KELEN Galvanized steel coil ye nɛgɛ ye min bɛ wuli ni zinki ye. Nin zinki layɛrɛ in bɛ nɛgɛ tanga nɔgɔ ni tiɲɛni ma, o bɛ kɛ sababu ye ka bobine barika sɔrɔ ani ka a to a bɛ mɛn. An ka tɔn bɛ nɛgɛberew dilan minnu ka ɲi kosɛbɛ, minnu bɛ kɛ ni nɛgɛ ye, iziniw ni sow jɔbagaw bɛ baara kɛ ni minnu ye kosɛbɛ, walasa ka so jɔ, ka fɛn dilan, ani ka mobili yɔrɔw dilan. San 2022, nɛgɛbere galvanisé tɔni miliyɔn 140 ɲɔgɔn bɔra diɲɛ fan bɛɛ, ni Siniwa jamana ka baara ɲɛmɔgɔya ye. An ka fɛn dilannenw dilannen don walasa ka nɛgɛbere galvaniséw ka ɲininiw dafa minnu bɛ ka bonya ka taa a fɛ izini suguya caman kɔnɔ.

Key takeaways .

Galvanisé nɛgɛ bobine ye nɛgɛ ye min datugulen don ni zinc ye. Zɛnki bɛ dɛmɛ ka nɔgɔ jɔ ani ka nɛgɛ kɛ ka mɛn. O bɛ nɛgɛ barika bonya ani ka a kɛ fɛn caman ye fɛn caman na.

Nɛgɛbere galvanisé suguya ni a suguya wɛrɛw bɛ yen. suguya kelen-kelen bɛɛ bɛ baara kɛ ka ɲɛ baara dɔw la. Zɛnki dajiw ka bon ka ɲɛ kɛnɛma. Datugulan finmanw ka fisa kɔnɔna walima ɲɛda cogoya ma.

Hot-dip, pre-galvanizing, ani electrogalvanizing ye zinki farali fɛɛrɛw ye. Fɛɛrɛ kelen-kelen bɛɛ bɛ a bonya ni a ɲɛda cogoya wɛrɛ di. U kelen-kelen bɛɛ bɛ kɛ mago kɛrɛnkɛrɛnnenw kama.

Galvanized steel coil bɛ baara kɛ kosɛbɛ so, mobili ani so masinw na. A bɛ dɛmɛ don ka wari mara bawo a mago bɛ dilanw na dɔɔnin ani ladonni ka dɔgɔn.

Ka bobine ɲuman ta, o kɔrɔ ye ka miiri a bonya la, a ka zinki dacogo la, a ka cogoya la, ani a bɛna kɛ yɔrɔ min na. O bɛ dɛmɛ ka a to a ka baara kɛ ka ɲɛ ani ka mɛn.

Galvanized acier coil overview .

Koli min ye galvanisé steel coil ye .

A bɛ kɛ ni nɛgɛ ye min bɛ kɛ ni nɛgɛ ye, o ye nɛgɛbere fla ye. A bɛ wuli ka kɛ bobine ye. Bobine bɛ datugu ni zinki layɛrɛ ye. Zɛnki bɛ nɛgɛ lakana ka bɔ nɔgɔ ni nɔgɔ la. iziniw ni so jɔbagaw i n’a fɔ galvanisé steel coil. A barika ka bon ani a bɛ mɛn sen na. A bɛ baara kɛ ka ɲɛ hali waati gɛlɛnw na. Zɛnki layini bɛ ji ni fiɲɛ bali. O bɛ dɛmɛ ka nɔgɔ bɔli dabila. Ni bobine bɛ kɛnɛma, zinki bɛ oksizɛni ni ji sɔrɔ. A bɛ filimu finman dɔ dilan min bɛ bobine lakana. Nin filimu in bɛ coil dɛmɛ ka tiɲɛniw kunbɛn.

Galvanized Steel Bobine ka nafolo nafama caman bɛ yen:

Ta |

Nafa typique . |

Nafa/nafa . |

Hakɛ |

7,85 g/cm⊃3 ɲɔgɔn; |

Kisɛ hakɛ dantigɛlen min bɛnnen don baarakɛcogo ma . |

Surface coating weight . |

30-350 g/m² (Fɛn fila bɛɛ) |

A bɛ sɔgɔli lakanani di sigidaw ma minnu bɛ se ka ladilan . |

Surface Smoothness . |

gɛlɛya (RA) 0,8-1,5 μm . |

A bɛ dɔ fara a dacogo kan ani a bɛ mɛn sen na . |

Sumaya min bɛ kɛ ni funteni ye . |

A ma nɔ bila galvanizing layer la . |

A bɛnnen don funteni jɛnsɛnni baarakɛcogo ma . |

Kuranko ɲɛnabɔli . |

A ka dɔgɔ dɔɔni ka tɛmɛ nɛgɛ saniyalen kan . |

A bɛ Industrial Conductivity wajibiyalenw dafa . |

Coefficient de expansion thermal . |

11,5 x 10⁻⁶/°C . |

A bɛ dimensions (hakɛ sabatili) sabati funteni caman yeli la . |

KƆLƆSI: Zɛnki layɛrɛ bɛ bobine dɛmɛ ka kemikɛlifɛnw kɛlɛ. A bɛ to a cogo la yɔrɔ minnu na pH bɛ bɔ 6 la ka se 12. Bobine bɛ se ka funteni kunbɛn fo ka se 200°C ma waati jan kɔnɔ. A bɛ se ka 300°C ta waati kunkurunnin kɔnɔ.

Fɛn minnu bɛ se ka kɛ fɛn jɔnjɔnw ye .

Dilanbagaw bɛ nɛgɛbere galɔn dilan hakɛ caman na. U fana bɛ u bonyacogo wɛrɛw Kɛ. Fɛn minnu ka ca kosɛbɛ olu ye u bonya, u bonya, u bonya ani u kɔnɔna janya ye. Olu bɛ sannikɛlaw dɛmɛ ka coil ɲuman ta u magow kama.

Paramɛtiri kɛrɛnkɛrɛnnen . |

A ka ca a la . |

A ka bon kosɛbɛ . |

0,12 mm ka se milimɛtɛrɛ 0,8 ma (dɔw bɛ se milimɛtɛrɛ 4,0 ma walima milimɛtɛrɛ 6,0) . |

Jayan |

600 mm ka se milimɛtɛrɛ 1500 ma (Sɔrɔ dɔw ye milimɛtɛrɛ 600 fo 1250 ye) |

Bobine girinya . |

3 ka se mɛtɛrɛ tɔni 8 ma (standard), fo ka se mɛtɛrɛ tɔni 25 ma ɲinini senfɛ . |

Coil kɔnɔna diamètre . |

508 mm walima 610 mm . |

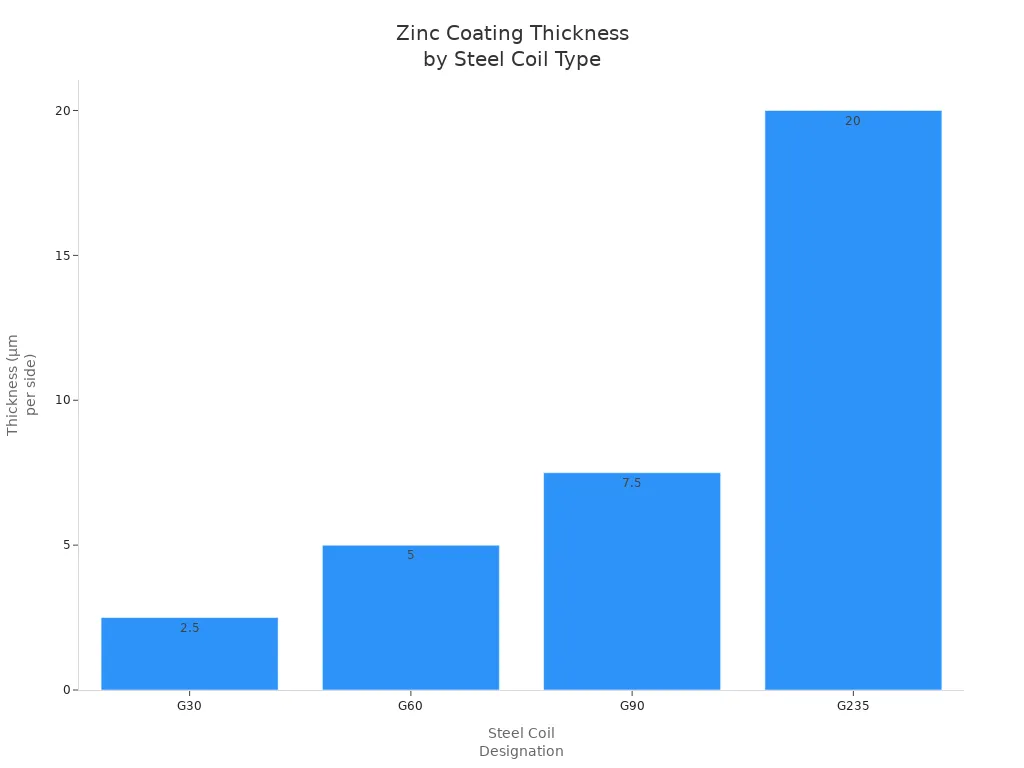

Zɛnki dacogo ka bon kosɛbɛ. A bɛ nɔ bila bobine bɛ nɔgɔ kɛlɛ cogo min na. A fana bɛ bobine bɛ mɛn cogo min na, o bɛ Changé. Coils différentes bɛ ni dacogo girinya ni u janya tɛ kelen ye. Tablo min bɛ duguma, o bɛ suguya caman jira ani u cogoyaw:

Welecogo |

Zɛnki dacogo girinya (Oz/FT⊃2;) . |

A janya jateminɛlen (μm fan kelen na) . |

A bɛ kɛ cogo min na , o ye ko resistance de corrosion . |

Aplikasi minnu bɛ kɛ tuma bɛɛ . |

G30 ye . |

0,30 bɛɛ lajɛlen (0,15 fan kelen na) . |

~2,5 . |

Yeelen lakanani . |

So kɔnɔ framing, minɛnw . |

G60 ye . |

0,60 bɛɛ lajɛlen (0,30 fan kelen na) . |

~5 . |

Lakanali damatɛmɛnen . |

HVAC, yeelen kɛnɛma framing . |

G90 ye . |

0,90 bɛɛ lajɛlen (0,45 fan kelen na) . |

~7,5 . |

Lakanaliba . |

So sanfɛla, Siding, Sɛnɛ |

G235 ye . |

2,35 bɛɛ lajɛlen (1,175 fan kelen na) . |

~20 . |

Lakanali maksimali . |

Kɔgɔjida la, garadiw, sigida minnu bɛ kɛ ni bɔgɔ ye . |

Zɛnki bɛ bila cogo min na bobine kan, o bɛ a bonya Changer. Hot-dip galvanizing bɛ kɛ ka finimugumuguw kɛ. A ka c’a la, olu bɛ kɛ mikromɛtiri 45 ni 100 cɛ. Electro-galvanizing bɛ finimugu finmanw dilan. Olu bɛ Bɔ 2,5 na ka Taa 25 la. finimugumuguw bɛ u tanga ka ɲɛ nka u musaka ka ca. Datugulan finmanw bɛ i ko u bɛ nɔgɔya ani u bɛ kɛ kɔnɔna na walima u bɛ kɛ ka u masiri.

Galvanized steel coil ka kan ka tugu diɲɛ sariyaw kɔ. O sariyaw bɛ a to bobine ka kɛ farati ye ani ka barika sɔrɔ. Sariya nafama dɔw ye:

Sariya |

Scope / Application . |

Fɛn minnu bɛ ɲɛfɔli kɛ kosɛbɛ . |

ASTM A653/A653M . |

Nɛgɛsɛbɛn, zinki-korati (galvanize) walima zinki-nɛgɛ-datugulan-suman ni hot-dip process ye . |

Coating weight, adhesion, surface quality, coating thickness minimums, fini, yecogo, adherence |

ASTM A924/A924M . |

A ka kan ka kɛ ko a bɛ kɛ ni nɛgɛ ye, nɛgɛ bɛ min na ni hot-dip process ye . |

General Coating wajibiyalenw i n’a fɔ a janya, a nɔrɔli, ani a sanfɛla cogoya . |

ASTM A123/A123M . |

Hot-dip galvanized coatings kan nɛgɛ ni nɛgɛ fɛnw kan . |

Coating thickness minimums, continuel smooth fini, yɔrɔ si tɛ yen min tɛ datugu, a bɛ tugu ɲɔgɔn kɔ kosɛbɛ baarakɛ waati bɛɛ la . |

ISO 3575 . |

A bɛ to ka kɛ hot-dip zinc-coated carbon steel sheet of commercial and drawing qualities . |

Datugulan janya, a ɲɛda cogoya, a sɔgɔli resistance . |

ISO 1461 . |

Hot dip galvanized coatings on fabricated fer and acier articles – Ɲɛfɔli ni sɛgɛsɛgɛli fɛɛrɛw . |

Datugulan janya, a ɲɛda cogoya, a sɔgɔli resistance . |

ASTM ni ISO sariyaw ye sariyaw sigi ka ɲɛsin fɛnw girinya ni u janya ma.

Kɔrɔbɔliw bɛ a lajɛ cogo min na zinki bɛ nɔrɔ nɛgɛ la ka ɲɛ ani cogo min na hali finimugu bɛ kɛ.

Corrosion resistance bɛ sɛgɛsɛgɛ ni kɔgɔ fiyɛli ye ani cogo wɛrɛw.

Suguw ni kalasiw .

Galvanized steel coil bɛ sɔrɔ suguya wɛrɛw la ani kalasi la. Sugu kelen-kelen bɛɛ bɛ ni fɛn kɛrɛnkɛrɛnnenw ye baara dɔw kama.

Hot-dip galvanized steel coils: Nin bobinew bɛ dilan ni nɛgɛ su ji la zinki wulilen na. O bɛ kɛ layɛrɛmugumugu ye min ka gɛlɛn, min bɛ nɔgɔ jɔ. So jɔbagaw bɛ baara kɛ ni hot-dip bobine ye kɛnɛma fɛnw kama i n’a fɔ so sanfɛlaw ani kogow.

Nɛgɛbere minnu bɛ kɛ ni kuran ye: O bobinew bɛ zinki sɔrɔ ni kuran ye furaji la. Layɛrɛ bɛ fin ani a bɛ nɔgɔya. iziniw bɛ baara kɛ ni nin bobine ninnu ye mobili yɔrɔw ni minɛnw kama minnu mago bɛ ɲɛnajɛ ɲuman na.

Jatedenw bɛ baara Kɛ ni 'g' ni jatebla ye. Jateden bɛ zinki hakɛ jira bobine kan. Jatedenw ka bon kɔrɔ ye zinki ka caya ani u lakanani ka ɲɛ. G60, G90, ani G275 ye kalan ye min bɛ kɛ tuma caman na.

Kalanso suguya . |

Cogojirali |

Aplikasi typique . |

Jagokɛla ka kalasi . |

Suguda hakɛ min ka bon kosɛbɛ; Baara kɛli ni mɔgɔw bɛɛ ye jɔli la . |

so sanfɛla, sidingɛ . |

Ja min bɛ kɛ ka ɲɛ . |

Baara bɛ kɛ ni nɛgɛ ye min bɛ se ka wuli ni nɛnɛ ye . |

Mobili, minɛnw . |

A ka fanga ka bon ni a ye . |

Fanga ni muɲuli ka bon . |

Bridges, sow, kurunw . |

Jatebɔcogo min bɛ kɛ ka ɲɛsin fɛnw ma . |

Baara bɛ kɛ ni bɔrɔw ni sow jɔli ye . |

Sigidaw ka sigidaw . |

Dɔ wɛrɛw . |

Kalanso kɛrɛnkɛrɛnnenw ni nafolo kɛrɛnkɛrɛnnenw . |

Aplikasi kɛrɛnkɛrɛnnenw suguya caman . |

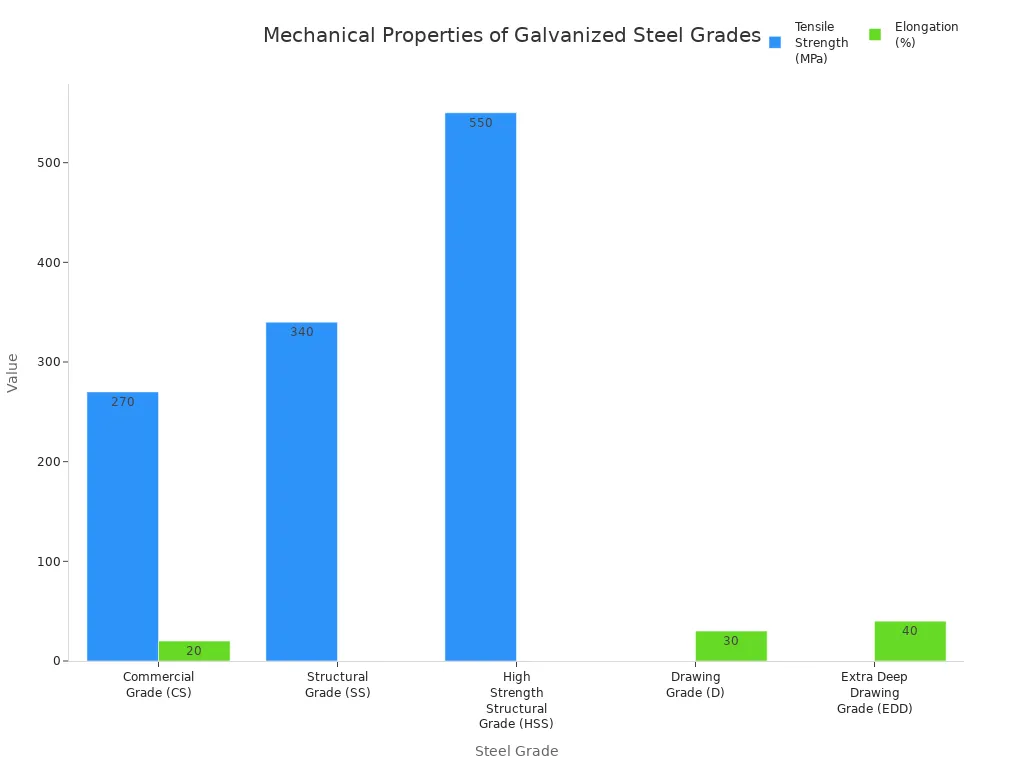

Mekaniki nafaw bɛ Changer ni grade kelen-kelen bɛɛ ye. Tablo min bɛ duguma, o b’a jira cogo min na fanga ni fɛn caman bɛ se ka wuli ka bɔ ɲɔgɔn na:

Jala |

Tensile fanga (MPa) . |

Sɔrɔ fanga (MPa) . |

janya (%) . |

nafa jɔnjɔn . |

A kɛcogo/baarakɛcogo cogoya . |

Jagokɛlaw ka jatebɔsɛbɛn (CS) . |

270 - 410 . |

N/A . |

≥ 20 . |

Basic rustproofing, general strength . |

Simple bind and cutting (no deep stamping) . |

Structure Grade (SS) . |

340 - 550 . |

≥ 230 . |

Ka bɛrɛbɛn |

Fanga ni welda ka bon . |

Load-bearing, welding, bolt connections . |

Jala grade (d) . |

Ka bɛrɛbɛn |

N/A . |

≥ 30 . |

Ductility (ductilité) ka bon ani janya kelen . |

Stamping medium . |

Extra deep drawing grade (EDD) . |

Ka lajigin |

N/A . |

≥ 40 . |

Formabilité extrême, resistance à la thinning . |

Stamping complexe ni moules précisions . |

fanga caman sɔrɔli structurel grade (HSS) . |

550 - 980 . |

Sɔrɔ hakɛ ≤ 0,85 . |

Ka bɛrɛbɛn |

Fanga ni girinya hakɛ caman, fanga caman sɔrɔli . |

Baarakɛcogo kɛrɛnkɛrɛnnen (laser tigɛ, hydraulique moulding) . |

Galvanized acier coil bɛ ni surface finiw ye minnu tɛ kelen ye:

Spangled régulier: Aw bɛ se ka zinki kristalɛw ye. A bɛ Kɛ jɔli la.

Spangle min ka dɔgɔn: Kristali misɛnninw bɛ kɛ yɔrɔ ye min bɛ nɔgɔya. Baara bɛ kɛ ni mobili ni minɛnw ye.

Zero Spangle: Kristali si tɛ ye. A sanfɛla bɛ manamana ani a bɛ kɛ ka ɲɛ. A bɛ kɛ dumuni ni kemikɛli baarakɛyɔrɔw la.

Kɛrɛnkɛrɛnnenya la, finimugu dɔw bɛ kɛ ni jiribolo dɔw ye minnu bɛ kɛ ni bolokɔniw ye, ni banakisɛw ye, walima ni funteni ye.

Ladilikan: Aw bɛ suguya ni hakɛ ɲuman ta aw ka baara la. Dakunmugumuguw ni u kalayaw ka fisa ni tɔw ye walima yɔrɔ gɛlɛnw na. Dakun finmanw ni finimugu nɔgɔlenw ka ɲi kɔnɔna walima u masirili kama.

Fɛn dilanni fɛɛrɛw .

Galvanizing hot-dip .

Hot-dip galvanizing ye fɛɛrɛ ye min ka di kosɛbɛ walasa ka nɛgɛberew lakana. Fɔlɔ, baarakɛlaw bɛ nɛgɛ saniya. U bɛ surface (yɔrɔ) pickle (ka a kɛ) ye. O kɔfɛ, u bɛ bobine su zinki wulilen na. O bɛ kɛ sababu ye ka zinki-nɛgɛlan barikama kɛ. Sumaya kɔfɛ, bobine bɛ nɛnɛ. Baarakɛlaw b’a minɛ ni passi ye ani tulu. Nin fɛɛrɛ ninnu bɛ finimugu dacogo dɛmɛ ani ka a ye ka ɲɛ. Sɛgɛsɛgɛlikɛlaw bɛ a janya ni a dacogo cogoya lajɛ. O kɔ, bobine bɛ sɔrɔ ka pake. Zɛnki layɛrɛ ka bon, a ka c’a la, a bɛ kɛ mikromɛtiri 45 fo 85 ye. O bɛ bɛn ASTM sariyaw ma i n’a fɔ A123 ani A653. O kɛcogo bɛ nɛgɛ dɛmɛ ka nɔgɔ ni sɔgɔsɔgɔninjɛ kɛlɛ. A ka ɲi kosɛbɛ kɛnɛma sow ni baara gɛlɛnw na.

Taabolow taabolo:

Aw bɛ o fɛnw labɛn ani k’u saniya .

pickle ani ka bɔ grease .

Aw bɛ a ko ani ka a kɛ fɛn ye .

Aw bɛ furakɛli daminɛ ka ɲɛ .

Aw bɛ a su ji la .

Cool ani ka bobine furakɛ .

Flatten ani trim ka bobine .

Aw bɛ a lajɛ ni a ka ɲi .

Aw bɛ a tigɛ ka a wuli ka kɛ bobinew ye .

Aw bɛ fura in pake ani ka a ci .

Pre-Galvanizing .

Pre-galvanizing bɛ kɛ nɛgɛdaga la ka sɔrɔ ka a cogoya. Baarakɛlaw bɛ nɛgɛdaga saniya fɔlɔ. O kɔ, u b’a boli zinki wulilen fɛ layini dɔ kɔnɔ. O bɛ kɛ ni zinki layɛrɛ ye min bɛ kɛ ka ɲɛ ani ka kɛ hali zinki ye. A ka c’a la, a dacogo bɛ kɛ mikromɛtiri 20 fo 30 ye. A laban bɛ yeelen bɔ ani a cogoya ka nɔgɔn. Nɛgɛso min tun bɛ sɔrɔ ka kɔn, o musaka ka dɔgɔ ani a bɛ baara kɛ koɲuman baarabaw kama. Nka, dakun tigɛlenw ni welda bɛ se ka nɛgɛ jɛlen jira. O kɔrɔ ye ko nɔgɔ lakanani ka dɔgɔn. Pre-galvanizing ka fisa ni so kɔnɔ fɛnw ye walima yɔrɔw ye minnu ka kan ka ɲɛ.

Suguya |

Galvanizing hot-dip . |

Pre-Galvanizing . |

Datugulan janya . |

45-85μm . |

20-30μm . |

Coverage . |

Full, o la, dakunw bɛ yen . |

A tɛ kɛ tigɛlanw kan . |

Laban |

Variable . |

Uniforme, brillant . |

Baara kɛcogo ɲuman . |

Kɛnɛma, gɛlɛn-dutiya . |

Yɔrɔ minnu bɛ so kɔnɔ, yɔrɔ minnu bɛ ye . |

Electrogalvanizing .

Electrogalvanizing bɛ baara kɛ ni kuran ye walasa ka nɛgɛ datugu ni zinki ye. Baarakɛlaw bɛ nɛgɛ saniya fɔlɔ. O kɔ, u b’a bila fura kɛrɛnkɛrɛnnen dɔ la. Zɛnki ionw bɛ nɔrɔ nɛgɛ la ka u kɛ fɛn finman ye, hali ka kɛ fɛn ye min bɛ kɛ ka a kɛ fɛn ye min bɛ kɛ ka a kɛ fɛn ye min bɛ se ka kɛ. A ka c’a la, a dacogo ka bon ni mikromɛtiri 5 fo 25 ye. Elektrogalvanisé nɛgɛ bɛ nɔgɔya ani a bɛ manamana. A bɛ biri nɔgɔya la ani a bɛ nɔgɔ kɛlɛ yɔrɔ ɲiginnenw na. A dilanni ka nɔgɔn fana. Mɔgɔw bɛ baara kɛ n’a ye mobili yɔrɔw, minɛnw ani ɛntɛrinɛti kan. Taabolo bɛ ASTM A879 sariyaw labato. A ka ɲi furaw ma minnu mago bɛ yɔrɔ ɲuman na ani nɔgɔ lakanani dɔw.

Kɔlɔsili: Nɛgɛ min bɛ kɛ ni kuran ye, o bɛ baara kɛ ka ɲɛ penti kɔnɔna ni a jukɔrɔ. A bɛ nɔgɔ jɔ ka ɲɛ nka a tɛ a yɛrɛ tanga sɛgɛn ma i n’a fɔ hot-dip fɛɛrɛw.

Galvanealing .

Galvanealing bɛ galvanizing ni so funteni ɲagami. Hot-dip galvanizing kɔfɛ, baarakɛlaw bɛ nɛgɛ sumaya kosɛbɛ. O bɛ kɛ zinki-nɛgɛ-la-yɔrɔ ye. Layɛrɛ bɛ dɛmɛ don welding ni penti la. Galvanealed steel ka nɔgɔn ka welda ani ka cogoya. A bɛ kɛ mobili, sow ani minɛnw na. ASTM A653 bɛ sariyaw di galakana nɛgɛ bobine kan. O bɛ a to a ka ɲi ani a ka baara kɛcogo bɛ to ka jɔ.

Fɛnw ni nafaw .

Corrosion resistance .

Nɛgɛ galɔn tɛ nɔgɔ nɔgɔya la k’a sababu kɛ a ka zinki dacogo ye. Zɛnki layini bɛ nɛgɛ lakana a jukɔrɔ. Ni ji walima fiɲɛ magara bobine la, zinc bɛ fɔlɔ ka jaabi di. O bɛ kɛ sababu ye ka oksizɛni ni ji bali ka se nɛgɛ ma. Zɛnki layini fana bɛ fɛn kɛrɛnkɛrɛnnenw dilan i n’a fɔ zincite (ZNO), hydrozincite ani simonkolleite. O fɛnɲɛnamafagalanw bɛ kɛ filimuba ye. Filimu bɛ nɔgɔ sumaya ani ka nɛgɛ mara. Hali ni bobine bɛ sɔgɔsɔgɔ walima ka tigɛ, zinki bɛ a lakana hali bi. Zɛnki dacogo bɛ fɛn caman Changer cogo min na nɛgɛ bɛ kɛ ka nɔgɔ. Zɛnki layɛrɛ minnu ka bon, olu bɛ lakana caman di. U bɛ mɛn yɔrɔ gɛlɛnw na.

Zɛnki dacogo bɛ sɛgɛn sani nɛgɛ ka kɛ.

Filimu minnu bɛ mɔgɔ tanga, olu bɛ oksizɛni ni ji bali ka bɔ nɛgɛ la.

O dacogo bɛ a yɛrɛ labɛn ni sɔgɔsɔgɔ walima tigɛw ye.

Zɛnki-nafolo primers bɛ lakana wɛrɛ di cogoya gɛlɛnw na.

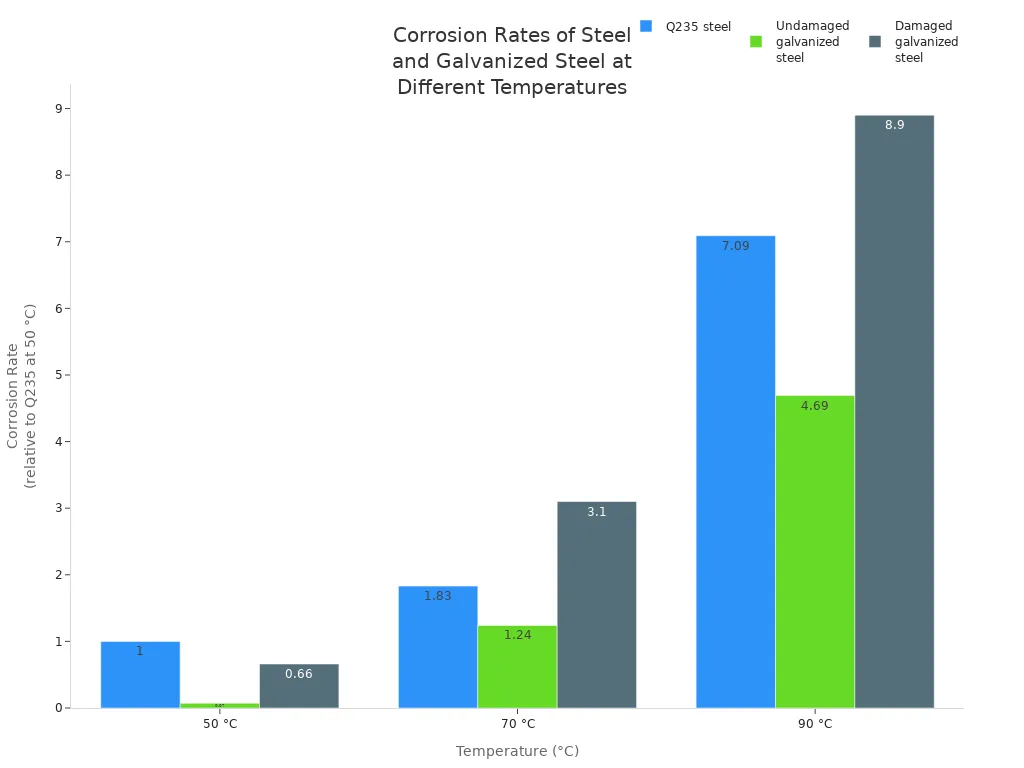

Kɔrɔbɔliw b’a jira ko galvanisé steel bɛ resists rust ka fisa kosɛbɛ ni steel plain ye. O ye tiɲɛ ye ji la walima kɛnɛma yɔrɔw la.

A ye fɛn minnu ye . |

A bɛ se ka kɛ ko a bɛ se ka kɛ (50°C) . |

Main Corrosion Products . |

Product morphologie . |

Q235 Nɛgɛ . |

1 |

FE3O4 ye. |

Bɔnɛ |

Nɛgɛ min ma tiɲɛ, o ye nɛgɛ ye min ma tiɲɛ . |

0.07 |

Zno . |

Dense . |

Nɛgɛ min tiɲɛna galɔn . |

0.66 |

FE3O4 + ZNO . |

Dense . |

A bɛ se ka muɲu ani ka a ladon .

Zɛnki dacogo bɛ nɛgɛ galɔn dɛmɛ ka mɛn. A bɛ baara kɛ koɲuman kɛnɛma sanji, tile ani fiɲɛ fɛ. Mɔgɔw bɛ baara kɛ n’a ye so sanfɛ, kogow ani masinw kama. Inox bɛ mɛn yɔrɔ gɛlɛnw na kosɛbɛ. Nka galvanisé steel bɛ lakana ka ɲɛ ani a musakaw ka dɔgɔ. Waati tɛmɛnen kɔfɛ, zinki layɛrɛ bɛ se ka sɛgɛn. Aw bɛ to ka sɛgɛsɛgɛli kɛ ani ka a dilan nɔgɔya la, aw bɛ nɛgɛ barika to a la.

Ladilikan: Aw bɛ nɛgɛ galɔn to yɔrɔ jalenw na. Aw bɛ bobinew siri walasa ka u lakana. Aw bɛ a lajɛ ni ji tɛ a la tuma caman. Ni aw ye tiɲɛni ye, aw bɛ a labɛn ni penisilini walima furaji ye min falen bɛ zinki la.

Ladonni kɛcogo minnu bɛ fɔ:

Aw bɛ kemikaliw walima tulu kɛ a la walasa ka ɲɔgɔnkanu ni tiɲɛni dabila.

Aw bɛ bobinew siri ni papiye walima plastiki ye ni aw bɛ u mara walima ka u ci.

Aw bɛ a lajɛ ni ji ni bobine jalenw bɛ a la joona ni a ɲiginnen don.

Aw bɛ pakew labɛn joona walasa ka sɔgɔsɔgɔninjɛw jɔ.

Magasinw bobinew kɔnɔ minnu bɛ sɔrɔ waati cogoya la. Aw kana u janya kojugu.

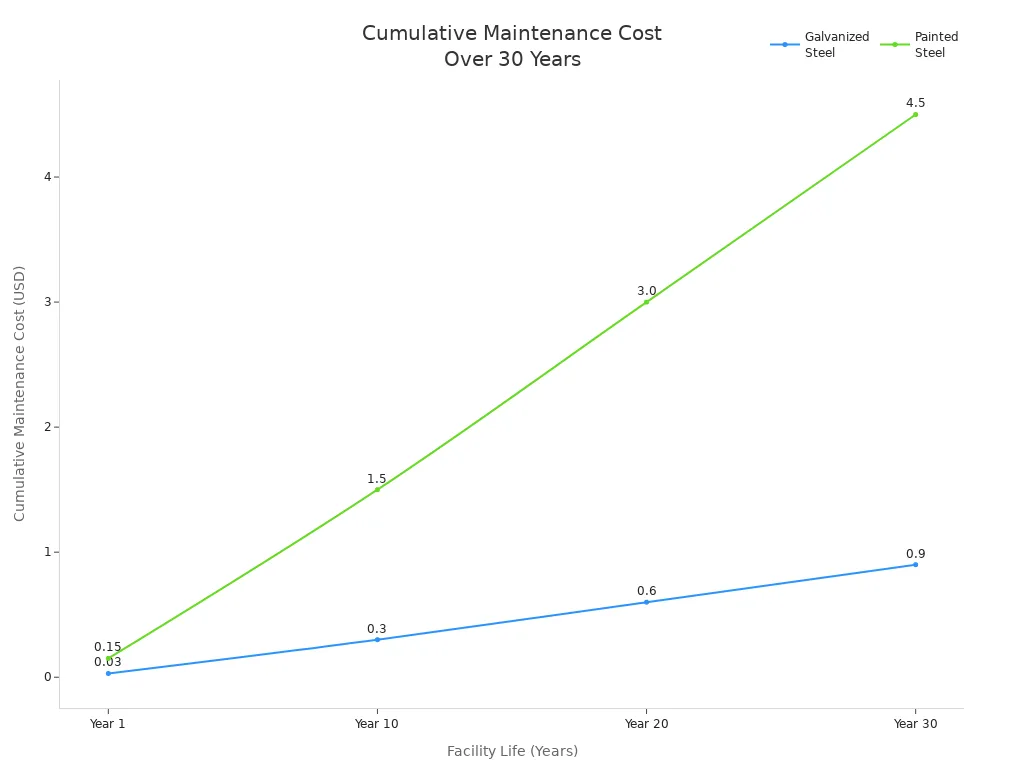

musaka kɛcogo ɲuman .

Galvanized steel bɛ nafa ɲuman di wari ma. A musaka ka ca ni nɛgɛ gansan ye a daminɛ na. Nka a sɔngɔ ka dɔgɔ ni nɛgɛ ye min tɛ sɔgɔ walima ni a pentirilen don. Zɛnki dacogo kɔrɔ ye ko dilanw man ca ani ko u tɛ penti kokura. O bɛ wari bɔ waati kɔnɔ.

musaka fan fɛ . |

Hot-dip galvanisé acier . |

Sisitɛmu min bɛ kɛ ni nɛgɛ ye (fi fila) . |

A daminɛ musaka . |

ɲɔgɔndan walima duguma . |

tuma dɔw la sanfɛ walima a bɔɲɔgɔnko . |

San o san ladonni . |

$0.03 san o san . |

$0.15 san kɔnɔ . |

Facilité ka ɲɛnamaya . |

San 30 . |

San 30 . |

Ladonni mago bɛ . |

Foɲisi |

A bɛ kɛ tuma bɛɛ . |

Ɲɛnamaya-taama musaka . |

Tuma caman na musaka fɔlɔ dɔrɔn . |

A ka bon kosɛbɛ ka da a kan u bɛ se ka kɛ . |

Galvanisé nɛgɛ bɛ dɛmɛ ka musakaw dɔgɔya waati jan kɔnɔ. A mago bɛ dilancogo ni fɛn wɛrɛw la minnu bɛ se ka kɛ u nɔ na. A bɛ fanga fana mara sow kɔnɔ. O b’a kɛ sugandili hakilitigi ye fɛnw jɔli n’u dilanni na.

Bobine min bɛ kɛ ni nɛgɛ ye min bɛ wele ko galon .

jɔli ni so jɔli .

Galvanisé nɛgɛ bobine nafa ka bon kosɛbɛ so jɔli la. So jɔbagaw bɛ baara kɛ n’a ye so sanfɛ, kogow, jirisunw ani baraw kama. Zɛnki layɛrɛ bɛ sow lakana ka bɔ nɔgɔ ni waati jugu la. O b’a to a bɛ kɛ sugandili ɲuman ye kɛnɛma baara kama. A barika ka bon wa a tɛ kari nɔgɔya la. A bɛ mɛn yɔrɔ gɛlɛnw na. So jɔbaga caman bɛ nɛgɛbere galvanisé ta ka ɲɛsin nɛgɛw ma, jibolisiraw ani kogow kan. Nɛgɛbere galvanisé bɛɛ tilancɛ ɲɔgɔn bɛ kɛ ka so jɔ. Dugu caman ani porozɛ kuraw b’a to o fɛn in mago bɛ ka bonya, kɛrɛnkɛrɛnnenya la Azi Pasifiki jamana na.

Fɛn dilanni ani mobili .

Factories bɛ baara kɛ ni galvanisé steel coil ye bawo a ka gɛlɛn ani a cogoya ka nɔgɔn. Mobili dilannikɛlaw bɛ baara kɛ ni hot-dip galvanized coils ye mobili farikolow, a karamɔgɔya ani a duguma yɔrɔw la. Zɛnki layini bɛ o yɔrɔw bali ka nɔgɔ. O bɛ mobili dɛmɛ ka to lafiya la ani ka baara kɛ ka ɲɛ. Mobili sosiyete minnu bɛ Sinuwa ni Ɛndujamana na, olu bɛ baara kɛ ni nɛgɛbere galvanisé caman ye sisan. U b’a fɛ ka mobili nɔgɔmanw ni mobili ɲumanw sɔrɔ. Kuranko mobili caman fana kɔrɔ ye ko mago bɛ nin fɛn in na kosɛbɛ. Sariya kura minnu bɛ nɔgɔ ni fɛnɲɛnamafagalanw marali kan, olu bɛ kɛ sababu ye ka tɔnw kɛ ka baara kɛ ni nɛgɛbere galvanisé ye. Datugucogo ɲumanw ani sigida iziniw bɛ dɛmɛ ka ɲininibaw dafa o yɔrɔw la.

Baarakɛcogo wɛrɛw .

Galvanisé nɛgɛ bobine bɛ kɛ ka tɛmɛn sow ni mobili dɔrɔn kan. Minɛn dilannikɛlaw bɛ baara kɛ n’a ye kolifɛnw, frigow ani fiɲɛdilanw kama. A tɛ nɔgɔ ani a ɲɛ ka ɲi. O fɛn in fana bɛ kɛ fanga jɛlen ni dugu hakilitigiw ka porozɛw la. Kuran mɔbiliw ni fanga jɛmanw mago bɛ nɛgɛ la min tɛ nɔgɔ fɛn kuraw la. Azi Pasifiki jamana na, nɛgɛbere min bɛ kɛ ni galɔn ye, o ka ca ni tilayɔrɔba kelen ye. Dugu porozɛ kuraw ani izini caman bɛ kɛ sababu ye ka nin nɛgɛ in mago ɲɛ. Sisan, iziniw bɛ baara kɛ ni fɛɛrɛ kuraw ye walasa ka nɛgɛ dilanfɛn hakilitigiw ni kɛrɛnkɛrɛnnenw dilan o sugu kuraw kama.

Jateminɛw ni dantigɛliw .

Ka bobine ɲuman sugandi .

Ka nɛgɛbere ɲuman ta baara kama, o nafa ka bon. Aw ka kan ka miiri fɛn caman na. O fɛnw bɛ ɲɔgɔn Changer cogo min na coil bɛ baara kɛ ka ɲɛ ani a bɛ mɛn cogo min na.

A janya : nɛgɛmugu bɛ girinya caman minɛ ka mɛn. So jɔbagaw bɛ baara kɛ ni bobinew ye minnu bɛ kɛ ka jiriw ni yɔrɔ barikamaw kɛ. Bobine finmanw ka ɲi fɛn nɔgɔmanw ma i n’a fɔ fiɲɛbɔyɔrɔw.

Coating girinya : zinki dacogo bɛ nɔgɔ bɔ. Datugulan gɛlɛnw, i n’a fɔ G90, olu ka fisa ni yɔrɔ ɲiginnenw walima yɔrɔ kɔgɔlenw ye. Datugulan nɔgɔmanw, i n’a fɔ G60, olu ka ɲi kɔnɔna walima yɔrɔ nɔgɔmanw ma.

Grade : Kalanso kelen-kelen bɛɛ n’a fanga n’a ka bεnkansεbεn don. Kalanso barikamaw ka ɲi ni aw mago bɛ nɛgɛ gɛlɛn na. Kalansenw ka fisa ni i mago bɛ ka bobine biri walima ka a cogoya.

Bonya ni janya : ladamu hakɛw bɛ dɛmɛ ka don poroze kelen-kelen bɛɛ la. O bɛ so jɔli ni a dilanni nɔgɔya.

Jateminɛ wɛrɛw : Miiri sɔngɔ la, baara suguya la, ani i bɛna baara kɛ ni bobine ye yɔrɔ min na. Hot-dip walima electrogalvanizing bɛ ta ka da i mago bɛ min na.

Ladilikan: Aw ye izini sariyaw lajɛ tuma bɛɛ ani ka aw ka feerekɛla ka jogo lajɛ sani aw ka san.

Sigidako koɲɛw .

I bɛ baara kɛ ni nɛgɛberew ye yɔrɔ min na, o bɛ se ka u ka baara kɛcogo Changer. Kɔgɔ min bɛ fiɲɛ na kɔgɔji kɛrɛfɛ, o bɛ zinki kari joona. Nɔgɔya min bɛ bɔ iziniw na, o bɛ kɛ asidi sanji ye min bɛ zinki tiɲɛ. Ni aw bɛ bobinew mara yɔrɔ ɲiginnenw na, o bɛ se ka ji minɛ ani ka nɔgɔ finmanw bila mɔgɔ la. Funteni min bɛ bɔ welding walima tigɛ la, o bɛ se ka zinki jeni ka sɔrɔ ka nɛgɛ da wuli ka kɛ nɔgɔ ye.

Sigida |

Faratiba . |

Lakanali wale . |

Coastal . |

Kɔgɔji la, pitting . |

Aw bɛ zinki gɛlɛn kɛ . |

Industrie . |

Asidi sanji, nɔgɔ . |

Aw bɛ passivation (passivation) kɛ, ka sigilanw kɛ . |

Storage humid . |

Rust formation blanc . |

Aw bɛ a mara yɔrɔ jalen na, fiɲɛ bɛ min na . |

Ko minnu bɛ kɛ tuma bɛɛ .

Nɛgɛberew bɛ se ka gɛlɛyaw sɔrɔ ni u kɛra walima ni u maralen don:

Nɔgɔ finman bɛ se ka jira ni ji tora bobine kan, kɛrɛnkɛrɛnnenya la ni passivation ma kɛ ka ɲɛ.

Sɔgɔsɔgɔ, tigɛw, walima welding bɛ se ka zinki layɛrɛ dimi ani ka nɔgɔ bɔ.

Ni zinki tɛ hali walima nɛgɛ bɛ nɔgɔ la, yɔrɔ barikamaw bɛ se ka sɔrɔ.

Nɔgɔw bɛ se ka kɛ ni nɔgɔ finmanw tora ka bonya.

Ka bobinew mara cogo jugu la, i n’a fɔ yɔrɔ ɲiginnenw na, o bɛ kɛ sababu ye ka nɔgɔ bɔ.

KƆLƆSI: Aw bɛ bobinew minɛ ni ladonni ye, ka u lajɛ tuma caman, ani ka u mara ka ɲɛ walasa ka gɛlɛya fanba bali.

Galvanisé nɛgɛ bobine bɛ nɛgɛ mara ka bɔ nɔgɔ la. A bɛ tiɲɛni fana dabila. Nin fɛn in barika ka bon, wa a bɛ mɛn sen na. A bɛ dɛmɛ don ka wari mara fana. So jɔbagaw bɛ baara kɛ n’a ye so sanfɛtaw ni kogow kama. Dilanbagaw bɛ baara kɛ n’a ye mobili ni minɛnw kama. Sannikɛlaw ka kan ka u bonya ni u girinya lajɛ. U ka kan fana ka kalan hakɛ lajɛ. ASTM sariyaw bɛ dɛmɛ ka a lajɛ ni bobine ka ɲi. Nɔgɔya ni kɔgɔ fiɲɛ kɔnɔ, o bɛ se ka a baara cogo Changer. Ka bobine ɲuman ta, o bɛ nɔ ɲumanw bɔ.

FAQ .

Galon bobine kunba ye mun ye?

Galvanisé nɛgɛ bobine bɛ nɛgɛ bali ka nɔgɔ walima ka tiɲɛni kɛ. Zɛnki layɛrɛ bɛ baara kɛ i n’a fɔ kala. So jɔbagaw ni iziniw bɛ baara kɛ n’a ye walasa ka yɔrɔw dilan minnu bɛ mɛn waati jan kɔnɔ ani ka to barika la.

zinki dacogo bɛ nɔgɔ bali cogo di?

Zɛnki bɛ ji ni fiɲɛ kunbɛn sani nɛgɛ ka kɛ. O bɛ kɛ layɛrɛ kɛrɛnkɛrɛnnen ye san fɛ. Layɛrɛ bɛ ji ni fiɲɛ bali ka maga nɛgɛ la.

Mɔgɔw bɛ baara kɛ ni bobine galvanisé ye min ka teli ka kɛ?

Mɔgɔw bɛ baara kɛ ni nɛgɛberew ye minnu bɛ kɛ ni nɛgɛ ye, mobili dilanni, mobili dilanni, ani minɛnw dilanni na. A ka ɲi so sanfɛlaw, mobili yɔrɔw ani masinw ma.

Yala galvanisé acier bobine bɛ se ka penta wa?

Aw bɛ se ka penti galvanisé acier bobine la. A sanfɛla ka kan ka saniya ani ka ja fɔlɔ. Primers kɛrɛnkɛrɛnnenw bɛ penisilini nɔrɔ zinki layɛrɛ la.

Sariya jumɛnw bɛ tali kɛ galonw ka bobine la?

ASTM A653 ani ISO 3575 ye sariya jɔnjɔnw ye minnu bɛ kɛ ni nɛgɛberew ye. O sariyaw bɛ kuma dacogo kan, a sanfɛla cogoya, ani a bɛ nɔgɔ kɛlɛ cogo min na.