A I-Calvanized Steel Coil ishidi eligoqiwe lensimbi ehlanganisiwe ngesendlalelo se-zinc. Le nhlangano ye-zinc ivikela insimbi ekugqekeleni nasekulimazeni, okwenza ikhoyili iqine futhi iqinile. Inkampani yethu inikezela ngemikhiqizo ye-coil yensimbi esezingeni eliphakeme esetshenziswa kabanzi ngamafektri kanye nabakhi bokwakha, ukukhiqiza, nezingxenye zezimoto. Ngo-2022, cishe amathani ama-metric ayizigidi eziyi-140 akhiqizwa yi-galvanized yensimbi emhlabeni wonke, ngokukhiqizwa okuholayo kweChina. Imikhiqizo yethu yenzelwe ukufeza isidingo esikhulayo samakhoyili ensimbi ethembekile emikhakheni ehlukahlukene.

Ukuthathwa Key

I-Calvanized Steel Coil yinsimbi embozwe nge-zinc. I-zinc isiza ukumisa ukugqwala futhi kwenze ngensimbi isikhathi eside. Lokhu kwenza insimbi iqine futhi ilunge izinto eziningi.

Kunezinhlobo ezahlukene kanye namamaki we-galvanized yensimbi coil. Uhlobo ngalunye lusebenza kangcono emisebenzini ethile. Imidwebo emibi ye-zinc ivikela kangcono ngaphandle. Imidwebo emincane ingcono ngaphakathi noma ukubukeka.

I-Hot-Pip, i-Pre-Galvaning, futhi i-Electrogalvaning iyizindlela zokungeza i-zinc. Ngaleyo ndlela inikeza ubukhulu obuhlukile nokubukeka. Ngayinye isetshenziselwa izidingo ezikhethekile.

I-Calvanized Steel Coil isetshenziswa kakhulu ekwakheni, izimoto kanye nemishini yasekhaya. Kuyasiza ukonga imali ngoba idinga ukulungiswa okumbalwa nokunakekelwa okuncane.

Ukukhetha ikhoyili efanele kusho ukucabanga ngobukhulu, i-zinc coating, ibanga, nokuthi izosetshenziswa kuphi. Lokhu kusiza ukuqiniseka ukuthi kusebenza kahle futhi kuhlala isikhathi eside.

I-Galvanized Steel Coil Overview

Kuyini ikhoyili yensimbi egayiwe

I-Calvanized Steel Coil iyiphepha lensimbi eliyisicaba. Igingqikala ibe yikhoyili. Ikhoyili imbozwe nge-zinc under. I-zinc igcina insimbi iphephile ekugqekezweni nasekugqwalweni. Amafektri kanye nabakhi njengekhoyili yensimbi ye-galvanized. Kuqinile futhi kuhlala isikhathi eside. Isebenza kahle ngisho nasesimweni sezulu esinzima. I-zinc under ivimba amanzi nomoya. Lokhu kusiza ukumisa ukugqwala kusuka ekubumbeni. Lapho ikhoyili ingaphandle, i-zinc ihlangana nomoya-mpilo kanye nomswakama. Kwenza ifilimu elincanyana elivikela ikhoyili. Le filimu isiza ikhoyili imelane nokulimala.

I-Calvanized Steel Coil inezakhiwo eziningi ezibalulekile:

Impahla |

Inani elijwayelekile |

Ukubaluleka / inzuzo |

Incekusana |

Cishe 7.85 g / cm³ |

Isisindo esijwayelekile esifanele izinhlelo zokusebenza zesakhiwo |

Isisindo se-surface coating |

30-350 g / m² (zombili izinhlangothi) |

Ihlinzeka ngokuvikelwa kokuqina kwezindawo |

Ubushelelezi obungaphezulu |

Ubulukhuni (RA) 0.8-1.5 μm |

Kuthuthukisa ukunamathela nokuqina |

Ukuvuselelwa okushisayo |

Kungathinteki ngongqimba lwe-galvaning |

Ilungele izinhlelo zokusebenza zokuhlanza ukushisa |

Ukuqina kukagesi |

Ephansi kancane kunensimbi emsulwa |

Ihlangabezana nezidingo zezezimboni zezezimboni |

I-coefficient of thermal expression |

11.5 x 10⁻⁶ / ° C |

Iqinisekisa ukuqina kobukhulu ngaphansi kwezinguquko zokushisa |

Qaphela: Isendlalelo se-Zinc sisiza ikhoyili vimbela amakhemikhali. Ihlala zizinzile ezindaweni ezinaba ngu-6 kuye kwayi-12. Ikhoyili ingaphatha ukushisa kuze kube ngu-200 ° C isikhathi eside. Kungathatha kuze kube ngu-300 ° C isikhashana esifushane.

Ukucaciswa Okubalulekile

Abakhiqizi benza ikhoyili yensimbi egayiselelwe ngosayizi abaningi. Futhi benza ubukhulu obuhlukile. Izici ezivame kakhulu zikhulu, ububanzi, isisindo semali, kanye nobubanzi bengaphakathi. Lokhu kusiza abathengi ukuthi bakhethe ikhoyili engcono kakhulu yezidingo zabo.

Ipharamitha ecacisiwe |

Ububanzi obujwayelekile / inani |

Ukujiya |

I-0.12 mm kuya ku-0.8 mm (abanye bafinyelela ku-4.0 mm noma u-6.0 mm) |

Ububanzi |

I-600 mm kuya ku-1500 mm (eminye imithombo engama-600 mm kuya ku-1250 mm) |

Inkanyezi |

Amathani ama-3 kuye kwayi-8 (okujwayelekile), kuze kufike kumathani ama-metric we-25 ngesicelo |

I-Coil Interner |

I-508 mm noma i-610 mm |

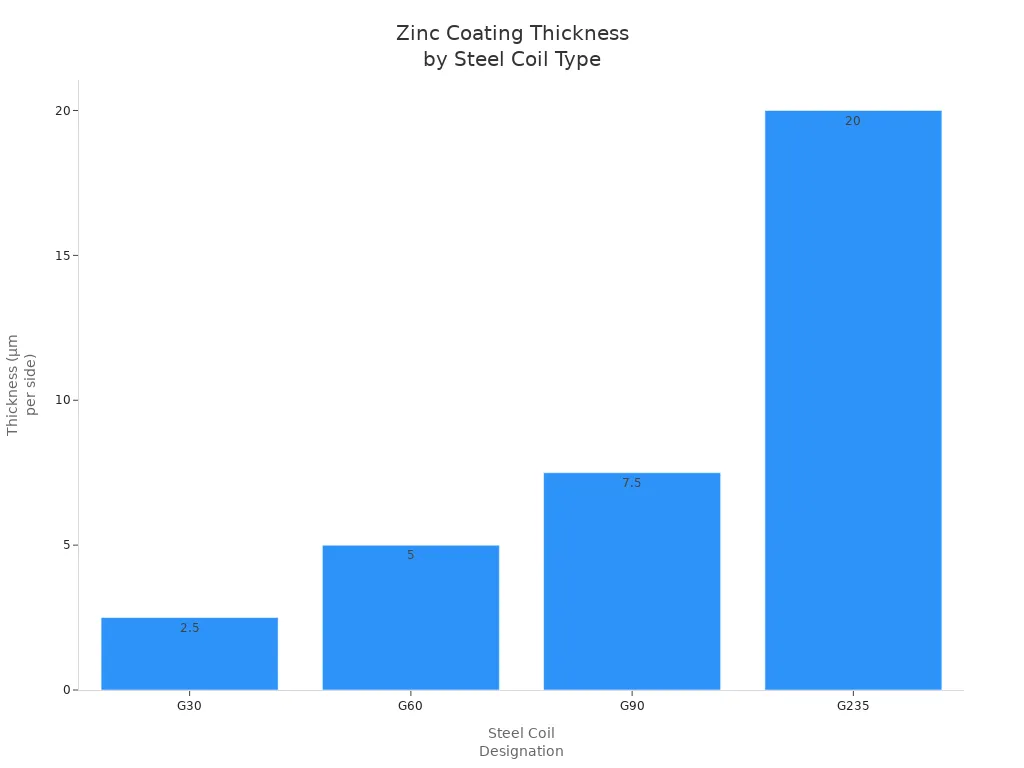

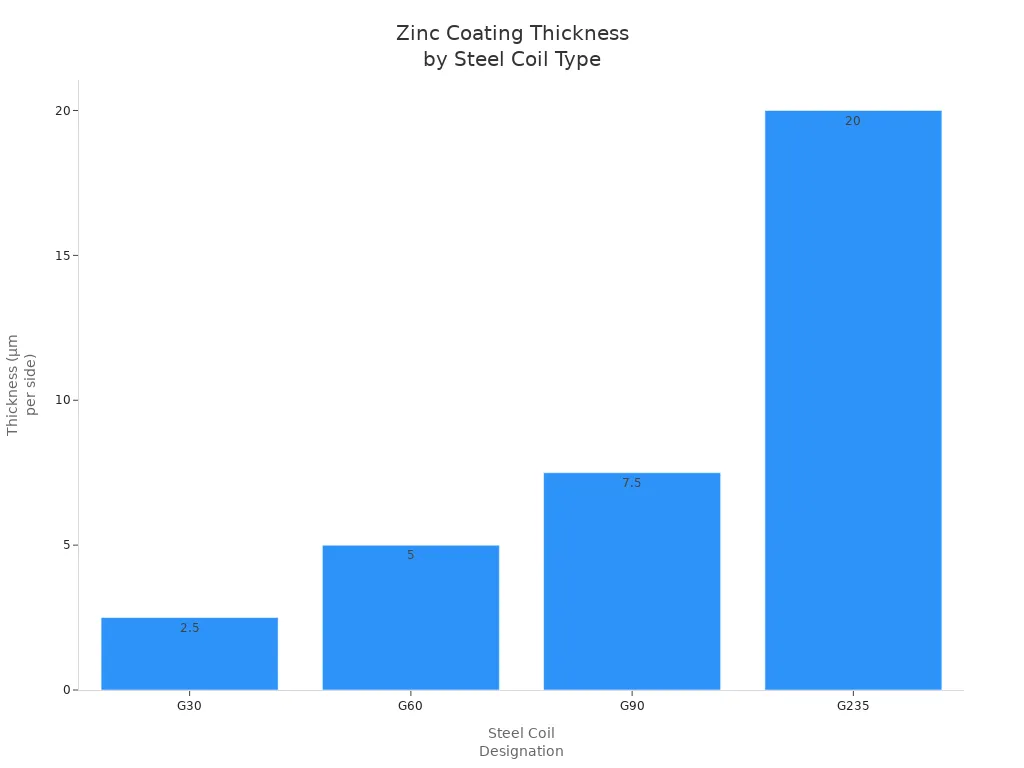

Ukuqina kokuqina kwe-zinc kubaluleke kakhulu. Kuthinta ukuthi ikholi lilwa kahle kangakanani ukugqwala. Ibuye iguqule futhi ukuthi ikholi lihlala isikhathi esingakanani. Amakhoyili ahlukene anezinsimbi ezihlukile zokuhlanganisa nobukhulu. Ithebula elingezansi libonisa izinhlobo ezijwayelekile nezici zalo:

Ukuqamba |

Isisindo se-zinc coating isisindo (OZ / FT⊃2;) |

Ubukhulu obusondelene (μm ngakunye) |

Ukumelana okujwayelekile kokugqwala |

Izicelo ezijwayelekile |

I-G30 |

I-0.30 Ingqikithi (0.15 ohlangothini ngakunye) |

~ 2.5 |

Ukuvikelwa Kokukhanya |

I-Indoor Framing, Izenzisi |

I-G60 |

I-0,60 isamba (0.30 ngakunye) |

~ 5 |

Ukuvikela okulinganiselwe |

I-HVAC, ukukhanya okukhanyayo kwangaphandle |

I-G90 |

I-0.90 isiyonke (0.45 uhlangothi ngakunye) |

~ 7.5 |

Ukuvikelwa okuphezulu |

Ukuphahla, ukusatshalaliswa, ezolimo |

G235 |

2.35 Ingqikithi (1.175 ohlangothini ngakunye) |

~ 20 |

Ukuvikelwa okukhulu |

Marine, Guarderaling, izindawo eziphakeme kakhulu |

Indlela i-zinc efakwa ngayo ikhoyili ishintsha ubukhulu bayo. I-tal-cpup galvanizing yenza ukugqokwa okukhulu. Lokhu kuvame ukuba phakathi kwama-micrometer angama-45 kuya kwayi-100. I-Electro-Galvanizing yenza izimbobo ezincanyana. Lokhu kusuka kuma-micrometer angama-2,5 kuya kwangama-25. Izambatho eziwugqinsi zivikela kangcono kepha zibize okuningi. Amageyimu amancanyana abukeka ebushelelezi futhi asetshenziswa ngaphakathi noma umhlobiso.

I-Calvanized Steel Coil kumele ilandele amazinga aphesheya. Le mithetho iqinisekisa ukuthi ikhoyili iphephile futhi iqinile. Amanye amazinga abalulekile yile:

-Vamile |

Scope / Isicelo |

Amaphuzu acacisiwe |

I-ASTM A653 / A653M |

Ishidi lensimbi, i-zinc-camera (gallvanised) noma i-zinc-iron alloy-ehlanganiswe nenqubo eshisayo |

Isisindo se-coation, ukunamathela, ikhwalithi ephezulu, ama-coation shuaning amancane, ukuqeda, ukubukeka, ukubambelela |

I-ASTM A924 / A924M |

Izidingo ezijwayelekile zeshidi lensimbi, i-metallic-cameras yinqubo eshisayo ye-hot-dip |

Izidingo ezijwayelekile zokuhlanganisa kufaka phakathi ubukhulu, ukunamathela, kanye nekhwalithi ephezulu |

I-ASTM A123 / A123M |

I-Hot-Dip Galvanized Coatings emikhiqizweni yensimbi neyensimbi |

Ama-Rooting areasnish amancane, ukuqeda okuqhubekayo okubushelelezi, akukho zindawo ezingacaciswanga, ukunamathela okuqinile kuyo yonke impilo yenkonzo |

ISO 3575 |

I-zinc-c cwice ephakathi eshisayo ye-zinc-cail ye-carbon yezentengiso nezimvo |

Ukuqina, ukubukeka, ukumelana nokugqwala |

ISO 1461 |

I-Hot Dip galvanized coatings ekwakhekeke kwensimbi nensimbi yensimbi - imininingwane nezindlela zokuhlola |

Ukuqina, ukubukeka, ukumelana nokugqwala |

Izindinganiso ze-ASTM ne-ISO zibekele imithetho yesisindo se-coating nobukhulu.

Ukuhlolwa Bheka ukuthi i-zinc inamathela kanjani ngensimbi nokuthi ngisho nokuhlanganiswa kanjani.

Ukuphikiswa kokugqwala kuhlolwe ngesifutho sikasawoti nezinye izindlela.

Izinhlobo namamaki

I-Calvanized Steel Coil iza ngezinhlobo ezahlukahlukene namamaki. Uhlobo ngalunye lunezici ezikhethekile zemisebenzi ethile.

Amakhoyili wensimbi eshisayo eshisayo: Lawa makhoyili enziwe ngensimbi ecwilisa i-zinc encibilikisiwe. Lokhu kwenza ungqimba olunzima, olunzima oluvimba ukugqwala. Abakhi basebenzisa amakhoyili e-hot-dip ngezinto ezingaphandle njengophahla nothango.

Amakhoyili wensimbi e-electro-galvanized: Lawa makhoyili athola i-zinc ngokusebenzisa ugesi kusisombululo. Ungqimba mncane futhi ubushelelezi. Amafektri Sebenzisa la makhoyili ezingxenye zemoto kanye nemishini edinga ukubukeka okuhle.

Amabanga asebenzisa i- 'g ' nenombolo. Inombolo ikhombisa ukuthi i-zinc engakanani ikhoyili. Izinombolo ezinkulu zisho ama-zinc amaningi nokuvikelwa okungcono. I-G60, G90, kanye ne-G275 amamaki ajwayelekile.

Uhlobo lwebanga |

Ukufanisa |

Izicelo ezijwayelekile |

Ibanga Lokuhweba |

Isabelo semakethe esikhulu kunazo zonke; ukusetshenziswa okujwayelekile ekwakhiweni |

Uphahla, ukuhambisa |

Ikhwalithi yokudweba |

Isetshenziswe ekukhiqizeni insimbi egoqwe elibandayo |

Izimoto, izinto ezisetshenziswayo |

Amandla aphezulu aphansi we-alloy |

Amandla aphezulu nokuqina |

Amabhuloho, izakhiwo, imikhumbi |

Ibanga lokuhleleka |

Isetshenziswe ekwakhiweni kwamabhuloho nezakhiwo |

Uhlaka lwezinhlaka |

Abanye |

Amamaki akhethekile anezakhiwo ezithile |

Izicelo ezahlukahlukene ezikhethekile |

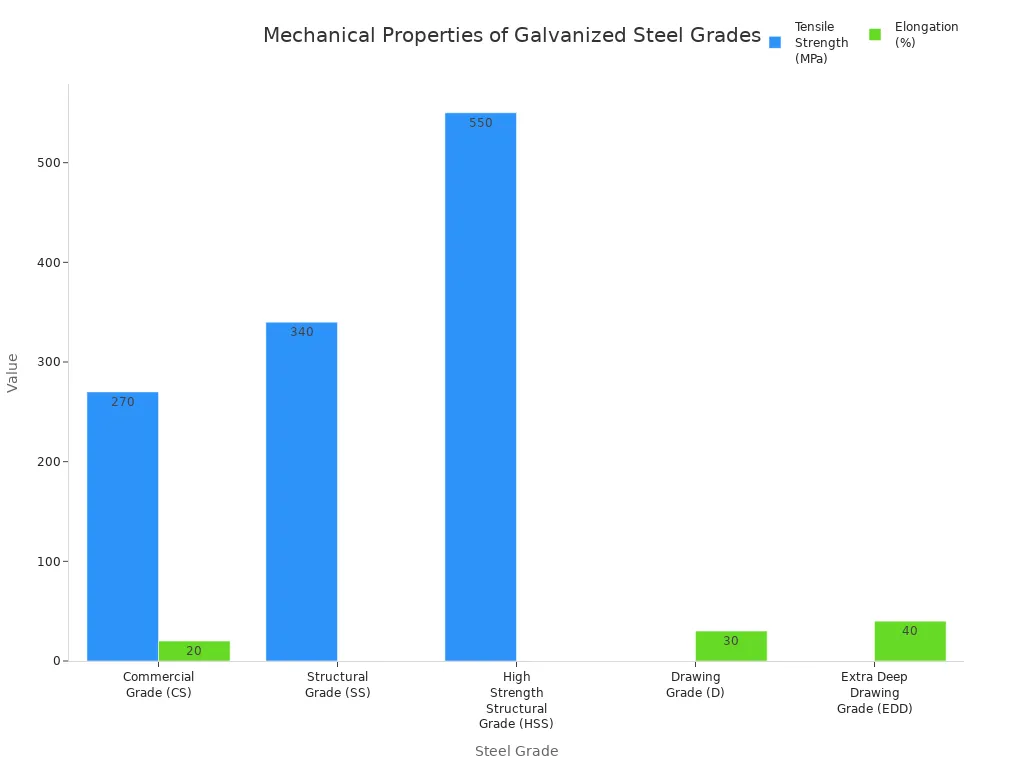

Izakhiwo zemishini zishintsha ngebanga ngalinye. Ithebula elingezansi libonisa ukuthi amandla nokuvumelana nezimo kuhlukile kanjani:

Khuphuka |

Amandla we-Tensile (MPA) |

Amandla Okuthela (MPA) |

I-Elongation (%) |

Inzuzo enkulu |

Isicelo esijwayelekile / Ukucutshungulwa |

Ibanga lokuhweba (cs) |

270 - 410 |

N / a |

≥ 20 |

Ukuqina okuyisisekelo, amandla ajwayelekile |

Ukugoba okulula nokusika (akukho ukunyathela okujulile) |

Ibanga (i-SS (SS) |

340 - 550 |

≥ 230 |

-Ngeqile |

Amandla aphezulu kanye nokushiswa |

Ukuthwala umthwalo, ukushibilika, ukuxhumana kwe-bolt |

Ibanga (D) |

-Ngeqile |

N / a |

≥ 30 |

I-auctility ephezulu kanye ne-elongation efanayo |

I-menty compleity stang |

Ibanga eliningi lokudweba okuphezulu (i-EDD) |

Shonisa |

N / a |

≥ 40 |

Ukwakheka okwedlulele, ukumelana nokuncipha |

Ukunyathela okuyinkimbinkimbi ngokubumba okunembile |

Ibanga eliphakeme lamandla e-HSS (HSS) |

I-550 - 980 |

Isilinganiso sesilinganiso ≤ 0.85 |

-Ngeqile |

Isilinganiso esiphakeme kakhulu sokuqina, ukumuncwa kwamandla okuphezulu |

Ukucutshungulwa okukhethekile (ukusika kwe-laser, ukubumba kwe-hydraulic) |

I-Calvanized Steel Coil inezinkinga ezihlukile zendawo:

Shintsha njalo: Ungabona amakristalu e-zinc. Isetshenziswa ekwakheni.

Isikhala esincishisiwe: amakristalu amancane enza indawo ebushelelezi. Isetshenziswe ezimotweni nasezintweni zokusebenza.

I-Zero Spangle: Azikho amakristalu abonile. Ingaphezulu liyacwebezela futhi libushelelezi. Isetshenziswa ezimbonini zokudla kanye namakhemikhali.

Imidwebo ekhethekile: Amanye amakhoyili anezendlalelo ezengeziwe zeminwe, amagciwane, noma ukushisa.

ICEBISO: Khetha uhlobo olufanele nebanga lomsebenzi wakho. Amageyimu amaningi namamaki aphezulu angcono kakhulu ngezindawo ezingaphandle noma ezinzima. Imidwebo emincane nemiphetho ebushelelezi ilungele ngaphakathi noma ekuhlobiseni.

Izindlela Zokukhiqiza

Hot-cxuse galvaning

I-hot-cpup galvaning iyindlela ethandwa kakhulu yokuvikela amakhoyili ensimbi. Okokuqala, abasebenzi bahlanza insimbi. Bayakhukhumeza futhi basebenzise indawo. Okulandelayo, bacwilisa ikhoyili ku-zinc encibilikisiwe. Lokhu kwenza ungqimba lwe-zinc-iron alloy oluqinile. Ngemuva kokucwilisa, ikhoyili ipholisa phansi. Abasebenzi bayiphatha ngokuhamba nangamafutha. Lezi zinyathelo zisiza induku ye-coating futhi zibukeke kangcono. Abahloli bahlole ubukhulu nokuthi ukuhlanganiswa kubukeka kanjani. Ngemuva kwalokho, ikhoyili iyagcwala. Isendlalelo seZinc sikhulu, imvamisa ama-micrometer angama-45 kuye kwangama-85. Lokhu kufana nemithetho ye-ASTM efana ne-A123 ne-A653. Inqubo isiza ukugqwala kwensimbi nokuklwebheka. Kuhle ngezakhiwo zangaphandle nemisebenzi enzima.

Inqubo yokugeleza:

Lungiselela futhi uhlanze lokho okuqukethwe

Ukhukhamba bese ususa amafutha

Geza futhi ungathathi hlangothi

Faka ukuhlanganiswa kokuhlehlisa

Cwilisa ku-zinc encibilikisiwe

Phola futhi uphathe ikhoyili

Flatten bese unquma ikhoyili

Hlola ikhwalithi

Sika bese ugoqa amakhoyili

Pack bese uthumela umkhiqizo

Pre-galvaning

I-pre-galvaning yenzeka emgodini wensimbi ngaphambi kokubumba. Abasebenzi bahlanza ishidi lensimbi kuqala. Ngemuva kwalokho, bayiqhuba nge-zinc encibilikisiwe emgqeni. Lokhu kwenza ungqimba olubushelelezi ngisho naze lube noZinn. I-coating imvamisa ama-micrometer angama-20 kuye kwangama-30. Ukuqedwa kukhanya futhi kulula ukukwenza. Izindleko zensimbi zangaphambi kwe-galvanized kancane futhi zisebenza kahle ngemisebenzi emikhulu. Kepha, imiphetho yokusika nama-welds kungakhombisa insimbi engenalutho. Lokhu kusho ukuvikela okuncane kokugqwala. I-Pre-Galvaning ilungele izinto zasendlini noma izingxenye ezidinga ukubukeka zinhle.

Ubuso |

Hot-cxuse galvaning |

Pre-galvaning |

Ukuqina kokuqina |

45-85μM |

20-30μM |

Ukuwahlangabezekayo |

Kugcwele, kufaka phakathi imiphetho |

Hhayi emaphethelweni asikiwe |

Pheza |

-Ngafani |

Umfaniswano, okhanyayo |

Ukusetshenziswa okuhle kakhulu |

Ngaphandle, umsebenzi osindayo |

Izingxenye zasendlini, ezibonakalayo |

Electrogalvaning

I-Electrogalvaning isebenzisa ugesi ukumboza insimbi nge-zinc. Izisebenzi zihlanza insimbi kuqala. Ngemuva kwalokho, bayibeka kwikhambi elikhethekile. I-zinc ion inamathela ngensimbi futhi yenze ungqimba omncane, noma ungqimba. I-coating imvamisa ingama-micrometer angama-5 kuye kwangama-25 aminyene. Insimbi ye-electrogalvalized ibushelelezi futhi icwebezela. Igoba kalula futhi iphikisa ukugqwala ezindaweni ezimanzi. Kulula futhi ukupenda. Abantu bayisebenzisela izingxenye zemoto, izinto zokwenza izinto, kanye ne-elekthronikhi. Inqubo ilandela imithetho ye-ASTM A879. Kuhle ngemikhiqizo edinga indawo enhle nokuvikelwa kokugqwala.

Qaphela: Insimbi ye-electrogalvalized isebenza kahle ngaphakathi nangaphansi ngopende. Imisa ukugqwala kahle kepha ayivikeli ekugqokeni njengezindlela ezishisayo.

Ukuhamba

I-Galvanealing ixubana ne-galvaning nokushisa. Ngemuva kokufaka ukushisa okushisayo, izisebenzi zishisa insimbi ephezulu kakhulu. Lokhu kwenza i-zinc-iron alloy ungqimba. Isendlalelo sisiza ekushiseni nasekupeyini. Insimbi ye-Galvanealed kulula ukuwela futhi ukwakheka. Isetshenziswa ezimotweni, ezakhiweni nasezintweni zokusebenza. I-ASTM A653 inikeza imithetho yekhoyili yensimbi egcwele i-galvanealed. Lokhu kugcina ikhwalithi nokusebenza kuqinile.

Izici nezinzuzo

Ukumelana nokugqwala

Insimbi ye-Galvanized ayigwinyi kalula ngenxa yokuhlanganiswa kwayo kwe-zinc. I-Zinc uryer ivikela insimbi ngaphansi. Lapho amanzi noma umoya uthinta ikhoyili, uZinc uphendula kuqala. Lokhu kwenza isihlangu esivimba umoya-mpilo namanzi ekufinyeleleni insimbi. I-Zinc uryer nayo yakha amakhompiyutha akhethekile afana ne-zincite (zno), i-hydrozinsite, ne-simomkolleite. Lezi zinhlanganisela zakha ifilimu elibanzi. Ifilimu linciphisa ukugqwala futhi ligcina insimbi iphephile. Noma ikhoyili ibanjiwe noma isikwe, i-zinc isakuvikela. I-zinc coating ishintsha ukuthi insimbi ibhekana kanjani nokugqwala. Izendlalelo ze-nzima ze-zinc zinikeza isivikelo esengeziwe. Bahlala isikhathi eside ezindaweni ezinzima.

I-zinc coating igqoke kude ngaphambi kwensimbi.

Amafilimu avikelayo avimba umoya-mpilo namanzi ensimbi.

Ukuhlanganiswa kulungiswa ngokwako ekukhuphukeni noma ekusikeni.

Ama-primers acebile acwebile anikeza ukuvikelwa okwengeziwe ezimeni ezinzima.

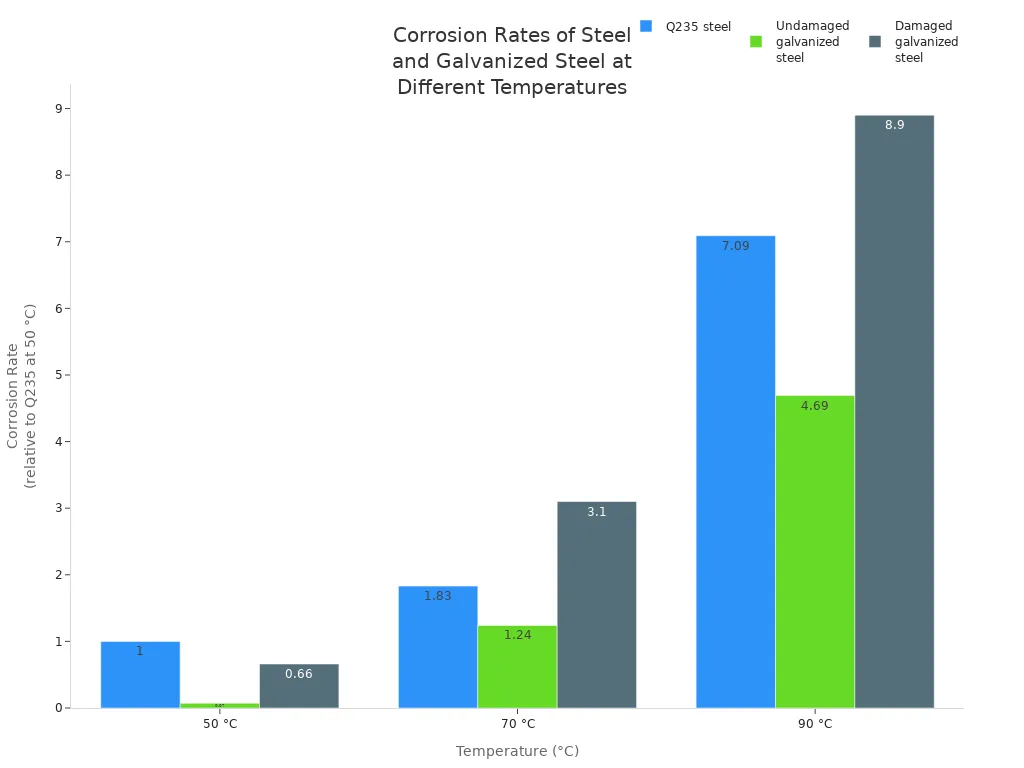

Ukuhlolwa Khombisa Insimbi Yensimbi Yenqaba Ukugqwala okungcono kakhulu kunensimbi ecacile. Lokhu kuyiqiniso ezindaweni ezimanzi noma zangaphandle.

Isifanekiso |

Inani lokugqwala (50 ° C) |

Imikhiqizo Eyinhloko Yokugqwala |

Umkhiqizo morphology |

I-Q235 yensimbi |

1 |

Fe3o4 |

-Ngakhulekiwe |

Insimbi engafanele ye-garyvanized |

0.07 |

Isifundo se-zno |

Cinene |

Insimbi eyenziwe yalonakalisiwe |

0.66 |

Fe3o4 + ZNO |

Cinene |

Ukuqina nokulungiswa

I-zinc coating isiza insimbi eyenziwe nge-galvanized isikhathi eside. Isebenza kahle ngaphandle kwemvula, ilanga nomoya. Abantu bayisebenzisela ophahleni, uthango, nemishini. Insimbi engagqwali ihlala isikhathi eside ezindaweni ezinokhahlo kakhulu. Kepha insimbi ye-galvanized ivikela kahle futhi ibiza kancane. Ngokuhamba kwesikhathi, i-Zinc under ingagqoka phansi. Amasheke ajwayelekile kanye nokulungiswa okulula kugcina insimbi iqinile.

ICEBISO: Gcina insimbi ye-galvanized ezindaweni eyomile. Songa amakhoyili ukuze uwavikele. Bheka amanzi kaningi. Uma ubona umonakalo, lungisa ngopende we-zinc-rich noma ufafaza.

Imikhuba Yokugcina Enconyelwe:

Sebenzisa amakhemikhali noma uwoyela ukumisa ukungqubuzana nomonakalo.

Songa amakhoyili ngephepha noma ngeplastiki lapho ugcina noma ukuhambisa.

Bheka amanzi namakhoyili owomile ngaso leso sikhathi uma umanzi.

Lungisa ukupakisha ngokushesha ukumisa ukuklwebheka.

Gcina amakhoyili emakamelweni alawulwa ngesimo sezulu. Ungazigcini isikhathi eside kakhulu.

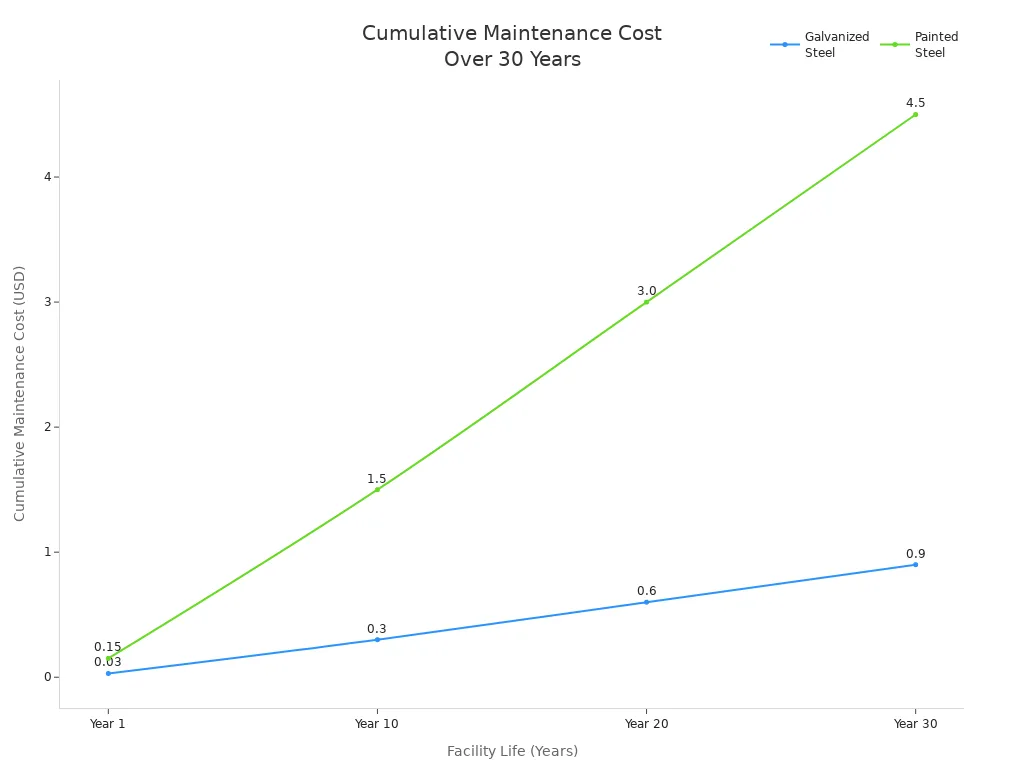

Ukusebenza kwezindleko

Insimbi ye-galvanized inika inani elihle lemali. Kubiza okungaphezu kokucacile kwensimbi ekuqaleni. Kepha kushibhile kunensimbi engagqwali noma amakhoyili apendwe. I-zinc coating isho ukulungiswa okumbalwa kanye nokuphinda kulungiswe kabusha. Lokhu kusindisa imali ngokuhamba kwesikhathi.

Isici esibizayo |

Insimbi eshisayo edonsa |

Uhlelo lwensimbi oludwetshwe (ijazi ezimbili) |

Izindleko zokuqala |

Ukuncintisana noma okuphansi |

Kwesinye isikhathi kuphakeme noma okufanayo |

Ukulungiswa konyaka |

$ 0.03 ngonyaka |

$ 0.15 ngonyaka |

Impilo Yendawo |

Iminyaka engama-30 |

Iminyaka engama-30 |

Ukulungiswa okudingekayo |

Namunye |

Ukulungiswa njalo |

Izindleko Zokuphila Zomjikelezo |

Imvamisa nje izindleko zokuqala |

Okuphezulu kakhulu ngenxa yokusebenziseka |

Insimbi ye-Galvanized isiza izindleko eziphansi ngokuhamba kwesikhathi. Idinga ukulungiswa okumbalwa nokubuyiselwa. Iphinde isindise amandla ezakhiweni. Lokhu kwenza kube ukukhetha okuhle kokwakha nokwenza izinto.

Izicelo zekhoyili yensimbi ye-galvanized

Ukwakhiwa nophahla

I-Calvanized Steel Coil ibaluleke kakhulu ekwakheni. Abakhi bayisebenzisela ophahleni, izindonga, imishayo nemigoqo. Isendlalelo seZinc sigcina izakhiwo ziphephile ekugqwabeni nasekulweni kwesimo sezulu esibi. Lokhu kwenza kube yisinqumo esihle sokusetshenziswa kwangaphandle. Kuqine futhi akuphuli kalula. Kuhlala isikhathi eside ezindaweni ezinzima. Abakhi abaningi bakhetha ikhoyili yensimbi eyenziwe nge-galvanized yezakhiwo zensimbi, ama-gut, kanye namaphaneli odonga. Cishe ingxenye yawo wonke amakhoyili wensimbi enziwe nge-galvanized ekwakhiweni. Amadolobha amaningi namaphrojekthi amasha enza isidingo salokhu kukhula, ikakhulukazi e-Asia-Pacific.

Ezokukhiqiza nezimoto

Amafektri Sebenzisa ikhoyili yensimbi ye-galvanized ye-galvanized ngoba kunzima futhi kulula ukulolo. Abenzi bemoto basebenzisa amakhoyili e-hot-dip galvanized ama-calvanized ama-car bodies, ozimele, kanye nezingxenye ezingezansi. Isendlalelo se-zinc siyama lezi zingxenye ekuguleni. Lokhu kusiza izimoto ukuthi zigcine ziphephile futhi zisebenze kahle. Izinkampani zezimoto eChina naseNdiya zisebenzisa ikhoyili yensimbi eyengeziwe manje. Bafuna izimoto ezilula nezingcono. Izimoto eziningi zikagesi nazo zisho isidingo esithe xaxa salokhu okuqukethwe. Imithetho emisha ngokungcoliswa kokonga kanye nokonga uphethiloli Yenza izinkampani zisebenzise ikhoyili yensimbi ehlanganisiwe. Izindlela ezingcono zokuhlanganisa kanye namafektri endawo zisiza ukufeza imfuno enkulu kulezi zindawo.

Okunye ukusetshenziswa

I-Calvanized Steel Coil isetshenziselwa ngaphezu kwezakhiwo nje nezimoto. Abenzi be-aclianceance bayisebenzisela ama-Washers, ama-fridge, kanye nezimo zomoya. Akugqwamu futhi kubukeka kukuhle. Okuqukethwe nakho kusetshenziswa emandleni aluhlaza kanye namaphrojekthi wedolobha elihlakaniphile. Izimoto zikagesi namandla aluhlaza adinga insimbi engagwiki ezintweni ezintsha. E-Asia-Pacific, ngaphezulu kwekota yensimbi yensimbi ye-galvanized kusetshenziselwa izinto zokusebenza. Amaphrojekthi amasha amasha namafektri amaningi enza isidingo sensimbi ukukhuphuka. Izinkampani manje zisebenzisa ubuchwepheshe obusha ukwenza imikhiqizo ebukhali futhi ekhethekile yensimbi yalezi zimakethe ezintsha.

Ukucatshangelwa kanye nokulinganiselwa

Ukukhetha ikhoyili efanele

Ukukhetha ikhoyili yensimbi efanele umsebenzi kubalulekile. Udinga ukucabanga ngezinto eziningi. Lezi zinto ziyashintsha indlela ikholi lisebenza kahle nokuthi lihlala isikhathi esingakanani.

Ubukhulu : Insimbi emnyama ibamba isisindo esengeziwe futhi ihlala isikhathi eside. Abakhi basebenzisa amakhoyili aminyene ukuthola imishayo nezingxenye eziqinile. Amakhoyili amancanyana alungele izinto ezilula njengemithombo yomoya.

Isisindo se-coating : I-zinc coating igcina ukugqwala kude. Izambatho ezisindayo, njenge-G90, zilungele izindawo ezimanzi noma ezinosawoti. Izimbobo ezilula, njenge-G60, zihamba kahle ngezindawo ezingaphakathi noma ezimnene.

Ibanga : Ibanga ngalinye linamandla alo nokuphanga. Amamaki aqinile alungile lapho udinga insimbi enzima. Amabanga aguqukayo angcono uma udinga ukugoba noma ukulola ikhoyili.

Ububanzi nobude : Amasayizi angokwezifiso asiza ukulingana nephrojekthi ngayinye. Lokhu kwenza ukwakha nokwakha kube lula.

Okunye ukucatshangelwa : Cabanga ngentengo, uhlobo lomsebenzi, nokuthi uzolisebenzisa kuphi ikhoyili. I-Hot-DIP noma i-Electrogalvanizing ikhethwe ngokusekelwe kulokho okudingayo.

ICEBISO: Hlala ubheka imithetho yezimboni futhi uhlole ikhwalithi yomhlinzeki wakho ngaphambi kokuthenga.

Izici zezemvelo

Indawo lapho usebenzisa khona amakhoyili ensimbi angashintsha indlela asebenza ngayo. Usawoti osemoyeni oseduze kolwandle uqhekeke i-zinc ngokushesha. Ukungcola okuvela ezimbonini kwenza imvula ye-acid egqoke i-zinc. Ukugcina amakhoyili ezindaweni ezinamanzi kungabamba amanzi futhi kubangele ukugqwala okumhlophe. Ukushisa okuphezulu kusuka ekushiseni noma ekusikeni kungashisa i-zinc bese ushiya insimbi ivulekele ukugqwala.

Indawo ezungezile |

Ubungozi obukhulu |

Isenzo sokuvikela |

-Ogwini |

Isifutho sikasawoti, ukupela |

Sebenzisa i-zinc coating esindayo |

-Kwezimboni |

Imvula ye-acid, ukugqwala |

Faka isicelo sokudlula, imiphetho ye-seal |

Ukugcinwa okunomswakama |

Ukwakheka okumhlophe kokugqwala |

Gcina endaweni eyomile, enomoya |

Izinkinga ezijwayelekile

Amakhoyili wensimbi angaba nezinkinga lapho esetshenziswa noma egcinwe:

Ukugqwala okumhlophe kungavela uma amanzi ehlala ekhondweni, ikakhulukazi uma ukudlula kungenziwa kahle.

Imihuzuko, ukusikeka, noma ukufudumeza kungalimaza ungqimba lwe-zinc futhi kwenze ukugqwala kube khona.

Uma i-zinc ingeyona noma insimbi inokungcola, izindawo ezibuthakathaka zingakha.

Amabala amnyama kungenzeka uma ukugqwala okumhlophe kuqhubeka kukhula.

Ukugcina amakhoyili okungalungile, njengasezindaweni ezimanzi, kwenza ukugqwala kungenzeka kakhulu.

Qaphela: phatha amakhoyili ngokunakekela, uzihlole kaningi, futhi uzigcine kwesokudla ukumisa izinkinga eziningi.

I-Calvanized Steel Coil igcina insimbi iphephe ngokugqwala. Iphinde ime ukulimala. Lokhu okuqukethwe kuqinile futhi kuhlala isikhathi eside. Kuyasiza ukonga imali. Abakhi bayisebenzisela ophahleni kanye nezindonga. Abakhiqizi bayisebenzisela izimoto kanye nemishini. Abathengi badinga ukubheka ubukhulu kanye nesisindo se-coating. Kufanele futhi bahlole ibanga. Amazinga we-ASTM asiza ukuqiniseka ukuthi ikhoyili yinhle. Umswakama nosawoti emoyeni kungashintsha ukuthi kusebenza kanjani. Ukukhetha ikhoyili kwesokudla kunikeza imiphumela engcono.

Umthandi

Iyini inhloso esemqoka yekhoyili yensimbi ye-galvanized?

I-Calvanized Steel Coil igcina insimbi ekujuleni noma ilimele. I-zinc under isebenza njengesihlangu. Abakhi kanye namafektri bakusebenzisa ukwenza izingxenye ezihlala isikhathi eside futhi zihlale ziqinile.

Ngabe uZinc Ukuhlangana uvimba kanjani ukugqwala?

I-zinc ihlangana namanzi nomoya ngaphambi kokuba insimbi yenza. Lokhu kwenza ungqimba olukhethekile ngaphezulu. Isendlalelo siyeka amanzi nomoya ekuthinteni insimbi.

Abantu basebenzisa kuphi i-coil yensimbi egcwele kakhulu?

Abantu basebenzisa ikhoyili yensimbi ye-galvanized ekwakheni, ekwenzeni izimoto, nokwenza izinto. Kuhle ophahleni, izingxenye zemoto, kanye nezingcezu zomshini.

Ngabe i-galvanized yensimbi yensimbi ingapendwe?

Ungapenda ikhoyili yensimbi ye-galvanized. Ingaphezulu lidinga ukuba lihlanzekile futhi lome kuqala. Ama-primers akhethekile asiza upende anamathele ku-zinc under.

Yiziphi izindinganiso ezisebenza kukhokhoyili yensimbi egcwele nge-galvanized?

I-ASTM A653 ne-ISO 3575 yimithetho eyinhloko yekhoyili yensimbi ye-galvanized. Le mithetho ikhuluma ngokuthi ukuhlanganiswa kangakanani, ingaphezulu libukeka kanjani, nokuthi lilwa kahle kangakanani ukugqwala.