Amakhoyili ensimbi enziwe nge-Galvanized asetshenziswa kabanzi ekwakheni, ezithunzini, kanye nokusebenza ngohlelo lokusebenza ngenxa yamandla awo nokutholakala kwawo.

Imikhiqizo yethu ifaka i-zinc coating esetshenziswe nge-galvanizing eshisayo eshisayo, esebenza njengesivikelo esivikelekile ngokumelene nomswakama nezinye izinto ezilonakalisayo. Noma ngabe ukuhlanganisa ikholi yensimbi ye-galvanized kukhukhunyiwe, i-zinc ilungisa kuqala, ivikela insimbi ngaphansi. Ungase uzibuze, Ingabe ukugqwala kwensimbi okwenziwe nge-galvaning? Impendulo inguyebo, kepha kwenzeka kancane kancane. I-Lifespan yamakhoyili ensimbi ye-garyvanized incike ezintweni ezifana nemvelo, ukuqina okuhlanganisiwe, kanye nokunakekelwa.

ICEBISO: Hlala uhlola amakhoyili wensimbi amasha we-garyvanized nganoma yimuphi umonakalo. Ukunakekelwa okufanele kwe-coil yakho yensimbi ye-galvanized akukugcini kuphela ukuthi kubukeka kukuhle kodwa futhi kunwebeka ukuqina kwamaphrojekthi akho nge inkampani yethu.

Ukuthathwa Key

Amakhoyili wensimbi enziwe nge-galvanized awagwimbi kalula. Lokhu kungenxa yokuthi bane-zinc coating. I-zinc isebenza njengesihlangu futhi igcina insimbi iphephile. Isendlalelo se-zinc siyama amanzi ekuthinteni

insimbi. Uma ukuhlanganiswa kukhuculwa, i-zinc isasiza ukumi ukugqwala. Lokhu kwenza ikhoyili ihlale isikhathi eside. Izinto ezifana nomoya onosawoti, ukungcoliswa komhlaba, kanye nesimo sezulu esimanzi senza ukugqwala kusheshe. Ngakho-ke, lapho usebenzisa khona izindaba zensimbi isikhathi esingakanani. Ukuhlanza amakhoyili kuvame ukuzisiza ukuba zihlale zinhle. Ukuhlola ukulimala nokukulungisa ngokushesha kuyasiza. Ukukhetha inani elifanele le-zinc coating kubalulekile. Ukugcina amakhoyili ngendlela efanele ibagcina bephephile. Lokhu kuyabasiza ukuthi bahlale isikhathi eside.

Ingabe ukugqwala kwensimbi ye-galvaning?

Uma ubuza uma ukugqwala kwensimbi ye-garvaning, ufuna impendulo elula. I-Calvanized Steel Coil imelana nokugqwala kahle, kepha kusengagqwala. I-zinc coating yenza njengesihlangu futhi ibambezele ukugqwala. Ngokuhamba kwesikhathi, izinto ezinjengesimo sezulu kanye nomonakalo zingasusa lesi sihlangu. Kubalulekile ukwazi ukuthi i-galvaning ime kanjani ukugqwala nokuthi yini ongayilindela kwikhoyili enhle egayiselelwe ezindaweni ezahlukahlukene.

Ukuvikelwa kwe-zinc coating

I-zinc coating coil ye-galvanized yenza isithiyo phakathi kwensimbi nomoya. Lesi sithintelo sigcina amanzi nomoya-mpilo, obangela ukugqwala. Uma ukhetha insimbi ehlanganiswe nge-zinc, kumi kuze kufike imvula, umswakama, nokungcola. I-Hot-Pip ye-Galvaning Bonds zinc in eless, ngakho-ke ukuhlanganiswa kuthatha iminyaka eminingi.

Izifundo zibonisa ukumbona kwe-zinc ziba ngcono ngezithasiselo ezikhethekile. Lezi izengezo zenza ukuhlanganiswa kube namandla futhi zibe ngcono ekunqandeni ukugqwala. Isibonelo, ukungeza ama-reanarcrecki we-ceria nanoparticles kanye ne-polyaniline kusiza i-zinc ivikela insimbi ekugcekeni. Olunye ucwaningo lwavivinya ikhoyili yensimbi eyenziwe ngolwandle iminyaka emihlanu. Izimbobo ezinkulu ze-zinc zehlise ubungozi bokugqwala okubomvu nopende upele, ikakhulukazi emaphethelweni. I-Zinc under yakha amafilimu futhi iyeka umoya-mpilo ekufinyeleleni kwensimbi.

Ungabona ukuthi imvelo ishintsha kanjani ukuthi ikhoyili ehamba phambili ye-galvanid ihlala etafuleni elingezansi:

Indawo ezungezile |

Isikhathi esijwayelekile sokugqwala okumele sivele |

Izici ezibalulekile zezemvelo |

Izincomo zokulungisa |

Ngaphandle okujwayelekile |

Iminyaka engama-20 kuye kwangama-50 |

Umoya omusha, ukungcola okuphansi |

Bheka ubukhulu be-coating njalo eminyakeni engu-5; Inketho ecacile ye-lacquer |

Indawo yasogwini |

Iminyaka emi-5 kuye kwayi-15 |

Okuqukethwe okuphezulu kasawoti emoyeni (isifutho sikasawoti) |

Hlola kabili ngonyaka (gxila kuma-welds / emaphethelweni); Hlanza ngekota |

Ukungcoliswa kwezimboni |

Iminyaka eyi-10 noma ngaphansi |

Ukungcola Kusheshisa i-Zinc Gqoka |

Ukuhlolwa okuvalekile nokuhlanza Kunconyiwe |

Qaphela: Ukuhlanza nokuhlola ikhoyili yakho egciniwe kuvame ukukwenza kube isikhathi eside. Uma ungayinakekeli, ukugqwala kuzokwenzeka ngokushesha, ikakhulukazi ezindaweni ezinzima.

I-Calvanized Steel Coil ingahlala iminyaka engama-20 kuye kwengama-50 noma ngaphezulu ngaphandle kwezimo ezijwayelekile. Ezindaweni ezisogwini noma ezimbonini, akuhlali isikhathi eside ngenxa kasawoti namakhemikhali. Ubukhulu bekhwalithi nokuhlanganisa kubalulekile. Izimbobo ezinkulu ze-zinc zivikela kangcono futhi zihlale isikhathi eside.

Ezindaweni eziphansi zangaphandle, insimbi eyenziwe nge-galvanized ingahlala ngaphezulu kweminyaka engama-50 ngaphambi kokugqwala.

Ezindaweni ezinzima njengezindawo ezisogwini noma zezimboni, kungahlala iminyaka engama-20 noma ngaphansi.

Insimbi ye-Galvanized ingahlala iminyaka engu-50-100 ezindaweni ezijwayelekile.

Ezindaweni zasolwandle noma zezimboni, kuthatha iminyaka engama-20-50 ngokunakekela.

I-zinc coating inika isithiyo nokuvikelwa komhlatshelo ekugqwaleni.

Amakhemikhali, amanzi, ukulimala, kanye nomswakama ophezulu kwenza ukuthi igqoke ngokushesha.

Insimbi ehlanganisiwe imvamisa ihlala iminyaka engama-25 kuye kwangama-50.

Ezindaweni ezinokhahlo okuncane, kungahlala iminyaka engama-75.

Izimbobo ezinkulu ze-zinc zivikela isikhathi eside.

Ukulungiswa kanye nezimbobo ezengeziwe zikusiza ekugcineni isikhathi eside.

Izindawo ze-GI zingahlala iminyaka engama-20 kuye kwengama-50 noma ngaphezulu ezindaweni ezijwayelekile, ezingezona ezonakalisayo.

Ukunakekelwa njalo nezimbobo kuyazenza isikhathi eside.

UMSEBENZI WOKUVIKELA

Ungase uzibuze ukuthi kungani ikhoyili eyenziwe nge-galvanid ivikela insimbi kahle. Isizathu yindlela yokuvikela umhlatshelo. I-zinc ayinhle kancane kunensimbi, ngakho iyagcwala kuqala. Uma ama-zinc coating ekhuphuka, izinhlayiya ze-zinc zisebenza njenge-anome yomhlatshelo. Banikeza ama-elektroni ngensimbi nensimbi yokumisa ukugqama. Lokhu kubizwa ngokuthi ukuvikelwa kweCathodic.

Lapho i-zinc igqwala, yenza i-zinc onide nosawoti we-hydroxycarbobonate. Lokhu kwenza ifilimu eliminyene, lokuzenzela lezensimbi. Le filimu ivimba amanzi nomoya-mpilo, enikeza isivikelo esithe xaxa. I-zinc coating akuyona nje isithiyo. Kwenza futhi isihlangu samakhemikhali esixosha izinto ezibangela ukugqwala futhi kunciphise ukugqwala.

Ezingeni elincane, uZinc oxide usiza ukuhambisa ama-elektroni ku-zinc kanye nonqenqemeni lwensimbi. Lokhu kusiza ukusabela okugcina kwensimbi iphephile. Njengoba uZinc ungqimba uguqa, ushintsho lokuvikelwa kusuka ku-Cathodic kuye esibaleni. Lokhu kuxuba kwemiphumela yomhlatshelo nemiphumela yomgoqo kunika amandla okuqina okuqinile okuqinile nokuphila okude.

ICEBISO: Khetha ikhoyili enziwe nge-galvanized ngenhlamvu, ngisho ne-zinc coating yokuvikelwa okuhle kakhulu. Hlola ikhoyili yakho kaningi ukuklwebheka noma ukulimala ukuze uvikeleke umnikelo wokuvikelwa.

Izimbangela Zokugqwala ku-Galvanized Steel Coil

Izici zezemvelo

Lapho usebenzisa ikhoyili egayisele ngaphandle, isimo sezulu sibaluleke kakhulu. Uma umoya unomswakama kakhulu, amanzi angahlala kwikhoyili. Lawo manzi asiza ifomu lokugqwala ngokushesha. Usawoti ovela olwandle noma emanzini anosawoti angalimaza ungqimba lwe-zinc. Lokhu kwenza ukugqwala kukhombisa kungekudala. Ukungcola emoyeni, njenge-sulfur dioxide kanye ne-nitrogen oxide, kuxubana namanzi. Lokhu kuxuba ukwenza ama-acid ahlukanise i-zinc. Imvula ye-acid emadolobheni ibuye ilimaze ungqimba oluvikelayo. UMoss noLichen bangakhula kwikhoyili. Babambe amanzi eduze kwensimbi bese benza izindawo ezincane ezimanzi. Lawa mabala asiza ukuntuleka kuqala.

Nazi izimbangela ezivame kakhulu zokugqwala ku-coil ye-galvanized:

Umswakama ophezulu (ngenhla kwama-60%)

Usawoti emoyeni noma emanzini (izindawo ezisogwini)

Ukumanzisa njalo noma ukugoqa

Ukungcoliswa Kwe-Sulfur Dioxide

Ukuvezwa kwe-Hydrogen Sulfide

Ukuxhumana ne-alkalis eqinile (usimende, udaka)

Ukubaleka kwemvula kwe-acid

Moss nokukhula kwe-lichen

Imbangela / isimo |

Incazelo |

Izindawo ezinomswakama nezivaliwe |

Ukugqwayiza kwe-electrochemical, ukugqwala okumhlophe ngenxa yomswakama nokugeleza komoya okumpofu |

Ukwehlukaniswa kwe-zinc carbonate |

Umswakama ophelile uvumela izixazululo ezilonakalisiwe zokwakha |

Izindawo ezibucayi ezimhlophe ezimhlophe |

Ungqimba we-zinc udliwe, kudalulwe insimbi |

Ukusabela kwamakhemikhali |

Umswakama, i-oksijini, i-CO2, no-oxides bakha izixazululo ze-electrorive ezilimazayo |

ICEBISO: Uma uhlala eduze nolwandle noma edolobheni, hlola ikhoyili yakho ye-galvanized kaningi. Lezi zindawo zenza ukugqwala kwenzeke ngokushesha futhi kunciphise impilo yekhoyili yakho.

Ukulimala ngokomzimba

Ukulimala ngokomzimba kungenye isizathu esikhulu sokugqwala kwikhoyili ye-galvanized. Imihuzuko, amamaki, noma ukunyakaza okunzima kungaphula i-zinc coating. Uma ubona ekuqaleni, insimbi ngaphansi kwayo ivulekele umoya namanzi. I-zinc ingavikela imihuzuko emincane, kepha hhayi emikhulu. Uma kukhona ukuklanywa okukhulu noma ukulimala endaweni enzima, udinga ukukulungisa. Lokhu kugcina ikhoyili kusuka ekugugeni ngokushesha. Kufanele ufune ukulimala ngemuva kokubeka ikhoyili ngaphakathi nangamasheke. Ngisho nama-chips amancane angavumela amanzi aqale ukugqwala.

QAPHELA: Yiba mnene ngekhoyili yensimbi ye-galvanized lapho uhambisa noma uyifaka. Sebenzisa imichilo ethambile futhi ungahuduli ikhoyili ukuyeka ukuklwebheka.

Ukuqina kokuqina

Ubukhulu be-zinc coating bubaluleke kakhulu ekunqandeni ukugqwala. Ama-Coatings amakhulu enza isihlangu esinamandla futhi agcine isikhathi eside ezindaweni ezinzima. Ucwaningo lukhombisa ukuthi izingqimba ze-zinc ezinkulu zinikeza ama-zinc ion amaningi. Lawa ma-ion asiza ukuvikela imiphetho eqinile nezindawo ezibuthakathaka. I-zinc isebenza njengesihlangu futhi ibambezela ukugqwala kwensimbi.

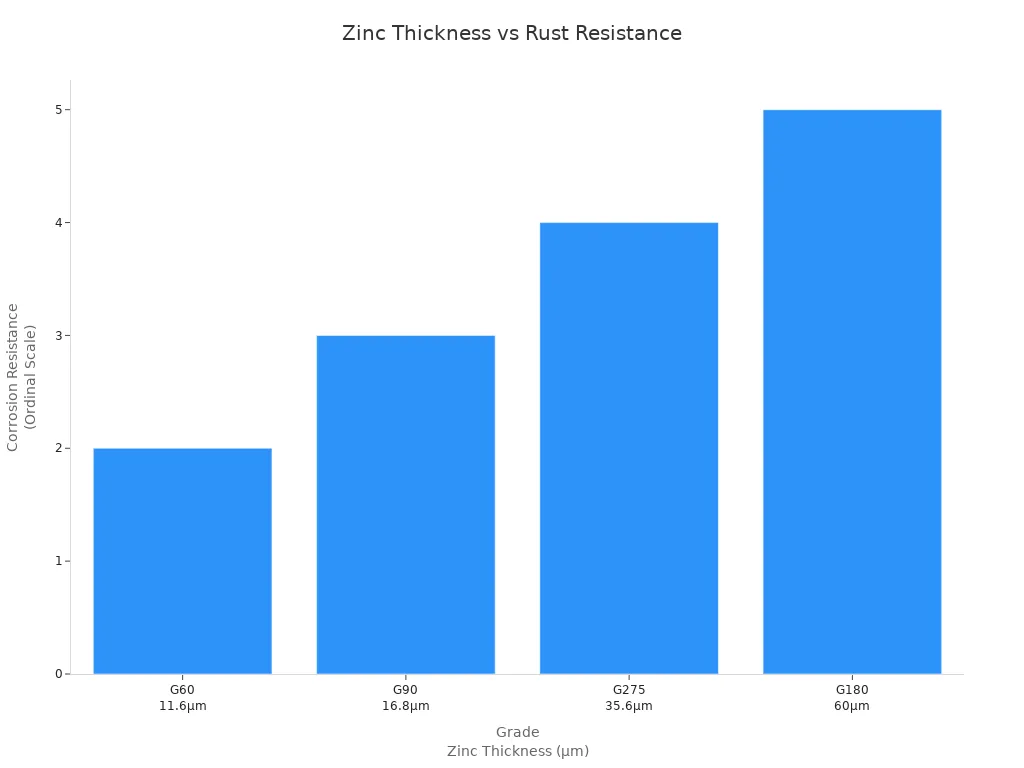

Khuphuka |

Cishe ukulingana kwe-zinc coating (μm) |

Izinga lokumelana nokugqwala |

Imvelo yesicelo ejwayelekile |

I-G60 |

11.6 |

-Ngeqile |

Izimo ezilimazayo ezilonakalisayo |

I-G90 |

16.8 |

Kuhle ngokuncomekayo |

Ukwakha okuningi nophahla |

I-G180 |

60 |

Phezulu kakhulu |

Izindawo eziphambene kakhulu ezilonakalisayo |

G275 |

35.6 |

-Phezulu |

Izimo ezinokhahlo |

Khetha ubukhulu be-banc coating obufanela iphrojekthi yakho nokuthi uyisebenzisa kuphi. Ama-coating amakhulu abiza okuningi, kepha avikela kangcono futhi ahlale isikhathi eside.

I-galvanized coil lungisondlo

Ukunakekela ikhoyili yakho ye-galvanized kuyindlela engcono kakhulu yokuvimbela i-galvanized yensimbi ekujuleni futhi igcine ikhwalithi yayo ephezulu. Izinyathelo ezilula njengokuhlanza, ukuhlola, nokulungisa kungakusiza ekutholeni okuningi ekutshalweni kwemali yakho. Ukulungiswa okujwayelekile nakho kukusindisa imali ngokugwema ukushintshwa okubizayo.

Ukuhlanza Okujwayelekile

Kufanele uhlanze ikhoyili yakho ye-galvanized okungenani kanye ngonyaka. Ezindaweni ezisogwini noma zezimboni, hlanza njalo ezinyangeni ezintathu. Ukuhlanza kususa usawoti, uthuli, kanye nezinsalela zemvula ze-acid ezingakwazi ukugqoka phansi i-zinc coating. Qala ngezindlela ezimnene futhi usebenzise kuphela abahlanza abanamandla uma kudingeka.

Sebenzisa ibhulashi elithambile leplastiki lokuhlanza. Gwema amabhulashi ensimbi, angaklaba futhi ahlukanise ama-zinc coating.

Geza ngensipho emnene noma imikhiqizo yokugeza izimoto namanzi acindezelayo aphansi.

Ngamabala athambile, sebenzisa izihlanza ze-ammonia zasendlini. Amabala okugqwala noma amadiphozithi wesemusi, sebenzisa i-oxalic acid, bese uhlamba kahle.

Susa upende nge-downer kanye nesikhafu seplastiki noma sokhuni. Sebenzisa ama-non-alkaline strippers ngopende onzima.

Njalo hlamba ikhoyili ngemuva kokuhlanza ukuze ususe noma iyiphi insalela yokuhlanza.

Ithiphu: Hlola noma iyiphi indlela entsha yokuhlanza endaweni encane, ecashile kuqala. Lokhu kukusiza ugweme ukulimaza i-zinc coating.

Ukuhlanza i-COIL yakho ye-galvanized njalo kusiza ukuvikela insimbi ye-galvanized ekujuleni futhi kugcina ubuso bubukeka bukhanya. Iphinde ivikele i-zinc under, okuyisihluthulelo sekhwalithi yesikhathi eside.

Ukuhlolwa nokulungisa

Kufanele uhlole ikhoyili yakho ye-galvanized okungenani kanye ngonyaka. Ezindaweni ezinokhahlo, hlola njalo ezinyangeni eziyisithupha. Funa izimpawu zokuqala zokugqwala noma ukulimala kwama coating. Gxila kulezi zindawo ezibalulekile:

Izindawo ezifulethi lapho amanzi angaqoqa khona.

Imiphetho kanye nama-welds, amathuba okuthi ahlulwe.

Amabala athinteke ngaphambili.

Izindawo ezinamabala ansundu noma ukugqwala okumhlophe.

Izindawo ezingenalutho lapho i-zinc coating ilahlekile.

Ama-crevices namakhona lapho amanzi nokungcola kungakha khona.

Izindawo lapho ikhola lithinta ezinye izinsimbi.

Sebenzisa igeji kazibuthe ubukhulu ukubheka i-zinc coating. Uma uthola imichilo noma amabala amancane ukugqwala, ukuwalungisa ngaso leso sikhathi:

Hlanza le ndawo ngensipho emnene namanzi.

Susa ukugqwala ngebhulashi le-zethusi noma i-sandpaper enhle.

Faka isicelo ngopende we-zinc-rich noma i-zinc enamakhaza ukuze ubuyisele ukuvikelwa.

Ngokulungiswa okukhulu, sebenzisa i-urethethane evutha umswakama noma upende osuselwa ku-vinyl.

QAPHELA: Ukulungiswa okusheshayo kokuma kokumiswa kusuka ekusakazeni nasekusizeni ukugcina ikhwalithi yekhoyili yakho ye-galvanized.

Ukugwema amakhemikhali anokhahlo

Amanye amakhemikhali angalimaza ukugcoba kwe-zinc futhi asheshise ukugqwala. Kufanele ugweme:

Umanyolo namakhemikhali engadini, anganciphisa ukuvikelwa kwe-zinc kufinyelela ku-40%.

Ama-acid aqinile kanye nezihlanza ze-alkaline, eziphula ungqimba lwe-zinc.

Amanzi anosawoti kanye nomswakama ophezulu, okhulisa amanani okugqwala.

Imvula ye-acid kanye nokungcoliswa kwezimboni, okususa ukumbamba ngokushesha.

Ukuxhumana nethusi noma ezinye izinsimbi, ezingadala ukugqwala kwe-galvanic.

Gcina ikhoyili yakho ye-galvanized endaweni eyomile, enomoya omuhle. Gcina kude namakhemikhali nezinye izinsimbi. Uma kufanele usebenzise okuhlanzayo, khetha eyodwa ephephile ezimbobeni ze-Zinc, njenge-acetone noma imikhiqizo yezentengiselwano ehlolwe ngensimbi ye-galvanized.

ICEBISO: Isitoreji esihle nokuhlanza ngokucophelela kuyizindlela ezilula zokuvikela ikhoyili yakho ye-galvanized futhi unwebe impilo yaso.

Ukusebenza kwezindleko zokulungiswa

Ukulungiswa okujwayelekile kubiza okungaphansi kokuthatha indawo yekhoyili ebunjiwe. Ukuhlanza nokulungiswa okuncane kugcina i-zinc coating eqinile futhi ivikele izinkinga ezinkulu. Uma weqa ukulungiswa, ukugqwala kungalimaza ikhoyili futhi kuphoqe ukuthi uthenge okusha. Ukutshala imali isikhashana nemali ku-UPEPEP kukusiza ukuthi uvikele ukushintshwa okubizayo futhi ugcina ikhoyili yensimbi yakho egayiselelwe ngaphezulu kweminyaka.

Umthelela Ezemvelo ku-Galvanized Steel Coil

Izindawo zangaphandle vs.

Indawo lapho usebenzisa khona izindaba zekhoyili ezi-galvanized kakhulu. Ezindaweni zezwe noma edolobheni, ikhoyili enziwe ngotshani ithatha iminyaka eminingi. Awungeke ubheke ukugqwala iminyaka engaphezu kwengu-70 kulezi zindawo. Lokhu kwenzeka ngoba umoya uhlanzekile futhi kukhona amanzi amancane emoyeni.

Kepha eduze kolwandle, izinto zehlukile. Usawoti emoyeni wenza ukugqwala kwenzeke ngokushesha. Uma ikhoyili ibhekene nomoya onosawoti, ukugqwala kungavela eminyakeni emi-5 kuye kwengu-7. Uma ikhoyili ivikelekile, ingahlala iminyaka eyi-15 kuye kwengama-25 ngaphambi kokuqala ukugqwala. Kufanele uhlanze futhi uhlole ama-Coil eduze nolwandle kaningi. Zigeze ngamanzi amasha njalo ezinyangeni ezimbalwa ukuqeda usawoti. Sebenzisa izigqoko ezengeziwe uma ukwazi. Funa ukugqwala noma ukulimala okungenani amahlandla amabili ngonyaka.

Uhlobo lwemvelo |

Isilinganiso sokubukeka kokuqala kokugqwala |

Izimo ezibalulekile namanothi |

Coastal (ngaphakathi kwe-1 Mile,> 250 ft kusuka ogwini) |

Iminyaka engu-5-7 (ukuvezwa okuqondile) |

Ukuvezwa ngqo emimoyeni onosawoti / ama-chloride-rich; izindawo ezivikelekile zeminyaka eyi-15-25 |

Ongaphandle (emaphandleni, inqwaba, i-marine eshisayo) |

Iminyaka eminingi eminyaka eminyaka engama-70 |

Kufaka phakathi izindawo zasemakhaya nezamanuban ezinezimo zasolwandle ezilimazayo; Kufakiwe izimo zasolwandle ezishisayo |

Ithiphu: Uma uhlala eduze nolwandle, hlanza futhi uhlole ikhoyili yakho kaningi. Lokhu kuyasisiza isikhathi eside.

Ukungcoliswa kwezimboni

Amafektri nemigwaqo ematasa yenza izinto zibe nzima kwikhoyili enziwe nge-galvanized. Babeka amagesi anjengeSulphur Dioxide kanye ne-nitrogen oxides emoyeni. Lawa magesi ahlangana nemvula futhi enza imvula ye-acid. Imvula ye-acid igqoke i-zinc coating. Kulezi zindawo, i-Calvanized Coil ithatha iminyaka engaba ngu-20 kuye kwengama-40 ngaphambi kokugqwala kuyabonakala. Lokhu akuyona inqobo nje emoyeni ohlanzekile.

Kufanele uhlole ikhoyili enziwe ngezindawo efektri kaningi. Funa ukugqwala okumhlophe, ukugqwala okubomvu, imihuzuko, futhi igqoke imidwebo. Hlanza ikhoyili njalo ezinyangeni ezintathu kuya kweziyisithupha. Naka amalunga, ama-welds, nezindawo ezisebenzisa okuningi. Sebenzisa izigqoko ezengeziwe uma ukwazi. Khetha ukunamathela okukhulu kwe-zinc ukuze uvikeleke kangcono ezindaweni ezinzima.

Hlola izimbobo ezingaphezulu njalo ezinyangeni ezintathu.

Bheka amalunga njalo ngenyanga ukuze ukugqwala.

Bukela izindawo ezisetshenziswa kakhulu njalo ezinyangeni ezimbili.

Hlanza futhi ulungise ukulimala ngokushesha nje lapho uyibona.

QAPHELA: Ukuhlola kaningi futhi usebenzisa ama-reak zins Coatings kusiza ukungcoliswa kwakho kwekhoyili nokugcina isikhathi eside.

Vikela ukugqwala okumhlophe ku-coil ye-galvanized

Kuyini ukugqwala okumhlophe?

Kwesinye isikhathi ubona ungqimba olumhlophe, olunamafutha ku-galvanized steel coil. Lokhu kubizwa ngokuthi ukugqwala okumhlophe. Kwenzeka lapho ikhoyili ihlala ezindaweni ezimanzi nomoya omncane. Ukugqwala okumhlophe kubukeka kubumbana noma chalky, hhayi njengokugqwala okubomvu. Kwenziwe ngemikhiqizo yokugqwala ye-zinc. Lokhu kufaka phakathi i-zinc hydroxide, i-zinc onide, kanye nama-zinc carbonate. Umswakama uphendula nge-zinc coating ukwenza lezi zinhlanganisela. Lokhu kwenzeka okuningi uma umoya ungakwazi ukuhamba uzungeze ikhoyili. Abantu futhi bakubiza ngokuthi 'Isitoreji Stain

' Ngokuhamba kwesikhathi, uZinc Hydroxide ushintsha ube uZinc onide kanye ne-zinc carbonate. Uma ushiya ikhoyili ngaphandle, ukugqwala okumhlophe kuvame ukuhamba njengoba kuguquka kube yizinhlanganisela ezinzile.

Qaphela: Ukugqwala okumhlophe kusho umswakama uhlanganiswe nokumabala kwe-zinc. Kuyisibonakaliso sokubheka ukuthi ugcina kanjani futhi uphatha ikhoyili yakho.

Izindlela Zokuvimbela

Ungamisa ukugqwala okumhlophe ngokwenza izinto ezimbalwa ezilula. Njalo gcina amakhoyili ensimbi enziwe nge-galvanized ezindaweni ezomile nge-airflow enhle. Ungazifaki emhlabathini. Sebenzisa ama-spacer ngakho umoya ungahamba phakathi kwamakhoyili. Musa ukufaka amakhoyili eduze kakhulu ndawonye. Lokhu kufaka umswakama futhi kusiza ifomu lokugqwala elimhlophe.

Lapho uhambisa amakhoyili, uzisonge ngesembozo esingangenzi manzi futhi uvikele imiphetho. Uma ubona noma yiliphi ikhoyili emanzi, yomise ngokushesha. Hlukanisa amashidi emanzi ukuze umoya ungawafinyelela.

Bheka amakhoyili kaningi ukuthola ukugqwala okumhlophe kusenesikhathi. Uma uyibona, hlanza indawo ngensipho emnene namanzi. Ngezindawo ezinzima, sebenzisa isisombululo esibuthakathaka se-acid futhi uhlanze kahle.

Faka izimbotshana ezivikelayo njengopende we-zinc-rich, epoxy, noma ukumbona okuvikelwa okwengeziwe. Uma ubona imichilo noma amabala angenalutho, zilungise nge-zinc yamakhaza noma i-zinc--rich coatings. Sebenzisa igeji ukuze uhlole ungqimba lwe-zinc futhi uqiniseke ukuthi kuvikele kahle.

Gcina ama-Coils kude ne-Copper, yethusi, noma ezinye izinsimbi ezibangela ukugqwala kwe-Galvanic. Qiniseka ukuthi indawo yokugcina ihlala ngaphansi komswakama ongu-60%. Uma kufanele ugcine ama-coils ngaphandle, ukumboza nge-tarps enamanzi futhi uphakamise ukuphela okukodwa ukuze ukhiphe.

ICEBISO: Ukugcina amakhoyili kahle futhi ukwenza okusheshayo kuyizindlela ezinhle kakhulu zokumisa ukugqwala okumhlophe bese ugcine i-coil yakho yensimbi eqinile.

Amakhoyili wensimbi enziwe nge-galvanized awagwimbi kalula. I-zinc coating ivikela insimbi ngaphansi. Kepha akukho kholi engamisa ukugqwala kuze kube phakade. Udinga ukuhlanza ikhoyili yakho kaningi. Lungisa noma yimuphi umonakalo ngokushesha ukusiza i-zinc isikhathi eside. Uma uyinakekela, ikhoyili yakho ingahlala iminyaka engama-20 kuye kwangama-50. Lapho ukhetha insimbi eyenziwe galvanized, cabanga ngalezi zinto:

Imvelo: Izindawo eziseduzane nolwandle noma amafektri zidinga ukuvikelwa okwengeziwe.

Ubukhulu obukhulu be-zinc

Isondlo: Hlanza futhi uhlole ikhoyili yensimbi yakho eyenziwe nge-galvanized kaningi.

Uma wenza izinqumo ezinhle futhi unakekela ikhoyili yakho, kungahlala iminyaka eminingi.

Umthandi

Ngabe i-galvaning yensimbi yensimbi yagcina isikhathi esingakanani ngaphandle?

Ungalindela ukuthi ikhoyili yensimbi ye-galvanized ibe yiminyaka engama-20 kuye kwangama-50 ngaphandle. I-zinc coating kusuka ku-hot-dip galvaning ivikela insimbi. Ezindaweni ezi-mnene, zihlala isikhathi eside. Ezindaweni ezisogwini noma zezimboni, ungabona ukugqwala kungekudala.

Ungakwazi ukupenda ikhoyili yensimbi ye-galvanized?

Yebo, ungapenda ngaphezulu kwekhoyili yensimbi ye-galvanized. Hlanza ingaphezulu kuqala. Sebenzisa i-primer eyenzelwe i-zinc coating. Upende lusiza ukuvikela ikhoyili futhi lingathuthukisa ukubukeka kwalo.

Yini ebangela ukugqwala okumhlophe ku-galvanized steel coil?

Amafomu amhlophe okugqwala lapho umswakama ubanjiswa e-zinc coating. Lokhu kwenzeka kaningi ngesikhathi sokugcina. Ungakuvimbela ngokugcina i-galvanized steel coil eyomile futhi uvumele umoya ukujikeleza.

Ngabe ulungisa kanjani ukukhahlela ku-galvanized yensimbi coil?

Hlanza ukubhala ngensipho emnene namanzi. Yomisa le ndawo. Faka isicelo ngopende ocebile we-zinc-rich noma okubandayo kwe-galvaning. Lokhu kubuyisela ama-zinc coating futhi kuvikele insimbi ngaphansi.

Ingabe i-coil yensimbi ye-galvanized iphephile ngezinhlelo zamanzi zokuphuza?

Ungasebenzisa ikhoyili yensimbi ye-galvanized yezinhlelo ezithile zamanzi. I-zinc coating iphikisa ukugqwala. Kodwa-ke, hlola njalo amakhodi wendawo namazinga ngaphambi kokuyisebenzisa ngokuphuza amanzi.