The galvanized steel coil market has experienced steady growth over the past decade, driven by rising construction activities, industrial expansion, and increasing demand for durable and corrosion-resistant materials. As global industries continue to prioritize efficiency and longevity, galvanized steel remains a material of choice for applications ranging from residential roofing and industrial fabrication to automotive components and infrastructure projects.

This article explores the emerging trends shaping the global galvanized steel coil market, analyzes the factors influencing demand, and highlights how manufacturers and buyers can navigate this evolving landscape.

Overview of the Galvanized Steel Coil Market

What is Galvanized Steel Coil?

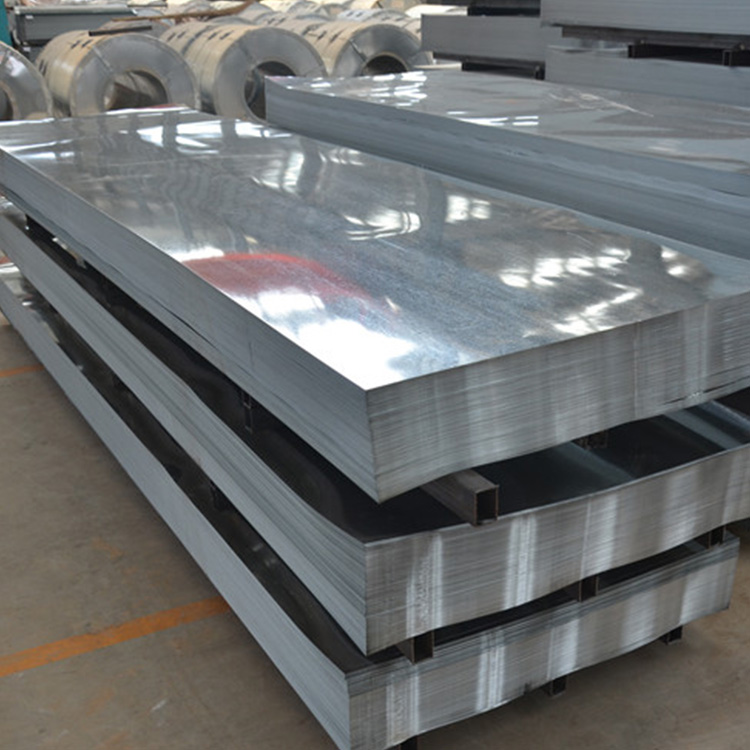

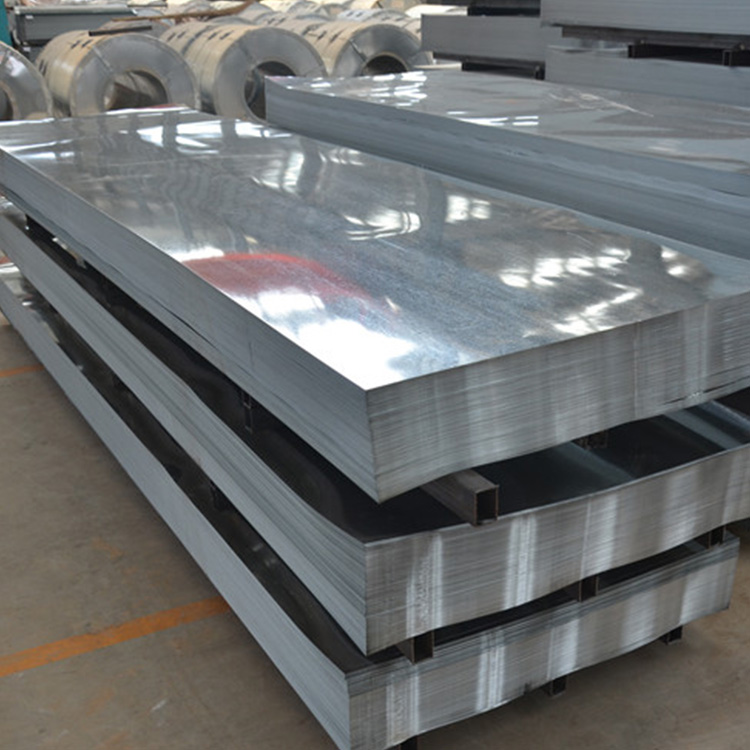

A galvanized steel coil is a steel sheet or strip coated with a protective layer of zinc to prevent corrosion. This coating enhances the durability of steel in harsh environments, making it suitable for outdoor and industrial applications. Galvanized steel coils are produced in various thicknesses, widths, and coating specifications to meet different industry requirements.

Global Market Size and Demand

The global galvanized steel coil market has witnessed consistent growth due to:

Expansion of the construction and infrastructure sectors

Rising urbanization in emerging economies

Increased investment in industrial and transportation sectors

Regions like Asia-Pacific dominate production and consumption due to high construction activity, while North America and Europe show steady demand for industrial and automotive applications.

Key Drivers of Market Growth

Construction Industry Expansion

Urbanization and large-scale infrastructure projects drive high demand for galvanized steel coils. The material is extensively used in:

Roofing and wall cladding

Gutter systems and water tanks

Industrial buildings and warehouses

Its corrosion resistance, longevity, and low maintenance make it ideal for long-term construction projects.

Automotive and Transportation Applications

Automobile manufacturers prefer galvanized steel coils for body panels, frames, and chassis due to their durability and corrosion protection. This trend is reinforced by stricter regulations for vehicle lifespan and safety, particularly in regions with high humidity or coastal exposure.

Industrial Equipment and Manufacturing

Galvanized steel coils are essential in industrial fabrication for:

HVAC ducts

Storage tanks

Conveyor systems

Machinery frames

The growth of manufacturing sectors globally contributes significantly to market expansion.

Emerging Trends in the Market

1. Shift Towards Higher-Quality Coatings

Manufacturers are increasingly producing galvanized steel with thicker or multilayer zinc coatings to enhance corrosion resistance. This trend responds to:

Harsh environmental conditions

Coastal and marine applications

Long-term structural requirements

Advanced coating technologies, including hot-dip galvanizing and continuous galvanizing, provide uniform zinc layers and improved adhesion, ensuring better performance over time.

2. Customized and Prepainted Solutions

The demand for prepainted galvanized steel coils (PPGI/PPGL) is rising. These coils are coated with durable paints, offering:

Architects and builders increasingly specify colored or patterned galvanized steel for commercial and residential projects, driving growth in this segment.

3. Regional Market Dynamics

Asia-Pacific: Rapid urbanization and infrastructure projects fuel massive demand. China, India, and Southeast Asia lead production and consumption.

North America: Industrial upgrades and replacement of aging infrastructure sustain steady demand.

Europe: Focus on green construction and sustainable materials shapes product specifications.

Middle East & Africa: Construction growth and industrialization create opportunities for imports of high-quality galvanized steel coils.

4. Technology Integration and Automation

Producers are adopting smart manufacturing systems, robotics, and real-time monitoring to improve:

Coating uniformity

Production efficiency

Quality control

These technological advancements allow faster response to market demands and reduce production costs.

5. Sustainability and Eco-Friendly Production

Sustainability is becoming a major factor in purchasing decisions. Manufacturers are:

Reducing energy consumption in galvanizing processes

Implementing recycling systems for scrap steel

Using environmentally friendly coatings

Buyers increasingly prefer suppliers that comply with environmental standards, promoting a greener supply chain.

Challenges Facing the Galvanized Steel Coil Market

Raw Material Price Volatility

The cost of zinc and base steel fluctuates with global commodity markets, affecting production costs and profit margins. Manufacturers must optimize sourcing and production efficiency to maintain competitiveness.

Competition from Alternative Materials

Materials such as stainless steel, aluminum, and polymer-coated metals present alternatives in certain applications. Galvanized steel maintains cost-effectiveness, but high-end projects may choose other solutions for aesthetic or lightweight requirements.

Corrosion Risks in Extreme Environments

Despite strong resistance, galvanized steel can corrode in highly aggressive environments, such as:

Proper coating selection and maintenance are essential to maximize durability.

Opportunities for Market Players

Expansion in Emerging Economies

Developing regions with rising construction and industrial activities offer substantial growth potential. Partnerships with local distributors, investment in regional production facilities, and flexible supply chains can strengthen market presence.

Innovation in Coating Technologies

Developing higher-performance coatings, duplex systems (galvanizing + painting), and environmentally friendly solutions provides a competitive edge and addresses evolving market needs.

Integration of Digital Solutions

Market players leveraging data analytics, IoT-enabled production, and predictive maintenance can improve operational efficiency and meet demand more accurately.

Conclusion: The Future of Galvanized Steel Coils

The global galvanized steel coil market continues to expand, driven by strong demand in construction, automotive, and industrial applications. Emerging trends such as advanced coating technologies, prepainted solutions, sustainability initiatives, and regional diversification shape the market landscape. Companies that invest in quality, innovation, and customer-oriented solutions are likely to gain significant advantages.

Why Choose Shandong Sino Steel Co.,Ltd

At Shandong Sino Steel Co.,Ltd, we provide high-quality galvanized steel coils, sheets, and prepainted products tailored to diverse industrial and construction needs. Our advanced coating technologies, rigorous quality control, and comprehensive production capabilities ensure consistent zinc-layer thickness, uniform surface finish, and enhanced corrosion resistance. Serving customers across 150+ countries, we deliver reliable, durable, and cost-effective solutions for roofing, structural projects, industrial applications, and long-term infrastructure requirements.

FAQ

1. What industries consume the most galvanized steel coils?

Construction, automotive, and industrial equipment manufacturing are the primary consumers.

2. How does prepainted galvanized steel differ from standard coils?

Prepainted coils include a durable paint layer, offering additional corrosion protection and aesthetic options.

3. Which regions are leading in galvanized steel coil production?

Asia-Pacific, especially China, India, and Southeast Asia, dominates production and consumption.

4. How long can galvanized steel coils last in moist environments?

With proper coating and maintenance, galvanized steel coils can last 20–70+ years depending on conditions.

5. How can buyers ensure high-quality galvanized steel?

Choosing suppliers with advanced coating lines, strict quality control, and consistent zinc-layer specifications ensures durability and performance.