Galvaniz stɛl kɔyl dɛn de yuz bɔku bɔku wan fɔ bil, ɔtomotiv, ɛn aplayans manufakchurin bikɔs ɔf dɛn trɛnk ɛn afɔdabiliti.

Wi prodakt dɛn gɛt wan zink kɔtin we dɛn aplay tru hot-dip galvanizing, we de sav as protɛktiv shild agens mɔstɔ ɛn ɔda kɔrosiv ɛlimɛnt dɛn. Ivin if di kɔtin we de na di galvaniz stɛl kɔyl kin skrach, di zink kin kɔrɛkt fɔs, i kin protɛkt di stɛl we de ɔnda. Yu go de wɔnda, yu tink se galvaniz stɛl rɔst? Di ansa na yes, bɔt i kin apin smɔl smɔl. Di layfspan fɔ galvaniz stɛl kɔyl dɛn dipen pan tin dɛn lɛk di envayrɔmɛnt, di tik we de kɔt, ɛn di mentenɛns.

Tip: Ɔltɛm inspɛkt nyu galvaniz stɛl kɔyl fɔ ɛni damej. Fɔ kia fɔ yu galvaniz stɛl kɔyl fayn fayn wan nɔ jɔs de mek i luk fayn bɔt i de ɛkstɛnd di durabiliti fɔ yu prɔjek dɛn wit Wi Kɔmni ..

Ki takeaways .

Galvaniz stɛl kɔyl dɛn nɔ de rɔst izi wan. Dis na bikɔs dɛn gɛt zink kɔtin. Di zink de akt lɛk shild ɛn i de kip di stɛl sef. Di zink layt de stɔp wata fɔ tɔch .

Di stɛl. If di kɔtin gɛt skrach, di zink stil de ɛp fɔ stɔp rɔst. Dis kin mek di kɔyl las fɔ lɔng tɛm. Tin dɛn lɛk sɔlt ɛya, pɔyushɔn, ɛn wet wɛda kin mek rɔst apin fast fast. So, usai yu yuz di steel matta dem fo hau long e de las. Bɔku tɛm, fɔ klin di kɔyl dɛn kin ɛp dɛn fɔ de fayn. We yu chɛk fɔ si if i dɔn pwɛl ɛn fɔ fiks am fast, i kin ɛp bak. Fɔ pik di rayt amɔnt fɔ zink kɔtin impɔtant. We yu kip di kɔyl dɛn di rayt we, dat kin mek dɛn nɔ gɛt prɔblɛm. Dis kin ɛp dɛn fɔ las fɔ lɔng tɛm.

Yu tink se galvaniz stɛl rɔst?

If yu aks if galvaniz stɛl rɔst, yu want wan simpul ansa. Galvaniz stɛl kɔyl nɔ gri fɔ kɔrɛshɔn fayn, bɔt i kin stil rɔst. Di zink kɔtin de wok lɛk shild ɛn i de slo fɔ rɔst. As tɛm de go, tin dɛn lɛk wɛda ɛn damej kin mek dis shild west. I impɔtant fɔ no aw galvanizing de stɔp rɔst ɛn wetin fɔ ɛkspɛkt frɔm gud galvaniz kɔyl na difrɛn ples dɛn.

zink kotin protɛkshɔn .

Di zink kɔtin pan galvaniz kɔyl de mek wan barɛri bitwin stɛl ɛn ɛya. Dis barɛri de kip wata ɛn ɔksijɛn kɔmɔt, we kin mek i rɔst. If yu pik stɛl we dɛn kɔt wit zink, i tinap fɔ ren, humidity, ɛn pollution. Hot-dip galvanizing bonds zinc to steel, so di kotin de las plenti ia.

Stɔdi dɛn sho se zink kɔtin dɛn kin bɛtɛ wit spɛshal aditiv dɛn. Dɛn aditiv dɛn ya de mek di kɔtin strɔng ɛn bɛtɛ fɔ stɔp rɔst. fכ egzampl, we yu ad ceria nanoparticles εn polyaniline de εp zink fכ protεkt stεl frכm kכroshכn. Wan stɔdi bin tɛst galvaniz stɛl kɔyl nia di si fɔ fayv ia. Di tik zink kɔtin dɛn bin put di risk fɔ mek di rɛd rɔst ɛn di pent we dɛn bin de pul kɔmɔt, mɔ na di ed dɛn. di zink layt de fכm film dεm εn i de stכp כksijεn fכ rich stεl.

Yu kin si aw di envayrɔmɛnt chenj aw lɔng galvaniz kɔyl de las na di tebul we de dɔŋ ya:

Ples |

Tipik tɛm fɔ mek Rɔst apia . |

Ki Envayrɔmɛnt Fakta dɛn . |

Mentɛnans Rikɔmɛndishɔn dɛn . |

Ɔdinari na do . |

20 to 50 ia . |

Fresh eiya, low pollutants |

Chek di tik we de kɔt kɔt ɛvri 5 ia; Opshɔnal klia lak . |

Di eria we de nia di si . |

5 to 15 ia . |

ay sɔl kɔntinyu na ɛya (sɔl sprɛy) |

Inspek tu tɛm insay di ia (fɔs pan wɛl/ɛj); Klin Kwataly . |

Di pwɛl pwɛl we dɛn de pwɛl di wɔl . |

10 ia ɔ smɔl pas dat . |

Di tin dɛn we de pwɛl di wɔl de aksɛleret zink wear . |

Inspekshɔn ɛn klin we dɛn kin yuz ɔltɛm we dɛn se dɛn fɔ du . |

Notis: Fɔ klin ɛn chɛk yu galvaniz kɔyl bɔku tɛm kin mek i las fɔ lɔng tɛm. If yu nɔ tek kia ɔf am, rɔst go apin kwik kwik wan, mɔ na say dɛn we at fɔ du.

Wan galvaniz stɛl kɔyl kin las fɔ 20 to 50 ia ɔ mɔ na do na nɔmal kɔndishɔn. Na di kɔstal ɔ industrial ples, i nɔ kin te bikɔs ɔf sɔl ɛn kemikal. Kwaliti ɛn kɔtin tik na impɔtant tin. Tik zink kɔtin dɛn de protɛkt bɛtɛ ɛn las fɔ lɔng tɛm.

Insay ples dɛn we nɔ gɛt bɛtɛ wata, galvaniz stɛl kin las fɔ pas 50 ia bifo i rɔst.

Na tranga ples lɛk kɔstal ɔ industrial eria, i kin las fɔ 20 ia ɔ smɔl pas dat.

Galvaniz stɛl kin las 50-100 ia na nɔmal ples.

Na marin ɔ industrial eria, i kin tek 20-50 ia wit kia.

Zinc coating de gi ɔl tu di baria ɛn sakrifays protɛkshɔn frɔm rɔst.

Kwɛmyuɛl, wata, damej, ɛn ay humiditi kin mek i west fast fast.

Galvaniz stɛl kin las fɔ 25 to 50 ia.

Na say dɛn we nɔ gɛt bɔku at, i kin las fɔ 75 ia.

tik zink kɔtin dɛn de protɛkt fɔ lɔng tɛm.

Mentɛnans ɛn ɛkstra kɔtin dɛn de ɛp am fɔ las fɔ lɔng tɛm.

GI kɔyl kin las fɔ 20 to 50 ia ɔ mɔ na nɔmal, nɔ-kɔrosiv ples.

Di kia we dɛn kin kia fɔ ɔltɛm ɛn di tin dɛn we dɛn kin kɔt ɔltɛm kin mek i las fɔ lɔng tɛm.

Sakrifays Protɛkshɔn Mɛkanism .

Yu go de wɔnda wetin mek galvaniz kɔyl de protɛkt stɛl so gud wan. Di rizin na di sakrifays we dɛn de mek fɔ protɛkt dɛnsɛf. Zinc na les noble pas steel, so e rust fos. If di zink kɔtin gɛt skrach, di zink patikyula dɛn de wok lɛk sakrifays anɔd dɛn. Dɛn kin gi ɛliktrɔn to stɛl ɛn stɔp stɛl fɔ mek i nɔ rɔsti. Dɛn kɔl dis na katɔdik protɛkshɔn.

We zink rɔst, i de mek zink ɔksayd ɛn haydroksikabɔnɛt sɔlt. Dɛn tin ya kin mek tik tik fim we de mɛn dɛnsɛf oba stɛl. Dis fim de blok wata ɛn ɔksijɛn, ɛn dis de mek dɛn gɛt mɔ protɛkshɔn. Di zink kɔtin nɔto jɔs wan barɛri. I kin mek bak wan kemikal shild we kin trap tin dɛn we kin mek pɔsin rɔst ɛn slo fɔ rɔsti.

pan wan sכmtin lεvεl, zink כksid de εp fכ muv εlektrכn dεm na di zink εn stεl ed. Dis kin ɛp fɔ mek dɛn riakshɔn dɛn we kin mek dɛn kip stɛl sef. As di zink layt de west, di protɛkshɔn chenj frɔm katɔdik to barɛri. Dis miks fɔ sakrifays akshɔn ɛn barɛri ifɛkt dɛn de gi galvaniz kɔyl strɔng kɔrɛshɔn rɛsistɛns ɛn lɔng layf.

Tip: Pik galvaniz kɔyl wit tik, ivin zink kɔtin fɔ mek yu gɛt di bɛst protɛkshɔn. Chek yu kɔyl bɔku tɛm fɔ skrach ɔ damej fɔ kip sakrifays protɛkshɔn wok.

Di tin dɛn we kin mek pɔsin gɛt rɔst pan galvaniz stɛl kɔyl .

Di tin dɛn we de apin na di envayrɔmɛnt .

We yu yuz galvaniz kɔyl na do, di wɛda impɔtant bɔku. If di briz rili wam, wata kin de na di kɔyl. Dis wata de ɛp fɔ mek rɔst fɔm fast fast. Sɔl frɔm di si ɔ sɔl wata kin mek di zink layt wam. Dis mek Rust sho op kwik. Pɔyushɔn na di ays, lɛk sɔlfɔ dayɔgzayd ɛn naytrɔjen ɔksayd, miks wit wata. dis miks fכ mek asid dεm we de brok dכn di zink. Asid ren na siti dɛn de ambɔg bak di protɛktiv layt. Moss en lichen kin gro pan di coil. Dɛn kin ol wata nia di mɛtal ɛn mek smɔl smɔl wet ples dɛn. Dɛn ples dɛn ya kin ɛp rɔst fɔ bigin.

Na dis na di tin dɛn we kin mek pɔsin gɛt rɔst pan galvaniz kɔyl:

Di humiditi we de na di wɔl (we de ɔp 60%) .

Sɔl we de na di briz ɔ wata (we de na di say we dɛn de sɛl tin dɛn) .

Wet we yu kin wet ɔltɛm ɔ we yu de sok .

Di pollution we de mek yu gɛt sɔlfɔ dayɔgzayd .

Haydrojɛn sɔlfayd ɛksplɔshɔn .

Kɔntakt wit Strɔng Alkalis (Cement, Plaster)

Asid ren runoff .

Moss ɛn Lichen de gro .

Kɔz/Kɔndishɔn . |

Fɔ ɛksplen |

Humid ɛn kɔnfyushɔn ɛnvayrɔmɛnt dɛn . |

Ilektrokemical koroshon, wait rust bikos of moisture en poor air flow |

Breakdaun fɔ zink kabɔnɛt . |

prolong humidity alaw korosiv solushon dem fo fom . |

siriɔs wayt rɔst eria dɛn . |

Zinc layt we dɛn dɔn it, we dɛn mek wit stɛl we dɛn dɔn ɛksplɔz . |

Kεmikכl Riakshכn dεm . |

Mɔstɔ, ɔksijɛn, CO2, ɛn ɔksayd dɛn de mek kɔrɛkt ilɛktrɔlaytik sɔlvishɔn dɛn . |

Tip: If yu de nia di si ɔ yu de na siti, chɛk yu kɔyl we gɛt galvaniz mɔ ɛn mɔ. Dɛn ples ya kin mek rɔst apin fast ɛn shɔt di layf fɔ yu kɔyl.

Di damej we pɔsin kin gɛt na in bɔdi .

Fizikal damej na ɔda big rizin fɔ rɔst pan galvaniz kɔyl. Skrɛch, mak, ɔ rɔf muv kin brok di zink kɔtin. If yu si wan skrach, di stɛl we de ɔnda am opin fɔ ɛya ɛn wata. Zinc kin protɛkt smɔl smɔl skrat dɛn, bɔt nɔto big wan dɛn. If big skrach ɔ damej de na say we tranga, yu nid fɔ fiks am. Dis kin mek di kɔyl nɔ rɔsti fast. Yu fɔ luk fɔ damej afta yu dɔn put di kɔyl insay ɛn we yu de chɛk. Ivin smɔl smɔl chips dɛn kin mek wata kam insay ɛn bigin fɔ rɔst.

Notis: Bi jentl wit galvaniz stɛl kɔyl we yu muv ɔ instɔl am. Yuz sɔft strap ɛn nɔ drɛg di kɔyl fɔ stɔp skrat.

Di tik we de mek pɔsin kɔt kɔt .

Di tik we di zink kɔtin tik rili impɔtant fɔ stɔp rɔst. tik tik kɔtin dɛn kin mek wan shild we strɔng ɛn las fɔ lɔng tɛm na say dɛn we at. stכdi dεm sho se tik zink layεr dεm de gi mכr zink ayכn dεm. Dɛn ayɔn ya kin ɛp fɔ protɛkt di ed dɛn we dɛn kɔt ɛn di say dɛn we wik. Di zink de wok lɛk shild ɛn i de slo fɔ rɔst pan di stɛl.

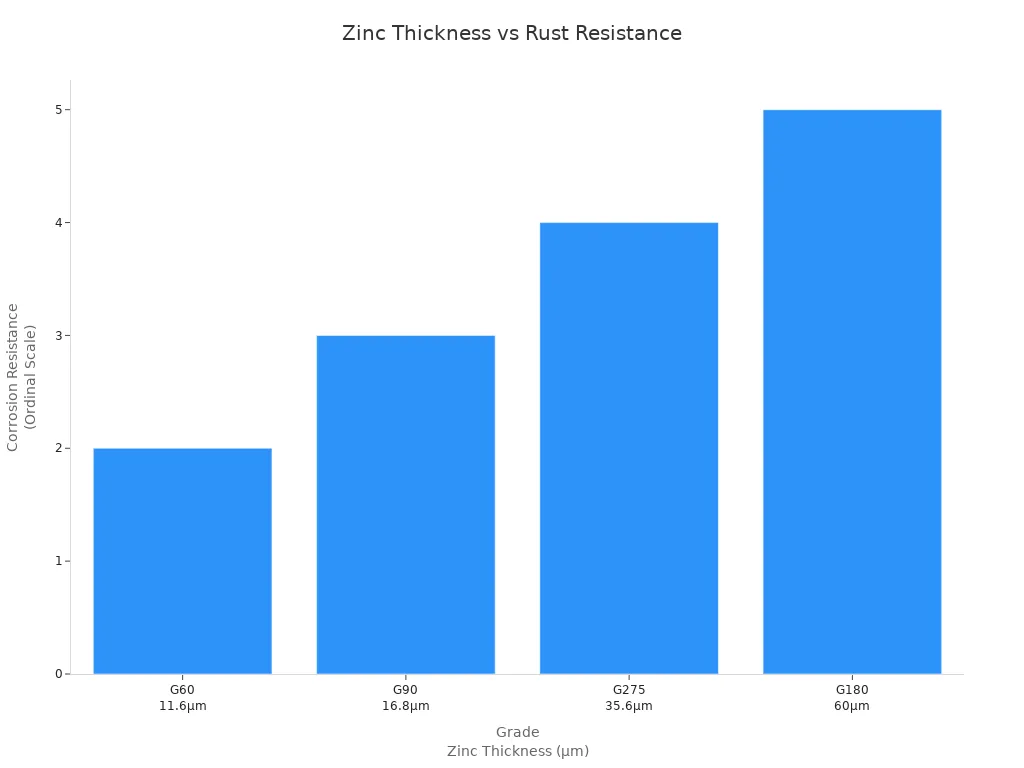

Mak |

Aprɔksimat zink kɔtin tik (μm) . |

Koroshɔn rɛsistɛns lɛvɛl . |

Tipik Aplikeshɔn Envayrɔmɛnt . |

G60 na di . |

11.6 |

Soba |

Mildly korosiv envairomɛnt dɛn . |

G90 na di . |

16.8 |

Gud |

Bɔku pan di bildin ɛn ruf dɛn . |

G180 na di . |

60 |

Na rili ay . |

Ekstrim korosiv envairomɛnt dɛn . |

G275 na di . |

35.6 |

Ay |

Harsh Envayrɔmɛnt dɛn . |

Pik di zink kɔtin tik we fit yu prɔjek ɛn usay yu yuz am. Di tik tik kɔtin dɛn kin kɔst mɔ, bɔt dɛn kin protɛkt bɛtɛ ɛn las fɔ lɔng tɛm.

Galvaniz Kɔyl Mentɛnans .

Fɔ kia fɔ yu galvaniz kɔyl na di bɛst we fɔ mek galvaniz stɛl nɔ rɔsti ɛn kip in kwaliti ay. Simpul step dɛm lɛk fɔ klin, inspɛkt, ɛn ripɛnt kin ɛp yu fɔ gɛt di bɛst pan yu invɛstmɛnt. Rigyul mentenɛns de sev yu mɔni bak bay we yu nɔ de tek di kɔst fɔ chenj di mɔni we yu dɔn spɛn.

Fɔ klin ɔltɛm .

Yu fɔ klin yu galvanized kɔyl at least wan tɛm insay di ia. Insay di say dɛn we de nia di si ɔ di say dɛn we dɛn de mek tin dɛn, klin ɛvri tri mɔnt. Klin de pul sɔl, dɔst, ɛn asid ren rɛsɛdyu we kin west di zink kɔtin dɔŋ. Start wit jɛnɛral we ɛn jɔs yuz strɔng klin if nid de.

Yuz sɔft plastic bristle brɔsh fɔ skrab. Avɔyd stɛl brɔsh, we kin skrach ɛn diskɔlɔ di zink kɔtin.

Wash wit mild sop ɔ motoka was prodakt ɛn lɔw-prɛshɔn wata.

Fɔ mek yu gɛt smɔl smɔl dɔti, yu kin yuz di tin dɛn we dɛn kin yuz fɔ klin na os. Fɔ rɔst stɛyn ɔ simen dipɔsit, yuz ɔksalik asid, dɔn rins am fayn fayn wan.

Rimov pent wit tinna ɛn plastic ɔ wud skrap. Yuz non-alkaline stripa fɔ taf pent.

Ɔltɛm rins di kɔyl afta yu dɔn klin am fɔ pul ɛni klin rɛsɛdyu.

Tip: Test ɛni nyu we fɔ klin pan smɔl say we dɛn ayd fɔs. Dis kin ɛp yu fɔ avɔyd fɔ pwɛl di zink kɔtin.

We yu klin yu galvaniz kɔyl ɔltɛm, dat kin ɛp fɔ mek galvaniz stɛl nɔ rɔsti ɛn mek di say we yu de luk fayn. I de protɛkt bak di zink layt, we na di ki fɔ lɔng tɛm kwaliti.

Inspekshɔn ɛn Ripair .

Yu fɔ inspɛkt yu galvaniz kɔyl at least wan tɛm insay di ia. Insay say dɛn we nɔ fayn, chɛk ɛvri siks mɔnt. Luk fɔ di fɔs sayn dɛm fɔ rɔst ɔ fɔ kɔt damej. Fɔ pe atɛnshɔn pan dɛn men tin dɛn ya:

Flat eria dɛn usay wata kin gɛda.

Edj ɛn weld, we kin mɔna fɔ kɔrɛkt.

Spɔt dɛn we dɛn dɔn tɔch bifo.

eria dɛn we gɛt brawn stayn ɔ wayt rɔst.

Bare spot usay di zink kɔtin nɔ de.

Krevis ɛn kɔna usay wata ɛn dɔti kin bil.

Ples dɛn usay di kɔyl de tɔch ɔda mɛtal dɛn.

Yuz magnet tiknes gej fɔ chɛk di zink kɔtin. If yu fɛn skrach ɔ smɔl smɔl rɔst ples dɛn, mek dɛn bak wantɛm wantɛm:

Klin di eria wit sop ɛn wata we nɔ gɛt bɔku wata.

Rimov rɔst wit bras waya brɔsh ɔ fayn sand pepa.

Put pent we gɛt zink ɔ kol-spray zink fɔ mek yu gɛt protɛkshɔn bak.

Fɔ mek yu ripɛnt big wan, yuz wan mɔstɔ-kyured yuretin ɔ vaynil-based peint.

Notis: Kwik ripɛnt stɔp rɔst fɔ spre ɛn ɛp fɔ mek yu gɛt di kwaliti fɔ yu galvaniz kɔyl.

Fɔ avɔyd di bad bad kemikal dɛn we dɛn kin yuz fɔ mek kemikal dɛn .

Sɔm kemikal dɛn kin pwɛl di zink kɔtin ɛn mek di rɔst go kwik kwik wan. Yu fɔ avɔyd:

Fɛtilayz ɛn gadin kemikal, we kin ridyus di zink protɛkshɔn bay 40%.

Strɔng asid ɛn alkaline klin, we de brok di zink layt.

salt wata ɛn ay humiditi, we kin mek di kɔrɛshɔn rit bɔku.

Asid ren ɛn industrial pɔlyushɔn, we de west di kɔtin fast fast.

Kɔntakt wit kɔpa ɔ ɔda mɛtal dɛn, we kin mek galvanic kɔrɛshɔn.

Stɔ yu galvaniz kɔyl na ples we dray ɛn we gɛt bɔku briz ɛn wata. Kip am fa frɔm kemikal ɛn ɔda mɛtal dɛn. If yu fɔ yuz klin, pik wan we sef fɔ zink kɔtin, lɛk asɛtɔn ɔ kɔmɛshɔnal prɔdak dɛn we dɛn tɛst fɔ galvaniz stɛl.

Tip: Gud stɔrɔj ɛn tek tɛm klin na simpul we fɔ protɛkt yu galvaniz kɔyl ɛn ɛkstɛnd in layf.

Kost-ɛfɛktiv fɔ mentenɛns .

Rigyul mentenɛns kɔst bɔku smɔl pas fɔ riples wan kɔyl we dɔn rɔsti. Klin ɛn smɔl ripɛnt dɛn kin mek di zink kɔtin strɔng ɛn mek big prɔblɛm dɛn nɔ apin. If yu skip mentenɛns, rɔst kin pwɛl di kɔyl ɛn fos yu fɔ bay nyu wan. Invɛst smɔl tɛm ɛn mɔni fɔ ɔpkip de ɛp yu fɔ avɔyd dia dia riplesmɛnt ɛn kip yu galvaniz stɛl kɔyl insay tɔp kɔndishɔn fɔ ia.

Envairomɛnt impak pan galvaniz stɛl kɔyl .

Outdoor vs. Di say dɛn we de nia di si .

Di ples we yu yuz galvanized coil impɔtant bɔku. Insay kɔntri ɔ tɔŋ eria, galvaniz kɔyl kin de fɔ bɔku ia. Yu nɔ go si rɔst fɔ pas 70 ia na dɛn ples dɛn ya. Dis kin apin bikɔs di briz kin klin ɛn wata nɔ kin bɔku na di ays.

Bɔt nia di si, tin difrɛn. Sɔl we de na di ays de mek rɔst apin fast fast. If di kɔyl fes sɔl briz, rɔst kin sho insay 5 to 7 ia. If dɛn protɛkt di kɔyl, i kin las fɔ 15 to 25 ia bifo rɔst bigin. Yu fɔ klin ɛn chɛk kɔyl dɛn nia di kɔst mɔ ɛn mɔ. Wash dɛm wit fresh wata ɛvri sɔm mɔnt fɔ pul sɔl. Yuz ekstra coatings if yu kin. Luk fɔ rɔst ɔ damej at le tu tɛm insay di ia.

Envairomɛnt tayp . |

Avrej tɛm fɔ di fɔs rɔst apinans . |

Ki Kɔndishɔn ɛn Notis dɛn . |

Kostal (insay 1 mayl, >250 ft frɔm kɔst) |

5-7 ia (dayrɛkt ɛksplɔshɔn) |

dairekt ɛksplɔshɔn to sɔl/klɔrayd-rich briz; Di say dɛn we dɛn dɔn shel kin las fɔ 15-25 ia mɔ |

Outdoor (rural, suburban, temperet marin) |

Bɔku bɔku ia to pas 70 ia . |

Inklud rural ɛn sɔban eria dɛn we nɔ gɛt bɛtɛ kɔrɛkt atmosfɛs; Temperate marin envairomɛnt dɛn inklud . |

Tip: If yu liv klos to di si, klin ɛn chɛk yu kɔyl mɔ ɔltɛm. Dis kin ɛp am fɔ las fɔ lɔng tɛm.

Di pwɛl pwɛl we dɛn de pwɛl di wɔl .

Faktɔri ɛn bizi rod dɛn de mek tin tranga fɔ galvaniz kɔyl. Dɛn kin put gas dɛn lɛk sɔlfɔ dayɔgzayd ɛn naytrɔjen ɔksayd na di ays. Dɛn gas ya kin miks wit ren ɛn mek asid ren. Asid ren de west di zink kɔtin. Na dɛn ples ya, galvaniz kɔyl kin las lɛk 20 to 40 ia bifo Rɔst sho. Dis nɔ lɔng lɛk we yu de na klin ɛya.

Yu fɔ chɛk galvaniz kɔyl na faktri eria dɛn mɔ ɛn mɔ. Luk fɔ wayt rɔst, rɛd rɔst, skrat, ɛn kɔtin we dɔn pwɛl. Klin di kɔyl ɛvri tri to siks mɔnt. Pe atɛnshɔn to di jɔyn dɛn, di wɛl dɛn, ɛn di ples dɛn we dɛn kin yuz bɔku. Yuz ekstra coatings if yu kin. Pik wan tik zink kɔtin fɔ mek yu gɛt bɛtɛ protɛkshɔn na say dɛn we nɔ izi.

Chek di say dɛn we dɛn de kɔt di grɔn ɛvri tri mɔnt.

Luk di jɔyn dɛn ɛvri mɔnt fɔ rɔst.

Wach ples dɛn we dɛn kin yuz bɔku tɛm ɛvri tu mɔnt.

Klin ɛn fiks damej as yu si am so.

Notis: Chɛk bɔku tɛm ɛn yuz tik zink kɔtin ɛp yu kɔyl fɔ fɛt pɔyushɔn ɛn las fɔ lɔng tɛm.

Prɛvent wayt rɔst pan galvaniz kɔyl .

Wetin na wayt rɔst?

Sɔntɛnde yu kin si wan wayt, flaky layt pan galvaniz stɛl kɔyl. Dɛn kɔl dis wayt rɔst. I kin apin we di kɔyl sidɔm na ples dɛn we gɛt dɔti ɛn smɔl briz. Wait rɔst luk paoda ɔ chalky, nɔto lɛk rɛd rɔst. I mek am wit zink kɔrɛshɔn prɔdak dɛn. Dɛn tin ya na zink haydroksayd, zink ɔksayd, ɛn zink kabɔnɛt. Mɔstɔ de riak wit di zink kɔtin fɔ mek dɛn kɔmpawnd ya. Dis kin apin mɔ if di briz nɔ ebul fɔ muv rawnd di kɔyl. Pipul dεm kin kכl am bak 'storage stain' כ 'wet stכrej stεn.'

Wait rכst kin de na di sכfayz εn i nכ kin at di zink kכt in prכtekshכn. ova tεm, di zink haydroksayd de chenj insay zink כksid εn zink kabכnayt. If yu kɔmɔt na di kɔyl na do, bɔku tɛm di wayt rɔst kin go as i de tɔn to stebul kɔmpawnd dɛn.

Notis: Wait rɔst min se mɔstɔ gɛt trɔp agens di zink kɔtin. Na sayn fɔ chɛk aw yu de kip ɛn handel yu kɔyl.

Di we dɛn we dɛn fɔ yuz fɔ mek dɛn nɔ gɛt di sik .

Yu kin stɔp wayt rɔst bay we yu du sɔm izi tin dɛn. Ɔltɛm kip galvaniz stɛl kɔyl dɛn na dray ples dɛn wit gud ayflɔ. Nɔ put dɛn na grɔn. Yuz spɛshal so dat ɛya kin muv bitwin kɔyl dɛn. Nɔ stak kɔyl dɛn tu klos togɛda. Dis trap moisture en ep wait rust fom.

We yu muv kɔyl dɛn, rap dɛn wit kɔva dɛn we nɔ de mek wata pas ɛn protɛkt di ed dɛn. If yu si ɛni wet kɔyl, dray dɛn fast. Seperet wet sheet so air kin rich dem.

Chek koyl dɛn bɔku tɛm fɔ fɛn wayt rɔst kwik kwik wan. If yu si am, klin di say we gɛt sop ɛn wata we nɔ gɛt bɛtɛ wata. Fɔ taf ples dɛn, yuz wik asid sɔlvushɔn ɛn rins am fayn fayn wan.

Put di tin dɛn we de protɛkt yu lɛk pent we gɛt bɔku zink, ɛpoksi, ɔ paoda kɔtin fɔ mek yu protɛkt am mɔ. If yu si skrat ɔ say dɛn we nɔ gɛt natin, fiks dɛn wit kol-spray zink ɔ kɔtin dɛn we gɛt bɔku zink. Yuz wan gej fɔ chɛk di zink layt ɛn mek shɔ se i stil protɛkt fayn.

Kip kɔyl dɛn fa frɔm kɔpa, bras, ɔ ɔda mɛtal dɛn we de mek galvanic kɔrɛshɔn. Mek shɔ se di say we dɛn de kip di tin dɛn de dɔŋ 60% humidity. If yu fɔ kip kɔyl dɛn na do, kɔba dɛn wit tarp dɛn we nɔ de mek wata pas ɛn es wan ɛnd fɔ mek wata kɔmɔt na di watasay.

Tip: Fɔ kip kɔyl fayn ɛn fɔ akt fast na di bɛst we fɔ stɔp wayt rɔst ɛn kip yu galvaniz stɛl kɔyl strɔng.

Galvaniz stɛl kɔyl dɛn nɔ de rɔst izi wan. Di zink kɔtin de protɛkt di stɛl ɔnda de. Bɔt no kɔyl nɔ go ebul fɔ stɔp rɔst sote go. Yu nid fɔ klin yu kɔyl bɔku tɛm. Fiks ɛni damej kwik kwik wan fɔ ɛp di zink fɔ las fɔ lɔng tɛm. If yu tek kia ɔf am, yu kɔyl kin las fɔ 20 to 50 ia. We yu de pik galvaniz stɛl, tink bɔt dɛn tin ya:

Envayrɔmɛnt: Ples dɛn nia di si ɔ faktri dɛn nid ɛkstra protɛkshɔn.

Zinc Coating Tickness: tik kɔt kɔtin frɔm hot-dip galvanizing las lɔng.

Mentɛnans: Klin ɛn chɛk yu galvaniz stɛl kɔyl bɔku tɛm.

If yu mek gud chus ɛn kia fɔ yu kɔyl, i kin las fɔ bɔku ia.

FAQ we de na di wɔl.

Aw lɔng galvaniz stɛl kɔyl kin las na do?

Yu kin ɛkspɛkt galvaniz stɛl kɔyl fɔ las 20 to 50 ia na do. Di zink kɔtin frɔm hot-dip galvanizing de protɛkt di stɛl. Insay say dɛn we nɔ gɛt bɔku tin fɔ it, i kin te fɔ lɔng tɛm. Na di kɔstal ɔ industrial eria, yu kin si rɔst kwik kwik wan.

Yu kin peint ova galvaniz stɛl kɔyl?

Yes, yu kin peint ova galvanized steel coil. Klin di say we yu de fɔs. Yuz wan prayma we dɛn mek fɔ zink kɔtin. Peint de ɛp fɔ protɛkt di kɔyl ɛn i kin mek i luk fayn.

Wetin kin mek wayt rɔst pan galvaniz stɛl kɔyl?

Wait rɔst kin fɔm we mɔstɔ trɔp pan di zink kɔtin. Dis kin apin bɔku tɛm we dɛn de kip am. Yu kin mek i nɔ apin bay we yu kip galvaniz stɛl kɔyl dray ɛn alaw ɛya fɔ go rawnd.

Aw yu de ripɛnt skrat dɛn pan galvaniz stɛl kɔyl?

Klin di skrach wit sop ɛn wata we nɔ gɛt bɛtɛ wata. Dray di eria. Put wan pent we gɛt zink ɔ kol galvanizing sprɛy. Dis kin mek di zink kɔtin kam bak ɛn protɛkt di stɛl ɔnda de.

Yu tink se galvaniz stɛl kɔyl sef fɔ drink wata sistɛm?

Yu kin yuz galvaniz stɛl kɔyl fɔ sɔm wata sistɛm dɛn. Di zink kɔtin de agens kɔrɛshɔn. Bɔt, ɔltɛm chɛk di lokal kɔd ɛn standad bifo yu yuz am fɔ drink wata.