Yes, you can galvanize coil steel. This process keeps steel from rusting and helps it last longer. It is a good choice for many industries. Galvanized Steel Coil is special because it does not corrode easily. It also lowers the need for repairs. You can find this material in many places. It is used a lot in building and making cars.

The construction industry uses more than 36% of all galvanized coil steel.

The automotive sector also uses it for car parts.

Other areas, like electronics and farming, also need it.

The global market for galvanized steel coil grows about 5% each year. This shows it is important all over the world.

Key Takeaways

Galvanizing coil steel keeps it safe from rust. This makes it last longer and saves money on repairs.

Pick the right galvanized steel coil for your project. Think about how thick it is and how much coating it has.

The hot-dip method is used most to galvanize steel. It gives the steel a strong and tough zinc layer.

Galvanized steel is used a lot in building and car making. People use it because it is strong and does not rust easily.

Store and handle galvanized steel coils the right way. This stops problems like white rust and helps them work well for a long time.

Galvanizing Process

Steel coil comes in many types. There are cold-rolled, hot-rolled, and alloyed steel coils. Each type is different. Cold-rolled coils are smooth and strong. Hot-rolled coils bend easily and are simple to shape. Alloyed coils have extra elements for special jobs. You pick the coil type based on what your project needs.

You galvanize steel coil to stop rust and damage. The zinc coating works like a shield. This helps steel products last longer. Galvanized Steel Coil is popular because it does not corrode fast and needs less fixing. You see it in building, cars, and other industries.

Hot-Dip Method

The hot-dip method is the most used way to coat steel coil. You follow steps to make sure the zinc sticks well and protects the steel.

Surface Preparation

First, you clean the steel coil. Degreasing takes away oil and dirt. Acidic pickling removes rust and smooths the coil. Fluxing gets rid of leftover oxides.

Galvanizing

Next, you dip the coil in hot zinc at about 450 °C. The zinc bonds to the steel and forms layers that stop rust.

Post Treatment

Then, you cool the coil in water or air. This step helps the coating set.

Inspection

Last, you check the coil for coating thickness and quality. You use visual checks and tests to make sure it worked.

Tip: Good cleaning helps you get a strong and even zinc layer.

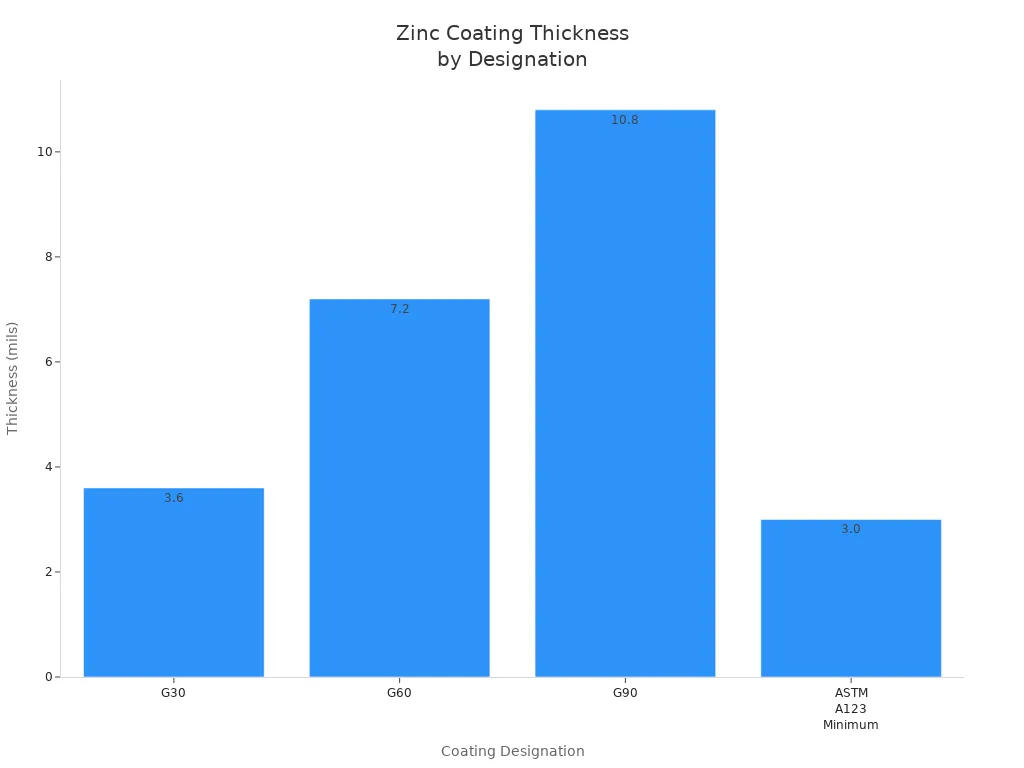

The zinc coating can be thick or thin. You see names like G30, G60, and G90. Thicker coatings give more protection. The table below shows common coating thicknesses:

Coating Designation | Coating Thickness (oz/ft⊃2;) | Approx. Thickness (mils) |

G30 | 0.30 | 3.6 |

G60 | 0.60 | 7.2 |

G90 | 0.90 | 10.8 |

ASTM A123 Minimum | N/A | 3.0 |

Quality control is very important in hot-dip galvanizing. You use tools like eddy current gauges to check coating thickness. Bend and peel tests check how well the coating sticks. Salt spray tests show how well the coating stops rust. Hardness tests show how tough the coating is. Looking under a microscope helps you find problems.

Electro-Galvanizing

Electro-galvanizing uses electricity to put zinc on steel coil. You put the coil in a solution with zinc ions. An electric current moves zinc onto the steel. This way gives a thinner and more even coating than hot-dip galvanizing.

Electro-galvanizing gives strong sticking power. The coating does not peel or flake off easily. The table below compares both ways:

Method | Coating Thickness | Coating Uniformity | Adhesion Characteristics |

Electro-Galvanizing | 5 to 30 microns | Thinner, more uniform | Strong adhesion, resistant to peeling and flaking |

Hot-Dip Galvanizing | Thicker | Less uniform | Strong adhesion due to zinc-iron alloy layers |

Electro-galvanized steel coil is good for parts that need a smooth finish. You often see it in car panels and electronics. The thin coating is best for inside use or where you do not need heavy rust protection.

Both galvanizing ways follow rules like ASTM A653 and A924. These rules help you get good quality and performance from Galvanized Steel Coil.

Galvanizing affects the environment. You use fewer resources because galvanized steel lasts longer. The process makes some waste, but you can recycle extra zinc. You also make less pollution since you do not replace steel as much.

Galvanized steel lasts a long time, so you do not fix or replace it often.

The process uses less power and gas, which lowers pollution.

You can collect and reuse extra zinc, which cuts down waste.

Galvanizing can change how steel acts. Sometimes, yield strength goes up. Other times, hardness goes down. You need to check these changes before picking a coil for your job.

Galvanized Steel Coil gives strong protection and lasts a long time. You can choose the way and coating thickness that fits your needs.

Galvanized Steel Coil Benefits

Corrosion Resistance

Galvanized Steel Coil protects steel from rust. The zinc coating acts like a shield. It stops water and air from touching the steel. This keeps steel safe in many places. Zinc also helps if the coating gets scratched. It protects the steel underneath. You can see the difference in this table:

Type of Steel | Corrosion Resistance Description |

Galvanized Steel | Coated with zinc, providing superior corrosion resistance, acting as a moisture barrier and sacrificial anode. |

Non-Galvanized Steel | Lacks protective coating, making it more susceptible to rust, especially in humid or chemically aggressive environments. Requires additional protective treatments. |

Galvanized Steel Coil works well outside. Do not use it near saltwater. Saltwater makes the zinc coating break down fast. You might see rust or flakes in these places. Stainless steel is better for marine use.

Durability

Galvanized Steel Coil lasts a long time. The zinc coating helps it stay strong for years. It works well even in tough places. Here is how long it lasts in different areas:

Environment Type | Average Service Life (Years) |

Industrial | 72 to 73 |

Tropical Marine | 75 to 78 |

Temperate Marine | 86 |

Suburban | 97 |

Rural | Over 100 |

The zinc layer thickness changes how long it lasts. Hot-dipped galvanized steel lasts 20 to 40 years in cities. Electro-galvanized steel lasts 10 to 15 years. You get more years in rural or suburban places.

Cost and Maintenance

Galvanized Steel Coil saves you money on repairs. The zinc coating stops rust. You do not need to fix or change parts often. Buildings made with galvanized steel stay strong and look nice for years. You spend less on upkeep, even in bad weather.

Tip: Pick the right gauge and width for your project. This helps you get good value and performance.

Galvanized Steel Coil comes in many sizes. You can choose what fits your job. It works for construction and making cars. This makes it a smart choice for many uses.

Standards and Specifications

ASTM Compliance

When you pick Galvanized Steel Coil, you should know the main standards. ASTM A653 and ASTM A924 are the main rules in the U.S. These standards help make sure your steel coil is strong and has a good coating. They also help with surface quality.

Requirement | ASTM A653/A653M | ASTM A924/A924M |

Coating Weight | Sets minimum coating weights for galvanized steel | Gives general rules for metallic coatings |

Adhesion | Requires tests for how well the coating sticks | Sets general adhesion rules for coatings |

Surface Quality | Lists what surface defects are allowed | Gives general surface quality rules |

You can trust these rules to help your steel coil last longer. They also help protect it from rust. Always check if your supplier follows these rules.

Product Range

Galvanized steel coils come in many sizes and thicknesses. This makes it easy to find the right coil for your job. Here is a quick look at what you can get in the U.S.:

Gauge Range (inches) | Width Range (inches) | Coating Weights |

0.0098 to 0.138 | 36 to 60 | G-30 to G-235, A-40 to A-60 |

14 to 10 | 60 | G60, G90 |

30 to 16 | 36 | G30, G40 |

28 to 14 | 36, 48, 60 | G30/G40, G60, G90 |

You can also ask for special processing. These choices help you get the best coil for your needs:

Post-Processing Option | Description | Benefits |

Passivated galvanized coils | Coated with a special film | More corrosion resistance |

Oiled galvanized coils | Covered with oil | Stops white rust |

Paint-sealed galvanized coils | Has a fingerprint-resistant film | Better surface and corrosion resistance |

Phosphated galvanized coils | Treated with a phosphating film | Less white rust |

Note: Most suppliers can cut, slit, or blank the coils. This means you can order the exact size you need.

You should also think about price. In the U.S., galvanized steel coil costs about $600 to $700 per ton. The price can change if you want a different size, coating, or special processing.

Limitations

White Rust

White rust is a problem with galvanized steel coil. It looks like gray-white powder. This powder forms when zinc touches water. You see it if coils are kept in wet places. Water sitting too long on the coil causes it. White rust does not just look ugly. It can make the zinc layer weaker. This means your steel coil will not last as long.

You can stop white rust by storing coils the right way. Here are some things that cause white rust:

Water builds up on the coil in humid air.

Changes in temperature make water drops form.

Humidity over 60% makes white rust more likely.

Dirt or dust on the coil holds water.

Bad packaging or storage traps water near the coil.

To keep coils safe, store them in a dry spot. The temperature should stay between 10°C and 30°C. Use fans or dehumidifiers to keep humidity under 60%. Always keep coils covered and away from open doors or windows. If you must keep coils outside, use plastic spacers for air flow. Cover them to keep out rain, but do not use tarps that trap water. If coils get wet, separate them so they can dry.

Manufacturers see other problems with galvanized steel coil. The table below lists common defects and what causes them:

Defect Type | Description | Causes |

Holes | Holes go through the steel strip | Bad steel or things stuck in the coil |

Dezincification | Zinc layer comes off | Rust or wrong conditions |

Air knife streaks | Lines show up along the strip | Air knife is blocked or broken |

Zinc slag | Bumpy bits on the surface | Temperature changes or dirty removal |

Roller marks | Long lines from rollers | Problems during rolling |

Uneven zinc flowers | Zinc flowers too big or small | Speed changes while making them |

Edge twill | Feather marks on the edge | Not enough cooling for the zinc layer |

White rust | Gray-white powder on the surface | High humidity or not dried well |

Temperature Sensitivity

Galvanized steel coil does not like high heat. If it gets hotter than 200°C (392°F), the zinc coating can break. This makes the steel rust faster. It also loses its protection. Do not weld or cut galvanized steel without safety steps. High heat can make dangerous zinc fumes.

When you work with galvanized steel coil, wear gloves and goggles. Work where air moves well so you do not breathe fumes. Store coils in a cool, dry place to keep them good. Training and safe habits help you avoid accidents. They also help your steel coil last longer.

Remember: Good storage, careful handling, and keeping coils cool help you get the best use from galvanized steel coil.

Applications

Construction

You see Galvanized Steel Coil used in many building projects. Builders choose it because it stands up to rain, wind, and sun. You can find it in roofing, siding, gutters, and decking. The zinc coating keeps these parts from rusting, so buildings last longer. When you use this material, you help protect homes and offices from water damage. Many schools, warehouses, and factories use it for strong, safe structures. You also find it in fences and support beams. This coil works well for both big and small projects.

Automotive

Car makers use Galvanized Steel Coil for many parts. The zinc layer helps stop rust, which keeps cars safe and looking good. You find this steel in:

Automobile body panels

Chassis

Frames

Suspension components

These parts need to be strong and last a long time. When you drive a car, you want it to stay safe in all kinds of weather. Using galvanized steel helps car makers build vehicles that last longer and need fewer repairs.

Other Uses

You can find new uses for galvanized steel coil outside of buildings and cars. Many companies use it in renewable energy projects. Wind turbines and solar panel frames need strong, rust-free metal. The transportation industry also uses this coil for making train cars and shipping containers. In homes, you see it in appliances and heating systems. More people choose it for new houses because it keeps pipes and ducts from rusting.

Note: Galvanized Steel Coil helps many industries by offering strength and protection. You can trust it for many jobs, from building homes to making cars and supporting clean energy.

You can galvanize coil steel using a simple process. This makes the steel strong and stops it from rusting. People like galvanized steel coil because it lasts a long time. It is useful for many things, like building and making cars. The coating type, such as aluminum-zinc, helps stop rust in tough places.

When picking galvanized steel coil, think about these things:

Factor | Description |

Thickness | Thicker steel is good for big jobs; thinner steel is for lighter work like ducts. |

Coating Weight | More coating protects better outside; less coating is fine inside. |

Grade | Strong grades last longer; ductile grades bend without breaking. |

Galvanized steel coil gives you many good things:

Stops rust

Lasts a long time

Is strong and safe

Has a shiny look

Is better for the environment

Needs little care

Can be made to fit your needs

Always check the rules and limits before buying. Galvanized steel coil is a trusted choice for many jobs.

Shandong Sino Steel Co., Ltd is a well-known steel supplier. They sell many kinds of steel coils, sheets, and plates. Their factories use new machines and check quality closely. They make products for building, cars, and more. You can trust their skill and strong supply for your next job.

FAQ

What is the main reason to galvanize steel coil?

You galvanize steel coil to stop rust. The zinc coating protects the steel from water and air. This makes the steel last longer and keeps it strong in many places.

How do you classify steel coils?

You can sort steel coils by how you make them. There are hot-rolled, cold-rolled, and alloyed coils. Each type has different strength, surface, and use.

What happens during the galvanizing process?

You clean the steel coil first. Then, you cover it with zinc using hot-dip or electro-galvanizing. The zinc forms a shield that keeps the steel safe from rust.

What standards should you check for galvanized steel coil?

You should look for ASTM A653 and A924. These standards make sure your coil has the right zinc coating and quality. Always ask your supplier about these standards.

Where can you use galvanized steel coil?

You can use galvanized steel coil in buildings, cars, and home appliances. It works well for roofing, siding, gutters, and even solar panel frames. The zinc coating helps in many jobs.