Understanding How Galvanized Steel Achieves Rust Resistance

Galvanized Steel is recognized across multiple industries for its exceptional resistance to rust. Whether used in construction, automotive parts, agricultural equipment, or outdoor infrastructure, this material is chosen because it performs reliably under conditions that would quickly damage ordinary steel. What makes Galvanized Steel so rust-resistant is the presence of a zinc coating, which shields the underlying steel from moisture, oxygen, and corrosive elements.

However, despite its strong durability, the question often arises: Is Galvanized Steel completely immune to rust? To answer this accurately, it is essential to explore how the zinc layer functions, what environmental conditions influence performance, and the situations in which corrosion may eventually occur.

How Galvanizing Protects Steel From Rust

The Role of Zinc in Corrosion Prevention

The key factor behind Galvanized Steel’s resistance to rust is the zinc layer applied through hot-dip galvanizing, electro-galvanizing, or continuous galvanizing. Zinc provides two primary forms of protection: a physical barrier and a sacrificial layer.

As a physical shield, the zinc coating prevents air and moisture from reaching the steel surface. As a sacrificial layer, zinc corrodes before the underlying steel, delaying the formation of rust for many years. This dual-function system allows Galvanized Steel to maintain structural stability even when exposed to harsh outdoor conditions.

Barrier Protection Explained

The outer zinc coating seals the steel from direct exposure. So long as the coating remains intact, water, oxygen, and atmospheric chemicals cannot penetrate to start the oxidation process. This simple yet effective barrier makes Galvanized Steel a preferred material in both structural and decorative applications.

Sacrificial Protection in Action

Even when the zinc coating is scratched or partially worn, it continues to protect the exposed steel. Zinc corrodes at a much slower and more controlled rate compared to raw steel, effectively sacrificing itself to prevent rust from forming on the base metal. This unique characteristic is what sets Galvanized Steel apart from painted or untreated steel.

Is Galvanized Steel Completely Rust-Proof?

While Galvanized Steel is highly resistant to rust, it is not entirely rust-proof. Over a very long period—often measured in decades—the zinc coating gradually wears down. Once enough zinc is consumed, the exposed steel can begin to oxidize.

The onset of rust is influenced by several factors:

In ideal conditions, Galvanized Steel can last more than 50 years without significant corrosion. In more aggressive environments, rust resistance may decline earlier.

Environmental Conditions That Influence Rust Resistance

Performance in Rural Areas

Rural environments typically promote the slowest zinc corrosion due to clean air and low pollutants. Galvanized Steel used in barns, grain silos, water tanks, or fencing can last for generations with only minimal surface change.

Performance in Cities and Urban Centers

Urban areas expose steel to higher levels of smog, carbon dioxide, and particulate matter. While these conditions still allow for good long-term durability, the zinc coating may deteriorate faster compared to rural environments.

Performance in Coastal Regions

This is where Galvanized Steel faces its toughest conditions. Salt-laden air, constant moisture, and warm temperatures accelerate zinc corrosion. Even so, with a sufficiently thick zinc layer, Galvanized Steel still performs well for many years before rust becomes a concern.

Performance in Industrial Zones

Environments with high chemical activity—such as areas near factories, power plants, or chemical plants—can significantly reduce the lifespan of the zinc coating. Acidic vapors, alkaline dust, or airborne contaminants react with zinc more aggressively, increasing the corrosion rate.

Coating Thickness and Its Impact on Rust Resistance

The durability of Galvanized Steel is closely connected to the thickness of the zinc coating. Different applications require different coating specifications to ensure optimal rust resistance.

Standard Zinc Coating Ranges

Typical coating weights include:

80–120 g/m² for indoor or mild climates

180–200 g/m² for moderate outdoor exposure

220–275 g/m² or higher for coastal or chemically active environments

A thicker coating means more zinc is available for sacrificial protection, resulting in a longer rust-free lifespan.

Matching Coating to Application

For roofing sheets, building cladding, guardrails, and heavy-duty industrial structures, higher coating levels are recommended to ensure strong resistance to moisture and pollutants.

For indoor uses, such as ducting or interior framing, thinner coatings are sufficient because environmental stress is minimal.

Common Signs of Early Corrosion on Galvanized Steel

White Rust

White rust appears as a chalky, powder-like deposit. It forms when freshly galvanized surfaces remain wet without proper ventilation. This type of rust affects zinc rather than the steel itself and usually does not compromise structural integrity unless severe.

Surface Darkening or Patina Formation

Zinc naturally develops a dull gray patina over time. This patina is protective, not harmful, and is actually a sign that the material is forming a stable corrosion-resistant layer.

Localized Rust Spots

When the zinc layer is mechanically worn away—such as by constant friction or deep scratches—localized rust may appear on the underlying steel. Quick action with zinc repair coatings can help restore corrosion protection.

How to Extend the Rust-Free Life of Galvanized Steel

Prevent Long-Term Moisture Exposure

Although Galvanized Steel tolerates moisture, preventing prolonged water buildup helps extend its lifespan. Ensure proper drainage for outdoor structures and avoid water traps.

Keep Surfaces Clean

Removing dirt, chemicals, or salt deposits slows zinc corrosion. Routine cleaning is especially important in coastal or industrial environments.

Add Supplementary Protective Coatings

Painting over Galvanized Steel, applying epoxy layers, or using powder coatings can significantly reinforce corrosion resistance, creating a multi-layer protection system.

Use Compatible Materials

Galvanized Steel should not be used in direct contact with copper or stainless steel in wet conditions, as galvanic corrosion may occur.

Reapply Zinc Repair Coatings When Needed

Welded edges, cut surfaces, or heavily abraded areas can be protected using zinc-rich paints or cold galvanizing sprays.

Applications That Benefit Most From Galvanized Steel’s Rust Resistance

Thanks to its durability, Galvanized Steel is widely used in more than a dozen industries, including:

Residential and commercial roofing

Wall cladding and façade systems

Transportation trailers and body panels

HVAC ducting

Agricultural barns and machinery

Outdoor fencing and frameworks

Water and wastewater infrastructure

Solar panel mounting systems

Utility poles and road barriers

Its low maintenance needs and long lifespan make it an economical choice for both small and large-scale projects.

Why Galvanized Steel Continues to Be a Top Material Choice

Galvanized Steel provides a combination of affordability, strength, and corrosion resistance that is difficult to match. Even though it can eventually rust, its protective zinc layer slows corrosion so effectively that the material remains structurally reliable for decades.

The stability offered by the zinc patina, combined with the self-sacrificial behavior of the coating, makes Galvanized Steel an ideal material for environments where moisture, weathering, or pollution are major concerns.

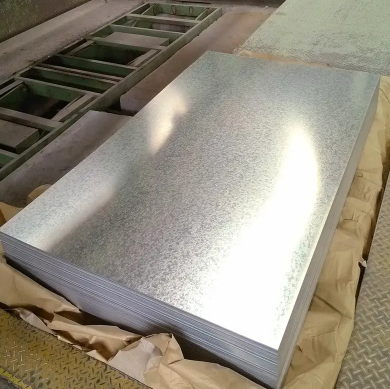

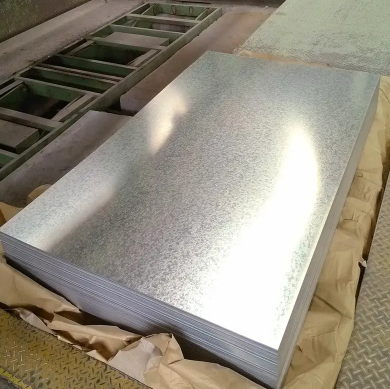

Partnering With a Trusted Galvanized Steel Supplier

For projects that require consistent quality and long-lasting performance, choosing the right supplier is essential. Shandong Sino Steel provides high-quality Galvanized Steel coils and sheets manufactured with precision and strict testing. With modern production lines, large annual capacities, and zinc coatings ranging from 20–275 g/m², we supply materials suitable for construction, roofing, appliances, and industrial applications. Our products are exported to over 150 countries, and our team ensures fast delivery, tailored specifications, and professional technical support. Working with a reliable supplier ensures your structures benefit from maximum rust resistance and long-term durability.

FAQ

1. Is Galvanized Steel completely rust-proof?

No. It is highly rust-resistant but may eventually corrode once the zinc layer is consumed.

2. Does Galvanized Steel perform well outdoors?

Yes. It is specifically designed for outdoor use and can endure decades of exposure.

3. Why does white rust form?

White rust forms when fresh zinc stays wet without airflow. It is mostly a surface effect.

4. Can Galvanized Steel be painted for extra protection?

Yes. Painting or coating enhances resistance, especially in coastal or industrial environments.

5. How do I choose the right zinc coating thickness?

Select the coating based on the environment—mild climates need less zinc, while coastal or chemical areas require higher coating levels.