WAN Galvanized Steel Coil na wan rol sheet we dɛn mek wit stɛl we dɛn kɔt wit wan layt zink. Dis zink layt de protɛkt di stɛl frɔm rɔst ɛn damej, we de mek di kɔyl strɔng ɛn te. Wi kɔmni de gi ay kwaliti galvaniz stɛl kɔyl prɔdak dɛn we bɔku bɔku faktri ɛn bilda dɛn de yuz bɔku bɔku wan fɔ bil, mek, ɛn ɔtomotiv pat dɛn. Insay 2022, dɛn bin mek lɛk 140 milyɔn mɛtrik tan galvaniz stɛl kɔyl ɔlsay na di wɔl, wit Chaina lida prodakshɔn. Wi prodak dɛm na fɔ mit di grow dimand fɔ rilibul galvaniz stɛl kɔyl dɛm akɔdin to difrɛn industri dɛm.

Ki takeaways .

Galvaniz stɛl kɔyl na stɛl we dɛn kɔba wit zink. Di zink de ɛp fɔ stɔp rɔst ɛn mek di stɛl las fɔ lɔng tɛm. Dis kin mek di stɛl strɔng ɛn fayn fɔ bɔku tin dɛn.

Difrɛn kayn ɛn gred dɛn de fɔ galvaniz stɛl kɔyl. Ɛni kayn kin wok fayn fɔ sɔm wok dɛn. Tik zink kɔtin dɛn de protɛkt bɛtɛ na do. Tin kɔtin dɛn bɛtɛ fɔ insay ɔ fɔ luk.

Hot-dip, pre-galvanizing, ɛn ilektrogalvaniz na we fɔ ad zink. Ɛni we de gi difrɛn tik ɛn luk. Dɛn kin yuz ɛni wan pan dɛn fɔ spɛshal nid dɛn.

Dɛn kin yuz galvaniz stɛl kɔyl bɔku tin fɔ bil, motoka, ɛn os mashin dɛn. I de ɛp fɔ sev mɔni bikɔs i nɔ nid fɔ ripɛnt smɔl ɛn nɔ nid fɔ kia fɔ am smɔl.

Pik di rayt kɔyl min fɔ tink bɔt tik, zink kɔtin, gred, ɛn usay dɛn go yuz am. Dis kin ɛp fɔ mek shɔ se i wok fayn ɛn i kin tek lɔng tɛm.

Galvaniz Stiɛl Kɔyl Ɔvaviu .

Wetin na galvaniz stɛl kɔyl .

Wan galvaniz stɛl kɔyl na flat stɛl sheet. Dɛn kin rol am ɔp insay wan kɔyl. Dɛn kɔba di kɔyl wit wan zink layt. Di zink de kip di stɛl sef frɔm rɔst ɛn kɔrɛshɔn. faktri ɛn bilda dɛn lɛk galvaniz stɛl kɔyl. I strɔng ɛn i de te fɔ lɔng tɛm. I kin wok fayn ivin we di wɛda tranga. Di zink layt de blok wata ɛn briz. Dis kin ɛp fɔ stɔp rɔst fɔ fɔm. We di kɔyl de na do, zink kin mit ɔksijɛn ɛn mɔstɔ. I de mek wan tin fim we de protɛkt di kɔyl. Dis fim de ɛp di kɔyl fɔ tinap agens di damej.

Galvanized Steel Coil gɛt bɔku impɔtant prɔpati dɛn:

Land |

Tipik Valyu . |

Siginifikɛns/bɛnifit . |

Tik |

arawnd 7.85 g/cm³ |

Standart weit we fit fɔ strɔkchɔral aplikeshɔn dɛn . |

Surface Coating Weight . |

30-350 g/m² (Ɔl tu di say dɛn) |

I de gi kɔrɛshɔn protɛkshɔn we dɛn ebul fɔ adap to envayrɔmɛnt dɛn . |

Surface smoothness . |

Roughness (RA) 0,8-1,5 μm |

I de ɛp fɔ mek di kɔtin adheshɔn ɛn di we aw i go de fɔ lɔng tɛm . |

Di kɔnduktiviti fɔ di tɛmral . |

Unafɛkt bay galvanizing layt . |

Suitabl fɔ ɔt dispɛpshɔn aplikeshɔn dɛn . |

Ilektrikal Kɔnduktiviti . |

Smɔl smɔl pas klin stɛl . |

Mit di Indastrial Kɔnduktiviti Rikwaymɛnt dɛn . |

Koefishiɛnt fɔ tɛmral ɛkspɛnshɔn . |

11,5 x 105 1000. |

Mek shɔ se dimɛnshɔnal stebiliti ɔnda tɛmpracha chenj . |

Notis: Di zink layt de ɛp di kɔyl fɔ tinap agens di kemikal dɛn. I de stebul na ples dɛn we gɛt pH frɔm 6 to 12. Di kɔyl kin ebul fɔ handel ɔt te to 200°C fɔ lɔng tɛm. I kin tek 300°C fɔ shɔt tɛm.

Ki spesifikeshɔn dɛn .

Di wan dɛn we de mek tin dɛn kin mek galvaniz stɛl kɔyl insay bɔku saiz dɛn. Dɛn kin mek difrɛn tik dɛn bak. Di tin dɛn we dɛn kin yuz mɔ na tik, dɛn wayd, dɛn gɛt kɔyl wet, ɛn dɛn gɛt dayamita insay. Dɛn kin ɛp pipul dɛn we de bay fɔ pik di bɛst kɔyl fɔ wetin dɛn nid.

Spesifikɛshɔn paramita . |

Kɔmɔn rɛnj / valyu . |

Tiknɛs . |

0.12 mm to 0.8 mm (sɔm te to 4.0 mm ɔ 6.0 mm) |

Wayd |

600 mm to 1500 mm (sɔm sɔs 600 mm to 1250 mm) |

Koil weit . |

3 to 8 mɛtrik tan (standad), te to 25 mɛtrik tan we dɛn aks fɔ am |

Koil iner diamita . |

508 mm ɔ 610 mm |

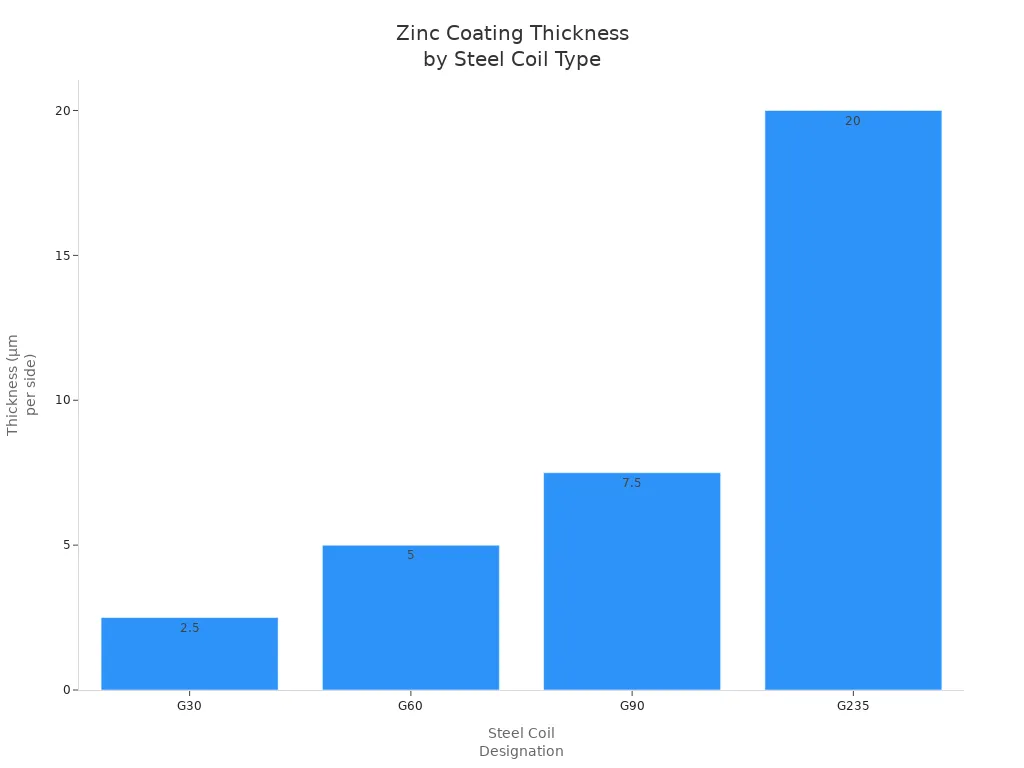

Di zink kɔtin tiknes rili impɔtant. I de afɛkt aw di kɔyl de fɛt rɔst fayn fayn wan. I kin chenj bak aw lɔng di kɔyl kin de. Difrɛn kɔyl dɛn gɛt difrɛn kɔtin wet ɛn tiknes. Di tebul we de dɔŋ ya de sho di kɔmɔn kayn dɛn ɛn dɛn ficha dɛn:

Taytul |

Zinc coating weit (OZ/FT⊃2;) |

Aprɔksimat tik (μm fɔ wan say) . |

Tipik koroshɔn rɛsistɛns . |

Kɔmɔn Aplikeshɔn dɛn . |

G30 na di . |

0.30 Tɔtɔl (0.15 fɔ wan say) |

~2.5. |

Layt Protɛkshɔn . |

Indoor framing, aplayans dɛn . |

G60 na di . |

0.60 Tɔtɔl (0.30 fɔ wan say) |

~5 pipul dɛn de. |

Protekshɔn fɔ di Mɔdaret . |

HVAC, Layt ɔda framing na do . |

G90 na di . |

0.90 Tɔtɔl (0.45 fɔ wan say) |

~7.5 Di wan dɛn we de wok. |

Ay Protɛkshɔn . |

Ruf, Saydin, Ɛgrikalyeshɔn |

G235 na di . |

2.35 Tɔtɔl (1.175 fɔ wan say) |

~20 pipul dɛn de. |

Maksimal protɛkshɔn . |

Marin, gadrɛl, ay-kɔroshɔn ɛnvayrɔmɛnt dɛn |

di we aw dεn put zink pan di kכyl de chenj in tik. Hot-dip galvanizing de mek tik kɔtin. Dɛn tin ya kin bi bitwin 45 ɛn 100 maykromita. Ilektro-galvanizing de mek tin kɔtin. Dɛn tin ya na frɔm 2.5 to 25 maykromita. Tik kɔtin dɛn de protɛkt bɛtɛ bɔt dɛn de kɔst mɔ. Tin kɔtin dɛn kin luk smol ɛn dɛn kin yuz dɛn insay ɔ fɔ dekɔret.

Galvaniz stɛl kɔyl fɔ fala intanashɔnal standad. Dɛn lɔ ya de mek shɔ se di kɔyl sef ɛn strɔng. Sɔm impɔtant standad dɛn na:

Advays |

Skɔp / Aplikeshɔn . |

Ki spesifikeshɔn pɔynt dɛn . |

ASTM A653/A653M |

Stilin sheet, zink-kot (galvaniz) ɔ zink-ayɛn alɔy-kɔt bay hot-dip prɔses |

di wet we dɛn de kɔt, adhesion, di kwaliti kwaliti, di kɔtin tiknes minimum, di finish, di apinans, di adherence |

ASTM A924/A924M |

Jɛnɛral rikwaymɛnt fɔ stɛl shit, mɛtal-kɔt bay hot-dip prɔses |

Jɛnɛral kɔtin rikwaymɛnt dɛn we inklud tik, adheshon, ɛn sɔfays kwaliti . |

ASTM A123/A123M |

Hot-dip galvanized coatings pan ayɛn ɛn stɛl prodakt dɛn . |

Kotin tiknes minim, kɔntinyu fɔ finish smol smol, nɔ gɛt eria dɛn we nɔ gɛt kɔt, strɔng adherence ɔlsay na di savis layf |

ISO 3575 na di . |

Kɔntinyu fɔ gɛt hot-dip zink-kɔt kabɔn stiɛl shit fɔ kɔmɛshɔnal ɛn drɔ kwaliti dɛn |

Kotin tik, apinans, koroshɔn resistans . |

ISO 1461 |

Hot dip galvaniz kɔtin dɛn pan fabrik ayɛn ɛn stɛl atikul dɛn – spɛsifikɛshɔn ɛn tɛst mɛtɔd dɛn |

Kotin tik, apinans, koroshɔn resistans . |

ASTM ɛn ISO standad dɛn de sɛt rul fɔ kɔtin wet ɛn tik.

Test de chɛk aw zink de stik to stɛl ɛn aw ivin di kɔtin de.

Dɛn kin tɛst kɔrɛshɔn rɛsistɛns wit sɔl sprɛy ɛn ɔda we dɛn.

Tayp ɛn gred dɛn .

Galvaniz stɛl kɔyl de insay difrɛn kayn ɛn gred dɛn. Ɛni kayn gɛt spɛshal tin dɛn fɔ sɔm wok dɛn.

Hot-dip galvanized steel coils: Dɛn mek dɛn kɔyl ya bay we dɛn dip stɛl insay mɛlt zink. Dis mek wan tik, tranga layt we de stɔp rɔst. Di wan dɛn we de bil kin yuz ɔt-dip kɔyl fɔ tin dɛn we de na do lɛk ruf ɛn fɛns.

Ilektro-galvaniz stɛl kɔyl dɛn: Dɛn kɔyl ya kin gɛt zink bay we dɛn de yuz ilɛktrishɔn na sɔlvushɔn. Di layt tan ɛn i smɔl. Faktɔri dɛn kin yuz dɛn kɔyl dɛn ya fɔ motoka pat ɛn aplayans dɛn we nid fɔ luk fayn.

Gret dɛn de yuz 'g' ɛn nɔmba. Di nɔmba de sho aw bɔku zink de na di kɔyl. Big big nɔmba dɛn min mɔ zink ɛn bɛtɛ protɛkshɔn. G60, G90, ɛn G275 na kɔmɔn gred dɛn.

Di kayn gred we dɛn gɛt . |

Tɔk bɔt |

Tipik Aplikeshɔn dɛn . |

Komersial Gred . |

di big big makit fɔ di makit; Jɛnɛral Yuz insay Kɔnstrɔkshɔn . |

Ruf, Saydin . |

Kwaliti fɔ drɔ . |

Dɛn kin yuz am fɔ mek kol-rɔl stɛl prodakshɔn . |

Ɔtomotiv, Aplayans dɛn . |

High Strength Low Alloy . |

Ay trɛnk ɛn durabiliti . |

brij, bildin, ship dɛn . |

strɔkchɔral gred . |

Dɛn kin yuz am fɔ bil brij ɛn bildin dɛn . |

Struktural Framwok dɛn . |

Ɔda wan dɛn . |

Speshal gred dɛn wit spɛshal prɔpati dɛn . |

Difrɛn spɛshal aplikeshɔn dɛn . |

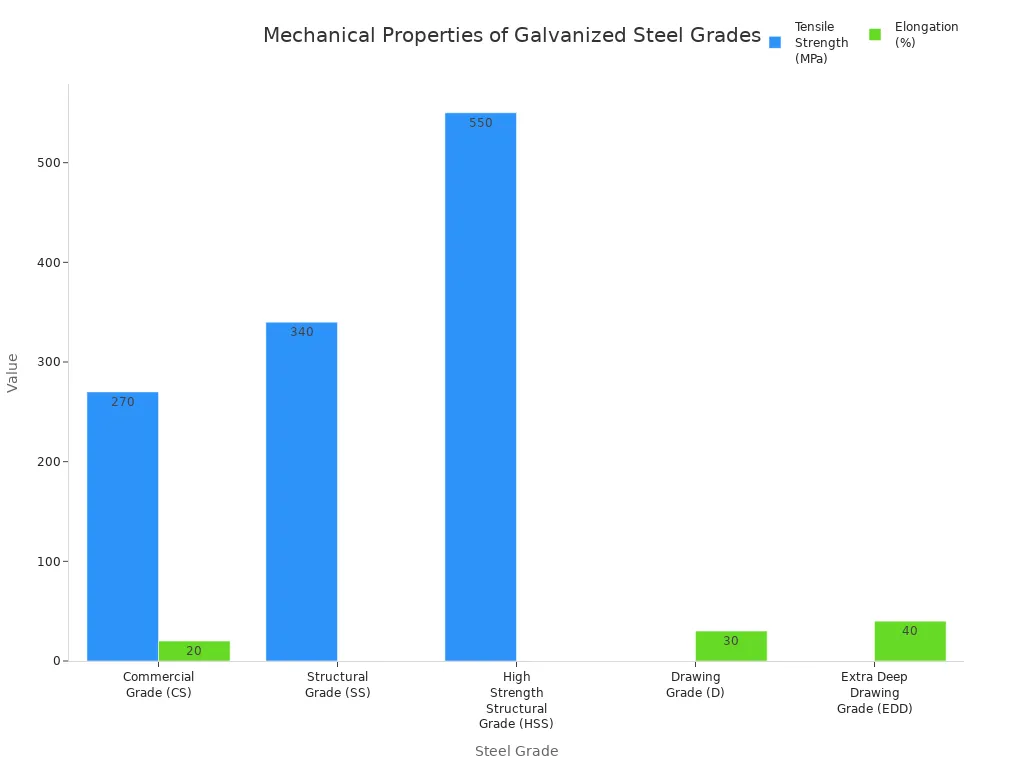

Mekanikal prɔpati dɛn kin chenj wit ɛni gred. Di tebul we de dɔŋ ya de sho aw trɛnk ɛn fleksibiliti difrɛn:

Mak |

Tensil Strɔng (MPA) . |

yield strɛngth (MPA) . |

Elongeshɔn (%) . |

Kor advantej . |

Tipik aplikeshɔn/prɔsɛsin . |

Kɔmishɔn gred (CS) . |

270 - 410 na di |

N/A we de na di wɔl. |

≥ 20 . |

Basic Rustproofing, Jɛnɛral Strɔng |

Simpul bɛnd ɛn kɔt (nɔ gɛt dip stamp) |

strɔkchɔral gred (SS) . |

340 - 550 na di |

≥ 230. |

Soba |

Ay trɛnk ɛn wɛldability . |

Lod-bearing, weldin, bolt konekshon |

Di gred we dɛn de drɔ (D) . |

Soba |

N/A we de na di wɔl. |

≥ 30 . |

High ductility ɛn yunifom elongeshɔn . |

Midul Komplexiti Stamping . |

Ekstra dip drɔin gred (EDD) |

Ridyus |

N/A we de na di wɔl. |

≥ 40 . |

Ekstrim fɔmabiliti, resistans to thinning . |

Kɔmpleks stamp wit prɛsishɔn mold dɛn . |

Ay trɛnk strɔkchɔral gred (HSS) . |

550 - 980. |

Yield ratio ≤ 0.85. |

Soba |

Di ayest trɛnk-to-weit ratio, ay ɛnaji absɔpshɔn |

Specialized processing (Laser Cutting, Haydrolik Moldin) |

Galvanized Steel Coil gɛt difrɛn sɔfays finish dɛn:

Regular Spangled: Yu kin si zink kristal. Dɛn kin yuz am fɔ bil.

Minimayz Spangle: Smɔl kristal dɛn kin mek wan say we smol smol. Dɛn kin yuz am na motoka ɛn tin dɛn fɔ yuz.

Ziro Spangle: Dɛn nɔ si kristal. Di say we di wata de shayn de shayn ɛn i smɔl. Dɛn kin yuz am na it ɛn kemikal industri.

Specialty Coatings: Sɔm kɔyl dɛn gɛt ɛkstra layers fɔ finga prɛnt, baktri, ɔ ɔt.

Tip: Pik di rayt kayn ɛn gred fɔ yu wok. Tik kɔtin ɛn ay gred na di bɛst fɔ ɔdasay ɔ tranga ples. Tin kɔtin ɛn smol smol finish dɛn fayn fɔ insay ɔ dɛkɔreshɔn.

Di we aw dɛn de mek di tin dɛn we dɛn de mek .

Hot-dip galvanizing .

Hot-dip galvanizing na di we we pipul dɛn lɛk fɔ protɛkt stɛl kɔyl dɛn. Fɔs, wokman dɛn kin klin di stɛl. Dɛn kin pik ɛn neutralize di surface. Neks, dɛn de dip di kɔyl insay mɛlt zink. Dis de mek wan strɔng zink-ayɛn alɔy layt. Afta dɛn dɔn dip, di kɔyl kin kol. Di wokman dɛn kin trit am wit pasiveshɔn ɛn ɔyl. Dɛn step ya de ɛp di kɔtin stik ɛn luk bɛtɛ. Inspekta dɛn kin chɛk di tik ɛn aw di kɔtin luk. Dɔn, di kɔyl kin pak. di zink layεr tik, we kin bi 45 to 85 maykromita. Dis de mach ASTM de rul laik A123 and A653. Di prɔses de ɛp stɛl fɔ fɛt rɔst ɛn skrat. I fayn fɔ bil os dɛn we de na do ɛn fɔ wok tranga wan.

Proses Flɔ: .

Pripia ɛn klin di tin dɛn we dɛn rayt .

Pik ɛn pul di gris .

Wash ɛn neutralize .

Add pretreatment coating .

Dip in zink we dɛn dɔn mɛlt .

Kul ɛn trit di kɔyl .

Flat ɛn trim di kɔyl .

Inspek fɔ kwaliti .

Kɔt ɛn rol insay kɔyl dɛn .

Pak ɛn ship di prɔdak .

Pre-galvanizing .

Pre-galvanizing de apin na di stɛl mil bifo i shep. Di wokman dɛn kin klin di stɛl sheet fɔs. Dɔn, dɛn kin rɔn am tru mɛlt zink insay wan layn. Dis kin mek wan smol ɛn ivin zink layt. Di kɔtin kin bi 20 to 30 maykromita tik. Di finish na brayt ɛn izi fɔ shep. Pre-galvanized steel costs less ɛn i de wok fayn fɔ big wok. Bɔt, kɔt ed ɛn wɛld kin sho bare stɛl. Dis min se dɛn nɔ fɔ protɛkt dɛnsɛf bɛtɛ. Pre-galvanizing na di bɛst fɔ indo tin ɔ pat dɛn we nid fɔ luk fayn.

Tin |

Hot-dip galvanizing . |

Pre-galvanizing . |

Di tik we de mek pɔsin kɔt kɔt . |

45-85μm we dɛn mek |

20-30μm na wan wan wan wan wan wan wan wan wan wan wan wan wan wan wan wan wan wan |

Kɔvarej . |

Ful, inklud edj dɛn . |

Nɔto pan di ed dɛn we dɛn kɔt . |

Dɔn |

Variable we de chenj chenj . |

yunifom, brayt . |

Di bɛst we fɔ yuz am |

Ɔdasay, Hevi-Duty |

Indoor, pat dɛn we pɔsin kin si |

Ilektrogalvanizing .

Ilektrogalvanizing de yuz ilɛktrishɔn fɔ kɔba stɛl wit zink. Di wokman dɛn kin klin di stɛl fɔs. Dɔn, dɛn put am na wan spɛshal sɔlv. Zinc ayɔn dɛn stik to di stɛl ɛn mek wan tin, ivin layt. Di kɔtin kin bi 5 to 25 maykromita tik. Ilektrogalvaniz stɛl na smol ɛn shayn. I kin bɛn izi wan ɛn i kin mek i nɔ rɔst na say dɛn we wet. I izi bak fɔ peint. Pipul dɛn kin yuz am fɔ motoka pat, aplayans, ɛn ilɛktroniks. Di prɔses de fala ASTM A879 rul dɛn. I fayn fɔ prɔdak dɛn we nid fayn fayn say ɛn sɔm rɔst protɛkshɔn.

Notis: Ilɛktrogalvaniz stɛl de wok fayn insay ɛn ɔnda pent. I de stɔp rɔst fayn bɔt i nɔ de protɛkt frɔm wear as mɔ as hot-dip mɛtɔd.

Galvanealing na di .

Galvanealing miks galvanizing wit itin. Afta hot-dip galvanizing, wokman dem hot di steel plenti hai. Dis de mek wan zink-ayɛn alɔy layt. Di layt de ɛp wit wɛldin ɛn peint. Galvanealed Steel na izi fɔ weld ɛn shep. Dɛn kin yuz am na motoka, bildin dɛn, ɛn tin dɛn fɔ yuz. ASTM A653 giv di rules fo Galvanealed Steel Coil. Dis de kip di kwaliti ɛn di pefɔmɛns stedi.

Fit ɛn bɛnifit dɛn .

Koroshɔn rɛsistɛns .

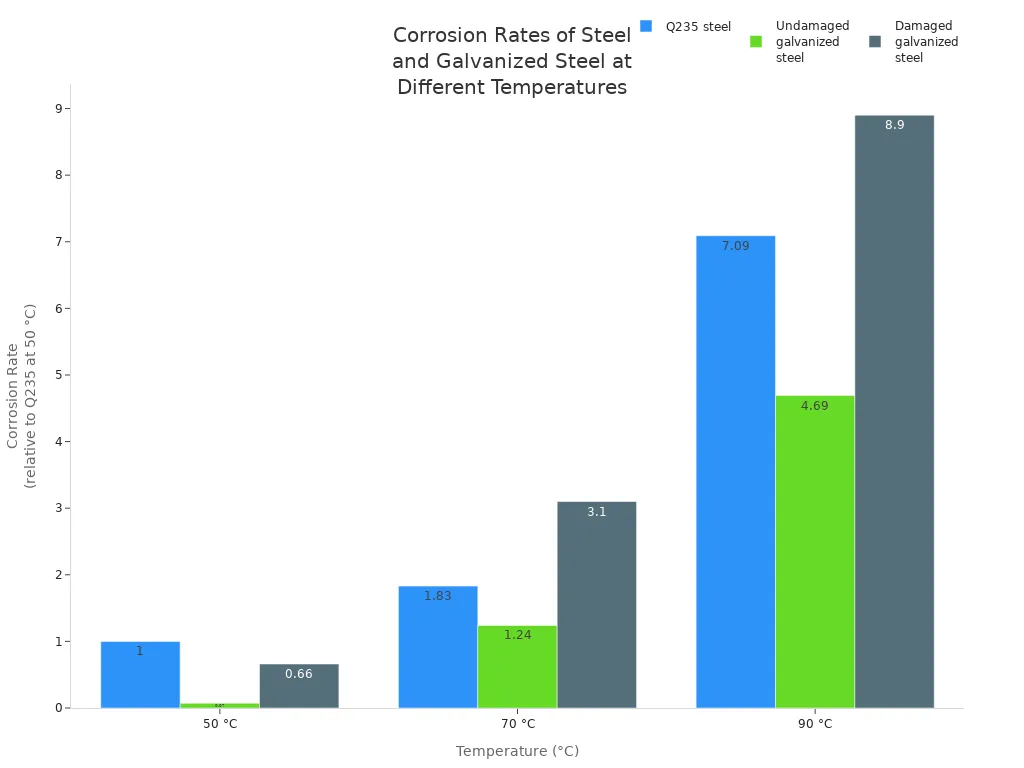

Galvaniz stɛl nɔ de rɔst izi wan bikɔs ɔf in zink kɔtin. Di zink layt de protɛkt di stɛl we de ɔnda. We wata ɔ ɛya tɔch di kɔyl, zink kin riak fɔs. Dis kin mek wan shild we kin mek ɔksijɛn ɛn wata nɔ rich di stɛl. di zink layεr de mek spεshal kכmpawnd dεm bak lεk zinsayt (ZNO), haydrozinsayt, εn simonkolleite. Dɛn kɔmpawnd dɛn ya kin mek wan tik tik fim. Di fim slo dɔŋ rɔst ɛn kip di stɛl sef. Ivin if di kɔyl gɛt skrach ɔ kɔt, di zink stil de protɛkt am. Di zink kɔtin chenj aw di stɛl de riak to rɔst. tik zink layers de gi mכr protεkshכn. Dɛn kin las fɔ lɔng tɛm na say dɛn we nɔ izi fɔ du.

Di zink kɔtin de west bifo di stɛl du.

Protɛktiv fim dɛn de blok ɔksijɛn ɛn wata frɔm di stɛl.

Di kɔtin de fiks insɛf na skrat ɔ kɔt.

Prayma dɛn we gɛt bɔku zink kin gi ɛkstra protɛkshɔn insay had kɔndishɔn.

Test sho se galvaniz stɛl de agens rɔst bɔku bɛtɛ pas plain stɛl. Dis na tru na wet ɔ na do ples dɛn.

Specimen |

Di rit we di kɔrɛshɔn (50°C) . |

Main Koroshɔn Prodakt dɛn . |

Produkt MƆFƆLƆJI . |

Q235 stɛl . |

1 |

Fe3O4 na di . |

Slak |

Gelvaniz stɛl we nɔ gɛt pwɛl at . |

0.07 |

ZnO na di 1999. |

Dense . |

Di stɛl we dɔn pwɛl we dɔn pwɛl . |

0.66 |

Fe3o4 + ZnO na di . |

Dense . |

Durability ɛn Mentɛnans .

Di zink kotin de ɛp galvaniz stɛl fɔ las fɔ lɔng tɛm. I kin wok fayn na do na ren, san, ɛn briz. Pipul dɛn kin yuz am fɔ ruf, fɛns, ɛn mashin dɛn. Stɛnlɛs stiɛl kin las fɔ lɔng tɛm na say dɛn we rili at. Bɔt galvaniz stɛl de protɛkt fayn ɛn i nɔ de tek bɔku mɔni. As tɛm de go, di zink layt kin west. Chɛk ɔltɛm ɛn izi fɔ ripɛnt kip di stɛl strɔng.

Tip: Kip galvaniz stɛl na dray ples. Wrap kɔyl dɛn fɔ protɛkt dɛn. Chek fɔ wata bɔku tɛm. If yu si damej, fiks am wit pent ɔ sprɛy we gɛt zink.

Di tin dɛn we dɛn kin yuz fɔ mek di os fayn:

Yuz kemikal ɔ ɔyl fɔ stɔp frikshɔn ɛn damej.

Wrap kɔyl dɛn wit pepa ɔ plastic we yu de kip ɔ ship.

Chek fɔ wata ɛn dray kɔyl dɛn wantɛm wantɛm if yu wet.

Fiks pak fast fɔ stɔp skrat dɛn.

Stɔ kɔyl dɛn na rum dɛn we di klaymat de kɔntrol. Nɔ kip dɛn tu lɔng.

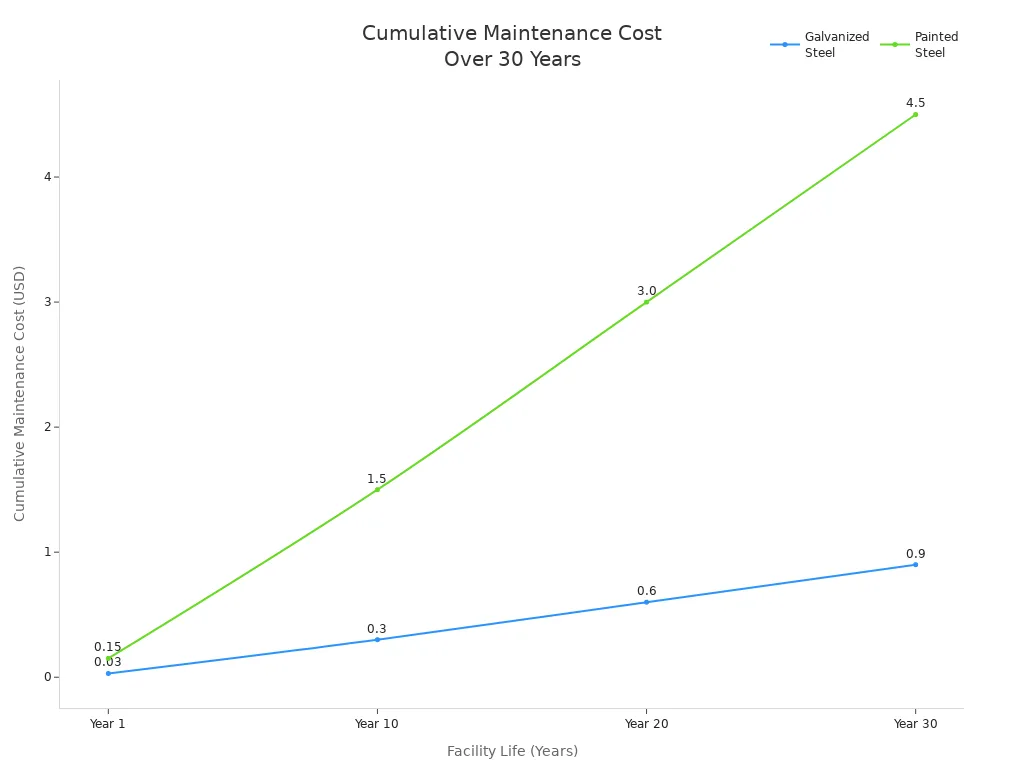

Efficiensi fɔ di kɔst .

Galvanized Steel de gi gud valyu fɔ di mɔni. I de kɔst mɔ pas plain stɛl fɔs. Bɔt i nɔ dia pas stenlɛs stiɛl ɔ kɔyl dɛn we dɛn dɔn pent. Di zink kɔtin min se dɛn nɔ fɔ ripɛnt smɔl ɛn dɛn nɔ de peint am bak smɔl. Dis kin sev mɔni as tɛm de go.

Aspɛkt fɔ di kɔst . |

stɛl we dɛn mek wit galvaniz we dɛn kɔl hot-dip galvaniz . |

Stiel sistem we dɛn dɔn pent (tu-kot) . |

Initial Kɔst . |

Kɔmpitishɔn ɔ Lɔwa . |

Sɔntɛnde, i kin ay ɔ i tan lɛk . |

Mentɛnans fɔ ɛni ia . |

$0.03 fɔ wan ia . |

$0.15 fɔ wan ia . |

Fasiliti Layf . |

30 ia . |

30 ia . |

Mentɛnans nid fɔ de . |

Nɔn |

Ripeint ɔltɛm . |

Layf-saykl kɔst . |

bɔku tɛm na jɔs di fɔs kɔst . |

bɔku ay pasmak bikɔs dɛn de kip dɛn . |

Galvaniz stɛl de ɛp fɔ mek di kɔst go dɔŋ fɔ lɔng tɛm. I nɔ nid fɔ mek dɛn ripɛnt ɛn chenj am smɔl. I de sev ɛnaji bak na bildin dɛn. Dis mek am wan smat choice fɔ bil ɛn mek tin.

Aplikeshɔn dɛn fɔ Galvaniz Stiɛl Kɔyl .

Kɔnstrɔkshɔn ɛn ruf .

Galvaniz stɛl kɔyl rili impɔtant fɔ bil. Di wan dɛn we de bil kin yuz am fɔ ruf, wɔl, bim, ɛn ba. Di zink layt de kip bildin dɛn sef frɔm rɔst ɛn bad wɛda. Dis kin mek i bi gud tin fɔ yuz fɔ yuz na do. I strɔng ɛn i nɔ de brok izi wan. I kin tek lɔng tɛm na say dɛn we at fɔ du. Bɔku bilda dɛn kin pik galvaniz stɛl kɔyl fɔ mek mɛtal bildin dɛn, gɔta dɛn, ɛn panɛl dɛn we dɛn mek na di wɔl. Na lɛk af pan ɔl di galvaniz stɛl kɔyl dɛn de yuz fɔ bil. Mɔ siti ɛn nyu prɔjek dɛn de mek di nid fɔ dis matirial gro, mɔ na Eshia-Pasifik.

Manufakchurin ɛn Ɔtomotiv .

Faktɔri dɛn kin yuz galvaniz stɛl kɔyl bikɔs i tranga ɛn izi fɔ shep. Di wan dɛn we de mek motoka kin yuz hot-dip galvaniz kɔyl fɔ motoka bɔdi, freym, ɛn pat dɛn we de dɔŋ. Di zink layt de stɔp dɛn pat ya frɔm rɔstin. Dis kin ɛp motoka dɛn fɔ de sef ɛn wok fayn. Kar kɔmni dɛn na Chaina ɛn India de yuz mɔ galvaniz stɛl kɔyl naw. Dɛn want layt ɛn bɛtɛ motoka dɛn. Mɔ ilɛktrik motoka dɛn min bak mɔ nid fɔ dis matirial. Nyu lɔ dɛn bɔt pɔyushɔn ɛn sev fiul mek kɔmni dɛn yuz galvaniz stɛl kɔyl. Bɛtɛ we fɔ kɔt ɛn di lokal faktri dɛn kin ɛp fɔ mit di big big dimand na dɛn eria dɛn ya.

ɔda we dɛn fɔ yuz am .

Dɛn kin yuz galvaniz stɛl kɔyl fɔ mɔ pas jɔs bildin ɛn motoka dɛn. Di wan dɛn we de mek aplayans kin yuz am fɔ was, frij, ɛn ay kɔndishɔn. I nɔ de rɔst ɛn i luk fayn. Di matiryal de yuz bak insay Grin Ɛnaji ɛn Smat Siti Projɛkt dɛn. Ilɛktrik motoka ɛn grɛn ɛnaji nid stɛl we nɔ rɔst fɔ nyu tin dɛn. Insay Eshia-Pasifik, dɛn kin yuz pas wan kwata pan di galvaniz stɛl kɔyl fɔ aplayans dɛn. Nyu siti projɛkt ɛn mɔ faktri dɛn de mek di nid fɔ dis stɛl go ɔp. Naw kɔmni dɛn de yuz nyu teknɔlɔji fɔ mek smat ɛn spɛshal stɛl prɔdak fɔ dɛn nyu makit dɛn ya.

Di tin dɛn we wi fɔ tink bɔt ɛn di tin dɛn we wi nɔ fɔ tink bɔt ɛn di tin dɛn we wi nɔ fɔ du .

Fɔ pik di rayt kɔyl .

Fɔ pik di rayt stɛl kɔyl fɔ wok impɔtant. Yu nid fɔ tink bɔt bɔku tin dɛn. Dɛn tin ya kin chenj aw di kɔyl de wok fayn ɛn aw lɔng i de te.

Tik : Tik stɛl de ol mɔ wet ɛn i de te fɔ lɔng tɛm. Di wan dɛn we de bil kin yuz tik kɔyl fɔ bim ɛn strɔng pat dɛn. Tin kɔyl dɛn gud fɔ layt tin dɛn lɛk ɛya dakt.

di wet we de kכt : Di zink kכt de kip rust away. Hevi coatings, lek G90, na dem de bes fo wet o salt ples. Layta kɔtin, lɛk G60, fayn fɔ insay ɔ smɔl eria dɛn.

Gred : Ɛni gred gɛt in yon trɛnk ɛn bɛnd. Strɔng gred dɛn gud we yu nid taf stɛl. Fleksibul gred dɛn bɛtɛ if yu nid fɔ bɛn ɔ shep di kɔyl.

Wid ɛn lɔng : kɔstɔm saiz dɛn de ɛp fɔ fit ɛni prɔjek. Dis kin mek i izi fɔ bil ɛn disayn.

Ɔda tin dɛn we yu fɔ tink bɔt : Tink bɔt prayz, di kayn wok, ɛn usay yu go yuz di kɔyl. Hot-dip or ilektrogalvanizing na wetin yu pik bays pan wetin yu nid.

Tip: Ɔltɛm luk di industri lɔ dɛn ɛn chɛk yu spɔlayt in kwaliti bifo yu bay.

Di tin dɛn we de apin na di envayrɔmɛnt .

Di ples usay yu yuz stɛl kɔyl kin chenj aw dɛn de wok. Sɔl we de na di ays nia di si de brok dɔŋ zink fast fast. Pɔyushɔn frɔm faktri dɛn de mek asid ren we de west di zink. We yu kip kɔyl dɛn na say dɛn we gɛt dɔti kin trap wata ɛn mek wayt rɔst. Ay ɔt frɔm wɛldin ɔ kɔt kin bɔn ɔf di zink ɛn lɛf stɛl opin to rɔst.

Ples |

Men Risk . |

Akshɔn fɔ protɛkt . |

Kostal . |

Sɔl sprɛy, pitting . |

Yuz Heavy Zinc Coating . |

Indastrial . |

Asid ren, koroshɔn . |

Aplay pasivashɔn, sil edj dɛn . |

Humid st ɔ r ɛ j . |

Wait Rust Fɔmeshɔn . |

Stɔ na dray, ples fɔ mek briz ɛn wata go insay di os |

Di tin dɛn we kin apin to pɔsin .

Stilin kɔyl kin gɛt prɔblɛm we dɛn yuz am ɔ kip am:

Wait rɔst kin sho if wata de na di kɔyl, mɔ if dɛn nɔ du pasiveshɔn fayn.

Skrɛch, kɔt, ɔ wɛldin kin ambɔg di zink layt ɛn mek rɔst go mɔs bi.

If di zink nɔ ivin ɔ di stɛl gɛt dɔti, wik spat dɛn kin fɔm.

Blak spat kin apin if wayt rɔst kɔntinyu fɔ gro.

Fɔ kip kɔyl dɛn we nɔ rayt, lɛk na wet ples, de mek rɔst go mɔs bi.

Notis: Handle coils with care, check dem plenti taims, en stoa dem rait fo stop most problem dem.

Galvaniz stɛl kɔyl de kip stɛl sef frɔm rɔst. I kin stɔp bak fɔ pwɛl. Dis matirial strɔng ɛn i de te fɔ lɔng tɛm. I de ɛp fɔ sev mɔni bak. Di wan dɛn we de bil de yuz am fɔ ruf ɛn wɔl dɛn. Di wan dɛn we de mek am kin yuz am fɔ motoka ɛn aplayans dɛn. Di wan dɛn we de bay nid fɔ luk di tik ɛn di wet we dɛn de kɔt. Dɛn fɔ chɛk di gred bak. ASTM standad de ɛp fɔ mek shɔ se di kɔyl fayn. Humidity ɛn sɔl na di ays kin chenj aw i de wok. We yu pik di rayt kɔyl, i de gi bɛtɛ rizɔlt.

FAQ we de na di wɔl.

Wetin na di men tin we mek dɛn mek galvaniz stɛl kɔyl?

Galvaniz stɛl kɔyl de mek stɛl nɔ rɔsti ɔ i de pwɛl. Di zink layt de wok lɛk shild. Di wan dɛn we de bil ɛn di faktri dɛn kin yuz am fɔ mek pat dɛn we kin las fɔ lɔng tɛm ɛn we kin strɔng.

Aw zink kɔtin de mek i nɔ rɔst?

Zink mit wata ɛn ɛya bifo di stɛl du. Dis kin mek wan spɛshal layt ɔp. Di layt de stɔp wata ɛn briz fɔ tɔch di stɛl.

Usay pipul dɛn kin yuz galvaniz stɛl kɔyl mɔ ɛn mɔ?

Pipul dɛn kin yuz galvaniz stɛl kɔyl fɔ bil, fɔ mek motoka, ɛn fɔ mek aplayans dɛn. I fayn fɔ ruf, pat pan motoka, ɛn mashin pat dɛn.

Yu tink se dɛn go ebul fɔ peint galvaniz stɛl kɔyl?

Yu kin peint galvaniz stɛl kɔyl. Di say we yu de nid fɔ klin ɛn dray fɔs. Speshal prayma dɛn de ɛp di pent stik to di zink layt.

Us standad dɛn de fɔ galvaniz stɛl kɔyl?

ASTM A653 ɛn ISO 3575 na di men lɔ dɛn fɔ galvaniz stɛl kɔyl. Dɛn lɔ ya de tɔk bɔt aw di kɔtin tik, aw di sɔfays luk, ɛn aw i de fɛt rɔst fayn fayn wan.