Salty/chloride tamna thlipui aanga direct-a a awm; Sheltered area te hi kum 15-25 chhung a rei zawk a ni. |

Pawn lam (rural, suburban, tuipui lian tak tak) . |

kum sawmhnih tam tak atanga kum 70 chuang . |

thingtlang leh khawpui pawn lama boruak chhe thei lo awmna hmun a huam a; Temperate marine environment te pawh a tel . |

Tip: Tuipui hnaih taka i awm chuan tifai la, i coil kha check fo ang che. Hei hian a rei zawk nan a pui a ni.

Industrial pollution 1.1.

Factory leh kawngpui busy tak takte hian galvanized coil tan thil a ti harsa hle. Sulfur dioxide leh nitrogen oxide ang chi gas te chu boruakah an dah a. Heng gas te hi ruah nen an inhmeh a, acid ruah an sur bawk. Acid ruah chuan zinc coating chu a wear chhuak a. Heng hmunah te hian Galvanized Coil hi Rust a rawn lang hma kum 20 atanga kum 40 vel a ni. Hei hi boruak thianghlim takah chuan a rei lo hle.

Factory area-ah galvanized coil i check tam zawk tur a ni. Rust dum, rust sen, scratch, leh coating chhe tawh tak tak zawng rawh. Thla thum atanga thla ruk danah coil chu tifai thin ang che. Joint, weld, leh hmun hrang hranga hman tangkai theihna hmunte ngaihven rawh. I theih chuan extra coatings hmang la. Hmun harsa tak takah venhimna tha zawk neih theih nan zinc coating thick zawk thlang rawh.

Thla thum danah surface coatings enfiah thin ang che.

Thla tin rust awm leh awm loh en rawh.

Thla hnih danah hmanna hmun sang tak tak en thin ang che.

I hmuh veleh a chhiatna chu tifai la, tifai rawh.

Note: Check fo leh thicker zinc coatings hman hian i coil do thei tur pollution a pui a, rei zawk a daih thei bawk.

Galvanized coil-a rust dum awm tur venna .

White rust chu eng nge ni?

A châng chuan galvanized steel coil-ah chuan layer dum, flaky tak i hmu ṭhin. Hei hi white rust an ti a. Coil chu boruak tlemte nena hmun hnim hring takah a thut hian a thleng thin. White rust chu powdery emaw chalky emaw a ni a, red rust ang a ni lo. Zinc corrosion product hmanga siam a ni. Chung zingah chuan zinc hydroxide, zinc oxide, leh zinc carbonate te pawh a tel. Moisture hian zinc coating nen a inrem a, heng compound te hi a siam a ni. Hei hi boruakin coil vel a inher theih loh chuan a thleng tam zawk. Mite chuan 'storage stain' emaw 'wet storage stain an ti bawk.'

White rust hi a tlangpuiin a chung lamah a awm tlangpui a, zinc coating venhimna a ti na lo. Hun a kal zel a, zinc hydroxide chu zinc oxide leh zinc carbonate ah a inthlak thin. Coil chu pawnah i dah a nih chuan white rust chu stable compound-ah a chantir angin a bo fo thin.

Note: White rust tih awmzia chu zinc coating-ah tui a tlakbuak tihna a ni. I coil dah dan leh i enkawl dan enfiahna tur chhinchhiahna a ni.

Inven dan tur .

Thil awlsam tlemte tih hian white rust i titawp thei. Galvanized steel coil te chu hmun vawt takah boruak a tha a, airflow tha tak nen dah fo ang che. Leiah dah suh. Coil inkar boruak a kal theih nan spacer hmang rawh. Coil te chu a hnaih lutuk a stack suh. Hei hian moisture a trap a, white rust form a pui bawk.

Coil i sawn dawnin waterproof cover hmangin khuh la, a sirte chu venhim rawh. Wet coils i hmuh chuan dry vat rawh. Wet sheet hrang hrang chu boruakin a thlen theih nan.

White rust hmuh hmasak nan coil check fo thin ang che. I hmuh chuan a hmun chu sahbawn leh tui nem tak hmangin tifai rawh. Spot harsa tak tak tan chuan acid solution chak lo tak hmang la, silfai tha rawh.

Zinc-rich paint, epoxy, emaw powder coatings ang chi protective coatings-ah dah la, a him zawk nan. Scratch emaw bare spot emaw i hmuh chuan cold-spray zinc emaw zinc-rich coatings emaw hmangin siam tha rawh. Gauge hmangin zinc layer chu check la, a la venghim tha em tih enfiah rawh.

Coil te chu copper, brass, emaw, galvanic corrosion thlentu metal dang emaw atanga hla takah dah tur a ni. Storage area chu 60% humidity hnuaiah a awm ngei ngei tur a ni. Coil pawnah i dah a ngai a nih chuan waterproof tarp hmangin khuh la, a tawp khat chu drainage atan chawi sang rawh.

Tip: Coils tha taka dah leh acting rang tak hi white rust tihtawp nan leh i galvanized steel coil chak taka awm theihna tur kawng tha ber a ni.

Galvanized steel coil te chu awlsam takin an rust lo. Zinc coating hian a hnuaia steel chu a venghim a ni. Mahse eng coil mahin rust chu chatuan atan an titawp thei lo. I coil tihfai fo a ngai a ni. Zinc chu rei zawk a awm theih nan damage awm apiang chu rang takin siam tha rawh. I enkawl chuan i coil hi kum 20 atanga 50 chhung a awh thei a ni. Galvanized steel i thlan dawnin heng thilte hi han ngaihtuah teh:

Environment: Tuipui bula hmun emaw factory emaw mamawhna tur venna tur extra a ngai.

Zinc coating thickness: hot-dip galvanizing atanga coating thick zawk chu a rei zawk.

Maintenance: I galvanized steel coil kha tifai la, check fo ang che.

Duhthlanna tha tak i siam a, i coil i enkawl chuan kum tam tak chhung a daih thei.

FAQ a ni.

Galvanized steel coil hi pawnah eng chen nge a awm?

Galvanized steel coil hi kum 20 atanga kum 50 chhung pawnah a daih theih i beisei thei ang. Hot-dip galvanizing atanga zinc coating hian steel a venghim a ni. Mild environment-ah chuan a rei zawk. Coastal emaw industrial area-ah chuan rust hi i hmu thuai mai thei.

Galvanized steel coil chungah i paint thei ang em?

Ni e, galvanized steel coil chungah i paint thei. A chung lam chu tifai hmasa phawt ang che. Zinc coating atana siam primer hmang la. Paint hian coil a venghim a, a hmel a ti tha thei bawk.

Eng thilin nge galvanized steel coil-ah white rust a thlen?

Zinc coating-a moisture a tlakbuak chuan white rust a lo awm thin. Hei hi storage laiin a thleng fo thin. Galvanized steel coil chu a vawt reng a, boruak a kal theih nan i veng thei bawk.

Galvanized steel coil-ah hian engtin nge scratch i siam that?

A hrual chu sahbawn leh tui nem tak hmangin silfai rawh. A hmun chu dry rawh. Zinc-rich paint emaw cold galvanizing spray emaw hmangin hnawih la. Hei hian zinc coating chu a siam tha leh a, a hnuaia steel chu a venghim bawk.

Galvanized steel coil hi tui in tur system atan a him em?

Tui system thenkhat atan chuan galvanized steel coil i hmang thei bawk. Zinc coating hian corrosion a do thei. Mahse, tui in tur atana hman hmain local code leh standard te chu enfiah hmasa thin ang che.