A galvanized steel coil is a rolled sheet of steel coated with a layer of zinc. This zinc layer protects the steel from rust and damage, making the coil strong and durable. Our company offers high-quality galvanized steel coil products that are widely used by factories and builders for construction, manufacturing, and automotive parts. In 2022, approximately 140 million metric tons of galvanized steel coil were produced worldwide, with China leading production. Our products are designed to meet the growing demand for reliable galvanized steel coils across various industries.

Key Takeaways

Galvanized steel coil is steel covered with zinc. The zinc helps stop rust and makes the steel last longer. This makes the steel strong and good for many things.

There are different types and grades of galvanized steel coil. Each type works best for certain jobs. Thick zinc coatings protect better outside. Thin coatings are better for inside or for looks.

Hot-dip, pre-galvanizing, and electrogalvanizing are ways to add zinc. Each way gives a different thickness and look. Each is used for special needs.

Galvanized steel coil is used a lot in building, cars, and home machines. It helps save money because it needs fewer repairs and less care.

Picking the right coil means thinking about thickness, zinc coating, grade, and where it will be used. This helps make sure it works well and lasts long.

Galvanized Steel Coil Overview

What Is Galvanized Steel Coil

A galvanized steel coil is a flat steel sheet. It is rolled up into a coil. The coil is covered with a zinc layer. The zinc keeps the steel safe from rust and corrosion. Factories and builders like galvanized steel coil. It is strong and lasts a long time. It works well even in tough weather. The zinc layer blocks water and air. This helps stop rust from forming. When the coil is outside, zinc meets oxygen and moisture. It makes a thin film that protects the coil. This film helps the coil resist damage.

Galvanized steel coil has many important properties:

Property | Typical Value | Significance/Benefit |

Density | Approximately 7.85 g/cm³ | Standard weight suitable for structural applications |

Surface Coating Weight | 30-350 g/m² (both sides) | Provides corrosion protection adaptable to environments |

Surface Smoothness | Roughness (Ra) 0.8-1.5 μm | Enhances coating adhesion and durability |

Thermal Conductivity | Unaffected by galvanizing layer | Suitable for heat dissipation applications |

Electrical Conductivity | Slightly lower than pure steel | Meets industrial conductivity requirements |

Coefficient of Thermal Expansion | 11.5 x 10⁻⁶/°C | Ensures dimensional stability under temperature changes |

Note: The zinc layer helps the coil resist chemicals. It stays stable in places with pH from 6 to 12. The coil can handle heat up to 200°C for a long time. It can take up to 300°C for a short time.

Key Specifications

Manufacturers make galvanized steel coil in many sizes. They also make different thicknesses. The most common features are thickness, width, coil weight, and inner diameter. These help buyers pick the best coil for their needs.

Specification Parameter | Common Range / Value |

Thickness | 0.12 mm to 0.8 mm (some up to 4.0 mm or 6.0 mm) |

Width | 600 mm to 1500 mm (some sources 600 mm to 1250 mm) |

Coil Weight | 3 to 8 metric tons (standard), up to 25 metric tons on request |

Coil Inner Diameter | 508 mm or 610 mm |

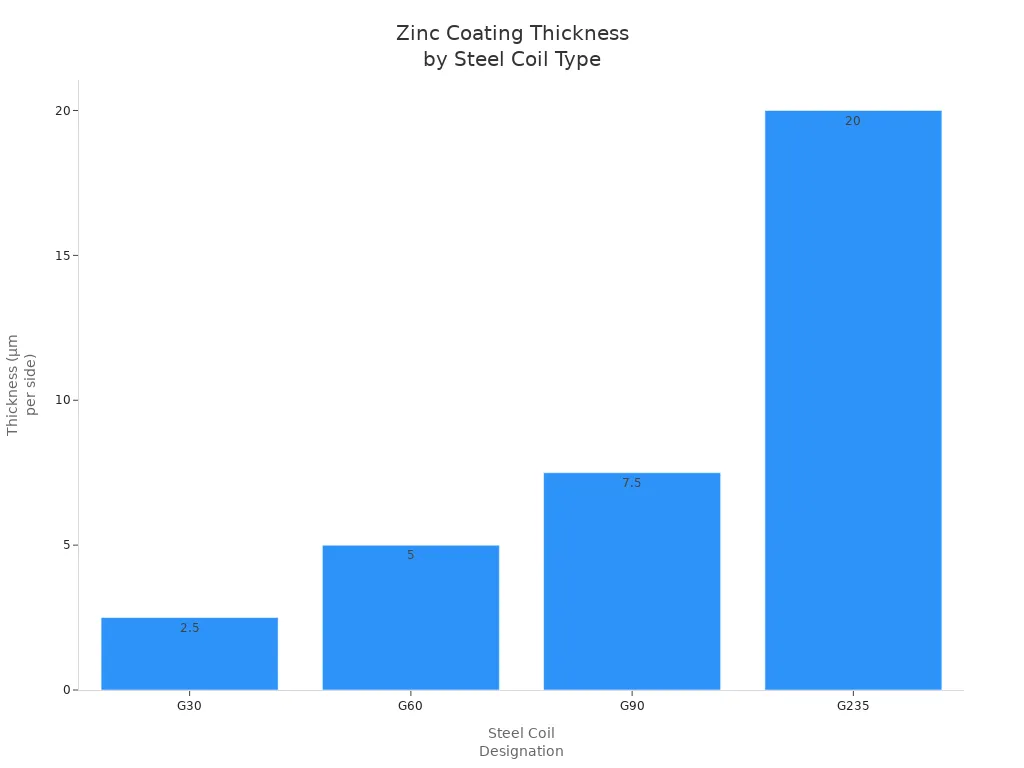

The zinc coating thickness is very important. It affects how well the coil fights rust. It also changes how long the coil lasts. Different coils have different coating weights and thicknesses. The table below shows common types and their features:

Designation | Zinc Coating Weight (oz/ft⊃2;) | Approximate Thickness (µm per side) | Typical Corrosion Resistance | Common Applications |

G30 | 0.30 total (0.15 per side) | ~2.5 | Light protection | Indoor framing, appliances |

G60 | 0.60 total (0.30 per side) | ~5 | Moderate protection | HVAC, light outdoor framing |

G90 | 0.90 total (0.45 per side) | ~7.5 | High protection | Roofing, siding, agriculture |

G235 | 2.35 total (1.175 per side) | ~20 | Maximum protection | Marine, guardrails, high-corrosion environments |

The way zinc is put on the coil changes its thickness. Hot-dip galvanizing makes thick coatings. These are usually between 45 and 100 micrometers. Electro-galvanizing makes thin coatings. These are from 2.5 to 25 micrometers. Thick coatings protect better but cost more. Thin coatings look smoother and are used inside or for decoration.

Galvanized steel coil must follow international standards. These rules make sure the coil is safe and strong. Some important standards are:

Standard | Scope / Application | Key Specification Points |

ASTM A653/A653M | Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated by Hot-Dip Process | Coating weight, adhesion, surface quality, coating thickness minimums, finish, appearance, adherence |

ASTM A924/A924M | General Requirements for Steel Sheet, Metallic-Coated by Hot-Dip Process | General coating requirements including thickness, adhesion, and surface quality |

ASTM A123/A123M | Hot-Dip Galvanized Coatings on Iron and Steel Products | Coating thickness minimums, continuous smooth finish, no uncoated areas, strong adherence throughout service life |

ISO 3575 | Continuous Hot-Dip Zinc-Coated Carbon Steel Sheet of Commercial and Drawing Qualities | Coating thickness, appearance, corrosion resistance |

ISO 1461 | Hot Dip Galvanized Coatings on Fabricated Iron and Steel Articles – Specifications and Test Methods | Coating thickness, appearance, corrosion resistance |

ASTM and ISO standards set rules for coating weight and thickness.

Tests check how well zinc sticks to steel and how even the coating is.

Corrosion resistance is tested with salt spray and other ways.

Types and Grades

Galvanized steel coil comes in different types and grades. Each type has special features for certain jobs.

Hot-Dip Galvanized Steel Coils: These coils are made by dipping steel in melted zinc. This makes a thick, tough layer that stops rust. Builders use hot-dip coils for outdoor things like roofs and fences.

Electro-Galvanized Steel Coils: These coils get zinc by using electricity in a solution. The layer is thinner and smoother. Factories use these coils for car parts and appliances that need a nice look.

Grades use a "G" and a number. The number shows how much zinc is on the coil. Bigger numbers mean more zinc and better protection. G60, G90, and G275 are common grades.

Grade Type | Description | Typical Applications |

Commercial Grade | Largest market share; general use in construction | Roofing, siding |

Drawing Quality | Used in cold-rolled steel production | Automotive, appliances |

High Strength Low Alloy | High strength and durability | Bridges, buildings, ships |

Structural Grade | Used in construction of bridges and buildings | Structural frameworks |

Others | Specialty grades with specific properties | Various specialized applications |

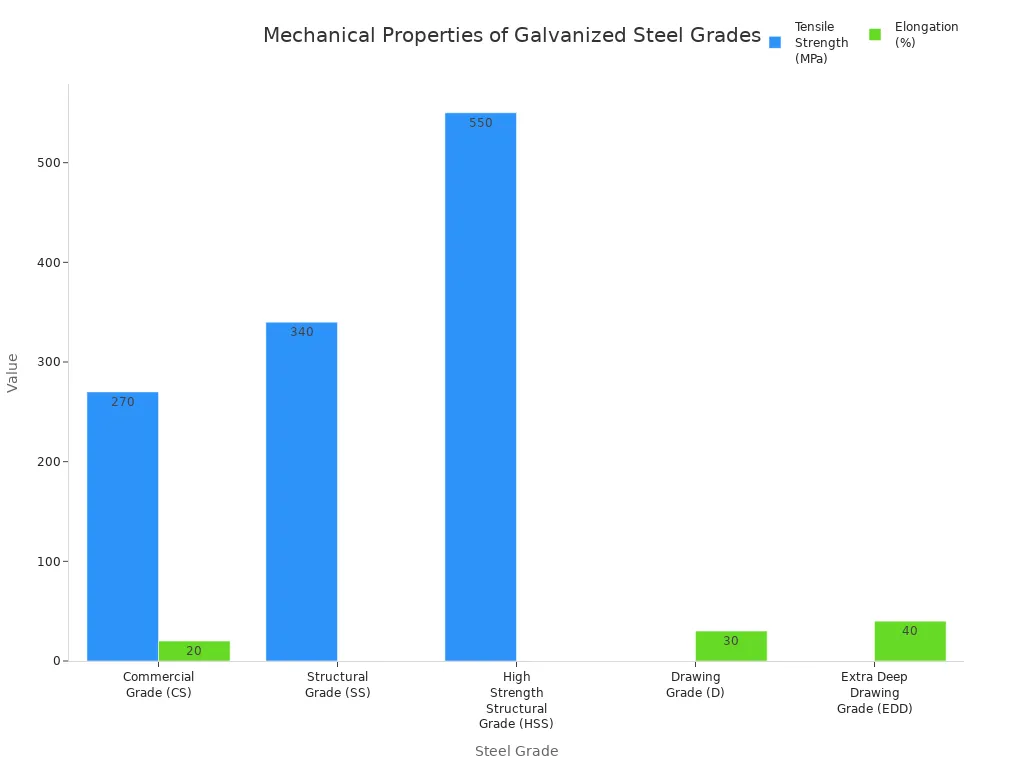

Mechanical properties change with each grade. The table below shows how strength and flexibility are different:

Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Core Advantage | Typical Application/Processing |

Commercial Grade (CS) | 270 - 410 | N/A | ≥ 20 | Basic rustproofing, general strength | Simple bending and cutting (no deep stamping) |

Structural Grade (SS) | 340 - 550 | ≥ 230 | Moderate | High strength and weldability | Load-bearing, welding, bolt connections |

Drawing Grade (D) | Moderate | N/A | ≥ 30 | High ductility and uniform elongation | Medium complexity stamping |

Extra Deep Drawing Grade (EDD) | Lower | N/A | ≥ 40 | Extreme formability, resistance to thinning | Complex stamping with precision molds |

High Strength Structural Grade (HSS) | 550 - 980 | Yield ratio ≤ 0.85 | Moderate | Highest strength-to-weight ratio, high energy absorption | Specialized processing (laser cutting, hydraulic molding) |

Galvanized steel coil has different surface finishes:

Regular Spangled: You can see zinc crystals. It is used in construction.

Minimized Spangle: Smaller crystals make a smoother surface. Used in cars and appliances.

Zero Spangle: No crystals are seen. The surface is shiny and smooth. Used in food and chemical industries.

Specialty Coatings: Some coils have extra layers for fingerprints, bacteria, or heat.

Tip: Pick the right type and grade for your job. Thick coatings and high grades are best for outside or tough places. Thin coatings and smooth finishes are good for inside or decoration.

Production Methods

Hot-Dip Galvanizing

Hot-dip galvanizing is the most popular way to protect steel coils. First, workers clean the steel. They pickle and neutralize the surface. Next, they dip the coil in melted zinc. This makes a strong zinc-iron alloy layer. After dipping, the coil cools down. Workers treat it with passivation and oil. These steps help the coating stick and look better. Inspectors check the thickness and how the coating looks. Then, the coil gets packed. The zinc layer is thick, usually 45 to 85 micrometers. This matches ASTM rules like A123 and A653. The process helps steel fight rust and scratches. It is great for outdoor buildings and tough jobs.

Process Flow:

Prepare and clean the material

Pickle and remove grease

Wash and neutralize

Add pretreatment coating

Dip in melted zinc

Cool and treat the coil

Flatten and trim the coil

Inspect for quality

Cut and roll into coils

Pack and ship the product

Pre-Galvanizing

Pre-galvanizing happens at the steel mill before shaping. Workers clean the steel sheet first. Then, they run it through melted zinc in a line. This makes a smooth and even zinc layer. The coating is usually 20 to 30 micrometers thick. The finish is bright and easy to shape. Pre-galvanized steel costs less and works well for big jobs. But, cut edges and welds can show bare steel. This means less rust protection. Pre-galvanizing is best for indoor items or parts that need to look nice.

Feature | Hot-Dip Galvanizing | Pre-Galvanizing |

Coating Thickness | 45-85μm | 20-30μm |

Coverage | Full, including edges | Not on cut edges |

Finish | Variable | Uniform, bright |

Best Use | Outdoor, heavy-duty | Indoor, visible parts |

Electrogalvanizing

Electrogalvanizing uses electricity to cover steel with zinc. Workers clean the steel first. Then, they put it in a special solution. Zinc ions stick to the steel and make a thin, even layer. The coating is usually 5 to 25 micrometers thick. Electrogalvanized steel is smooth and shiny. It bends easily and resists rust in wet places. It is also easy to paint. People use it for car parts, appliances, and electronics. The process follows ASTM A879 rules. It is good for products that need a fine surface and some rust protection.

Note: Electrogalvanized steel works best inside and under paint. It stops rust well but does not protect from wear as much as hot-dip methods.

Galvanealing

Galvanealing mixes galvanizing with heating. After hot-dip galvanizing, workers heat the steel very high. This makes a zinc-iron alloy layer. The layer helps with welding and painting. Galvanealed steel is easy to weld and shape. It is used in cars, buildings, and appliances. ASTM A653 gives the rules for galvanealed steel coil. This keeps the quality and performance steady.

Features and Benefits

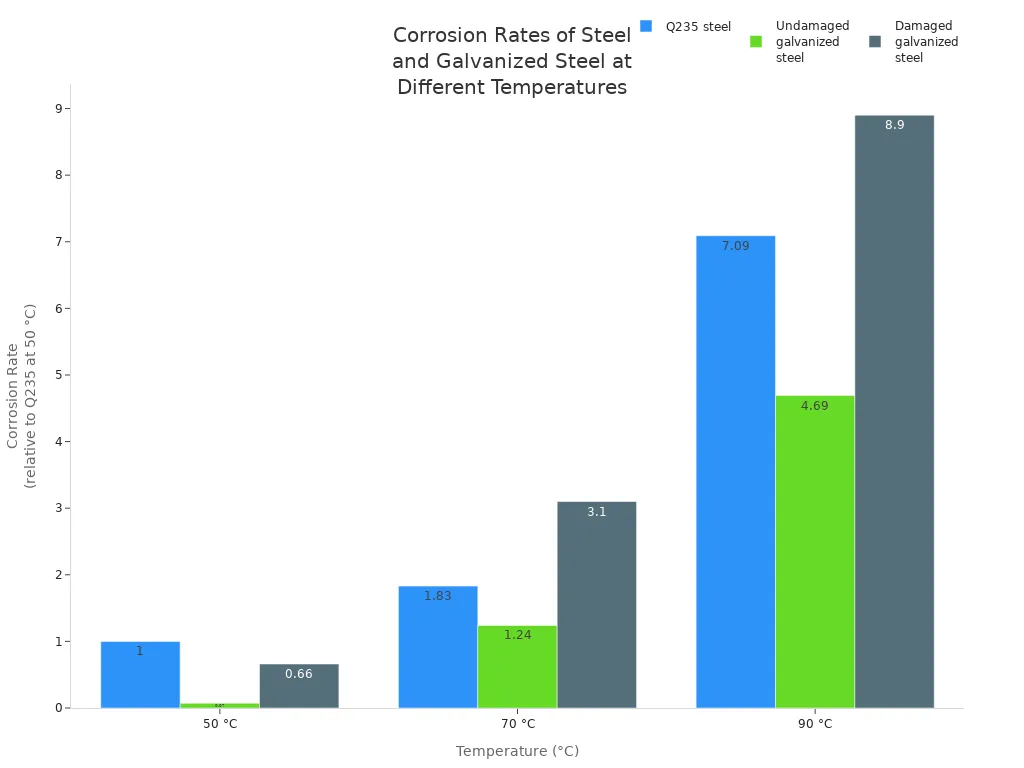

Corrosion Resistance

Galvanized steel does not rust easily because of its zinc coating. The zinc layer protects the steel underneath. When water or air touches the coil, zinc reacts first. This makes a shield that stops oxygen and water from reaching the steel. The zinc layer also creates special compounds like zincite (ZnO), hydrozincite, and Simonkolleite. These compounds form a thick film. The film slows down rust and keeps the steel safe. Even if the coil gets scratched or cut, the zinc still protects it. The zinc coating changes how the steel reacts to rust. Thicker zinc layers give more protection. They last longer in tough places.

The zinc coating wears away before the steel does.

Protective films block oxygen and water from the steel.

The coating fixes itself at scratches or cuts.

Zinc-rich primers give extra protection in hard conditions.

Tests show galvanized steel resists rust much better than plain steel. This is true in wet or outdoor places.

Specimen | Corrosion Rate (50°C) | Main Corrosion Products | Product Morphology |

Q235 steel | 1 | Fe3O4 | Loose |

Undamaged galvanized steel | 0.07 | ZnO | Dense |

Damaged galvanized steel | 0.66 | Fe3O4 + ZnO | Dense |

Durability and Maintenance

The zinc coating helps galvanized steel last a long time. It works well outside in rain, sun, and wind. People use it for roofs, fences, and machines. Stainless steel lasts longer in very harsh places. But galvanized steel protects well and costs less. Over time, the zinc layer can wear down. Regular checks and easy repairs keep the steel strong.

Tip: Keep galvanized steel in dry places. Wrap coils to protect them. Check for water often. If you see damage, fix it with zinc-rich paint or spray.

Recommended maintenance practices:

Use chemicals or oil to stop friction and damage.

Wrap coils with paper or plastic when storing or shipping.

Check for water and dry coils right away if wet.

Fix packaging fast to stop scratches.

Store coils in climate-controlled rooms. Do not keep them too long.

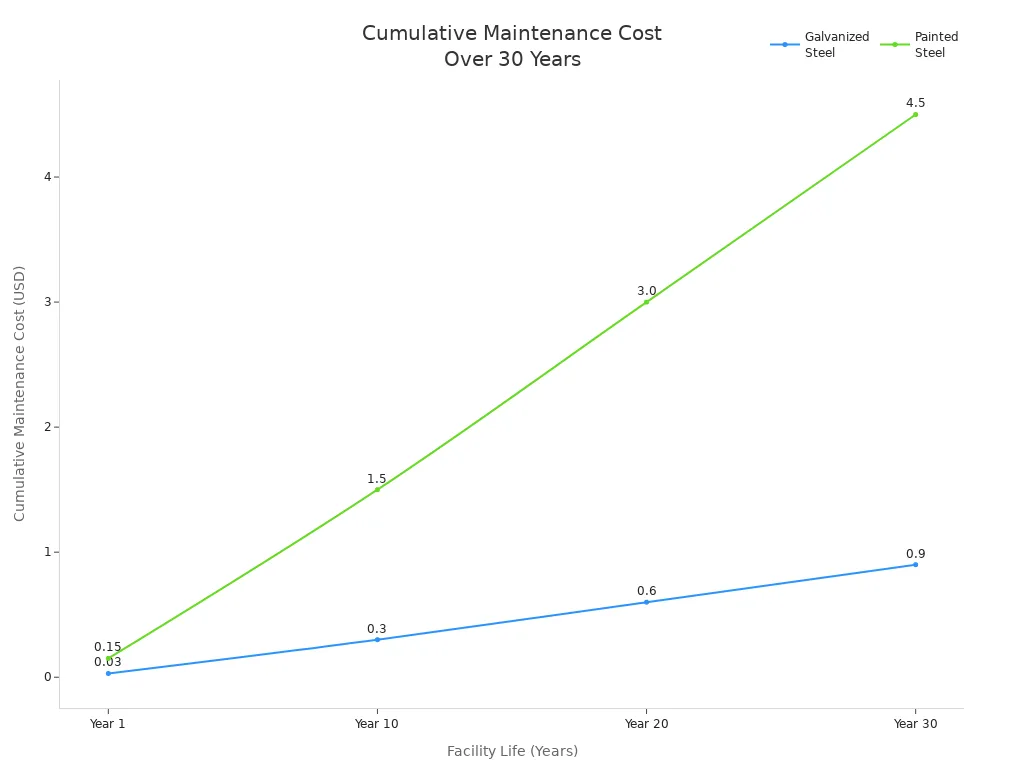

Cost Efficiency

Galvanized steel gives good value for the money. It costs more than plain steel at first. But it is cheaper than stainless steel or painted coils. The zinc coating means fewer repairs and less repainting. This saves money over time.

Cost Aspect | Hot-Dip Galvanized Steel | Painted Steel System (Two-Coat) |

Initial Cost | Competitive or lower | Sometimes higher or similar |

Annual Maintenance | $0.03 per year | $0.15 per year |

Facility Life | 30 years | 30 years |

Maintenance Needed | None | Regular repainting |

Life-Cycle Cost | Often just initial cost | Much higher due to upkeep |

Galvanized steel helps lower costs in the long run. It needs fewer repairs and replacements. It also saves energy in buildings. This makes it a smart choice for building and making things.

Applications of Galvanized Steel Coil

Construction and Roofing

Galvanized steel coil is very important in building. Builders use it for roofs, walls, beams, and bars. The zinc layer keeps buildings safe from rust and bad weather. This makes it a good choice for outdoor use. It is strong and does not break easily. It lasts a long time in hard places. Many builders pick galvanized steel coil for metal buildings, gutters, and wall panels. About half of all galvanized steel coil is used in building. More cities and new projects make the need for this material grow, especially in Asia-Pacific.

Manufacturing and Automotive

Factories use galvanized steel coil because it is tough and easy to shape. Car makers use hot-dip galvanized coils for car bodies, frames, and bottom parts. The zinc layer stops these parts from rusting. This helps cars stay safe and work well. Car companies in China and India use more galvanized steel coil now. They want lighter and better cars. More electric cars also mean more need for this material. New rules about pollution and saving fuel make companies use galvanized steel coil. Better coating methods and local factories help meet the bigger demand in these areas.

Other Uses

Galvanized steel coil is used for more than just buildings and cars. Appliance makers use it for washers, fridges, and air conditioners. It does not rust and looks nice. The material is also used in green energy and smart city projects. Electric vehicles and green energy need steel that does not rust for new things. In Asia-Pacific, more than a quarter of galvanized steel coil is used for appliances. New city projects and more factories make the need for this steel go up. Companies now use new technology to make smarter and special steel products for these new markets.

Considerations and Limitations

Choosing the Right Coil

Picking the right steel coil for a job is important. You need to think about many things. These things change how well the coil works and how long it lasts.

Thickness: Thick steel holds more weight and lasts longer. Builders use thick coils for beams and strong parts. Thin coils are good for lighter things like air ducts.

Coating Weight: The zinc coating keeps rust away. Heavy coatings, like G90, are best for wet or salty places. Lighter coatings, like G60, are fine for inside or mild areas.

Grade: Each grade has its own strength and bendiness. Strong grades are good when you need tough steel. Flexible grades are better if you need to bend or shape the coil.

Width and Length: Custom sizes help fit each project. This makes building and design easier.

Other Considerations: Think about price, the job type, and where you will use the coil. Hot-dip or electrogalvanizing is picked based on what you need.

Tip: Always look at industry rules and check your supplier’s quality before you buy.

Environmental Factors

The place where you use steel coils can change how they work. Salt in the air near the ocean breaks down zinc faster. Pollution from factories makes acid rain that wears away the zinc. Storing coils in damp places can trap water and cause white rust. High heat from welding or cutting can burn off the zinc and leave steel open to rust.

Environment | Main Risk | Protective Action |

Coastal | Salt spray, pitting | Use heavy zinc coating |

Industrial | Acid rain, corrosion | Apply passivation, seal edges |

Humid Storage | White rust formation | Store in dry, ventilated area |

Common Issues

Steel coils can have problems when used or stored:

White rust can show up if water stays on the coil, especially if passivation is not done well.

Scratches, cuts, or welding can hurt the zinc layer and make rust more likely.

If the zinc is not even or the steel has dirt, weak spots can form.

Black spots can happen if white rust keeps growing.

Storing coils wrong, like in wet places, makes rust more likely.

Note: Handle coils with care, check them often, and store them right to stop most problems.

Galvanized steel coil keeps steel safe from rust. It also stops damage. This material is strong and lasts a long time. It helps save money too. Builders use it for roofs and walls. Manufacturers use it for cars and appliances. Buyers need to look at thickness and coating weight. They should also check the grade. ASTM standards help make sure the coil is good. Humidity and salt in the air can change how it works. Picking the right coil gives better results.

FAQ

What is the main purpose of galvanized steel coil?

Galvanized steel coil keeps steel from rusting or getting damaged. The zinc layer works like a shield. Builders and factories use it to make parts that last a long time and stay strong.

How does zinc coating prevent rust?

Zinc meets water and air before the steel does. This makes a special layer on top. The layer stops water and air from touching the steel.

Where do people use galvanized steel coil most often?

People use galvanized steel coil in building, car making, and making appliances. It is good for roofs, car parts, and machine pieces.

Can galvanized steel coil be painted?

You can paint galvanized steel coil. The surface needs to be clean and dry first. Special primers help the paint stick to the zinc layer.

What standards apply to galvanized steel coil?

ASTM A653 and ISO 3575 are the main rules for galvanized steel coil. These rules talk about how thick the coating is, how the surface looks, and how well it fights rust.