BI Galvanized steel coil yɛ dade a wɔabobɔw a wɔde zinc akata so. Saa zinc layer yi bɔ dade no ho ban fi rust ne damage ho, na ɛma coil no yɛ den na ɛyɛ den. Yɛn adwumakuw no de galvanized steel coil nneɛma a ɛyɛ papa a adwumayɛbea ne adansifo de di dwuma kɛse ma adansi, nneɛma a wɔyɛ, ne kar afã horow ma. Wɔ afe 2022 mu no, wɔyɛɛ dade coil a wɔde galvanized ayɛ metric tɔn ɔpepem 140 wɔ wiase nyinaa, na China na edii anim. Wɔayɛ yɛn nneɛma no sɛnea ɛbɛyɛ a ebetumi adi ahwehwɛde a ɛrenya nkɔanim a ɛne sɛ wobenya dade a wɔde galvanized galvanized coils a wotumi de ho to so di dwuma wɔ nnwuma ahorow mu no ho dwuma.

Key Takeaways .

galvanized steel coil yɛ dade a wɔde zinc akata so. Zinc no boa ma rust gyae na ɛma dade no kyɛ. Eyi ma dade no yɛ den na eye ma nneɛma pii.

Nneɛma ahorow ne nea ɛwɔ galvanized steel coil ahorow mu wɔ hɔ. Ɔkwan biara so no, ɛyɛ adwuma yiye ma nnwuma bi. Zinc a ɛyɛ den a wɔde kata so no bɔ abɔnten ho ban yiye. Nneɛma a wɔde kata so a ɛyɛ tratraa no ye ma mu anaasɛ ɛyɛ hwɛ.

Hot-dip, pre-galvanizing, ne electrogalvanizing yɛ akwan a wɔfa so de zinc ka ho. Ɔkwan biara ma ɛsono ne kɛse ne sɛnea ɛte. Wɔde emu biara di dwuma ma ahiade soronko.

Wɔde galvanized steel coil di dwuma kɛse wɔ adansi, kar, ne fie mfiri mu. Ɛboa ma wɔkora sika so efisɛ enhia sɛ wosiesie no pii na ɛho nhia pii.

Sɛ wopaw coil a ɛfata no a, ɛkyerɛ sɛ wobɛdwene thickness, zinc coating, grade, ne baabi a wɔde bedi dwuma ho. Eyi boa ma wɔhwɛ hu sɛ ɛyɛ adwuma yiye na ɛtra hɔ kyɛ.

Galvanized Steel Coil Nsɛm a Wɔka Kyerɛ .

Nea ɛyɛ galvanized dade coil .

Dade a wɔde galvanized ayɛ no yɛ dade a ɛyɛ tratraa. Wɔabobɔw no ayɛ no coil. Wɔde zinc layer akata coil no so. zinc no ma dade no yɛ nea ahobammɔ wom fi rust ne nsɛe ho. Nnwumayɛbea ne adansifo te sɛ galvanized steel coil. Ɛyɛ den na ɛtra hɔ kyɛ. Ɛyɛ adwuma yiye wɔ wim tebea a emu yɛ den mpo mu. Zinc layer no siw nsu ne mframa ano. Eyi boa ma rust gyae sɛ ɛbɛhyehyɛ. Sɛ coil no wɔ abɔnten a, zinc hyia oxygen ne nsu. Ɛyɛ ade a ɛyɛ tratraa a ɛbɔ coil no ho ban. Saa sini yi boa ma coil no ko tia ɔsɛe.

Galvanized steel coil no wɔ agyapade ahorow pii a ɛho hia:

Agyapadeɛ |

Botae ahorow a wɔtaa de di dwuma . |

Nea ɛho hia/mfaso . |

Muduro |

bɛyɛ 7.85 g/cm³ |

Standard weight a ɛfata ma structure applications . |

Nneɛma a wɔde kata so no mu duru . |

30-350 g/m² (afã abien no nyinaa) . |

Ɛma ahobammɔ a ɛyɛ corrosion no yɛ nea wotumi sesa ma ɛne nneɛma a atwa yɛn ho ahyia no hyia . |

Nneɛma a ɛwɔ soro a ɛyɛ mmerɛw . |

Nneɛma a ɛyɛ mmerɛw (RA) 0.8-1.5 μm . |

Ɛma coating adhesion ne durability yɛ kɛse . |

Ɔhyew mu nsu a ɛkɔ nipadua no mu . |

galvanizing layer no nnyaa ne so nkɛntɛnso . |

Ɛfata ma ɔhyew a wɔsɛe no ho nhyehyɛe . |

Electrical conductivity . |

a ɛba fam kakra sen dade a ɛho tew . |

Edi mfiridwuma mu nsu a ɛkɔ nipadua no mu ho ahwehwɛde ahorow ho dwuma . |

Ɔhyew mu ntrɛwmu ho nsusuwii . |

11.5 x 10⁻⁶/°C . |

hwɛ hu sɛ dimensional stability wɔ ɔhyew nsakrae ase . |

Hyɛ no nsow: Zinc layer no boa coil no ma ɛko tia nnuru. Ɛtra hɔ pintinn wɔ mmeae a pH fi 6 kosi 12. Coil no tumi di ɔhyew a ɛkɔ 200°C ho dwuma bere tenten. Ebetumi agye 300°C bere tiaa bi.

Nsɛm titiriw a wɔakyerɛw .

Wɔn a wɔyɛ no yɛ galvanized steel coil wɔ akɛse pii mu. Wɔsan nso yɛ nneɛma ahorow a ɛyɛ den. Nneɛma a ɛtaa ba ne ne kɛse, ne tɛtrɛtɛ, ne mu duru, ne ne mu ntwemu. Eyinom boa adetɔfo ma wɔpaw coil a eye sen biara ma wɔn ahiade.

Nkyerɛkyerɛmu parameter . |

Common range / value . |

Nneɛma a ɛyɛ den . |

0.12 mm kosi 0.8 mm (ebi yɛ 4.0 mm anaa 6.0 mm) . |

Ntrɛmu |

600 mm kosi 1500 mm (nsuo bi wɔ hɔ a ɛyɛ 600 mm kɔsi 1250 mm) . |

Coil mu duru . |

metric tɔn 3 kosi 8 (gyinabea), ɛkɔ soro kodu metric tɔn 25 bere a wɔabisa no . |

Coil mu ntwemu . |

508 mm anaa 610 mm . |

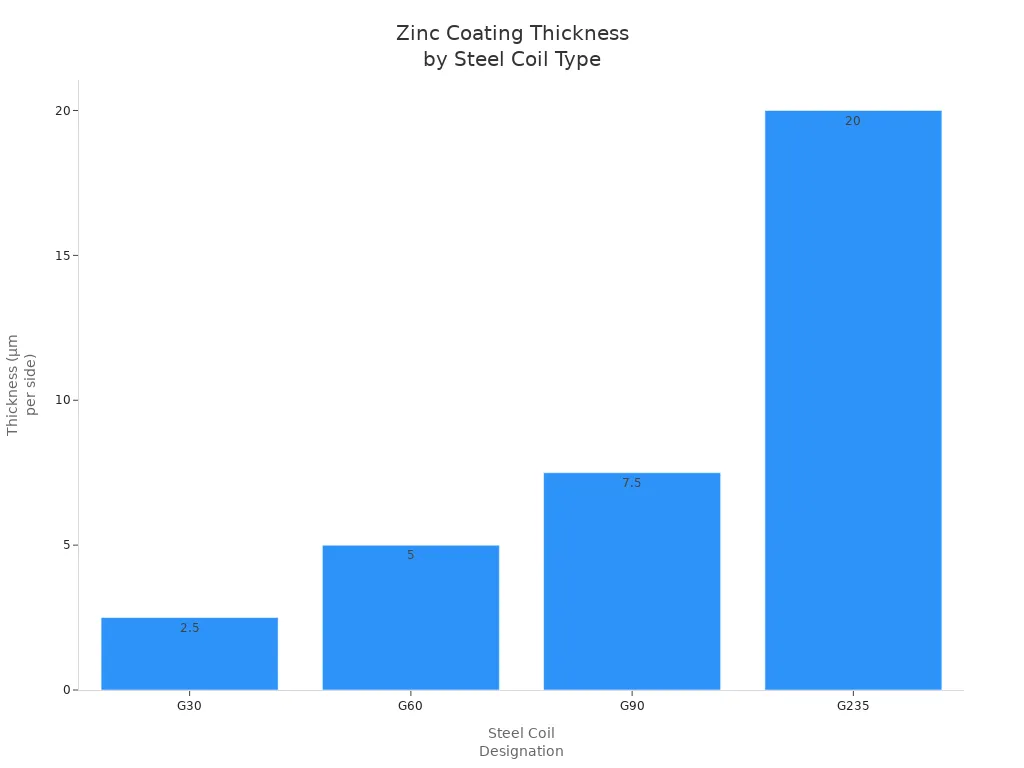

Zinc coating thickness no ho hia yiye. Ɛka sɛnea coil no ko tia rust yiye no. Ɛsan nso sesa bere tenten a coil no tra hɔ no. Coil ahorow ahorow wɔ coating weights ne thickness ahorow. Nsɛm a ɛwɔ ase hɔ no kyerɛ ahorow a wɔtaa yɛ ne nea ɛwɔ mu:

Nkyekyɛmu |

Zinc a wɔde kata ade so no mu duru (oz/ft⊃2;) . |

bɛyɛ sɛ ne kɛse (μm wɔ ɔfã biara) . |

corrosion resistance a ɛtaa ba . |

Nneɛma a wɔtaa de di dwuma . |

G30. |

0.30 nyinaa (0.15 wɔ ɔfã biara) . |

~2.5. |

Hann ho banbɔ . |

Nneɛma a wɔde yɛ dan mu, nneɛma a wɔde yɛ adwuma . |

G60. |

0.60 nyinaa (0.30 wɔ ɔfã biara) . |

~5. |

Ahobammɔ a ɛkɔ fam . |

HVAC, abɔnten so framing a ɛyɛ hare . |

G90 . |

0.90 nyinaa (0.45 wɔ ɔfã biara) . |

~7.5. |

Ahobammɔ a ɛkorɔn . |

Ɔdan atifi, siding, kuayɛ . |

G235 na ɛwɔ hɔ. |

2.35 nyinaa (1.175 wɔ ɔfã biara) . |

~20 . |

Ahobammɔ a ɛsen biara . |

Po so, Awɛmfo, Nneɛma a Ɛwɔ Ahunmu a Ɛkorɔn . |

Ɔkwan a wɔfa so de zinc gu coil no so no sesa ne kɛse. Hot-dip galvanizing yɛ ade a ɛyɛ den a wɔde kata so. Mpɛn pii no, eyinom yɛ micrometer 45 kosi 100. Electro-galvanizing ma nneɛma a wɔde kata so no yɛ teateaa. Eyinom fi micrometer 2.5 kosi 25. Nneɛma a wɔde kata so a ɛyɛ den no bɔ ho ban yiye nanso ne bo yɛ den. Nneɛma a wɔde kata so a ɛyɛ tratraa no hwɛ yiye na wɔde di dwuma wɔ mu anaasɛ wɔde siesie.

Ɛsɛ sɛ galvanized steel coil di amanaman ntam gyinapɛn ahorow akyi. Saa mmara yi hwɛ hu sɛ coil no yɛ nea ahobammɔ wom na ɛyɛ den. Gyinapɛn ahorow bi a ɛho hia ne:

Susudua |

scope / dwumadie . |

Nsɛm titiriw a ɛfa nkyerɛkyerɛmu ho . |

ASTM A653/A653M . |

Dade krataa, zinc-a wɔde adura ho (galvanized) anaa zinc-iron alloy-a wɔde hot-dip nhyehyɛe adura ho . |

Coating mu duru, adhesion, soro su, coating thickness minimums, finish, anim, abata . |

ASTM A924/A924M . |

Ahwehwɛde a ɛwɔ hɔ nyinaa ma dade krataa, a wɔde dade ayɛ a wɔde hot-dip ayɛ no . |

Ahwehwɛde a ɛfa ade a wɔde kata ade so nyinaa a nea ɛka ho ne ne kɛse, nea ɛbata ho, ne ne soro a ɛyɛ papa . |

ASTM A123/A123M . |

Hot-dip galvanized coatings wɔ dade ne dade nneɛma so . |

Coating thickness Minimums, continuous smooth finish, mmeae a wɔmfa nkata so biara nni hɔ, a wɔbata ho denneennen wɔ ɔsom asetra nyinaa mu . |

ISO 3575 na ɛwɔ hɔ. |

Carbon dade krataa a ɛkɔ so yɛ zinc a wɔde zinc adura ho a ɛyɛ aguadi ne mfonini ahorow a ɛyɛ fɛ . |

Coating thickness, sɛnea ɛte, corrosion resistance . |

ISO 1461 . |

Hot dip galvanized coatings wɔ dadeɛ ne dadeɛ a wɔayɛ so – nkyerɛkyerɛmu ne akwan a wɔfa so sɔ hwɛ . |

Coating thickness, sɛnea ɛte, corrosion resistance . |

ASTM ne ISO gyinapɛn ahorow no de mmara a ɛfa sɛnea wɔde kata ade so duru ne ne kɛse ho no si hɔ.

Sɔhwɛ ahorow hwɛ sɛnea zinc bata dade ho yiye ne sɛnea ade a wɔde kata so mpo te.

Wɔde nkyene a wɔde petepete ne akwan foforo so sɔ corrosion resistance hwɛ.

ahorow ne abasobɔde ahorow .

Galvanized steel coil no wɔ ahorow ahorow ne nea ɛwɔ mu. Ɔkwan biara wɔ nneɛma titiriw bi a ɛwɔ hɔ ma nnwuma bi.

Hot-dip galvanized steel coils: Wɔde dade a wɔde hyɛ zinc a ayɛ hyew mu na ɛyɛ saa coils yi. Eyi ma ɛyɛ ade a ɛyɛ den na ɛyɛ den a ɛma nkannare gyina. Adansifo de nneɛma a ɛyɛ hyew di dwuma de yɛ abɔnten nneɛma te sɛ adan atifi ne ban.

Electro-galvanized steel coils: Saa coils yi nya zinc denam anyinam ahoɔden a wɔde di dwuma wɔ aduru bi mu so. Layer no yɛ mmerɛw na ɛyɛ mmerɛw. Nnwumayɛbea ahorow de saa coils yi di dwuma ma kar akwaa ne mfiri a ehia sɛ wɔhwɛ no fɛfɛɛfɛ.

abasobɔdeɛ de 'g' ne nɔma di dwuma. Akontaabu no kyerɛ sɛnea zinc dodow te wɔ coil no so. Nnipa dodow a ɛsõ no kyerɛ zinc pii ne ahobammɔ a eye. G60, G90, ne G275 yɛ adesua a wɔtaa yɛ.

Grade Type . |

Nkyerɛmu |

Application ahorow a wɔtaa de di dwuma . |

aguadi mu abasobɔde . |

gua so kyɛfa kɛse; Nneɛma a wɔde di dwuma wɔ ɔkwan a ɛkɔ akyiri so wɔ adansi mu . |

Ɔdan atifi, siding . |

Mfoniniyɛ a ɛyɛ fɛ . |

Wɔde di dwuma wɔ dade a wɔde ayɛ nwini mu . |

Kar, Nnwinnade . |

ahoɔden a ɛkorɔn a ɛba fam alloy . |

Ahoɔden a ɛkorɔn ne nea ɛtra hɔ kyɛ . |

Adaka, Adan, Ahyɛn . |

Structural grade . |

Wɔde di dwuma wɔ abɔnten so adan ne adan a wosisi mu . |

Nneɛma a wɔde yɛ nhyehyɛe . |

afoforo nso . |

Nkonimdi soronko a ɛwɔ agyapade pɔtee bi . |

Application ahorow titiriw ahorow . |

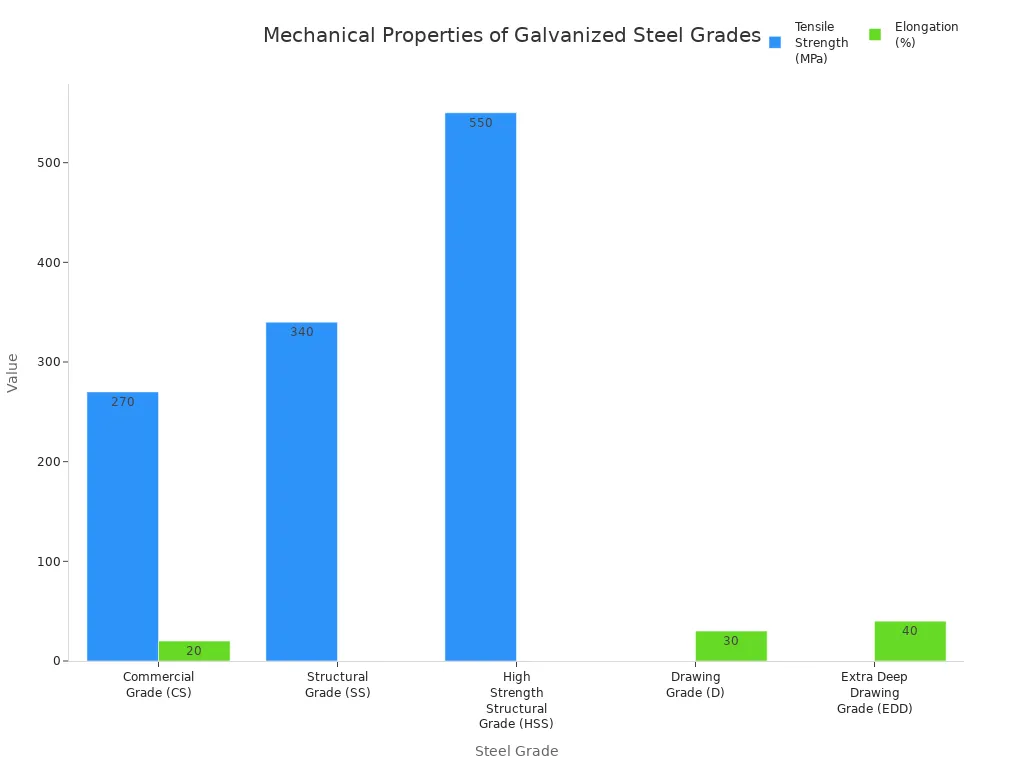

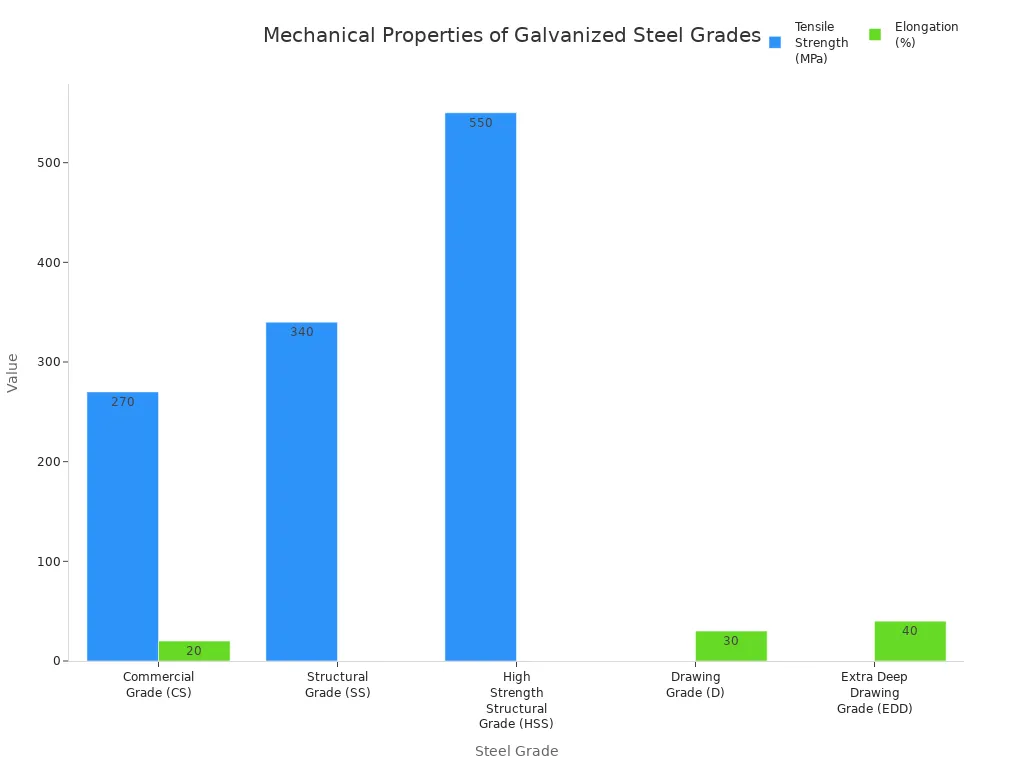

Mfiridwuma mu nneɛma sesa wɔ grade biara mu. Nsεmfua a εwכ aseε ha yi kyerε sεdeε ahoɔden ne ahokeka yɛ soronko:

Aba |

Ahoɔden a ɛyɛ den (MPa) . |

aba a ɛma wonya ahoɔden (MPa) . |

elongation (%) . |

Core Advantage . |

Application/processing a wɔtaa de di dwuma . |

Adwumayɛ mu abasobɔde (CS) . |

270 - 410 na ɛwɔ hɔ. |

N/A . |

≥ 20 . |

Mfitiase rustproofing, ahoɔden a ɛwɔ hɔ nyinaa . |

Bending ne cutting a ɛyɛ mmerɛw (nsɔano a emu dɔ biara nni hɔ) . |

Structural grade (SS) . |

340 - 550 na ɛwɔ hɔ. |

≥ 230 . |

Kakra |

Ahoɔden a ɛkorɔn ne weldability . |

Adesoa-soa, welding, bolt nkitahodi . |

Mfonini a wɔde yɛ mfonini (d) . |

Kakra |

N/A . |

≥ 30 . |

ductility a ɛkorɔn ne elongation a ɛyɛ pɛ . |

Medium complexity stamping . |

Extra deep drawing grade (Edd) . |

Deɛ ɛwɔ fam |

N/A . |

≥ 40 . |

formability a ɛtra so, resistance to thinning . |

Stamping a ɛyɛ den a ɛwɔ nsusuwso a ɛyɛ pɛpɛɛpɛ . |

Ahoɔden a ɛkorɔn a wɔde yɛ nhyehyɛe (HSS) . |

550 - 980 na ɛwɔ hɔ. |

Nneɛma a wonya fi mu ≤ 0.85 . |

Kakra |

Ahoɔden ne emu duru a ɛkorɔn sen biara, ahoɔden a ɛkɔ soro a ɛtwetwe . |

Nneɛma titiriw a wɔyɛ (Laser twa, hydraulic molding) . |

Galvanized steel coil no wɔ soro a ɛsono nea ɛwɔ so:

Daa Spangled: Wubetumi ahu zinc crystals. Wɔde di dwuma wɔ adansi mu.

Spangle a wɔatew so: ahwehwɛ nketewa ma ɛyɛ mmerɛw. Wɔde di dwuma wɔ kar ne mfiri mu.

Zero Spangle: Wonhu ahwehwɛ biara. Ne soro no yɛ hyerɛn na ɛyɛ mmerɛw. Wɔde di dwuma wɔ aduan ne nnuruyɛ mu.

Nneɛma titiriw a wɔde kata so: coils binom wɔ layers foforo a wɔde yɛ nsateaa, mmoawa, anaa ɔhyew.

Afotu: Paw ɔkwan a ɛfata ne abasobɔde a wode bɛyɛ w’adwuma. Nneɛma a ɛyɛ den a wɔde kata so ne nea ɛkorɔn no ye ma abɔnten anaa mmeae a ɛyɛ den. Nneɛma a wɔde kata so a ɛyɛ tratraa ne nea wɔde awie no ye ma mu anaasɛ nneɛma a wɔde siesie hɔ.

Akwan a wɔfa so yɛ nneɛma .

Hot-dip galvanizing .

Hot-dip galvanizing ne ɔkwan a agye din sen biara a wɔfa so bɔ dade coil ho ban. Nea edi kan no, adwumayɛfo tew dade no ho. Wɔn pickle na wɔma ɔfasu no yɛ nea ɛnyɛ hwee. Afei, wɔde coil no hyɛ zinc a ayɛ hyew mu. Eyi ma ɛyɛ zinc-iron alloy layer a ɛyɛ den. Sɛ wode dipping di dwuma wie a, coil no dwo. Adwumayɛfo de passivation ne ngo di ho dwuma. Saa anammɔn yi boa ma coating stick no yɛ fɛ na ɛyɛ fɛ. Nhwehwɛmufo hwɛ sɛnea ne kɛse te ne sɛnea ade a wɔde kata so no te. Afei, coil no yɛ ma. Zinc layer no yɛ den, mpɛn pii no ɛyɛ micrometer 45 kosi 85. Eyi ne ASTM mmara te sɛ A123 ne A653 hyia. Adeyɛ no boa ma dade ko rust ne scratches. Ɛyɛ kɛse ma abɔnten adan ne nnwuma a emu yɛ den.

Adeyɛ a ɛsen: .

Siesie na siesie nneɛma no .

Pickle na yi srade fi mu .

Hohoro na fa wo ho hyɛ mu .

Fa aduru a wɔde kata aduru a wɔde di kan yɛ aduru ka ho .

Dip wɔ zinc a ayɛ hyew mu .

Ma onwini na yɛ coil no ho adwuma .

Flatten na twitwa coil no .

Hwɛ sɛ ɛyɛ papa anaa .

Twitwa na bobɔ mu kɔ coils mu .

Fa ade no hyɛ mu na fa mena .

Ansa na wɔreyɛ galvanizing .

Pre-galvanizing si wɔ dade afiri no mu ansa na wɔayɛ. Adwumayɛfo di kan siesie dade krataa no. Afei, wɔde tu mmirika fa zinc a ayow mu wɔ nkyerɛwde bi mu. Eyi ma ɛyɛ mmerɛw na ɛyɛ zinc mpo. Mpɛn pii no, nea wɔde kata so no mu duru yɛ micrometer 20 kosi 30. Nea wɔde wie no yɛ nea ɛhyerɛn na ɛnyɛ den sɛ wɔbɛyɛ. Pre-galvanized dade bo yɛ mmerɛw na ɛyɛ adwuma yiye ma nnwuma akɛse. Nanso, cut edges ne welds betumi akyerɛ dade a ɛda hɔ kwa. Eyi kyerɛ sɛ rust ahobammɔ a ɛba fam. Pre-galvanizing ye sen biara ma nneɛma a ɛwɔ dan mu anaa afã horow a ɛsɛ sɛ ɛyɛ fɛ.

Su |

Hot-dip galvanizing . |

Ansa na wɔreyɛ galvanizing . |

Coating a ɛyɛ den . |

45-85μm . |

20-30μm . |

Nsɛm a wɔka kyerɛ . |

Full, a anoano ka ho . |

Ɛnyɛ nea wɔatwa wɔ anoano . |

Wie |

Nsakraeɛ . |

Ɛyɛ pɛ, ɛyɛ hyew . |

Fa di dwuma yiye sen biara . |

Abɔnten, a ɛyɛ adwuma kɛse . |

Afã horow a ɛwɔ dan mu a wotumi hu . |

Electrogalvanizing .

Electrogalvanizing de anyinam ahoɔden di dwuma de kata dade so wɔ zinc mu. Adwumayɛfo di kan siesie dade no. Afei, wɔde gu ano aduru soronko bi mu. Zinc ions bata dade no ho na ɛyɛ teateaa, mpo layer. Mpɛn pii no, nea wɔde kata so no mu duru yɛ micrometer 5 kosi 25. Electrogalvanized dade yɛ mmerɛw na ɛhyerɛn. Ɛkotow ntɛmntɛm na ɛko tia nkannare wɔ mmeae a ɛhɔ yɛ nsu. Ɛnyɛ den nso sɛ wobɛbɔ ho mfonini. Nkurɔfo de di dwuma ma kar akwaa, mfiri, ne ɛlɛtrɔnik mfiri. Adeyɛ no di ASTM A879 mmara akyi. Ɛyɛ papa ma nneɛma a ehia sɛ wonya no yiye na ɛbɔ rust ho ban kakra.

Hyɛ no nsow: Electrogalvanized dade yɛ adwuma yiye wɔ paint mu ne ase. Ɛgyae rust yie nanso ɛmmɔ ho ban firi sɛ ɛbɛwe te sɛ hot-dip akwan.

Galvanealing .

Galvanealing frafra galvanizing ne ɔhyew. Bere a adwumayɛfo no ayɛ hyew akyi no, adwumayɛfo ma dade no yɛ hyew kɛse. Eyi ma ɛyɛ zinc-iron alloy layer. Layer no boa wɔ welding ne mfoniniyɛ mu. Galvanealed dade yɛ mmerɛw sɛ weld ne shape. Wɔde di dwuma wɔ kar, adan, ne mfiri mu. ASTM A653 de mmara a ɛfa galvanealed steel coil ho ma. Eyi ma su ne adwumayɛ kɔ so gyina hɔ ma.

Nneɛma a ɛwɔ mu ne mfaso a ɛwɔ so .

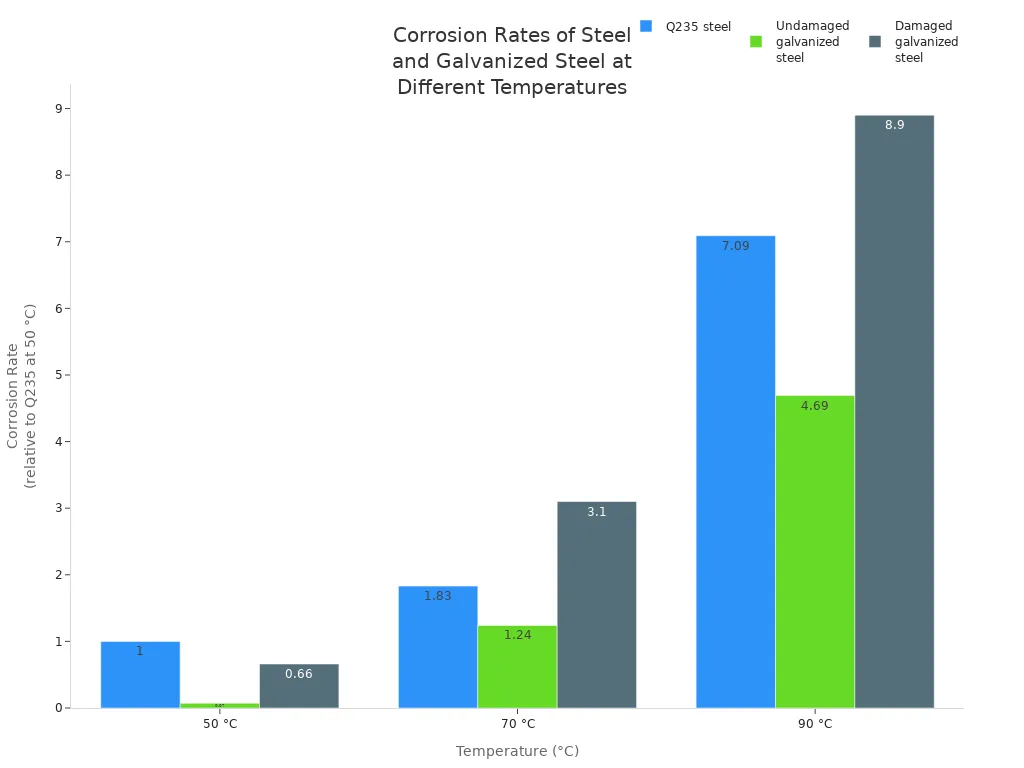

Nneɛma a ɛko tia corrosion .

galvanized steel no nnyɛ mmerɛw esiane sɛ wɔde zinc akata so nti. Zinc layer no bɔ dade a ɛwɔ ase no ho ban. Sɛ nsu anaa mframa ka coil no a, zinc di kan yɛ ho biribi. Eyi ma ɛyɛ kyɛm a ɛma oxygen ne nsu ntumi nkɔ dade no mu. Zinc layer no nso yɛ nnuru soronko te sɛ zincite (ZNO), hydrozincite, ne simonkolleite. Saa nneɛma yi yɛ sini a ɛyɛ den. Sini no ma nkannare brɛ ase na ɛma dade no kɔ so yɛ adwuma. Sɛ mpo coil no twetwe anaasɛ wotwa a, zinc no da so ara bɔ ho ban. Zinc a wɔde kata so no sesa sɛnea dade no yɛ wɔn ade wɔ nkannare ho. Zinc layers a ɛyɛ den no ma ahobammɔ kɛse. Wɔtra hɔ kyɛ wɔ mmeae a emu yɛ den.

zinc a wɔde kata so no sɛe ansa na dade no ayɛ kɛse.

Nneɛma a ɛbɔ ho ban no siw oxygen ne nsu ano fi dade no ho.

Nkataso no siesie ne ho wɔ nsensanee anaa nea wɔatwitwa so.

zinc-rich primers ma ahobammɔ foforo wɔ tebea horow a emu yɛ den mu.

Sɔhwɛ ahorow kyerɛ sɛ dade a wɔde galvanized ayɛ no gyina rust ano yiye sen dade a ɛnyɛ den. Eyi yɛ nokware wɔ mmeae a ɛhɔ yɛ nsu anaa abɔnten.

Nhwɛsode . |

Nneɛma a ɛyɛ mmerɛw (50°C) . |

Nneɛma titiriw a wɔde yɛ corrosion . |

Nneɛma a wɔyɛ . |

Q235 dade . |

1 |

FE3O4. |

Mrɛ |

Dade a wɔde galvanized ayɛ a ɛnyɛ nea asɛe . |

0.07 |

Zno . |

Ɛyɛ den . |

Dade a wɔde galvanized ayɛ a asɛe . |

0.66 |

FE3O4 + ZNO . |

Ɛyɛ den . |

Durability ne ne siesie .

Zinc coating no boa galvanized steel bere tenten. Ɛyɛ adwuma yiye wɔ abɔnten wɔ osutɔ, owia, ne mframa mu. Nkurɔfo de di dwuma ma adan atifi, ban, ne mfiri. Dade a ɛnyɛ den no kyɛ wɔ mmeae a ɛyɛ den yiye. Nanso dade a wɔde galvanized ayɛ no bɔ ho ban yiye na ɛho ka sua. Bere kɔ so no, zinc layer no betumi asɛe. Nhwehwɛmu a wɔyɛ no daa ne nea ɛyɛ mmerɛw sɛ wobesiesie no ma dade no kɔ so yɛ den.

Afotu: Fa dade a wɔde galvanized ayɛ sie mmeae a ɛhɔ yɛ kusuu. Fa coils kyekyere ho de bɔ wɔn ho ban. Hwɛ sɛ nsu taa ba anaa. Sɛ wuhu sɛ asɛe a, fa paint anaa aduru a wɔde petepete zinc so siesie.

Nneyɛe a wɔkamfo kyerɛ sɛ wɔmfa nsiesie:

Fa nnuru anaa ngo di dwuma de gyae akasakasa ne nneɛma a ɛsɛe.

Fa krataa anaa plastic kyekyere coils bere a worekora so anaasɛ wode rekɔ no.

Hwɛ sɛ nsu ne dry coils ntɛm ara sɛ ɛyɛ nsu a.

Siesie nneɛma a wɔde ahyɛ mu no ntɛmntɛm na ama agyae nsensanee.

Store coils wɔ adan a wim tebea hwɛ so mu. Mma wɔnntra hɔ nkyɛ dodo.

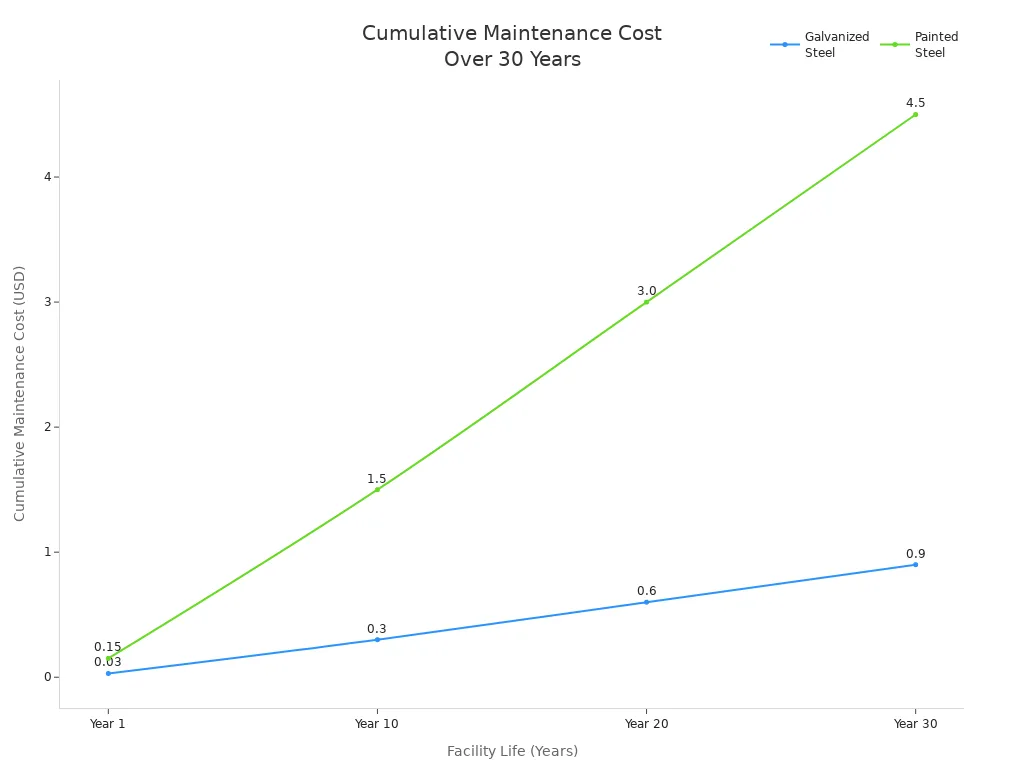

Ka a wɔbɔ no yiye .

galvanized steel ma sika no nya mfaso pa. Ɛyɛ nea ne bo yɛ den sen dade a ɛnyɛ den mfiase no. Nanso ne bo yɛ mmerɛw sen dade a ɛnyɛ den anaasɛ coil a wɔayɛ ho adwini. zinc a wɔde kata so no kyerɛ sɛ wɔbɛsiesie no kakraa bi na wɔansan ayɛ ho mfonini pii. Eyi ma bere kɔ so no sika pii.

Afã a ɛho ka yɛ den . |

Hot-dip galvanized dade . |

dade nhyehyɛe a wɔayɛ ho mfonini (atade abien) . |

Ka a wɔbɔ mfiase no . |

akansi anaasɛ ɛba fam . |

Ɛtɔ mmere bi a, ɛkɔ soro anaasɛ ɛte saa ara . |

Afe afe nsiesie . |

$0.03 afe biara . |

$0.15 afe biara . |

Facility asetra . |

Mfe 30 . |

Mfe 30 . |

Nsiesiei a Ɛho Hia . |

Ɛnyɛ ebiara |

Nneɛma a wɔde yɛ mfonini daa . |

Asetra-kyinhyia ho ka . |

Mpɛn pii no, ɛka a wɔbɔ mfiase no ara kwa . |

Nea ɛkorɔn sen saa esiane sɛ wosiesie nti . |

galvanized steel boa ma ɛho ka so tew bere tenten. Ɛho nhia sɛ wosiesie nneɛma pii na wɔde si ananmu. Ɛsan nso sie ahoɔden wɔ adan mu. Eyi ma ɛyɛ nyansa kwan a wɔfa so si nneɛma na wɔyɛ nneɛma.

Nneɛma a wɔde di dwuma wɔ galvanized steel coil mu .

Ɔdansi ne ɔdan atifi .

Galvanized steel coil ho hia yiye wɔ ɔdansi mu. Adansifo de di dwuma ma adan atifi, afasu, nnua, ne nnua. Zinc layer no ma adan no yɛ nea ahobammɔ ne wim tebea nye. Eyi ma ɛyɛ ade pa a wobetumi apaw de adi dwuma wɔ abɔnten. Ɛyɛ den na ɛnyɛ mmerɛw sɛ ebebubu. Ɛtra hɔ kyɛ wɔ mmeae a ɛyɛ den. Adansifo pii paw dade a wɔde galvanized ayɛ a wɔde yɛ dade adan, nsu a ɛkɔ nsu mu, ne ɔfasu ho ntama. Wɔde galvanized steel coil nyinaa mu fã na ɛyɛ adwuma. Nkurow akɛse ne nnwuma foforo ma ɛho hia sɛ saa nneɛma yi kɔ so yɛ kɛse, titiriw wɔ Asia-Pacific.

Nneɛma a wɔyɛ ne kar a wɔyɛ .

Nnwumayɛbea ahorow de galvanized steel coil di dwuma efisɛ ɛyɛ den na ɛnyɛ den sɛ wɔbɛyɛ. Wɔn a wɔyɛ kar no de galvanized coils a ɛyɛ hyew di dwuma ma kar nipadua, nnua a wɔde ayɛ nneɛma, ne ase afã horow. Zinc layer no siw saa afã horow yi ano ma ɛyɛ mmerɛw. Eyi boa ma kar ahorow tra hɔ a ahobammɔ wom na ɛyɛ adwuma yiye. Nnwumakuw a wɔyɛ kar a ɛwɔ China ne India no de galvanized steel coil pii di dwuma mprempren. Wɔpɛ kar a emu yɛ hare na eye sen saa. Kar a anyinam ahoɔden wom pii nso kyerɛ sɛ ɛho hia kɛse ma saa ade yi. Mmara foforo a ɛfa efĩ ne pɛtro a wɔkora so ho no ma nnwumakuw de galvanized steel coil di dwuma. Akwan pa a wɔfa so kata so ne mpɔtam hɔ adwumayɛbea ahorow boa ma wodi ahwehwɛde kɛse a ɛwɔ saa mmeae yi ho dwuma.

Nneɛma afoforo a wɔde di dwuma .

Wɔde galvanized steel coil di dwuma ma nea ɛsen adan ne kar ahorow kɛkɛ. Wɔn a wɔyɛ mfiri no de yɛ ahohoro, frigye, ne mframa a wɔde yɛ adwuma. Ɛnnyɛ rust na ɛyɛ fɛ. Wɔde nneɛma no nso di dwuma wɔ green energy ne smart city projects mu. Electric kar ne green energy hia dade a ɛnyɛ rust ma nneɛma foforo. Wɔ Asia-Pacific no, wɔde galvanized steel coil bɛboro nkyem anan mu biako yɛ mfiri. Kurow mu nnwuma foforo ne adwumayɛbea afoforo ma ɛho hia sɛ dade yi kɔ soro. Mprempren nnwumakuw de mfiridwuma ho nimdeɛ foforo yɛ dade nneɛma a ɛyɛ anifere na ɛyɛ soronko ma gua foforo yi.

Nsusuwii ne anohyeto ahorow .

Sɛ wopaw coil a ɛfata .

Dade a ɛfata a wɔbɛpaw ama adwuma no ho hia. Ɛsɛ sɛ wususuw nneɛma pii ho. Saa nneɛma yi sesa sɛnea coil no yɛ adwuma yiye ne bere tenten a ɛkɔ so no.

Thickness : Thick steel kura mu duru pii na ɛtra hɔ kyɛ. Adansifo de coils a ɛyɛ den di dwuma ma beams ne afã horow a ɛyɛ den. Coils a ɛyɛ tratraa no ye ma nneɛma a emu yɛ hare te sɛ mframa a ɛkɔ nsu mu.

Coating Weight : zinc a wɔde kata so no ma rust kɔ. Nneɛma a emu yɛ duru a wɔde kata so, te sɛ G90 no, ye sen biara ma mmeae a ɛyɛ nsu anaa nkyene. Nneɛma a ɛyɛ hare a wɔde kata so, te sɛ G60 no, yɛ papa ma mmeae a ɛwɔ mu anaasɛ ɛnyɛ den.

Grade : Grade biara wɔ n’ankasa ahoɔden ne bendiness. Grades a ɛyɛ den yɛ papa bere a wuhia dade a ɛyɛ den no. Sɛ ɛho hia sɛ wokotow anaasɛ wohyɛ coil no mu a, ɛyɛ papa.

Trɛw ne Tenten : Amanneɛbɔ akɛse boa ma ɛfata adwuma biara. Eyi ma ɔdan ne adwini yɛ mmerɛw.

Nneɛma foforo a ɛsɛ sɛ wususuw ho : Susuw bo, adwuma no su, ne baabi a wode coil no bedi dwuma no ho. Wɔgyina nea wuhia so na ɛpaw hot-dip anaa electrogalvanizing.

ATIRIMKA: Bere nyinaa hwɛ nnwuma mu mmara na hwɛ nea ɔde ma wo no su ansa na woatɔ.

Nneɛma a atwa yɛn ho ahyia .

Beae a wode dade coils di dwuma no betumi asesa sɛnea ɛyɛ adwuma no. Nkyene a ɛwɔ wim a ɛbɛn po no mu no bubu zinc ntɛmntɛm. Efĩ a efi adwumayɛbea ahorow mu ba no ma osu a ɛyɛ acid a ɛma zinc no sɛe. Sɛ wode coils sie mmeae a ɛhɔ yɛ nwini a, ebetumi akyere nsu na ama ayɛ fitaa. Ɔhyew kɛse a efi welding anaasɛ nea wɔde twa mu no betumi ahyew zinc no na ama dade abue ama nkannare.

Atenaeɛ |

Asiane titiriw . |

Adeyɛ a ɛbɔ ho ban . |

Mpoano . |

Nkyene a wɔde petepete so, pitting . |

Fa zinc a emu yɛ duru a wɔde kata so di dwuma . |

Mfiridwuma mu . |

Acid osu, nsɛe . |

Fa passivation, nsɔano ano gu so . |

Nneɛma a wɔde sie a ɛyɛ nwini . |

Ntini fitaa a ɛyɛ fɛ . |

Fa sie baabi a ɛhɔ yɛ kusuu na mframa fa mu . |

Nsɛm a ɛtaa ba .

Steel coils betumi anya ɔhaw bere a wɔde di dwuma anaa wɔde sie:

Sɛ nsu kɔ so tra coil no so a, rust fitaa betumi ada adi, titiriw sɛ wɔanyɛ passivation no yiye a.

Scratches, cuts, anaa welding betumi apira zinc layer no na ama rust ayɛ mmerɛw.

Sɛ zinc no nyɛ pɛ anaasɛ dade no wɔ efĩ a, mmeae a ɛyɛ mmerɛw no betumi ayɛ.

Sɛ nsensanee fitaa kɔ so nyin a, nsensanee tuntum betumi asi.

Coils a wɔde sie no yɛ mfomso, te sɛ mmeae a nsu wɔ no, ma ɛyɛ mmerɛw sɛ nkannare bɛba.

Hyɛ no nsow: Fa ahwɛyiye di coils ho dwuma, hwɛ mu mpɛn pii, na fa sie yiye na ama woagyae ɔhaw dodow no ara.

Galvanized dade coil ma dade ahobammɔ fi rust. Ɛsan nso gyae ɔsɛe. Saa nsɛm yi mu yɛ den na ɛtra hɔ kyɛ. Ɛboa ma wɔkora sika so nso. Adansifo de di dwuma ma adan atifi ne afasu. Wɔn a wɔyɛ no de di dwuma ma kar ne mfiri. Ɛsɛ sɛ adetɔfo hwɛ sɛnea ne kɛse yɛ den na ɛkata so. Ɛsɛ sɛ wɔhwɛ abasobɔde no nso. ASTM gyinapɛn boa ma wɔhwɛ hu sɛ coil no ye. Nsu a ɛyɛ nwini ne nkyene a ɛwɔ mframa mu no betumi asakra sɛnea ɛyɛ adwuma no. Sɛ wopaw coil a ɛfata a, ɛma wunya nea eye sen biara.

FAQ .

Dɛn ne galvanized steel coil no atirimpɔw titiriw?

galvanized steel coil mma dade ntumi nsɛe anaasɛ ɛbɛsɛe. Zinc layer no yɛ adwuma te sɛ kyɛm. Adansifo ne adwumayɛbea ahorow de yɛ afã horow a ɛtra hɔ kyɛ na ɛtra hɔ yɛ den.

Ɔkwan bɛn so na zinc coating siw rust ano?

Zinc hyia nsu ne mframa ansa na dade no ayɛ saa. Eyi yɛ layer soronko bi wɔ soro. Layer no siw nsu ne mframa ano na atumi aka dade no.

Ɛhe na nkurɔfo de galvanized steel coil di dwuma mpɛn pii?

Nkurɔfo de galvanized steel coil di dwuma wɔ adansi, kar yɛ, ne mfiri a wɔyɛ mu. Ɛyɛ papa ma adan atifi, kar afã horow, ne mfiri asinasin.

So wobetumi ayɛ galvanized steel coil ho adwini?

Wubetumi ayɛ galvanized steel coil ho adwini. Ɛsɛ sɛ nea ɛwɔ soro no ho tew na ɛyow kan. Primers soronko boa ma paint no bata zinc layer no ho.

Gyinapɛn bɛn na ɛfa galvanized steel coil ho?

ASTM A653 ne ISO 3575 ne mmara titiriw a ɛfa galvanized steel coil ho. Saa mmara ahorow yi ka sɛnea ade a wɔde kata so no yɛ duru, sɛnea asase ani te, ne sɛnea ɛko tia nkannare yiye no ho asɛm.