Galvanized steel is widely used in construction, manufacturing, agriculture, and daily applications because of its strong corrosion resistance. Many buyers choose galvanized steel for outdoor projects, roofing, guardrails, HVAC systems, and metal structures. But one common question always appears: Can galvanized steel rust?

Although galvanized steel is designed to resist corrosion, it is not entirely immune to rust under certain conditions. Understanding how galvanized steel protects itself—and the situations that may cause rust—helps you make better purchasing decisions and extend the lifespan of your projects. This article provides a clear explanation of why galvanized steel can rust, how long it stays rust-free, common rust-causing factors, and the best protection practices. It also integrates real-world usage cases and practical maintenance tips, making this guide suitable for engineers, contractors, and end-users.

What Is Galvanized Steel?

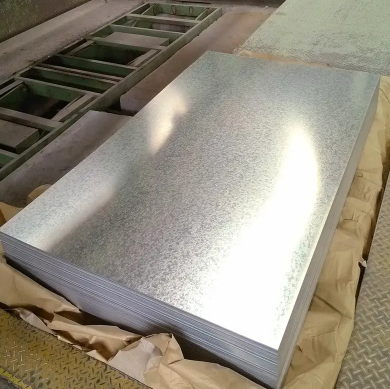

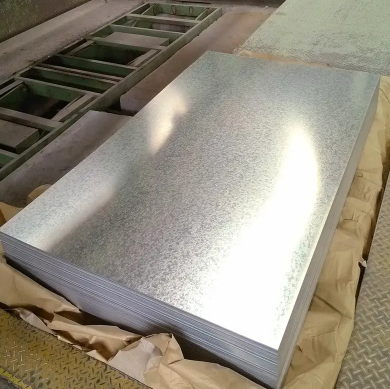

Galvanized steel is essentially carbon steel coated with a layer of zinc. The zinc coating acts as a protective barrier to prevent moisture, chemicals, and oxygen from directly contacting the steel surface. This coating delays oxidation and significantly extends the metal’s service life.

The most common types include:

Hot-dip galvanized steel

Electro-galvanized steel

Galvannealed steel

Among them, hot-dip galvanized steel offers the thickest coating and the best corrosion resistance, making it popular for roofing sheets, galvanized steel coil, structural beams, fences, and metal roofing systems.

Because the zinc layer sacrifices itself to protect the underlying steel, galvanized steel maintains a clean, long-lasting surface even in harsh environments.

Why Does Galvanized Steel Resist Rust?

The anti-rust performance of galvanized steel is mainly achieved through the following mechanisms:

The Zinc Barrier Effect

Zinc forms a physical shield between the steel and the environment. Water and air cannot directly reach the steel, preventing typical red rust.

Galvanic Protection (Sacrificial Protection)

If the surface is scratched, the zinc coating corrodes first.

This sacrificial reaction prevents the exposed steel from rusting immediately.

Formation of Zinc Patina

Over time, zinc reacts with oxygen, carbon dioxide, and moisture to form zinc carbonate—a stable film that further slows corrosion.

This is why the surface of galvanized steel gradually becomes matte or dull instead of shining.

With these three protective mechanisms, galvanized steel offers excellent long-term performance, especially in outdoor and industrial environments.

So, Can Galvanized Steel Rust?

Yes. Galvanized steel can rust, but only under specific conditions where the protective zinc coating is compromised, overloaded, or exposed to severe chemical environments.

It does not rust as quickly as non-coated steel, but it is not completely rust-proof. Understanding the common reasons behind rust can help you prevent premature corrosion.

Common Reasons Why Galvanized Steel Rusts

Coating Damage or Scratches

If the galvanized layer is scratched deeply, the exposed steel becomes vulnerable. Small scratches usually do not cause rapid rust because zinc still offers sacrificial protection, but large damaged areas can rust quickly.

Prolonged Exposure to Standing Water

Galvanized steel performs best when exposed to moisture that dries normally.

However, permanent immersion—such as in puddles, water tanks, or unventilated environments—accelerates corrosion significantly.

Acidic or Highly Polluted Environments

Industrial areas with acid rain, high sulfur levels, or chemical fumes can attack the zinc layer.

Acids react with zinc quickly, wearing down the protective coat and exposing the steel beneath.

Saltwater & Marine Environment

Salt is highly corrosive. Chlorides in marine air can gradually break down the zinc coating, especially if the steel is installed near coastlines or used in ships, ports, and offshore structures.

High Abrasion or Mechanical Friction

Structures exposed to friction—such as guardrails, moving components, or frequently touched surfaces—may lose their coating over time.

By identifying these conditions, users can take preventive actions and extend the durability of galvanized steel in their applications.

How Long Does Galvanized Steel Take to Rust?

Depending on the environment, galvanized steel can remain rust-free for decades.

Estimated Service Life (General Guideline)

Rural outdoor environment: 50–70 years

Suburban conditions: 40–60 years

Coastal conditions: 10–25 years

Industrial acidic environment: 5–15 years

These numbers vary according to coating thickness. A thick hot-dip galvanized layer can last dramatically longer than a thin electro-galvanized coating.

In typical building and roofing applications, galvanized steel coil and galvanized steel sheet often last over 20–30 years with minimal maintenance.

Is Rust on Galvanized Steel Dangerous?

Generally, small surface rust spots are not immediately dangerous.

Since galvanized steel normally corrodes slowly, rusting often starts superficially and spreads gradually. But ignoring rust for a long period can lead to structural weakening, especially if moisture penetrates the underlying layers.

If rust appears unexpectedly, it often indicates:

Early inspection and repair are the best ways to prevent long-term damage.

How to Prevent Galvanized Steel from Rusting

Regular Inspection

Check the surface every 6–12 months for discoloration, white rust, scratches, or moisture accumulation.

Avoid Constant Water Exposure

Ensure proper drainage for roofs, gutters, and metal structures. Eliminate any condition that keeps galvanized steel soaked.

Apply Paint or Sealant for Extra Protection

Painting galvanized steel with a compatible primer extends its lifespan in aggressive environments.

Epoxy or polyurethane coatings work well.

Avoid Contact with Strong Acids or Salt

If the steel must be used in marine or chemical settings, consider upgrading to:

Repair Damaged Zinc Coating

Cold galvanizing spray or zinc-rich paint can restore protection when scratches or cuts appear.

Galvanized Steel vs Other Anti-Corrosion Metals

Galvanized Steel vs Stainless Steel

Stainless steel is naturally rust-resistant due to its chromium content.

It outperforms galvanized steel in marine and chemical environments but is more expensive.

Galvanized Steel vs Galvalume Steel

Galvalume (Al-Zn coated) offers better corrosion resistance and heat reflectivity.

It is often preferred for roofing sheets or outdoor structures in humid or coastal regions.

Galvanized Steel vs Painted Steel

Painted steel adds color and aesthetic value but still relies on the underlying zinc coating for corrosion protection.

Best Applications for Galvanized Steel

Galvanized steel is ideal for:

roofing sheets & wall panels

galvanized steel coil for fabrication

HVAC ducting

fencing & gates

car frames & chassis

agricultural greenhouses

electrical poles

scaffolding & structural beams

Because it provides strong rust resistance and excellent cost-performance, it remains one of the most commonly used materials in construction and manufacturing.

Signs That Your Galvanized Steel Is Starting to Rust

Dull staining or brown spots

White rust (zinc oxide powder)

Coating flaking or peeling

Water pooling areas turning dark

Rough texture patches

Spotting these early warnings helps prevent deeper corrosion and structural weakness.

Should You Worry If Galvanized Steel Rusts?

Not always, especially if the rust is minor.

Small rust spots do not mean the entire structure will fail immediately. However, localized rust should be addressed as soon as possible, especially in load-bearing or outdoor installations.

How to Remove Rust from Galvanized Steel

Light Rust

Clean with mild detergent and a nylon brush.

Avoid steel brushes, which can scratch the surface.

Medium Rust

Use a vinegar solution or a non-acidic rust cleaner suitable for zinc-coated metals.

Severe Rust

Mechanical cleaning followed by zinc-rich repair coating may be necessary.

If the corrosion is widespread, replacement might be more cost-effective.

Final Thoughts: Can Galvanized Steel Rust?

Galvanized steel can rust, but usually only in harsh or poorly maintained environments. With proper coating thickness, correct installation, and regular inspections, galvanized steel can offer decades of reliable performance. It remains one of the most cost-effective corrosion-resistant materials for construction, manufacturing, and infrastructure applications.

For users looking for high-quality galvanized steel coil, galvanized steel sheet, roofing sheet, or other metal building materials, choosing a reliable manufacturer is essential. Our company provides certified, premium-grade galvanized steel and a full range of coated steel solutions with strict quality control, stable coating thickness, and customized specifications. Whether for industrial projects, roofing systems, or structural applications, we deliver durable products that ensure long service life and consistent performance.

FAQ

1. Does galvanized steel rust underwater?

Yes. Long-term immersion accelerates zinc corrosion, especially if the water contains minerals or salt.

2. Can you paint galvanized steel to prevent rust?

Yes. After proper surface preparation, painting significantly enhances rust resistance.

3. Why does white rust appear on new galvanized steel?

White rust is zinc oxide caused by moisture exposure before the zinc forms its protective patina.

4. Is galvanized steel suitable for coastal environments?

It works, but the lifespan is shorter. Galvalume or stainless steel performs better near the ocean.

5. How can I fix scratches on galvanized steel?

Use cold galvanizing compound or zinc-rich paint to restore protection.